Wind turbine rotor blade comprising a trailing edge section of constant cross section

A technology for blades and blade profiles, applied in the field of profile series, to solve problems such as inaccuracies, damage, tolerances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

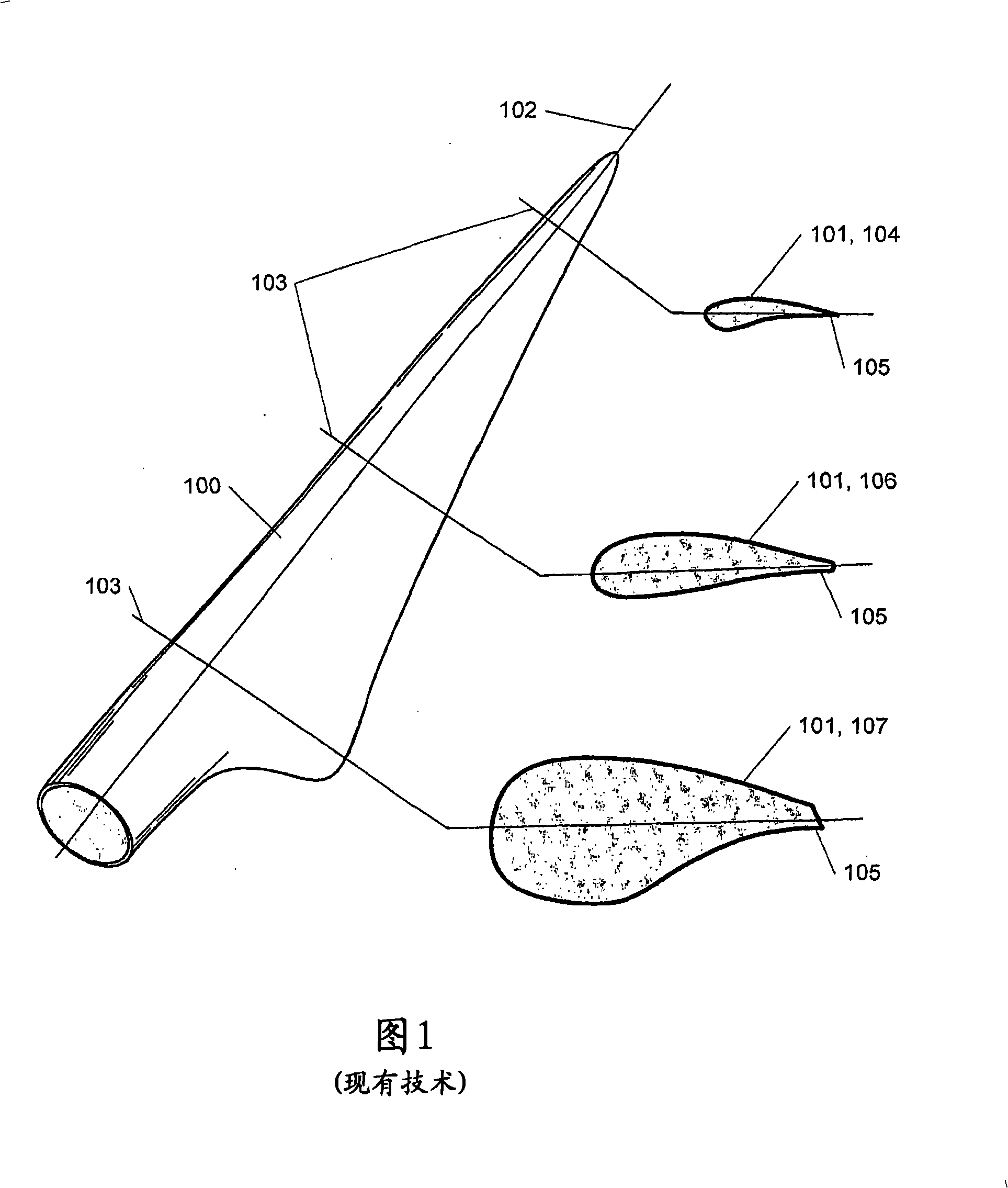

[0027] Fig. 1 shows a wind turbine blade 100 according to the prior art. The blade is depicted by a number of cross-sections 101 drawn alongside the blade. Each profile 101 indicates the outer contour of the blade 100 in the form of a cross-sectional view corresponding to a cross-section taken along the marking line 103 at a given position on the blade longitudinal axis 102 . Section families for aircraft wings usually consist of sections of the same type, and then the section size changes towards the outside of the wing. This is not usually the case for wind turbine blades, which can be given by a series of sections characterized by different section patterns, and therefore the blade surface is interpolated or blended between sections to create a smooth transition between the different sections . This is illustrated by the blade shown in FIG. 1 , which is defined by a profile 104 characterized by a sharp trailing edge 105 at the extreme point of the blade tip. The advantag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com