Production process of super-thin touch screen

A production process and touch screen technology, applied in the field of ultra-thin touch screen production process, can solve the problems of complex structure, numerous processes, heavy weight, etc., and achieve the effect of reduced process, simple and cheap process, and lighter and thinner structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order for those skilled in the art to better understand the technical solutions provided by the present invention, the following will be described in conjunction with specific embodiments.

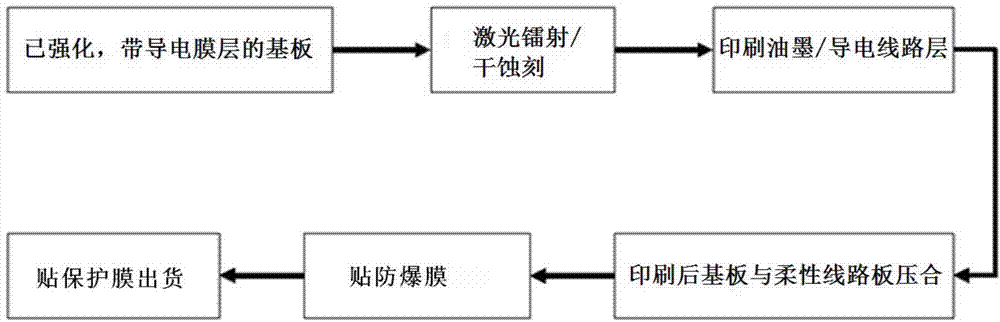

[0019] See figure 1 , which is a flow chart of the production process of the ultra-thin touch screen in the embodiment of the present invention.

[0020] The production process of the ultra-thin touch screen provided by the embodiment of the present invention includes the following steps:

[0021] (1) Ultrasonic cleaning of the strengthened substrate coated with a conductive film layer in an ultrasonic cleaning machine;

[0022] (2) Use a laser cutting machine or printing machine to perform laser laser or dry etching on the substrate, and then perform functional testing;

[0023] (3) The functionally qualified substrate needs to be printed with two layers of ink first, namely: color insulating ink layer, color conductive ink layer; then print the conductive circuit layer; final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com