Patents

Literature

139 results about "Linear alpha olefin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

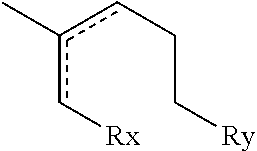

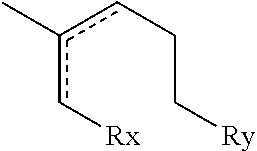

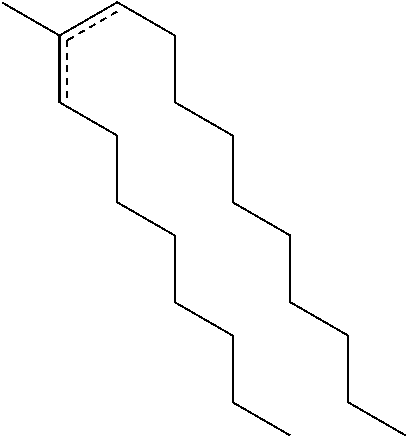

Linear alpha olefins (LAO) or normal alpha olefins (NAO) are olefins or alkenes with a chemical formula CₓH₂ₓ, distinguished from other mono-olefins with a similar molecular formula by linearity of the hydrocarbon chain and the position of the double bond at the primary or alpha position.

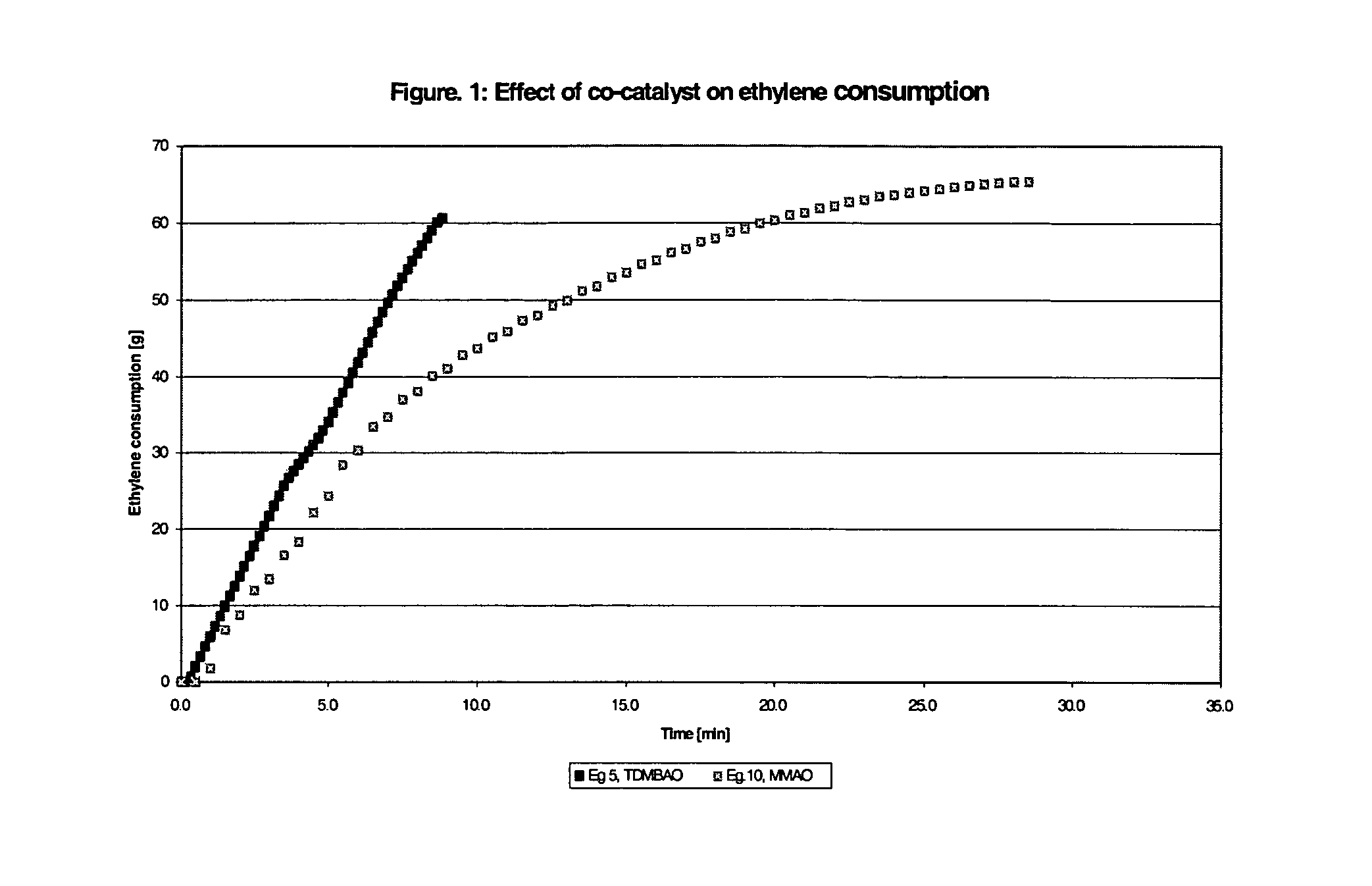

Catalyst systems for ethylene oligomerisation to linear alpha olefins

InactiveUS7053020B2Organic-compounds/hydrides/coordination-complexes catalystsIron organic compoundsAluminoxaneHydrogen

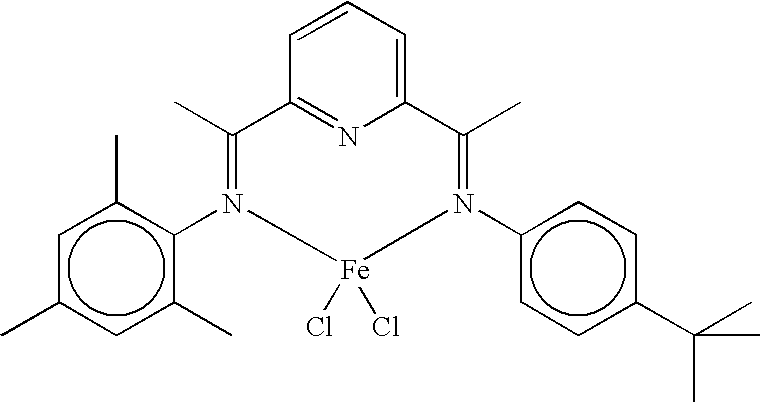

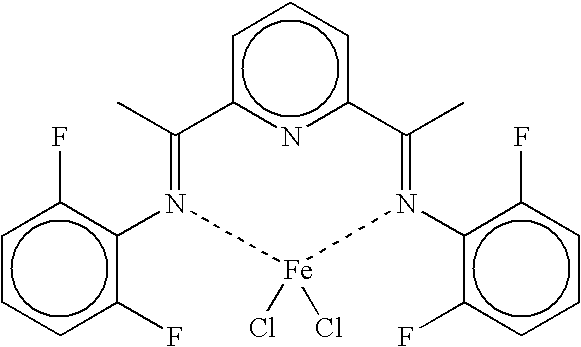

A catalyst system comprising:(a) one or more bisarylimino pyridine iron or cobalt catalysts;(b) a first co-catalyst compound which is selected from aluminium alkyls, aluminoxanes, and mixtures thereof; and(c) a second co-catalyst compound which comprises one or more compounds of the formula ZnR′2 wherein each R′, which may be the same or different, is selected from hydrogen, optionally substituted C1–C20 hydrocarbyl, phenyl, Cl, Br, I, SR″, NR″2, OH, OR″, CN, NC wherein R″, which within the same molecule may the same or different, is C1–C20 hydrocarbyl.

Owner:SHELL OIL CO

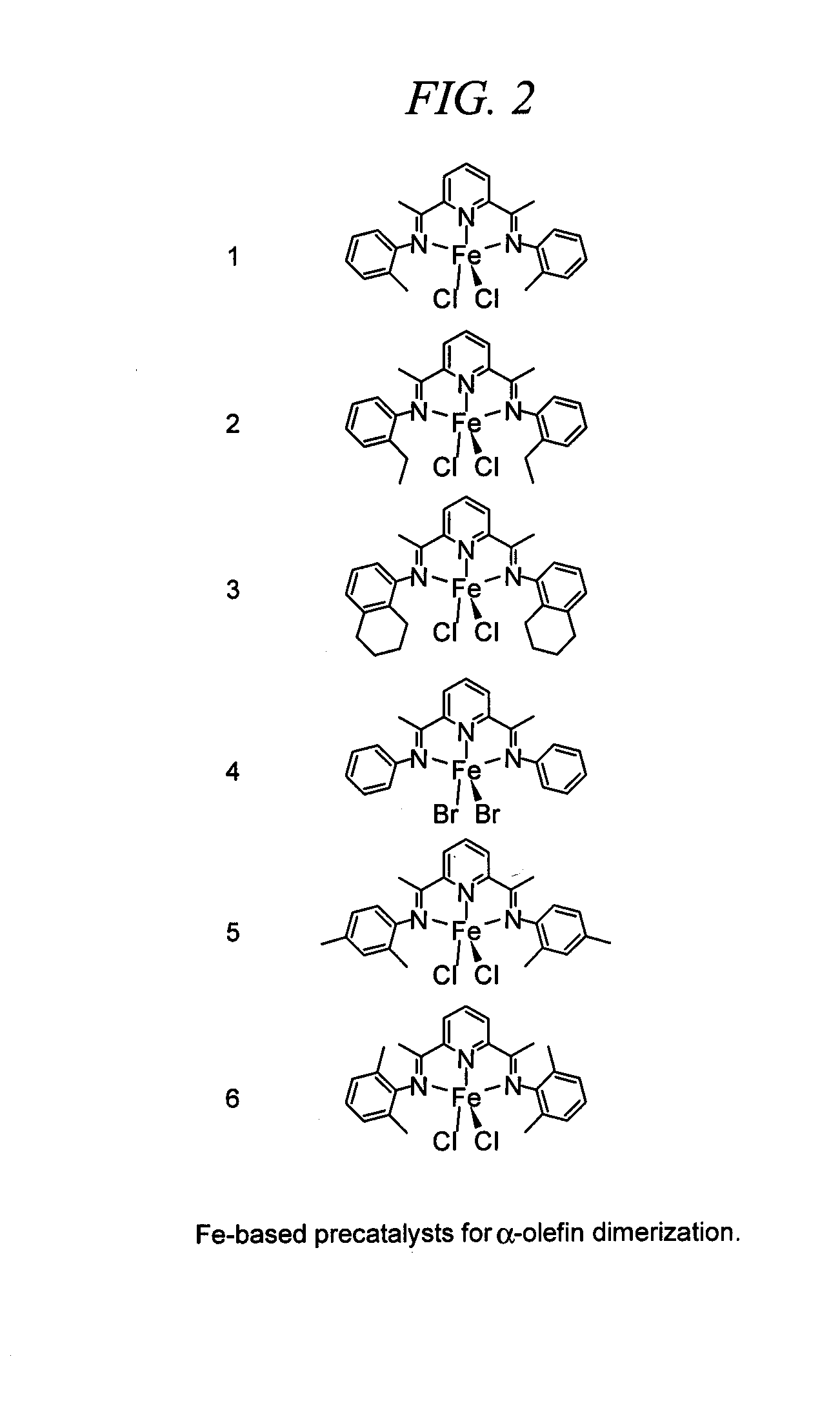

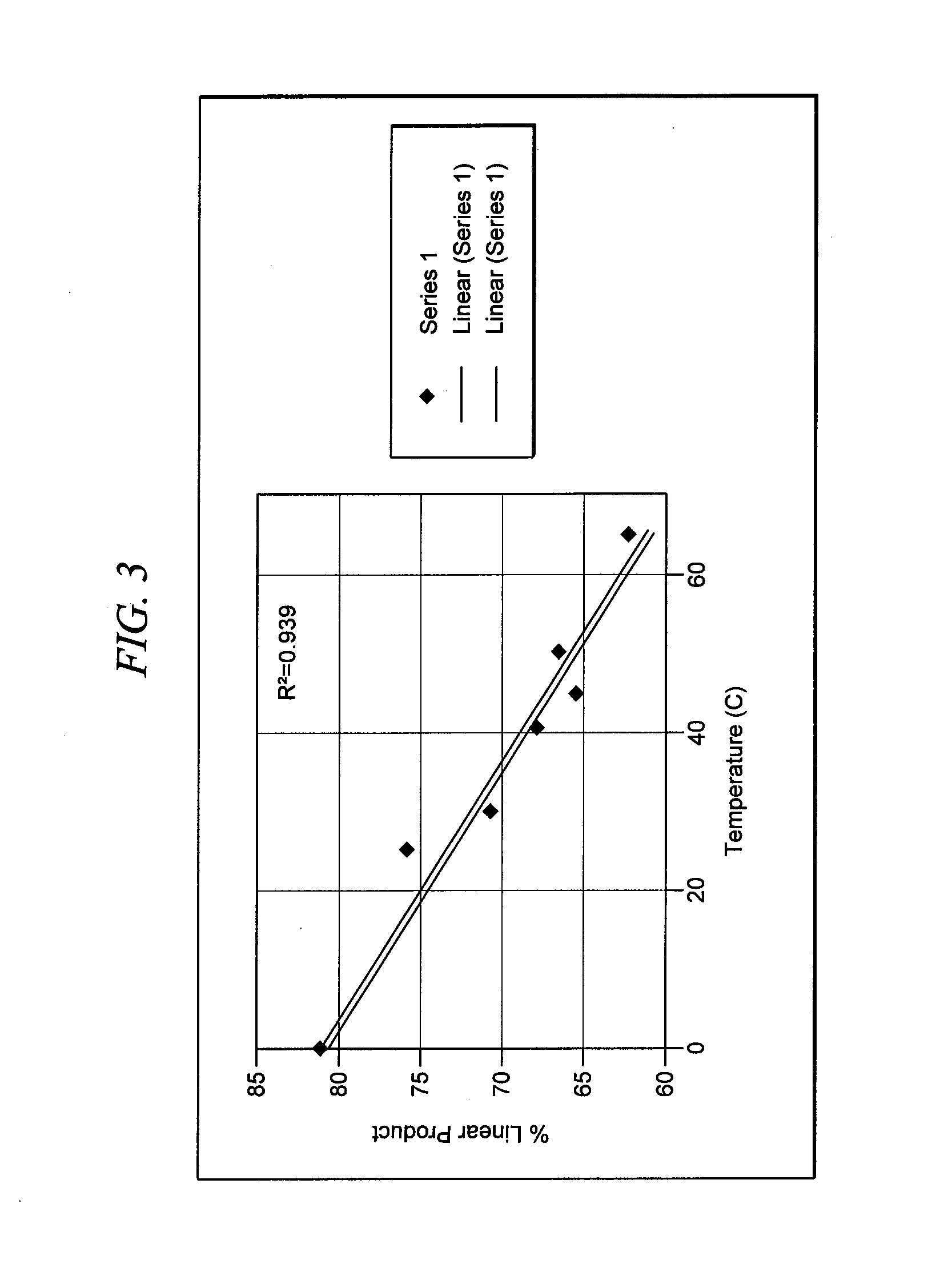

Linear alpha-olefin dimers possessing substantial linearity

InactiveUS7223893B2Less leachingQuality improvementHydrocarbons from unsaturated hydrocarbon additionCatalystsAlcoholPlasticizer

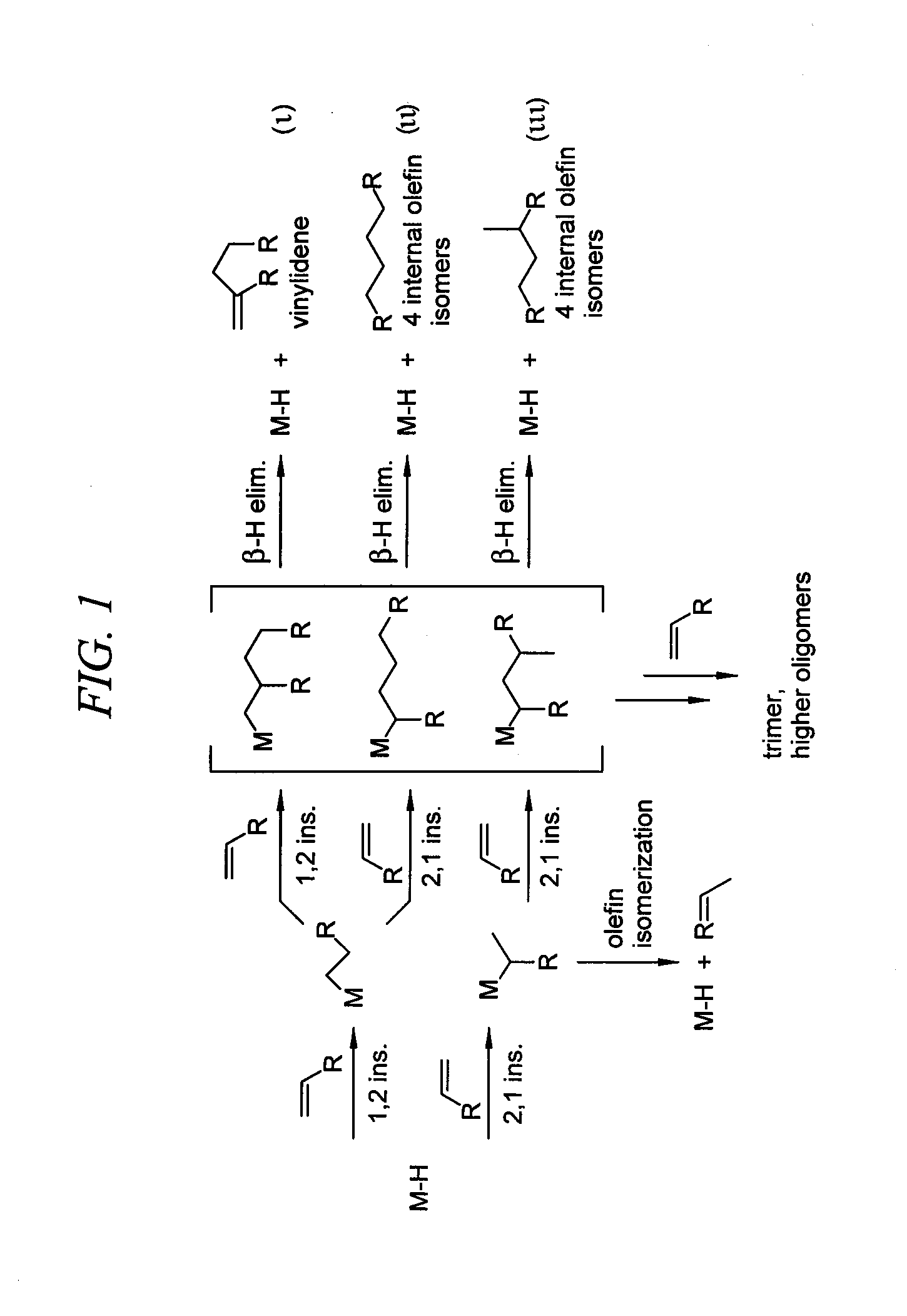

Linear 1-butene dimers and other linear alpha-olefin dimers are manufactured in high yield and with high selectivity by coupling of alpha-olefins. The coupling is accomplished by contacting alpha olefins with an iron-based catalyst activated with an aluminum-based co-catalyst. The catalyst is structured to preclude formation of multiple dimer products, and the byproducts of the olefin coupling consist almost exclusively of methyl branched olefin dimers. The dimers have potentially diverse use in areas stretching form pharmaceuticals to plastics. Linear 1-butene dimers may be particularly useful in the production of plasticizer alcohols which may in turn be used to manufacture high quality plastics with reduced leaching.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Process for the preparation of liniear low molecular weight olefins by the oligomerization of ethylene

InactiveUS20020147375A1Reduce inactivation rateHigh yieldHydrocarbons from unsaturated hydrocarbon additionCatalystsAromatic solventAlpha-olefin

A process for the preparation of low molecular weight linear alpha olefins is disclosed. The process comprises oligomerising ethylene in an inert aliphatic or aromatic solvent in the presence of a catalyst comprising of a first component selected from zirconium alkoxide and zirconium aryloxide and a second component selected from alkyl aluminum halide and / or alkyl aluminum.

Owner:INDIAN PETROCHEMICALS CORPORATION LIMITED

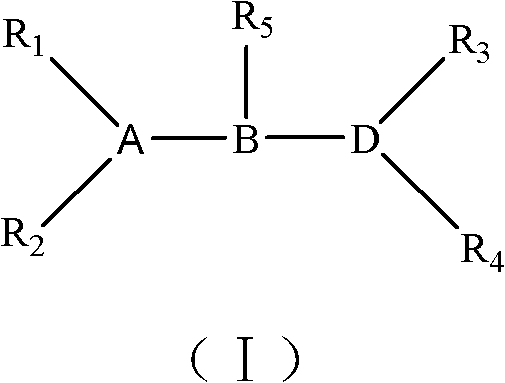

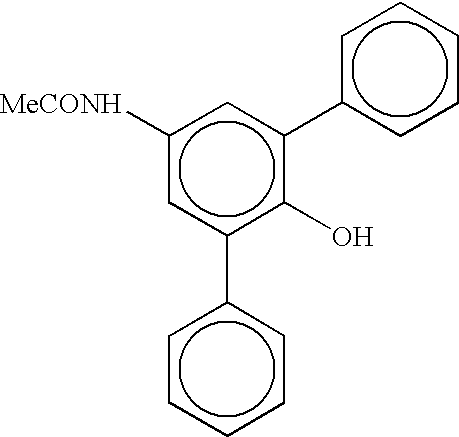

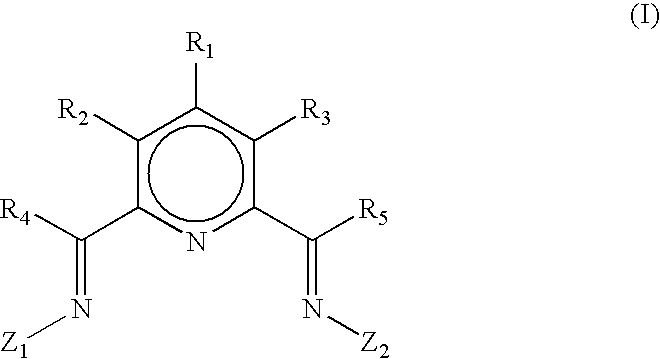

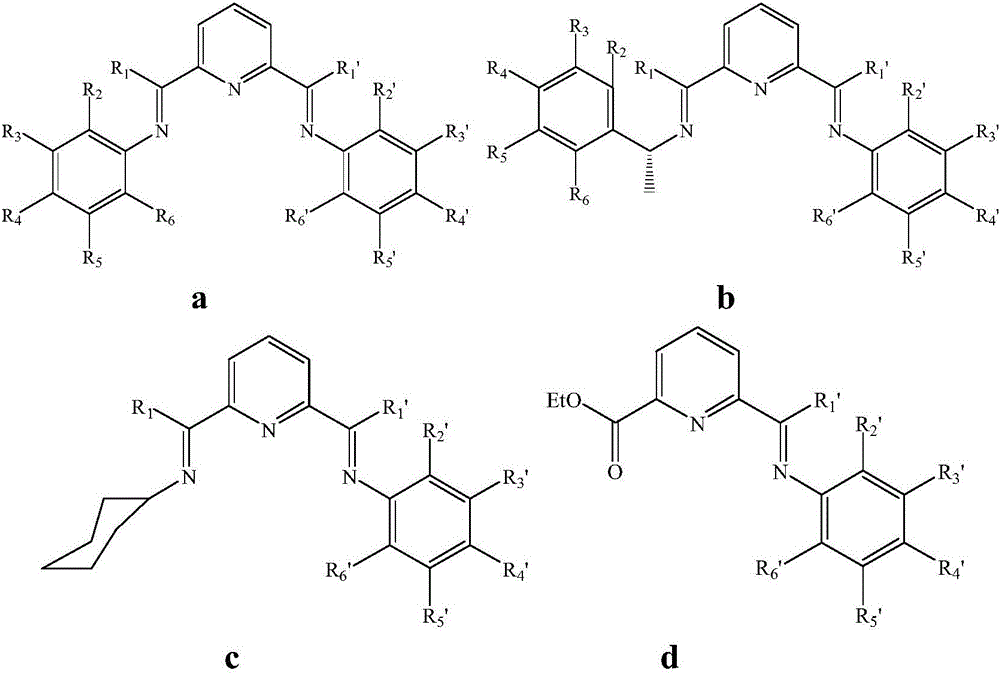

Ligands and catalyst systems thereof for ethylene oligomerisation to linear alpha olefins

InactiveUS7049442B2Iron group organic compounds without C-metal linkagesHydrocarbons from unsaturated hydrocarbon additionArylAlpha-olefin

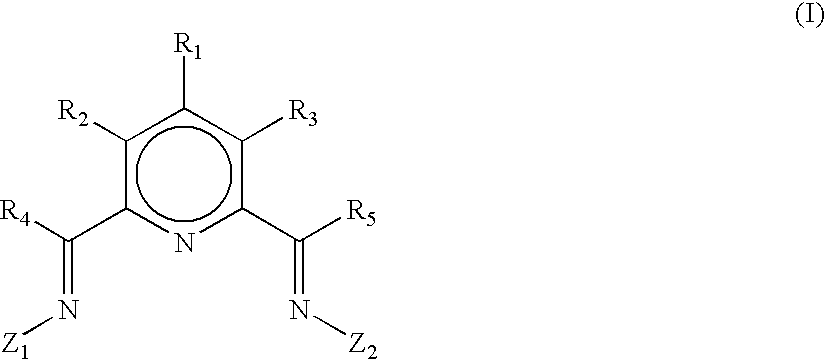

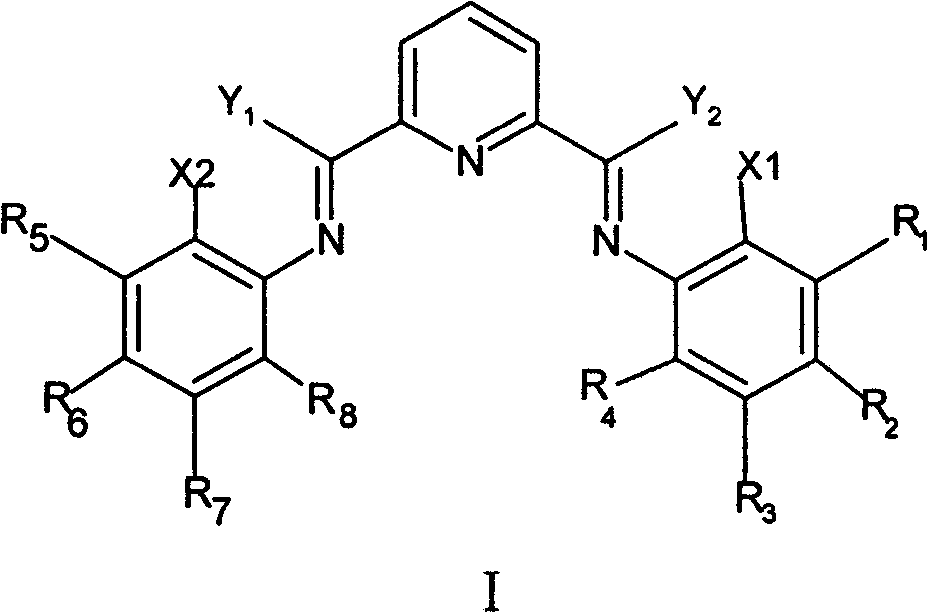

Mixed bis-imine pyridine ligands of formula (I), wherein Z1, which is different from Z2, is an optionally substituted aryl group; and Z2 comprises an optionally substituted heterohydrocarbyl moiety, or an optionally substituted aryl group in combination with a metal, said optionally substituted aryl group being π-co-ordinated to the metal;mixed bis-imine pyridine complexes comprising a ligand of formula (I); mixed ionic bis-imine pyridine complexes comprising a ligand of formula (I); and processes for the production of alpha olefins from ethylene, using said complexes.

Owner:SHELL OIL CO

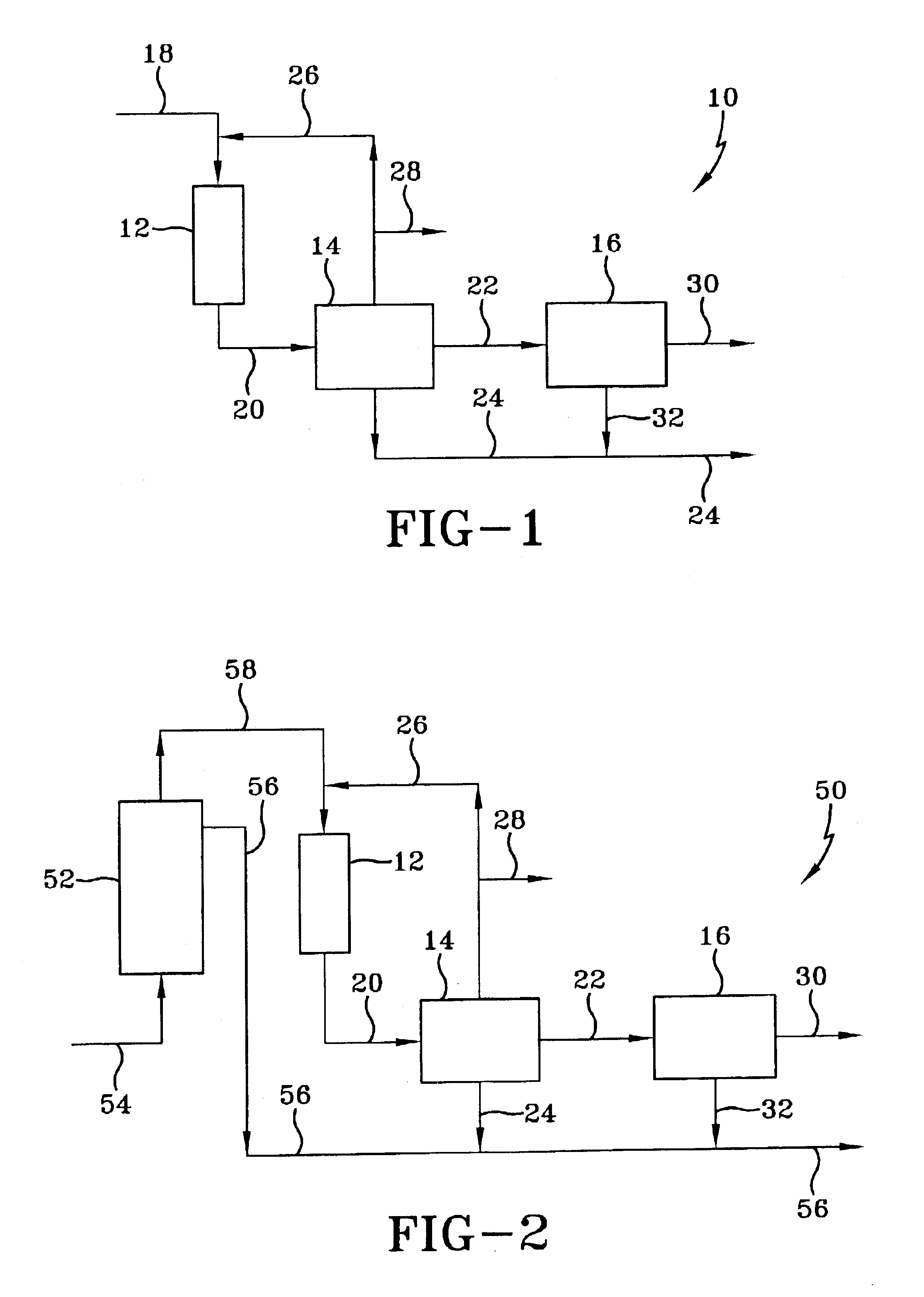

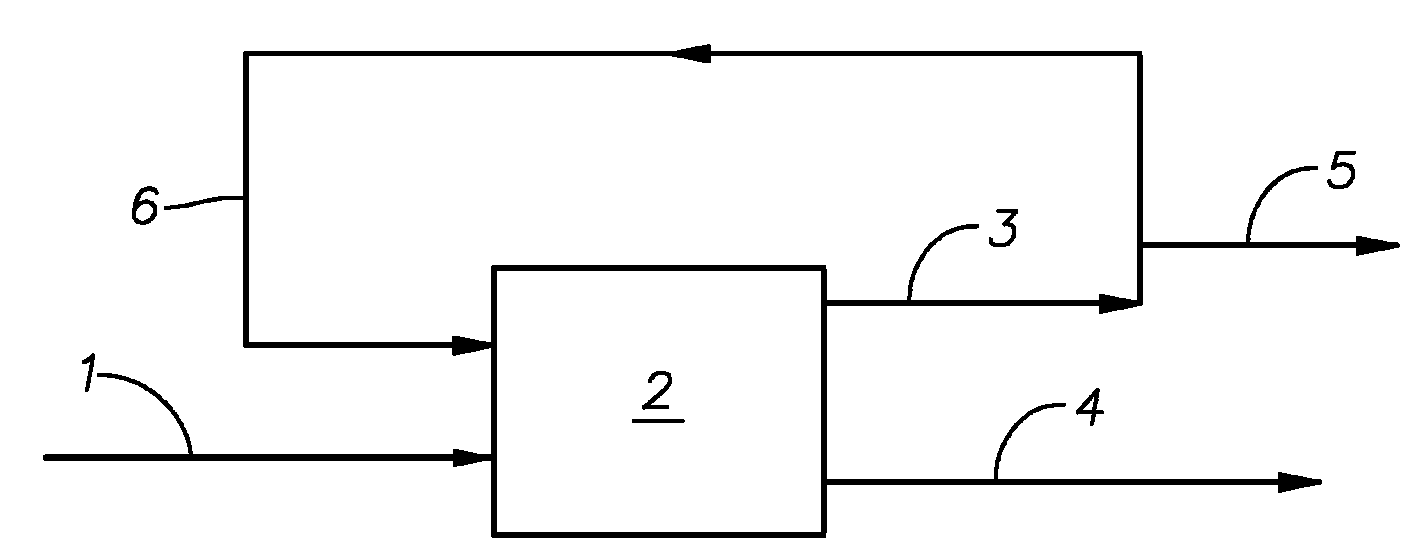

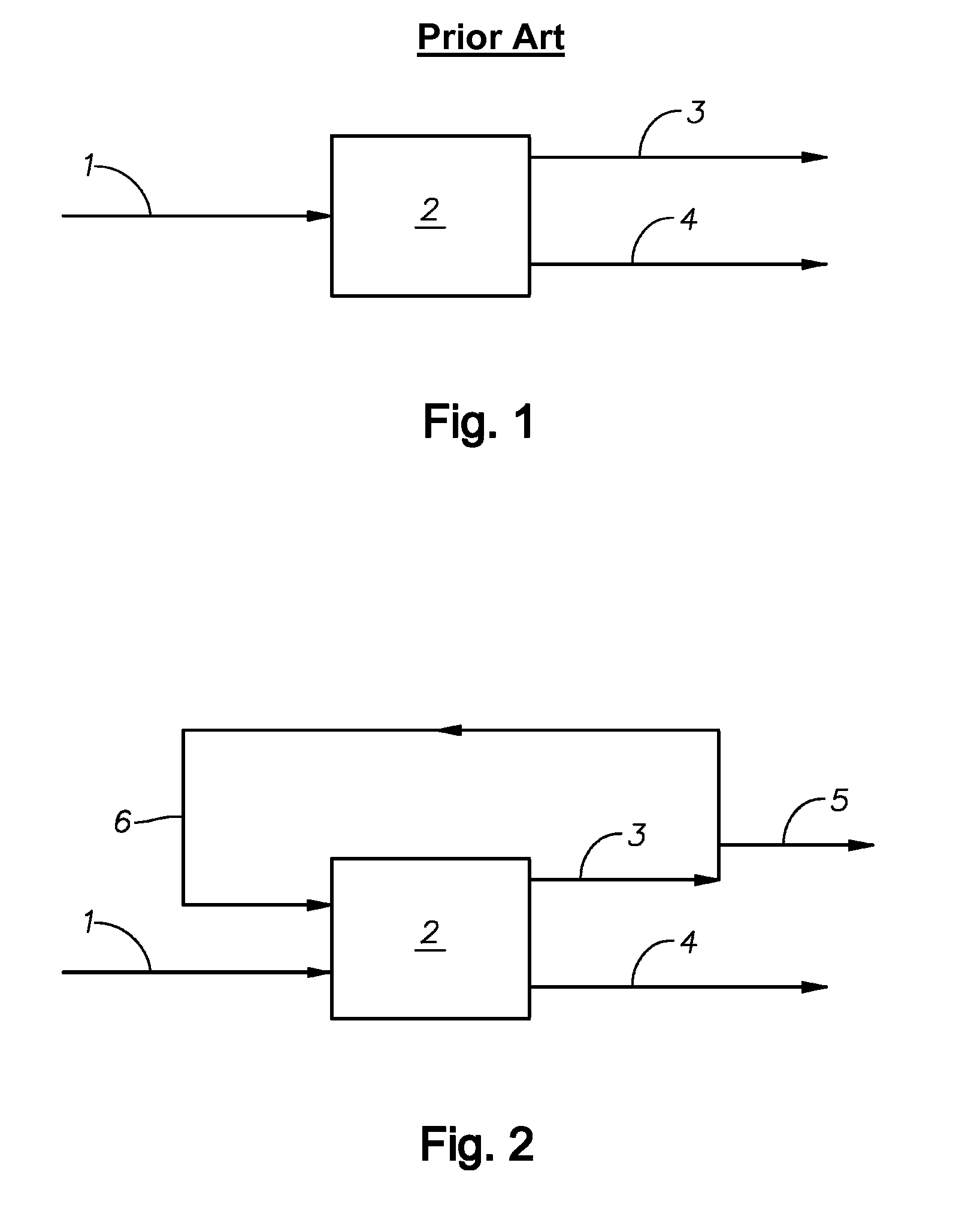

Process for preparing polyolefin products

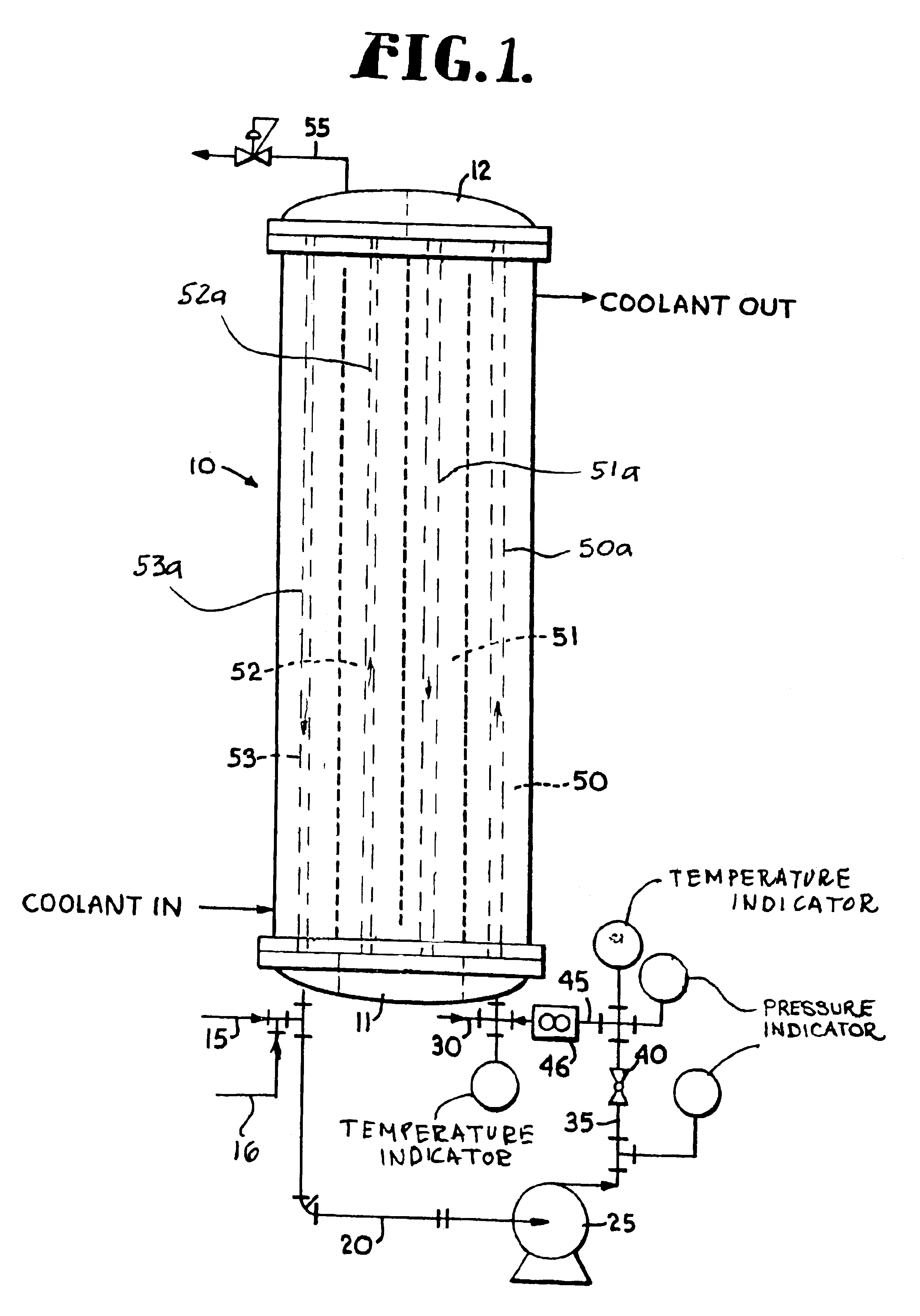

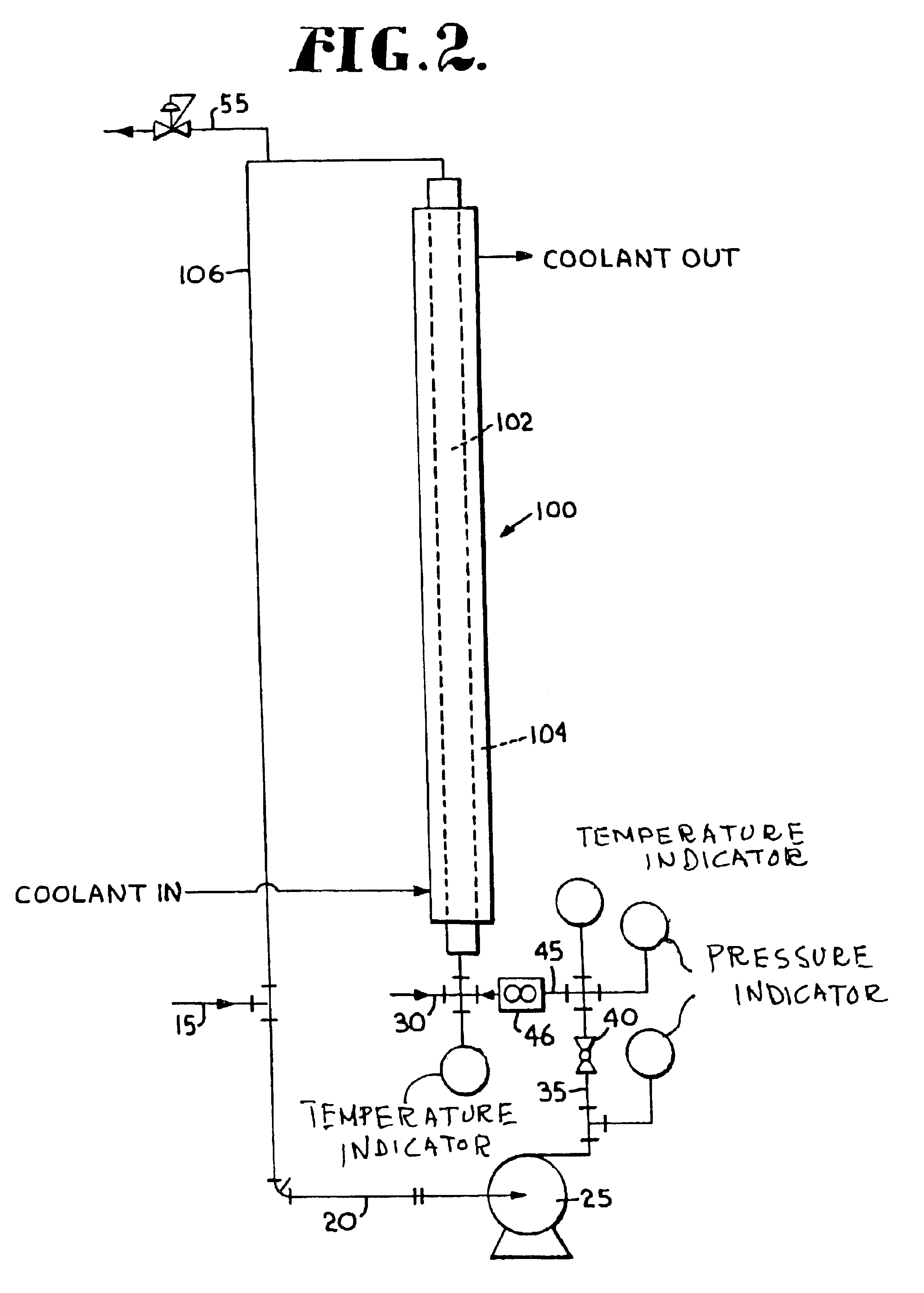

InactiveUS6884858B2Efficient and economical productionDelayed reaction timeHydrocarbons from unsaturated hydrocarbon additionHydrocarbonsPolyolefinShell and tube heat exchanger

A novel liquid phase polymerization process for preparing a polyolefin product having preselected properties is disclosed. The process includes the steps of providing a liquid feedstock which contains an olefinic component and a catalyst composition consisting of a stable complex of BF3 and a complexing agent therefor. The feedstock may comprise any one or more of a number of olefins including branched olefins such as isobutylene, C3 to C15 linear alpha olefins and C4 to C15 reactive non-alpha olefins. The feedstock and the catalyst composition are introduced into a residual reaction mixture recirculating in a loop reactor reaction zone provided in the tube side of a shell and tube heat exchanger at a recirculation rate sufficient to cause intimate intermixing of the residual reaction mixture, the added feedstock and the added catalyst composition. The heat of the polymerization reaction is removed from the recirculating intimately intermixed reaction admixture at a rate calculated to provide a substantially constant reaction temperature therein while the same is recirculating in said reaction zone. The conditions in the reactor are appropriate for causing olefinic components introduced in said feedstock to undergo polymerization to form the desired polyolefin product in the presence of the catalyst composition. A product stream containing the desired polyolefin product is withdrawn from the reaction zone. The introduction of the feedstock into the reaction zone and the withdrawal of the product stream from the reaction zone are controlled such that the residence time of the olefinic components undergoing polymerization in the reaction zone is appropriate for production of the desired polyolefin product.

Owner:TPC GROUP

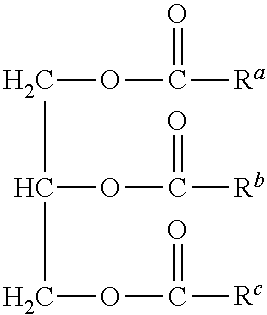

Process to Produce Improved Poly Alpha Olefin Compositions

This invention is directed to a two-step process for the preparation of improved poly alpha olefins wherein the first step involves oligomerizing low molecular weight linear alpha olefins in the presence of a single site catalyst and the second step involves oligomerization of at least a portion of the product from the first step in the presence of an oligomerization catalyst. The dimer product from the first oligomerization is characterized by a tri-substituted vinylene olefin content of at least 25 wt %.

Owner:EXXONMOBIL CHEM PAT INC

Additive for increasing the density of an oil-based fluid and fluid comprising such additive

A wellbore fluid having an oleaginous phase and an additive for increasing the density of the wellbore fluid. The additive comprises solid colloidal particles coated with a dispersant during the comminution process of forming the particles. Exemplary starting materials for the colloidal particles include commonly known weighting agents as well as mixture and combinations thereof. The dispersant in one embodiment, is selected from carboxylic acids of molecular weight of at least 150 Daltons. Alternatively, the dispersant coating may be made of compounds including oleic acid, polybasic fatty acids, alkylbenzene sulfonic acids, alkane sulfonic acids, linear alpha-olefin sulfonic acid or the alkaline earth metal salts of any of the above acids, and phospholipids as well as mixtures and combinations of these compounds. In another embodiment the dispersant is a polyacrylate ester having an average molecular weight from about 10,000 Daltons to about 200,000 Daltons.

Owner:MI

Additive for increasing the density of an oil-based fluid and fluid comprising such additive

A wellbore fluid having an oleaginous phase and an additive for increasing the density of the wellbore fluid. The additive comprises solid colloidal particles coated with a dispersant coated onto the colloidal particle during the comminution process of forming the particles. Exemplary starting materials for the colloidal particles include commonly known weighting agents including barite, calcium carbonate, dolomite, ilmenite, hematite or other iron ores, olivine, siderite, and strontium sulfate as well as mixture and combinations of these and other similar weighting materials. The dispersant in one illustrative embodiment, is selected from carboxylic acids of molecular weight of at least 150 Daltons. Alternatively, the dispersant coating may be made of compounds including oleic acid, polybasic fatty acids, alkylbenzene sulfonic acids, alkane sulfonic acids, linear alpha-olefin sulfonic acid or the alkaline earth metal salts of any of the above acids, and phospholipids as well as mixtures and combinations of these compounds. In another illustrative embodiment the dispersant is a polyacrylate ester. The illustrative polymeric dispersant should have an average molecular weight from about 10,000 Daltons to about 200,000 Daltons.

Owner:MI

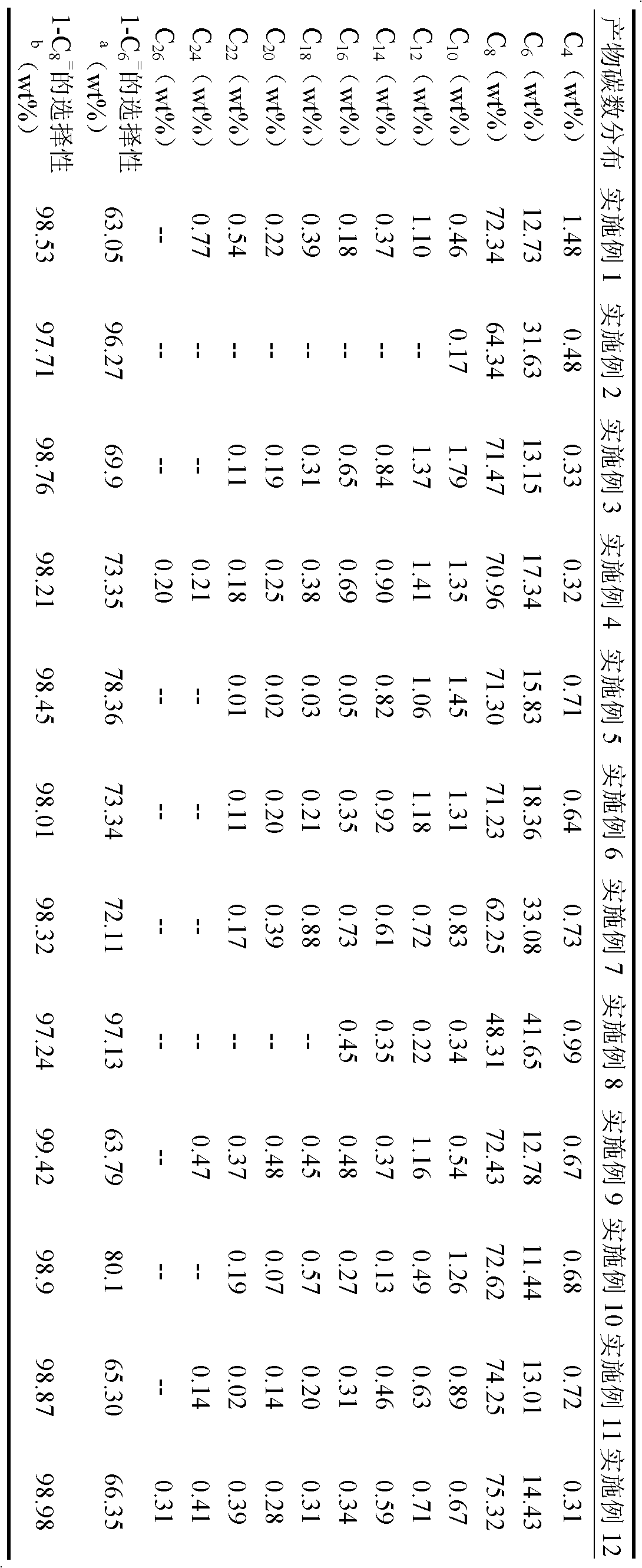

Method for preparing linear alpha-olefin

InactiveCN101906009AEasy to adjustChange typeHydrocarbonsHydrocarbon preparationDistillationMixed materials

The invention discloses a method for preparing linear alpha-olefin. The method comprises the following steps of: introducing catalytic solution and ethylene into a first reactor and reacting at the temperature of between 30 and 120 DEG C and under the pressure of 0.1 to 3 MPa for 1 to 40 min to prepare a first mixed material flow of first linear alpha-olefin, the ethylene and the catalytic solution; introducing the first mixed material flow and the ethylene into a second reactor and reacting at the temperature of between 40 and 90 DEG C and under the pressure of 0.5 to 4 MPa for 5 to 120 min to prepare a second mixed material flow of second linear alpha-olefin, the ethylene and the catalytic solution; performing gas-liquid separation on the second mixed material flow to obtain the ethylene and a liquid-phase product; cycling the separated ethylene to the first reactor or the second reactor for continuous reaction; and performing distillation separation on the liquid-phase product to prepare the linear alpha-olefin. The method has the advantages of mild reaction condition, simple operation and suitability for industrialized production.

Owner:ZHEJIANG UNIV

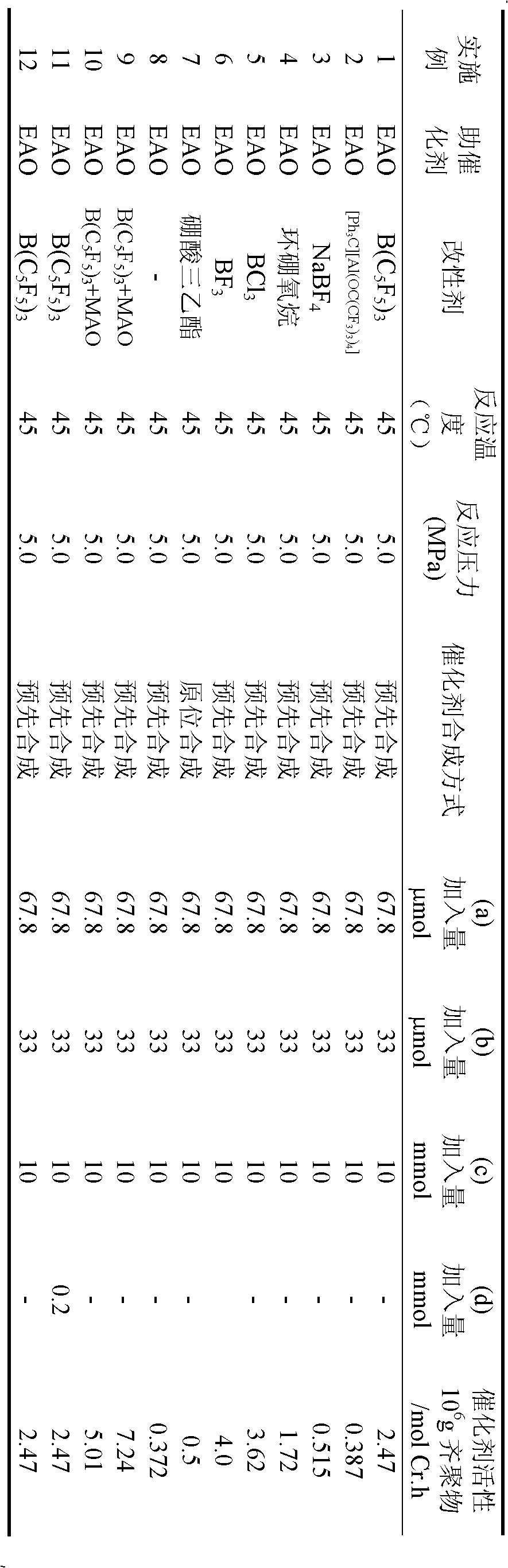

Catalyst system for ethylene selective oligomerization and ethylene oligomerization method

ActiveCN108097322ASolution to short lifeEasy to synthesizeGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsBackbone chain1-Hexene

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

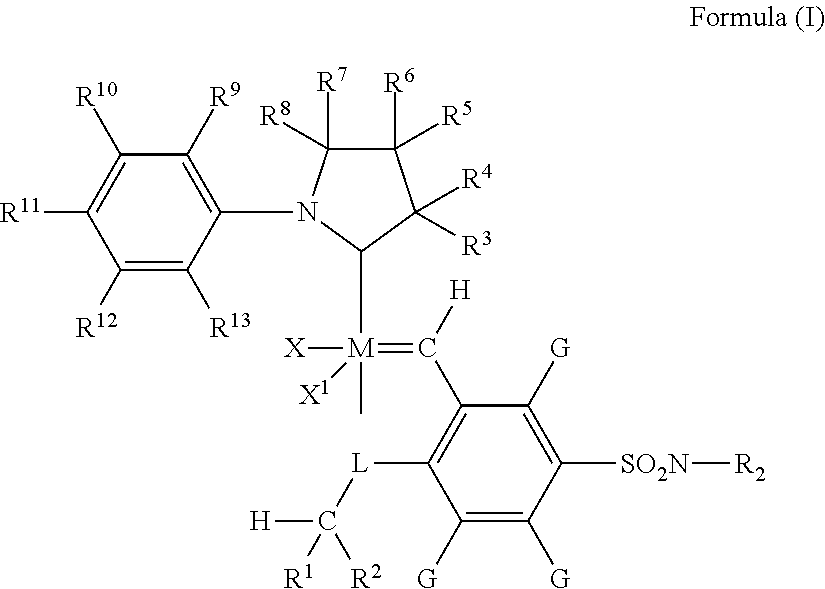

Metathesis catalyst and process for use thereof

This invention relates to a catalyst compound comprising a combination of a cyclic alkyl amino carbene ligand and a benzylidene both attached to a Group 8 metal, preferably ruthenium atom.This invention also relates to a process to make linear alpha-olefins comprising contacting a feed material and an optional alkene (such as ethylene) with the catalyst described above, wherein the feed material is a triacylglyceride, fatty acid, fatty acid alkyl ester, and / or fatty acid ester, typically derived from seed oil (e.g., biodiesel).

Owner:EXXONMOBIL CHEM PAT INC

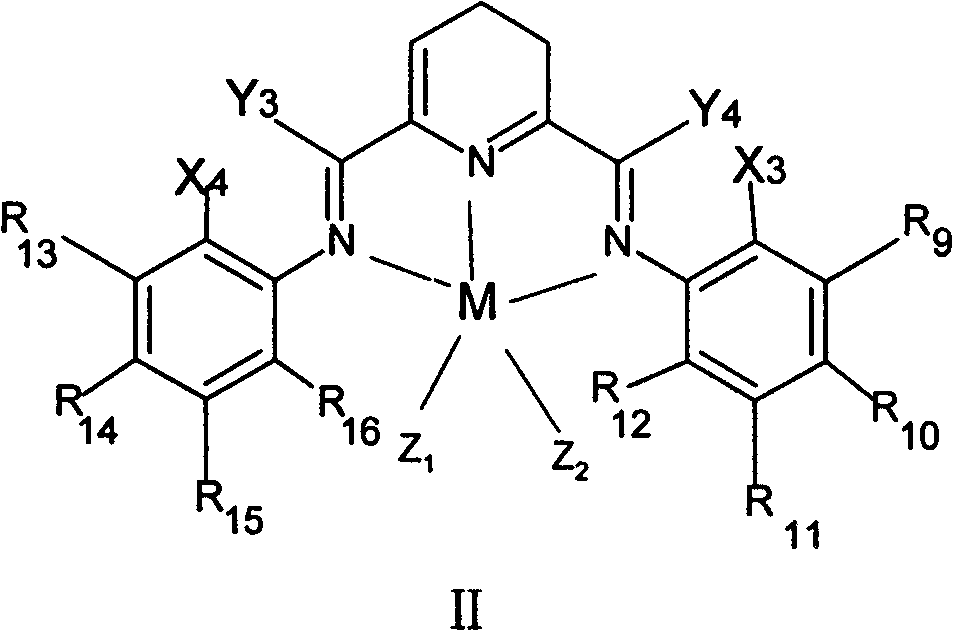

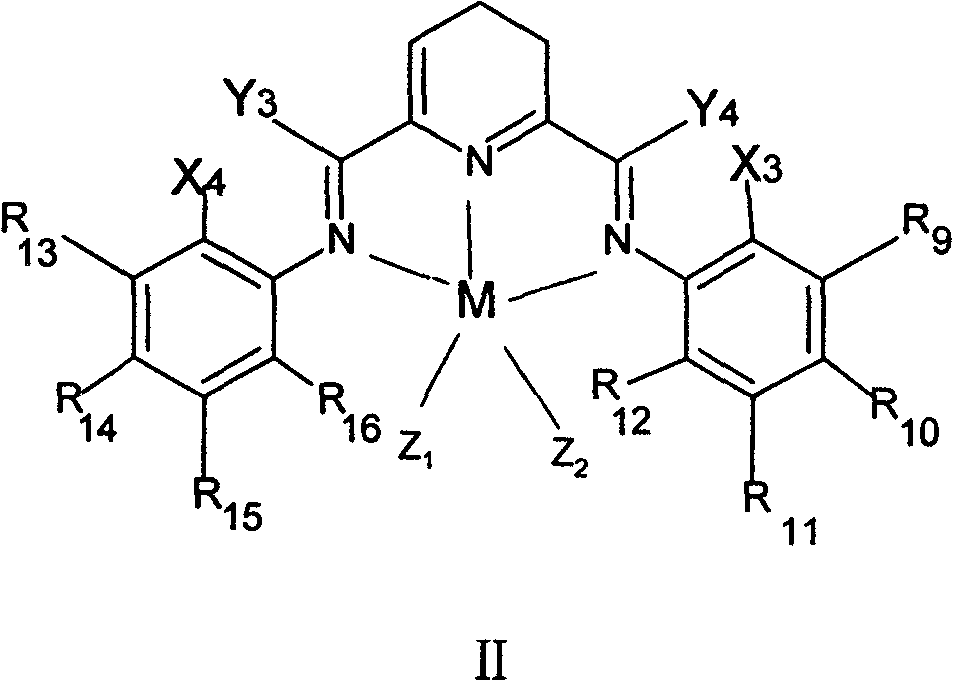

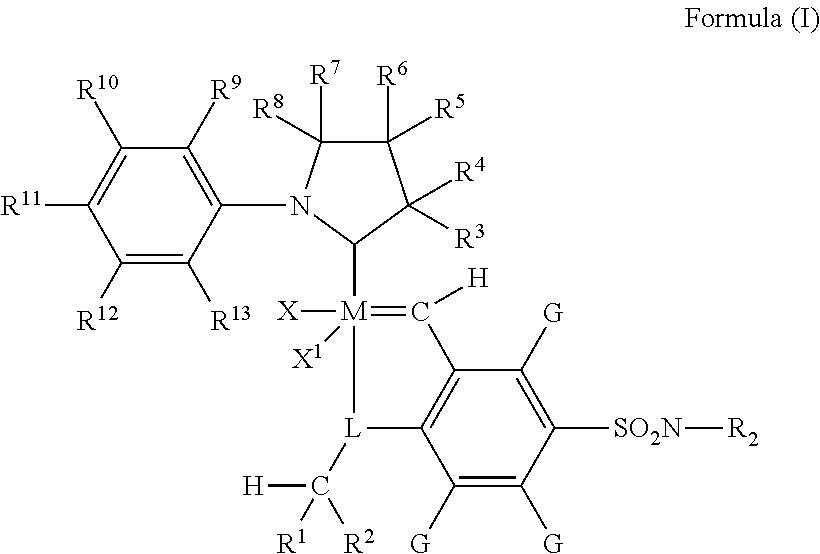

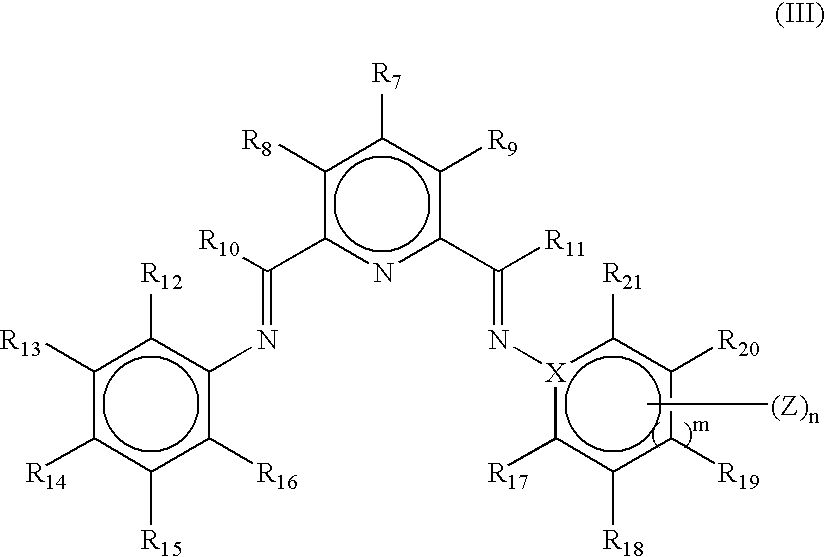

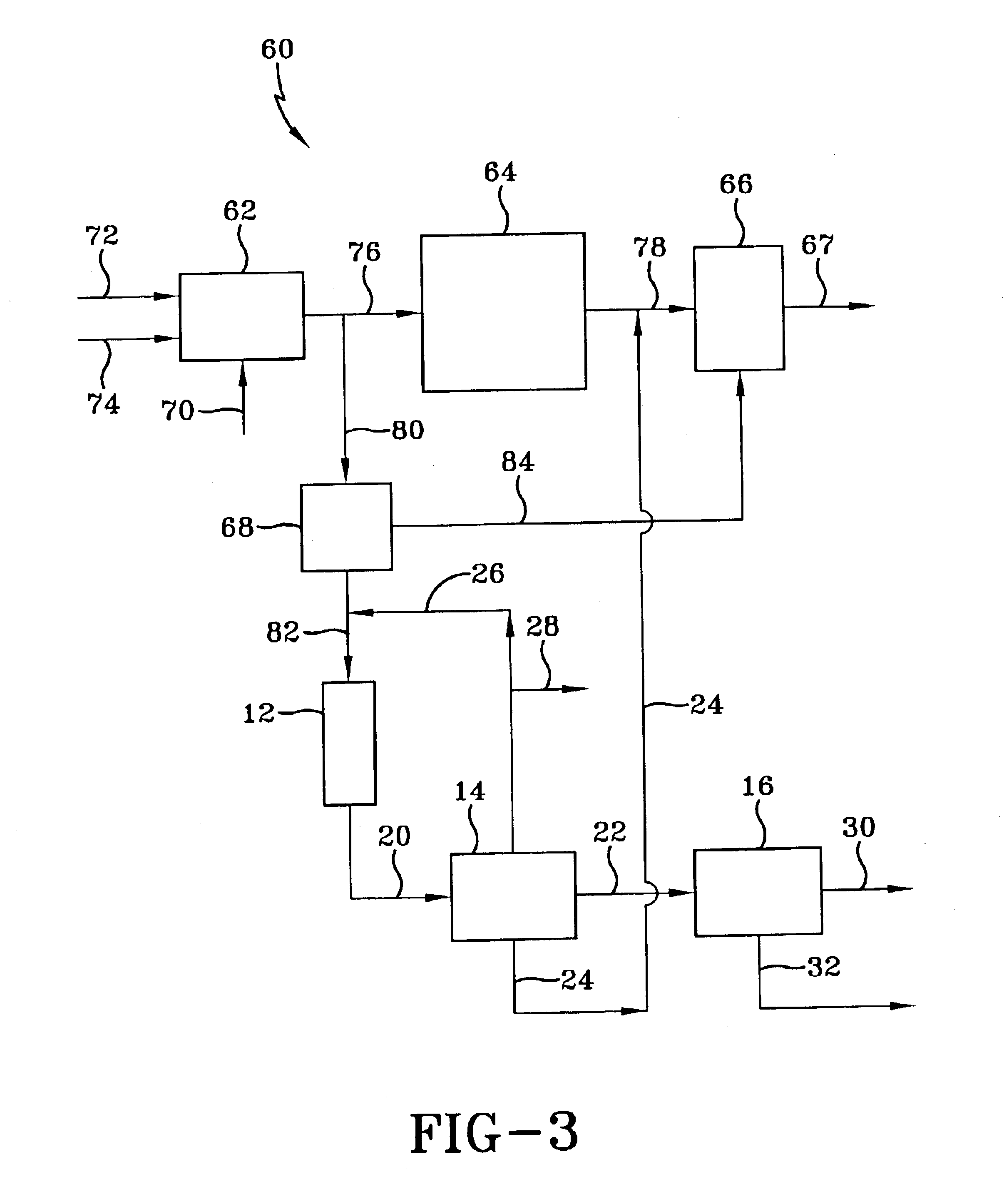

Non-symmetrical ligands and catalyst systems thereof for ethylene oligomerization to linear alpha olefins

InactiveUS7179871B2Organic-compounds/hydrides/coordination-complexes catalystsOrganic chemistry methodsNon-coordinating anionAlpha-olefin

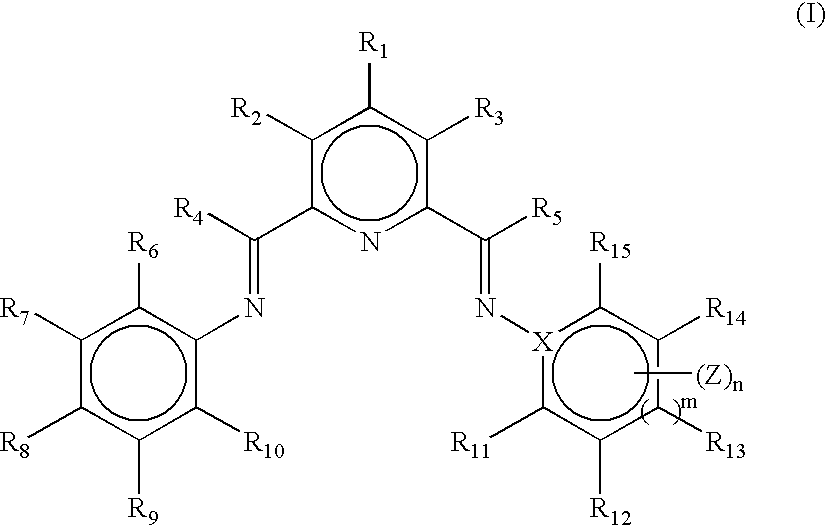

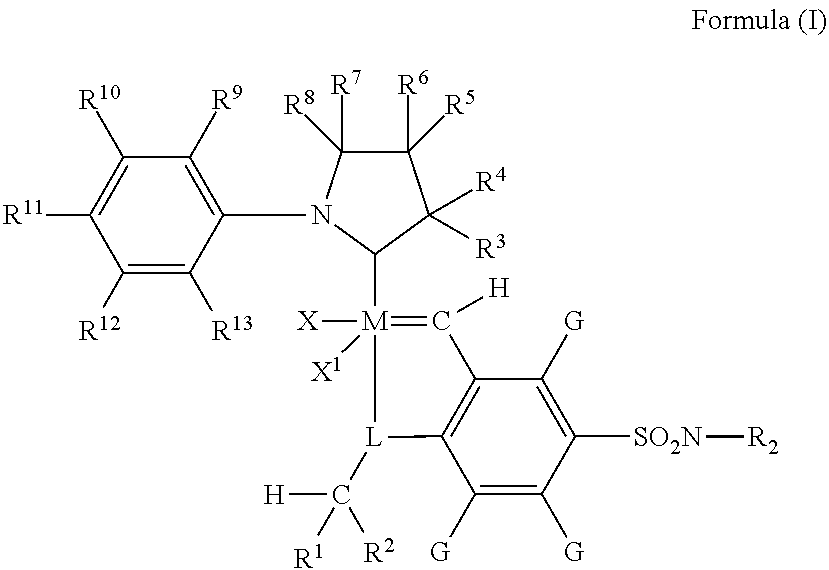

Non-symmetrical ligands of formula (I);bis-aryliminepyridine MXn complexes comprising a non-symmetrical ligand of formula (I), wherein M is a metal selected from Fe or Co, n is 2 or 3, and X is halide, optionally substituted hydrocarbyl, alkoxide, amide, or hydride; [bis-aryliminepyridine MYp.Ln+][NC−]q complexes, comprising a non-symmetrical ligand of formula (I), wherein Y is a ligand which may insert an olefin, M is Fe or Co, NC− is a non-coordinating anion and p+q is 2 or 3, matching the formal oxidation of the metal atom M, L is a neutral Lewis donor molecule and n=0, 1, or 2; and processes for the production of alpha-olefins from ethylene, using said complexes.

Owner:SHELL OIL CO

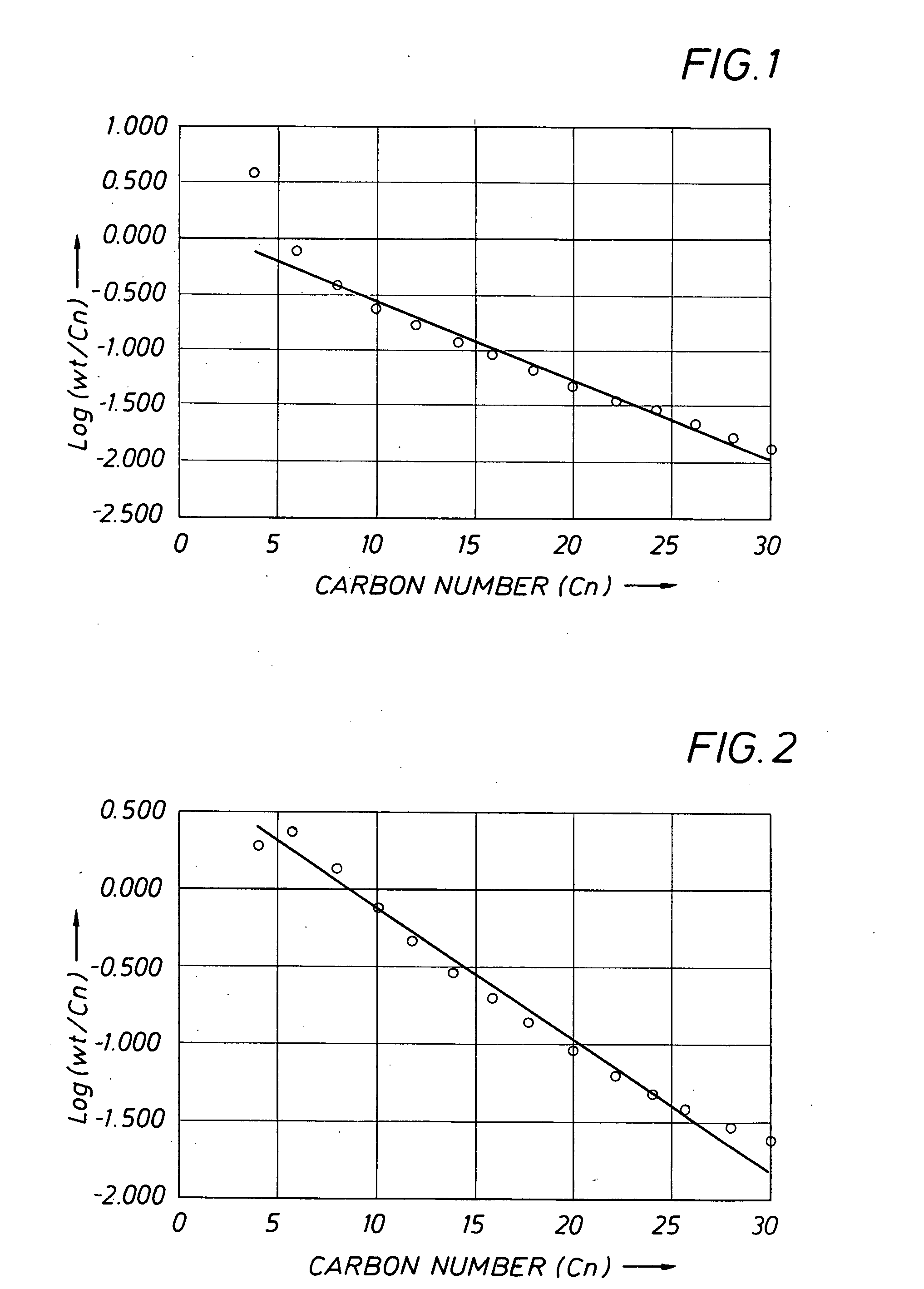

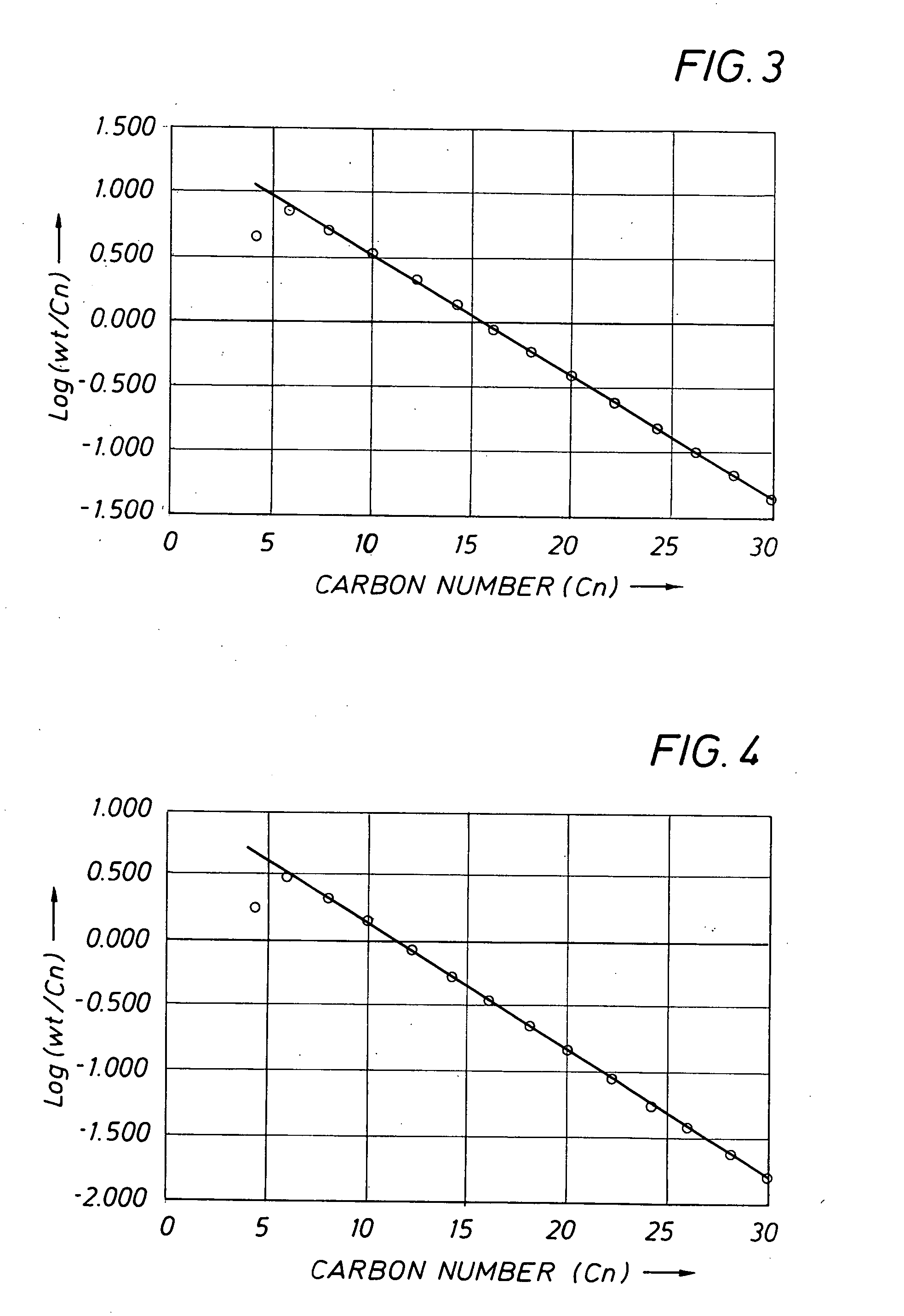

Linear alpha olefins from natural gas-derived synthesis gas over a nonshifting cobalt catalyst

InactiveUS20040127582A1Hydrocarbon from carbon oxidesOrganic compound preparationWater vaporAlpha-olefin

Linear alpha olefins having from four to twenty carbon atoms and low amounts of oxygenates are synthesized, by producing a synthesis gas containing H2 and CO from natural gas and passing it over a non-shifting cobalt catalyst at reaction conditions of temperature, % CO conversion, and gas feed H2:CO mole ratio and water vapor pressure, effective for the mathematical expression 200-0.6T+0.03PH2O-0.6XCO-8(H2:CO) to have a numerical value greater than or equal to 50. This process can be integrated into a conventional Fischer-Tropsch hydrocarbon synthesis process producing fuels and lubricant oils.

Owner:EXXON RES & ENG CO

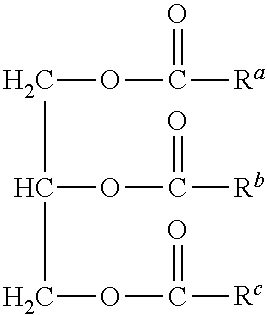

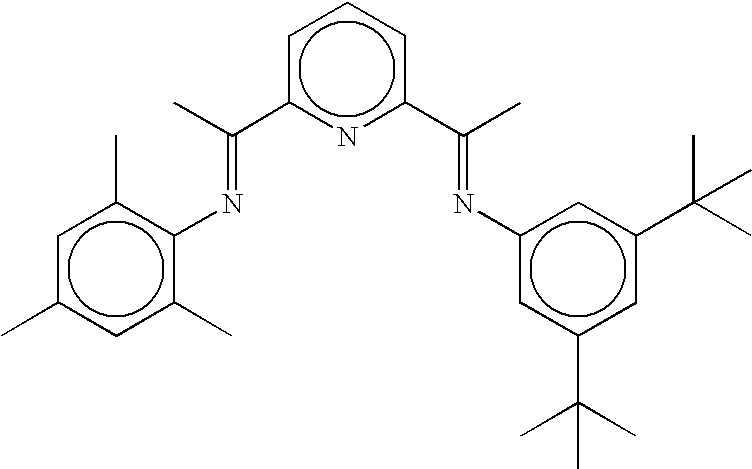

Process for producing linear alpha olefins

InactiveUS20050014983A1Organic-compounds/hydrides/coordination-complexes catalystsCatalystsAlpha-olefinSolvent

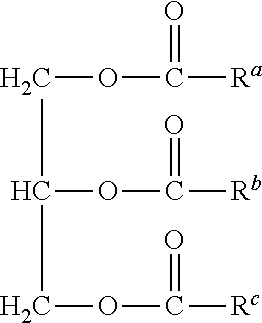

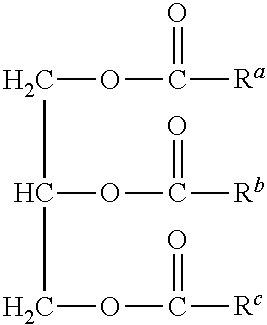

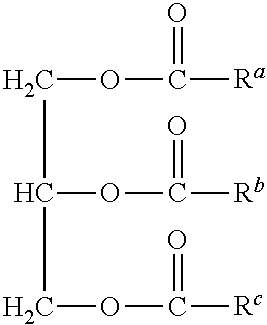

A process for the production of alpha-olefins comprising reacting ethylene under oligomerization conditions in the presence of a mixture comprising: (a) a metal salt based on Fe(II), Fe(III), Co(II) or Co(III); (b) a pyridine bis-imine ligand; and (c) a co-catalyst which is the reaction product of water with one or more organometallic aluminium compounds, wherein the one or more organometallic aluminium compounds is selected from: (i) βδ-branched compounds of formula (I): Al(CH2—CR1R2—CH2—CR4R5R6)xR3yHz; (ii) βγ-branched compounds of formula (II) Al(CH2—CR1R2—CR4R5R6)xR3yHz and mixtures thereof; wherein when the metal salt and the bis-arylimine pyridine ligand are mixed together they are soluble in aliphatic or aromatic hydrocarbon solvent.

Owner:SHELL OIL CO

Method for preparing octylene-1 by ethylene tetramerization reaction

InactiveCN103044181AEasy to synthesizeLow costOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsBenzeneChromium(III) acetylacetonate

The invention relates to a method for preparing octylene-1 by ethylene tetramerization reaction. The catalyst is composed of components (a), (b), (c) and / or (d) in a mol ratio of 1:(0.5-100):(0.1-5000):(0-500), wherein the component (a) is 1,2-bis(N(P(phenyl2)2)-benzene, 1,4-bis(N(P(phenyl)2)2)-benzene or N(CH2CH2N(P(phenyl)2)2)3; the component (b) is CrCl3(THF)3, chromium isooctoate or chromium acetylacetone; the component (c) is the product of reacting an alkyl aluminum compound or aluminoxane compound with a modifier containing at least two heteroatoms; and the component (d) is ortho-trichloromethylfluorobenzene, ortho-trifluoromethylchlorobenzene, ortho-trichloromethylchlorobenzene, ortho-trifluoromethylchlorobenzene, or 2 or 6-dichloro-trichloromethylbenzene. The mass percentage of the C8 linear alpha-olefin in the product is greater than 60%.

Owner:PETROCHINA CO LTD +1

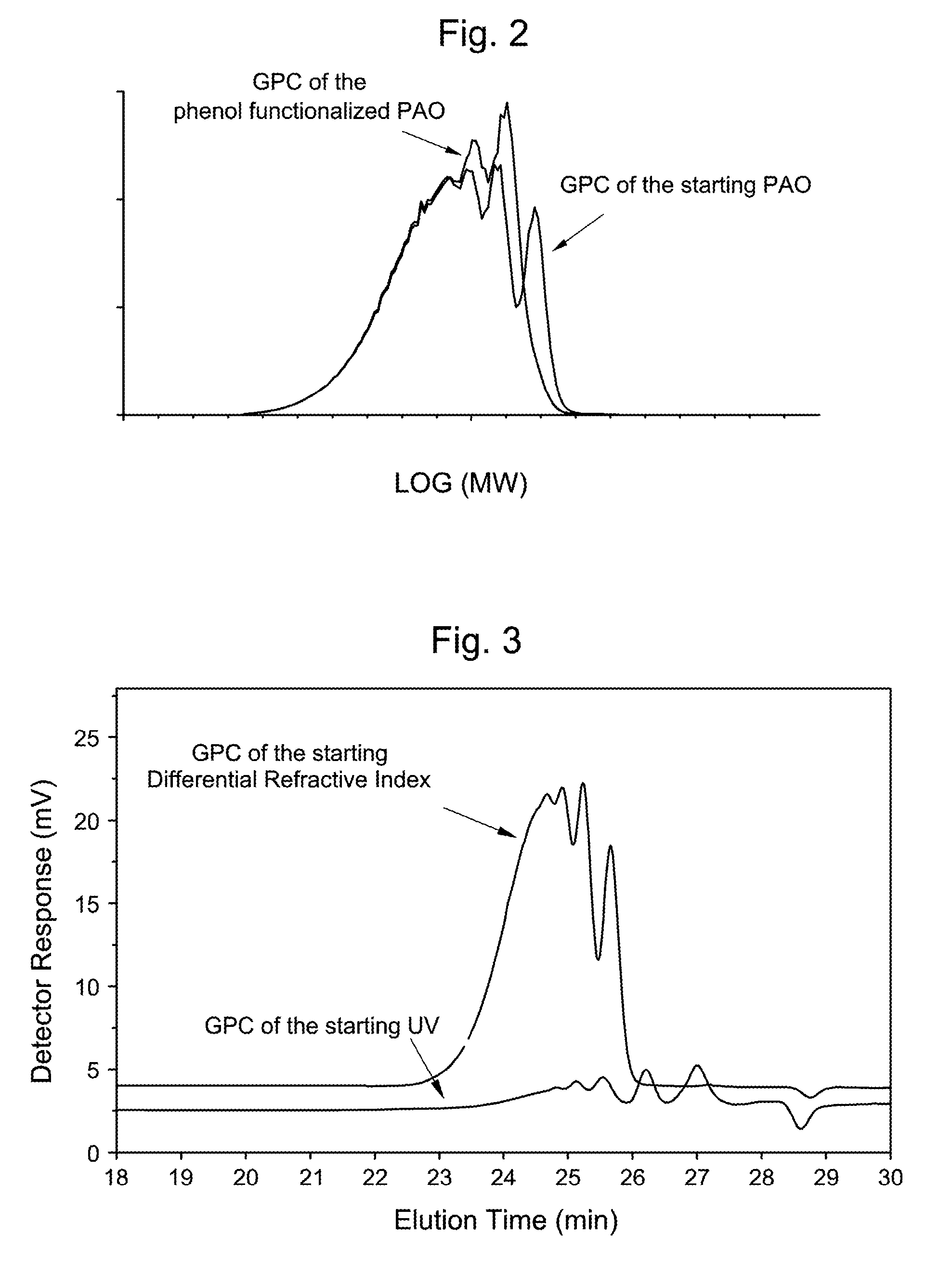

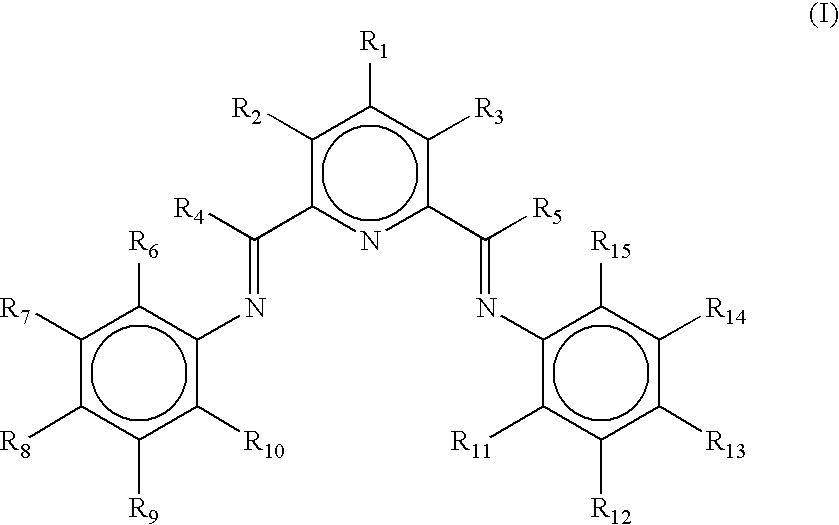

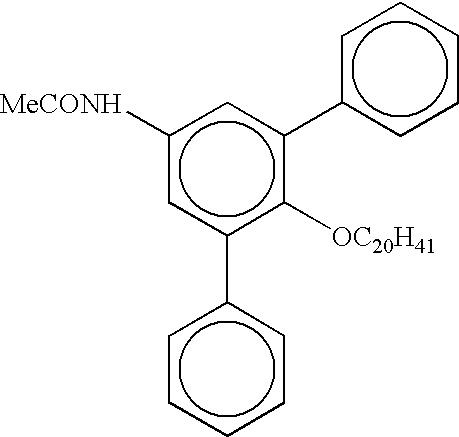

HydroxyAromatic Functionalized Polyalpha-Olefins

This invention relates to a hydroxyaromatic functionalized polyalpha-olefin comprising the product of the combination of:a) a polyalpha-olefin comprising one or more C3 to C20 linear alpha-olefins and having at least 10% vinylidene unsaturation, a viscosity index of 80 to 400, an Mn of 300 to about 20,000, and a pour point of 0° C. or less; andb) a hydroxyaromatic moiety;wherein the analine point of the functionalized polyalpha-olefin is at least 10° C. lower than the analine point of the polyalpha-olefin.

Owner:EXXONMOBIL CHEM PAT INC

Process for preparing linear alpha olefins

InactiveUS7589245B2High yieldHigh selectivityHydrocarbons from unsaturated hydrocarbon additionCatalystsPolymer scienceIsomerization

A process for the preparation of linear alpha olefins having 2n carbon atoms from linear alpha olefins having n carbon atoms comprising the steps of (a) dimerizing a linear alpha olefin having n carbon atoms in the presence of a dimerization catalyst to produce a linear internal olefin having 2n carbon atoms; (b)(i) reacting the linear internal olefin having 2n carbon atoms produced in step (a) with a trialkylaluminium compound in the presence of a catalytic amount of an isomerization / displacement catalyst in order to cause isomerization of the linear internal olefin and to displace alkyl group(s) from said trialkylaluminium compound to form an alkyl aluminium compound wherein at least one of the alkyl groups bound to aluminium is a linear alkyl which has been derived from the isomerization of said linear internal olefin; and (b)(ii) reacting said alkyl aluminium compound with an alpha olefin optionally in the presence of a displacement catalyst so as to displace said linear alkyl from said alkyl aluminium compound to form a linear alpha olefin having 2n carbon atoms.

Owner:SHELL OIL CO

Ligands and catalyst systems thereof for ethylene oligomerisation to linear alpha olefins

InactiveUS20050159601A1Group 1/11 element organic compoundsIron group organic compounds without C-metal linkagesArylAlpha-olefin

Mixed bis-imine pyridine ligands of formula (I), wherein Z1, which is different from Z2, is an optionally substituted aryl group; and Z2 comprises an optionally substituted heterohydrocarbyl moiety, or an optionally substituted aryl group in combination with a metal, said optionally substituted aryl group being π-co-ordinated to the metal; mixed bis-imine pyridine complexes comprising a ligand of formula (I); mixed ionic bis-imine pyridine complexes comprising a ligand of formula (I); and processes for the production of alpha olefins from ethylene, using said complexes.

Owner:SHELL OIL CO

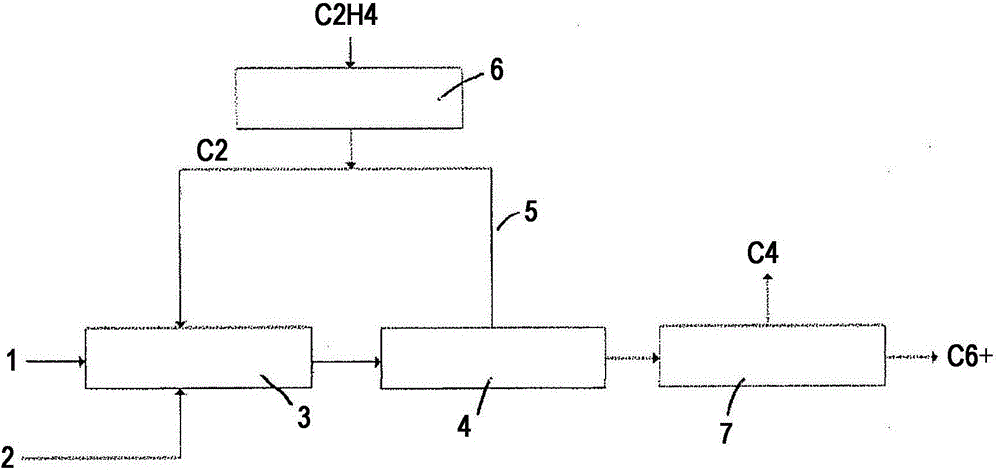

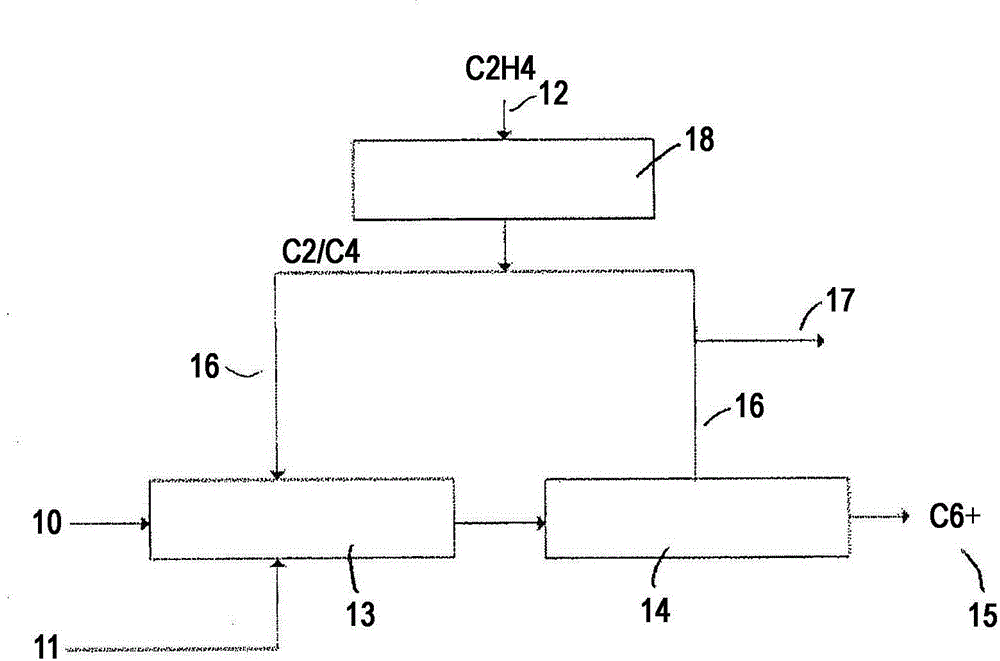

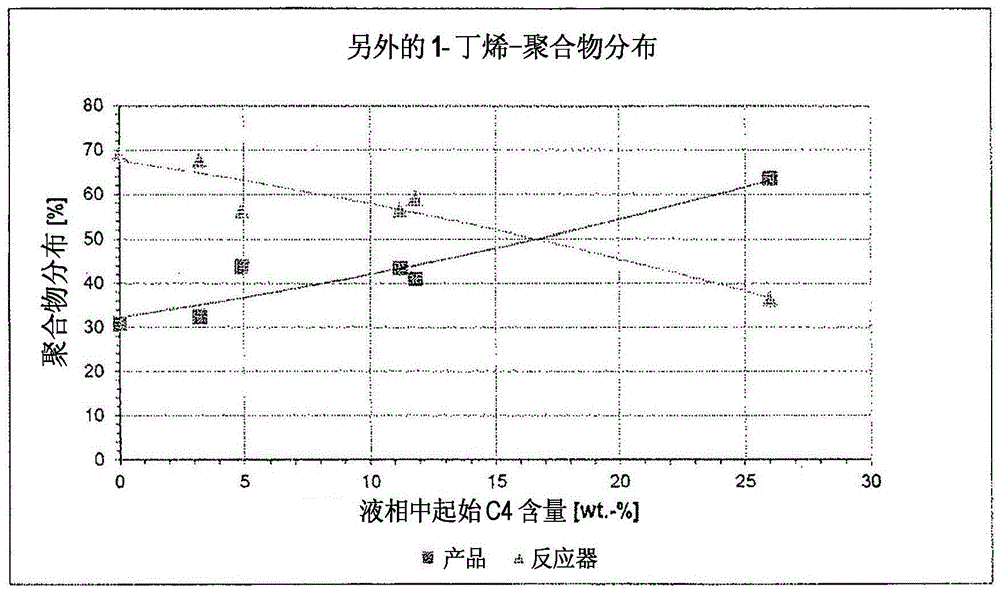

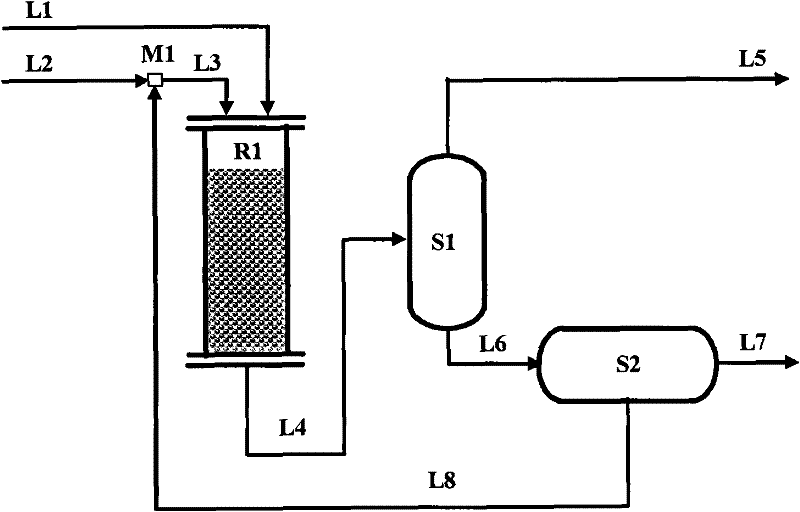

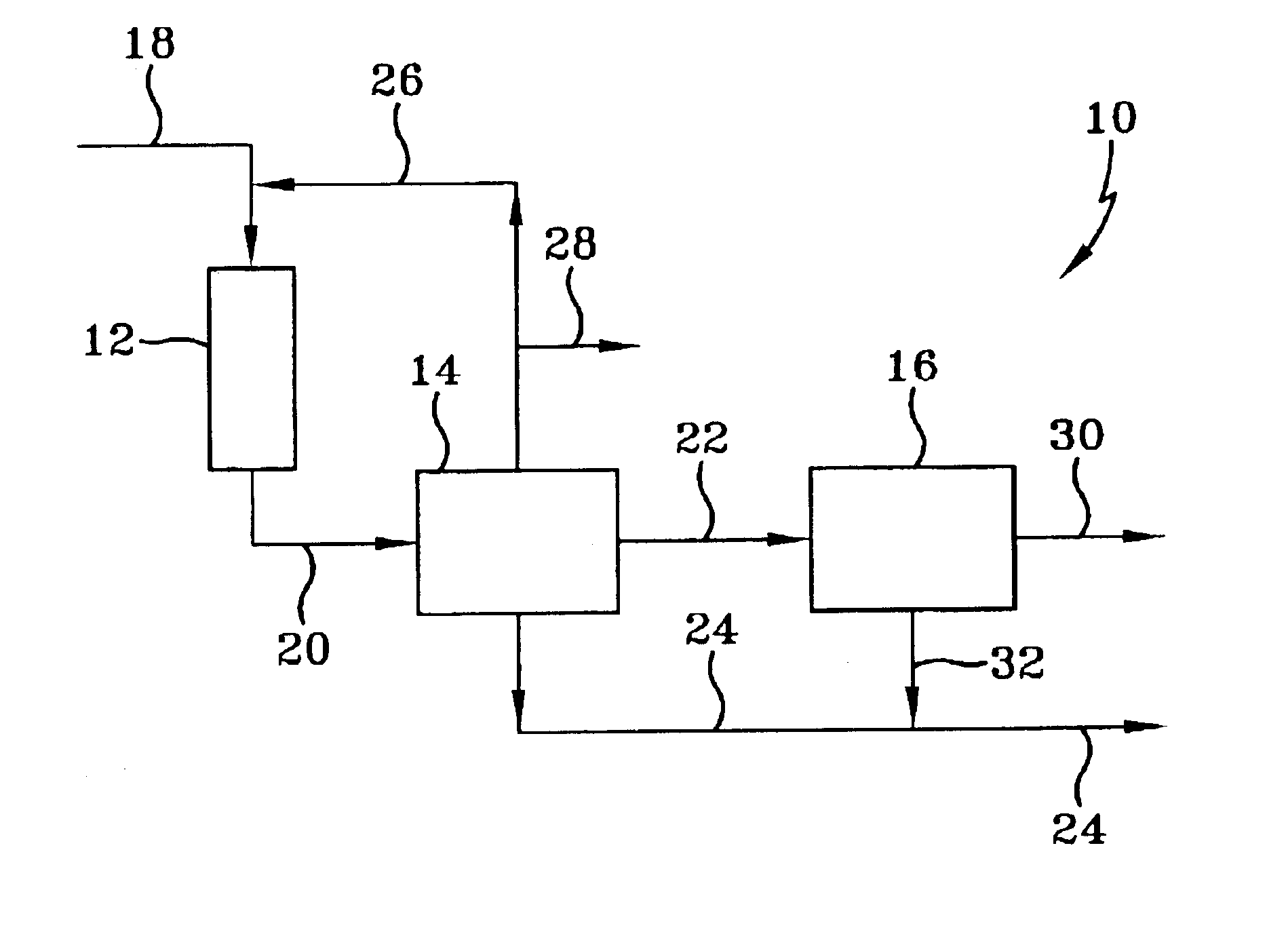

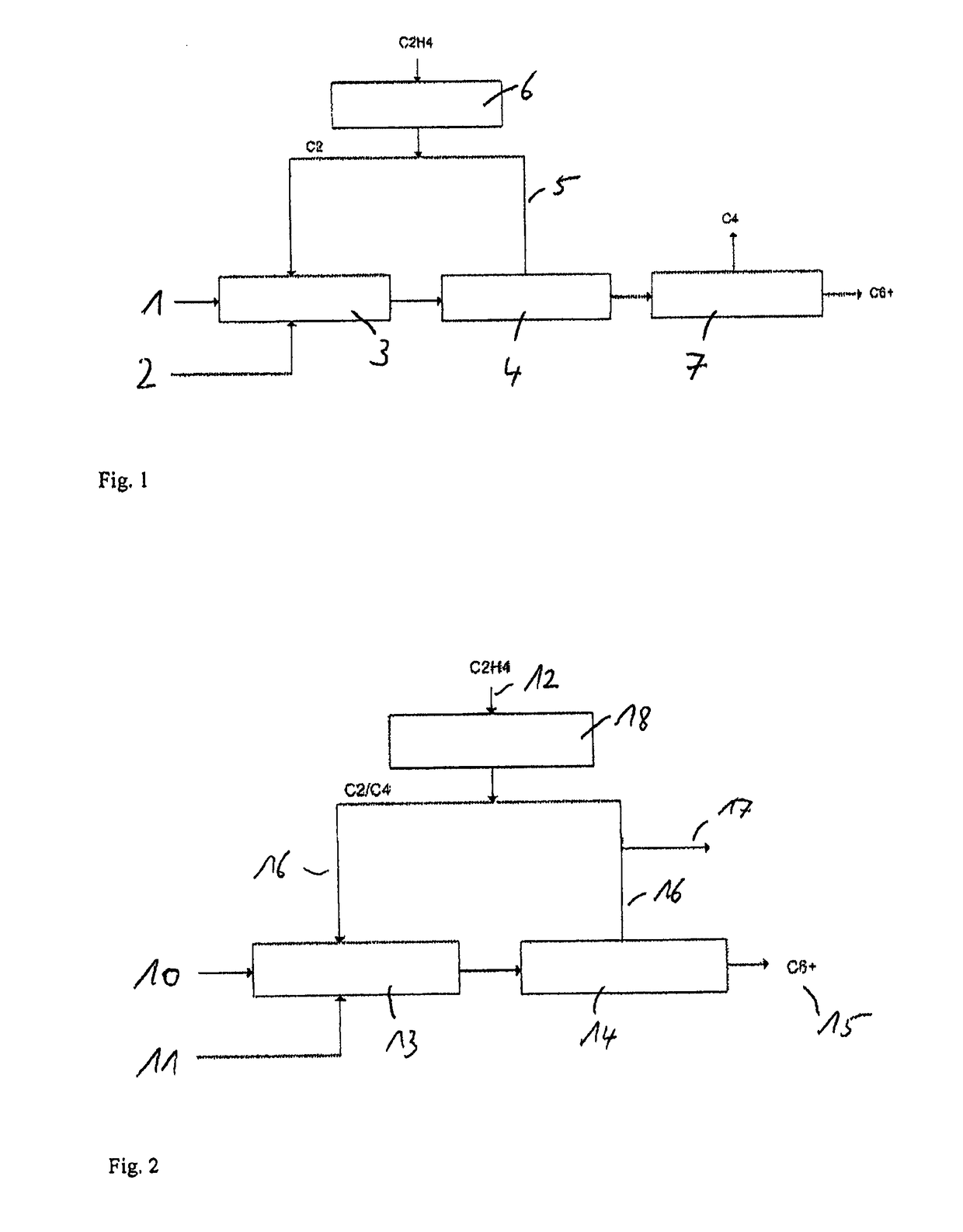

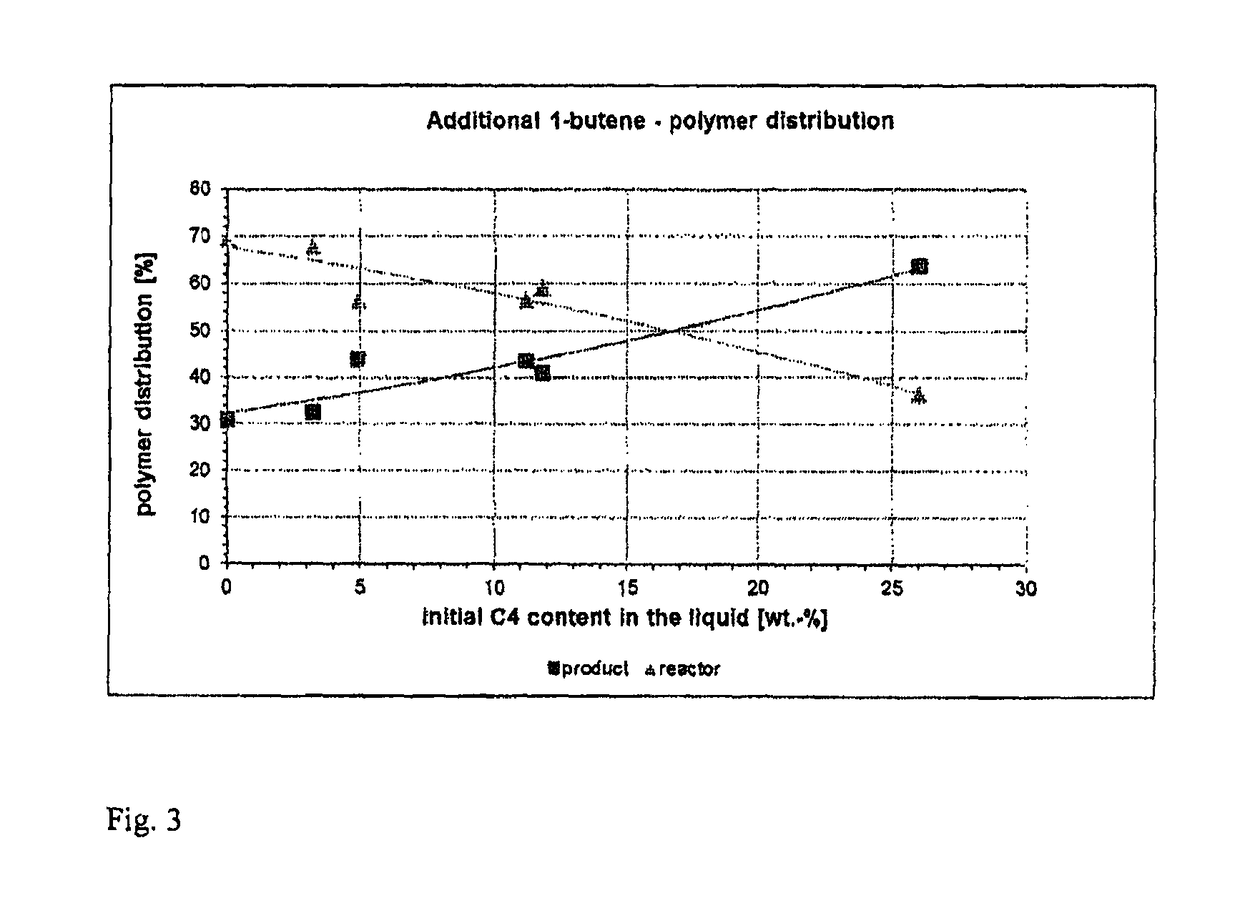

Method for oligomerization of ethylene

InactiveCN104661989ALow investment costExtended run timeHydrocarbon from carbon oxidesOrganic-compounds/hydrides/coordination-complexes catalystsButeneSolvent

The present invention relates to a method for oligomerization of ethylene, comprising the steps: a) feeding ethylene, solvent and a catalyst composition comprising catalyst and cocatalyst into a reactor, b) oligomerizing ethylene in the reactor, c) discharging a reactor effluent comprising linear alpha-olefins including I-butene, solvent, unconsumed ethylene dissolved in the reactor effluent, and catalyst composition from the reactor, d) separating ethylene and 1-butene collectively from the remaining reactor effluent, and e) recycling at least a part of the ethylene and the 1-butene separated in step d) into the reactor.

Owner:SAUDI BASIC IND CORP SA +1

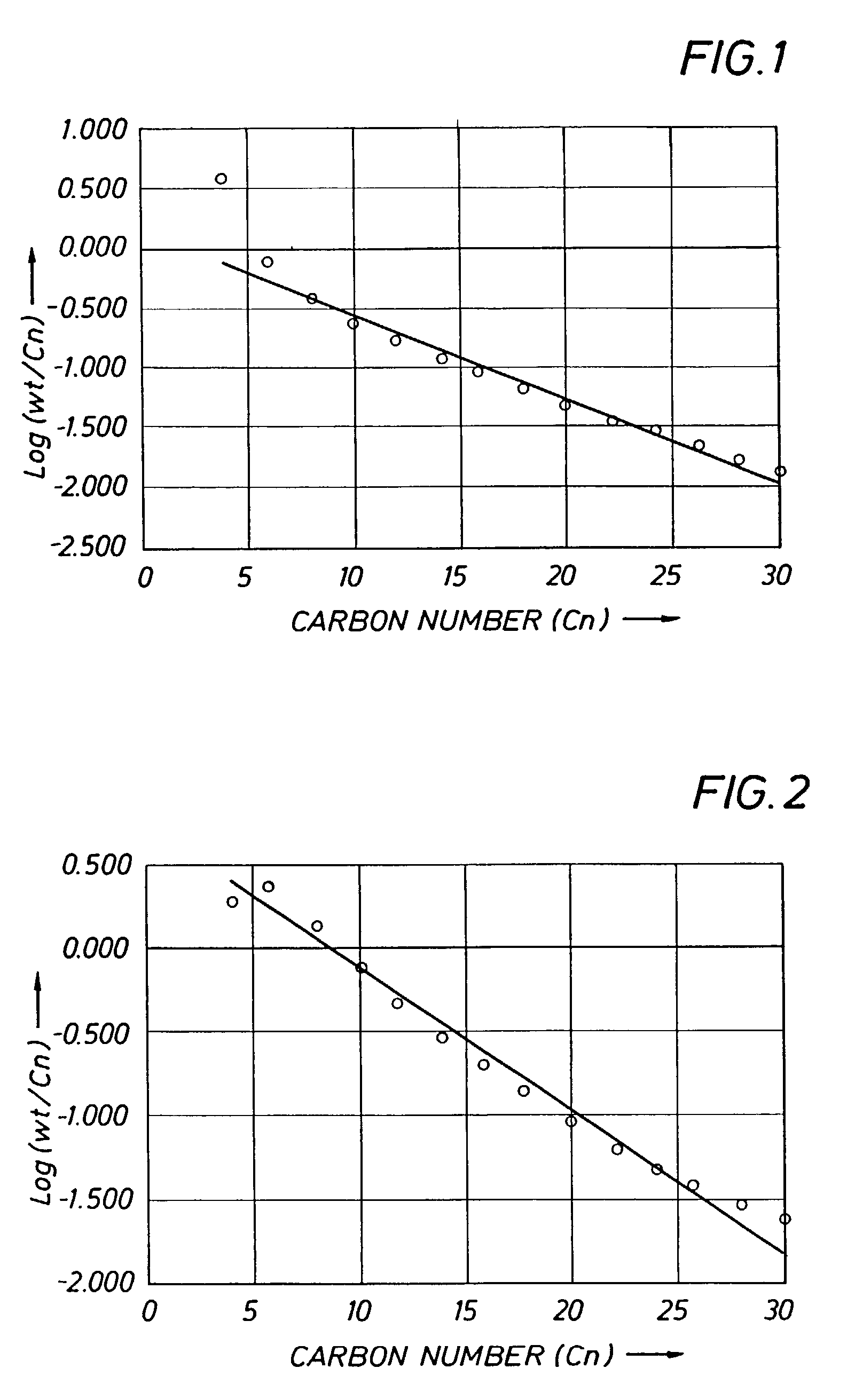

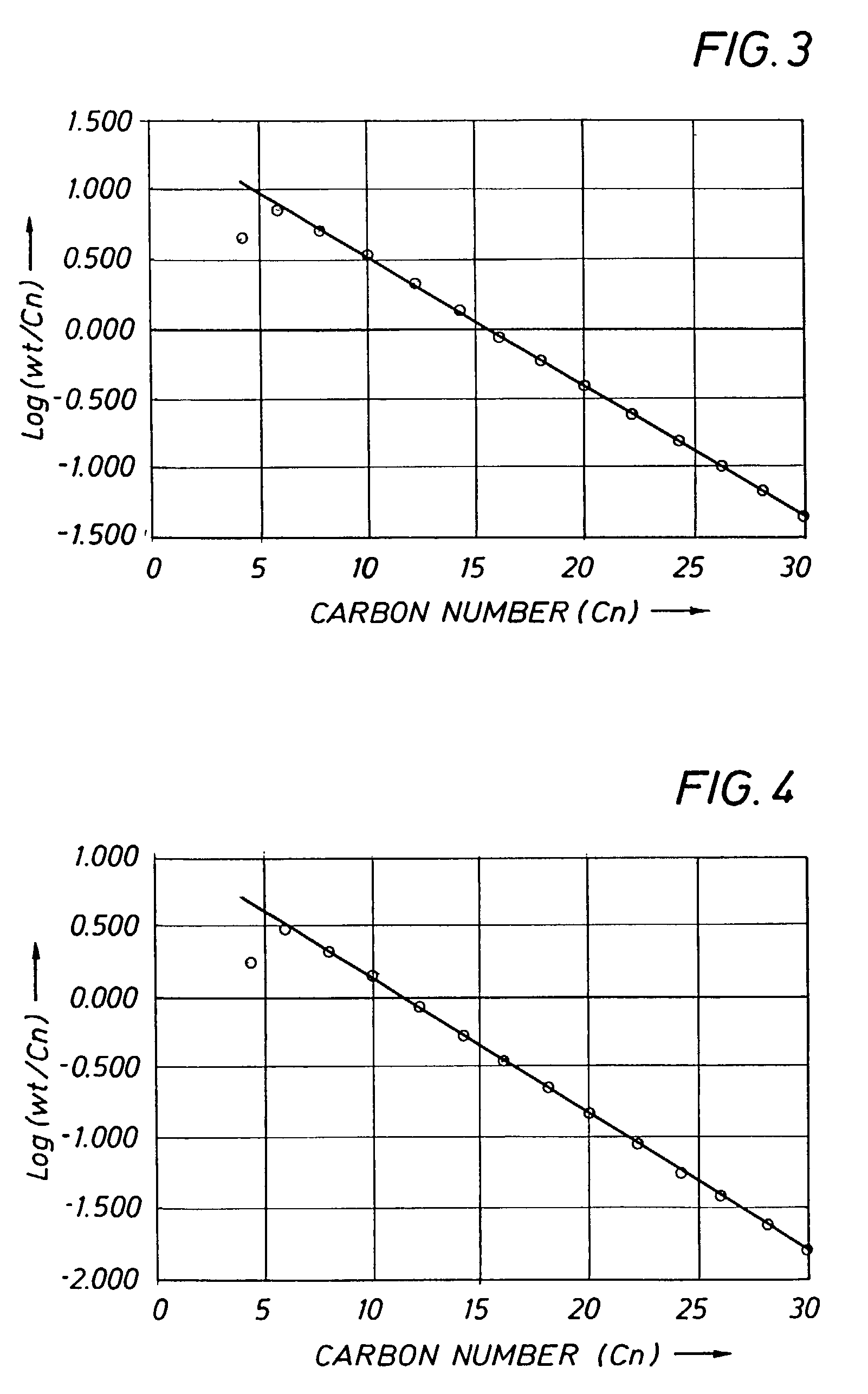

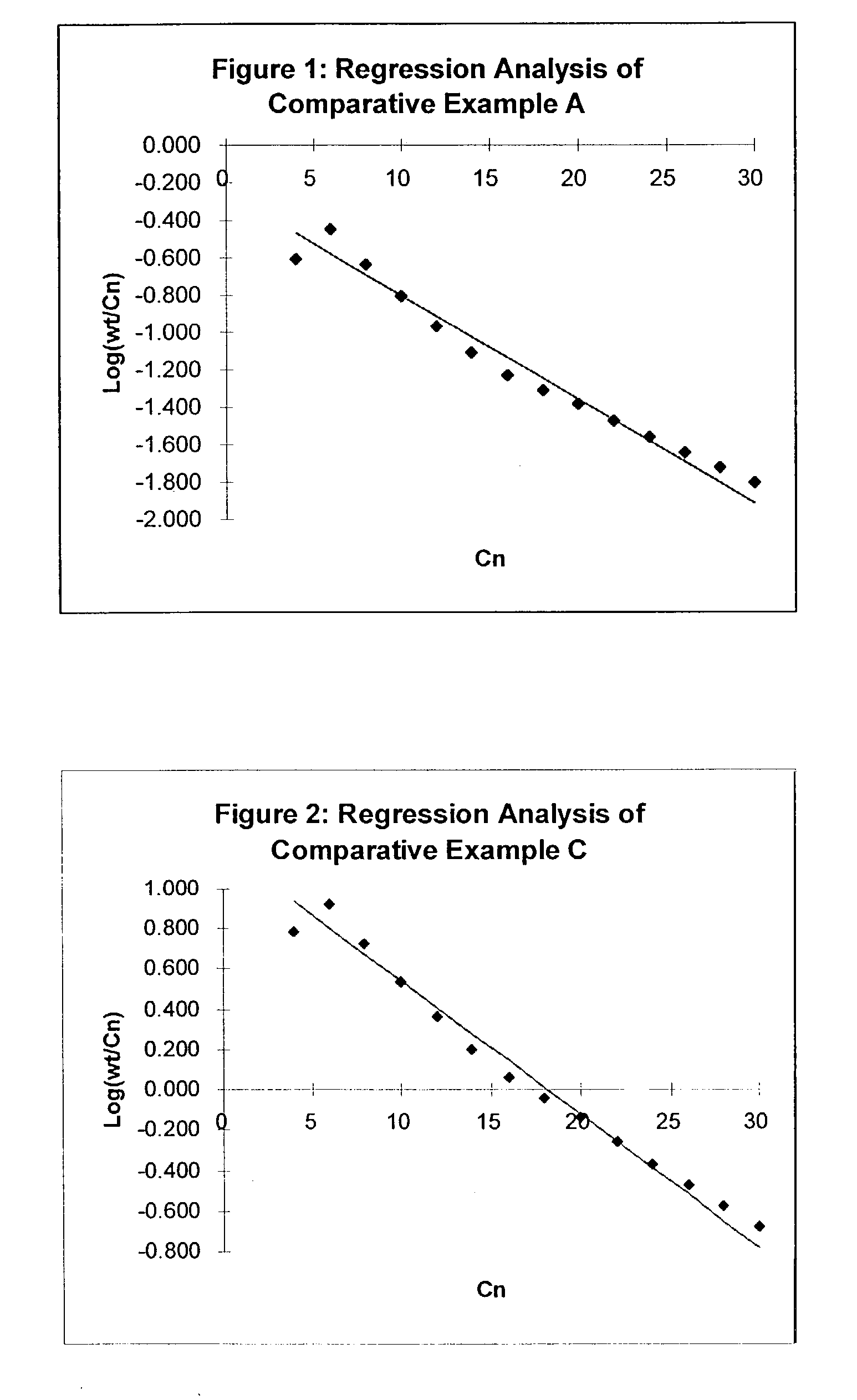

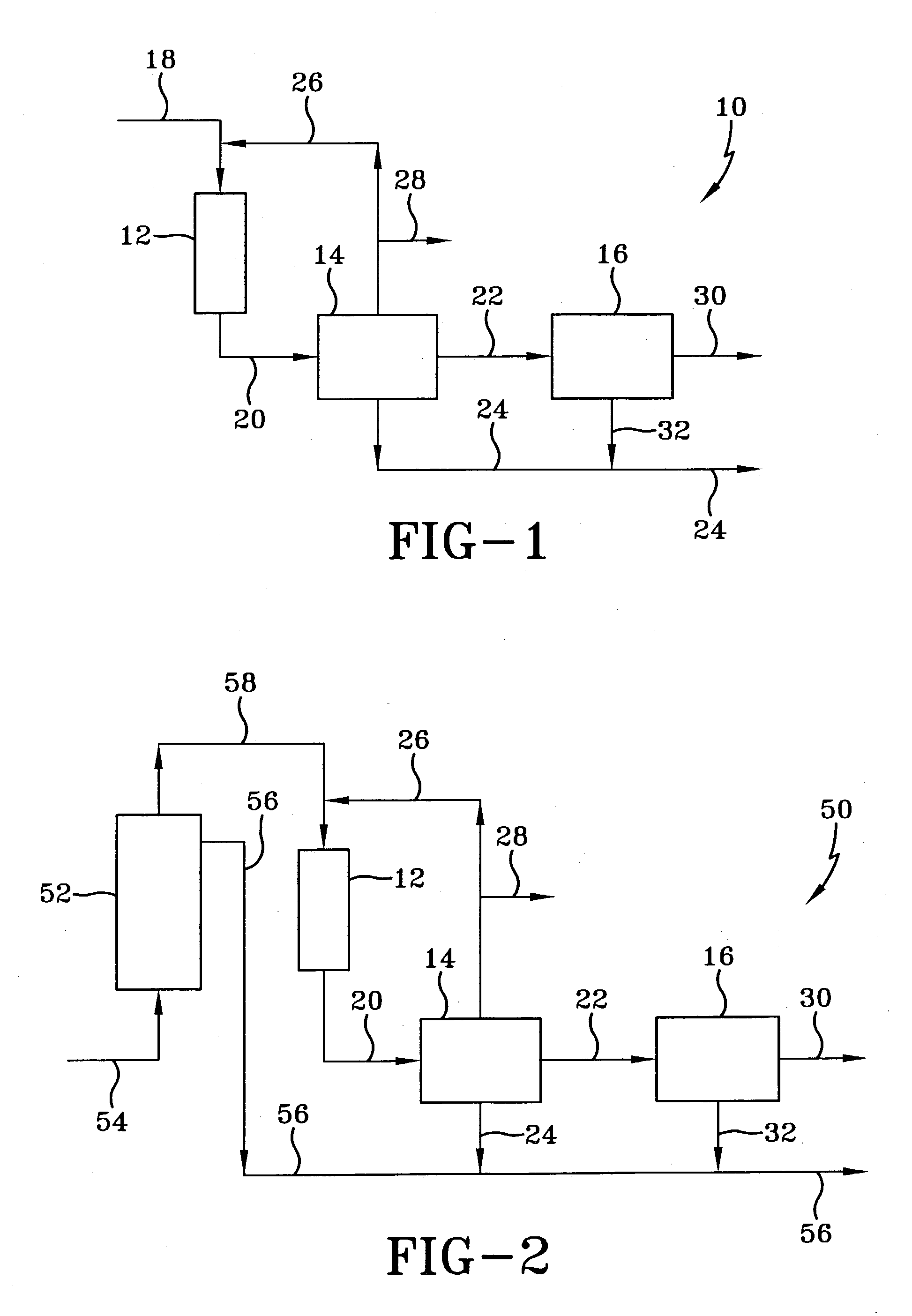

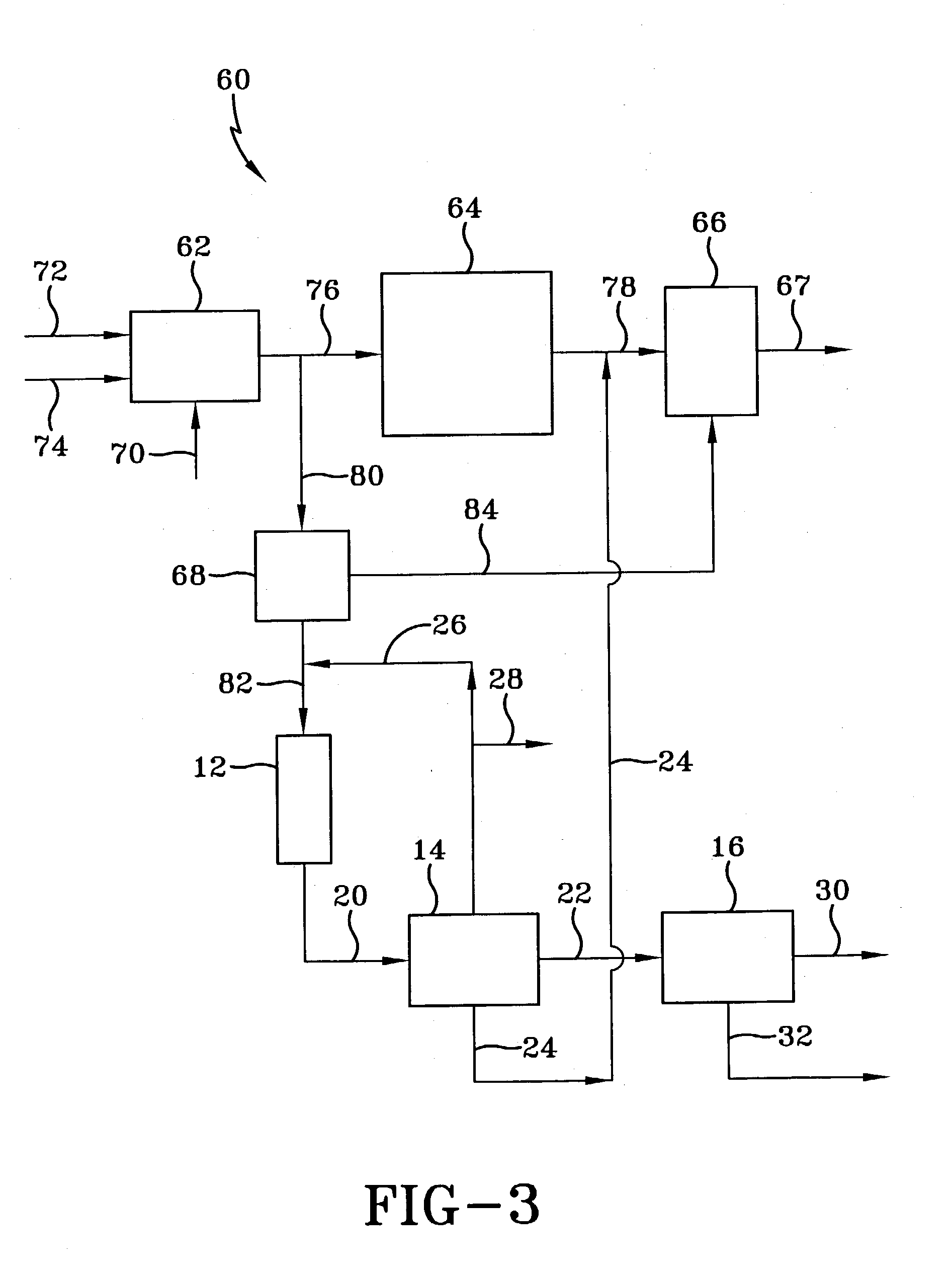

Method for producing linear alpha-olefins (LAOs) through Fischer-Tropsch synthesis of solvent phase

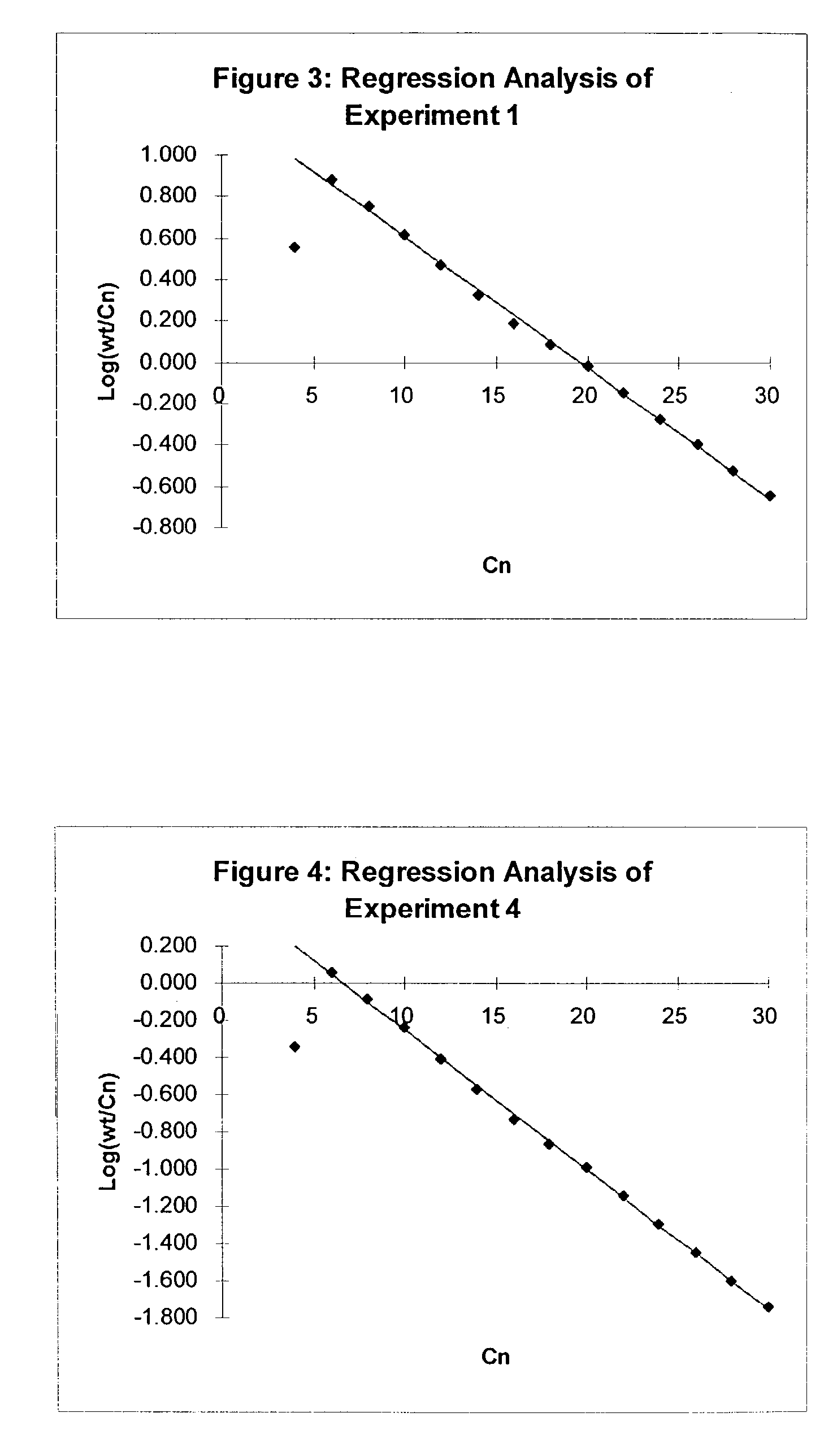

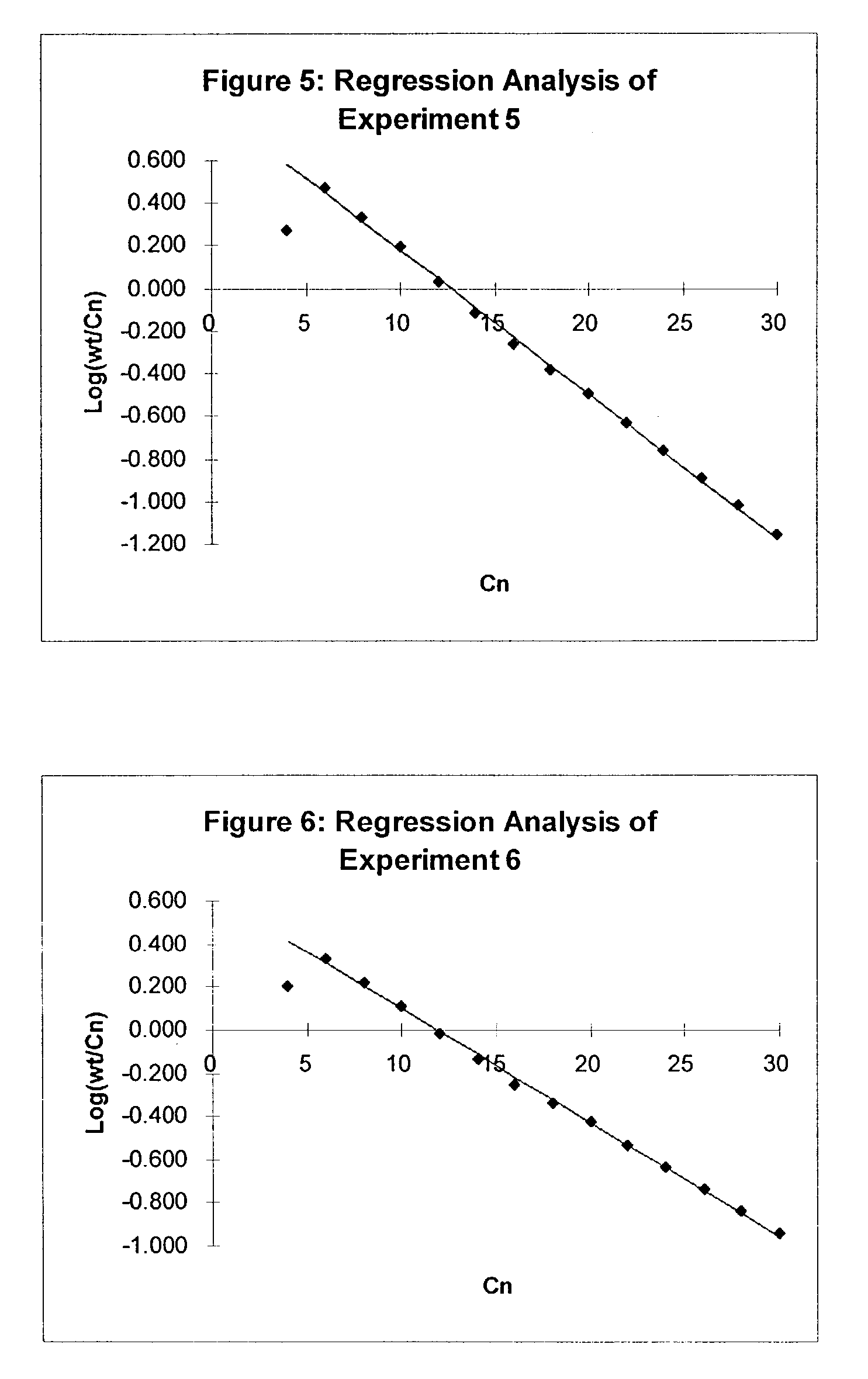

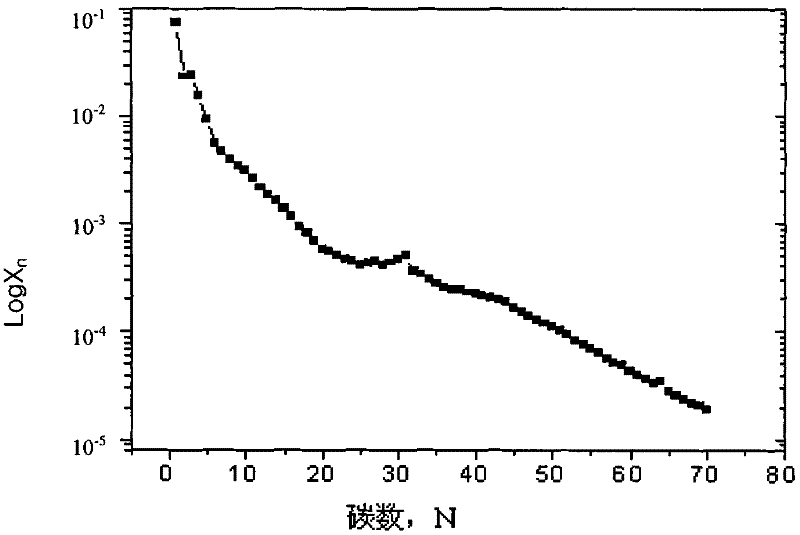

ActiveCN102408908AImprove scalabilityImprove operational flexibilityHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionCarbon numberSynthesis methods

The invention discloses a solvent phase Fischer-Tropsch synthesis method. The method is characterized in that a Fischer-Tropsch synthesis reaction is carried out in a heterogeneous reaction system; a polar solvent is taken as the reaction medium; a traditional granular Fischer-Tropsch synthesis catalyst is suspended or soaked in the polar solvent phase to carry out the Fischer-Tropsch synthesis reaction; and as the generated hydrocarbon products are insoluble in the polar solvent, the phases are voluntarily split. The method can be used for producing linear alpha-olefins (LAOs) with various carbon numbers. By applying the method, the reaction products can rapidly leave the inner and outer surfaces of the catalyst to reduce the probability of readsorption and secondary reaction, thus improving the yield of the LAOs. The Fischer-Tropsch synthesis reaction can be carried out in the conventional Fischer-Tropsch synthesis reactor by using the common catalyst. By applying the method, the mass content of the LAOs in the reaction products is more than 70%, thus being very beneficial to separation and purification. Meanwhile, by applying the method, the CO conversion rate can be improved, the methane selectivity can be reduced and the yield of heavy hydrocarbons can be greatly increased.

Owner:SYNFUELS CHINA TECH CO LTD

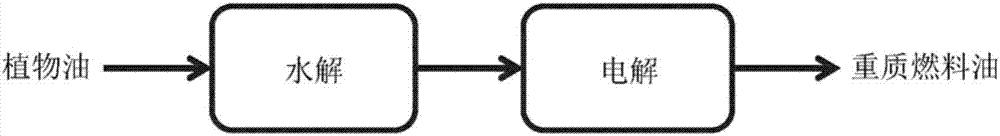

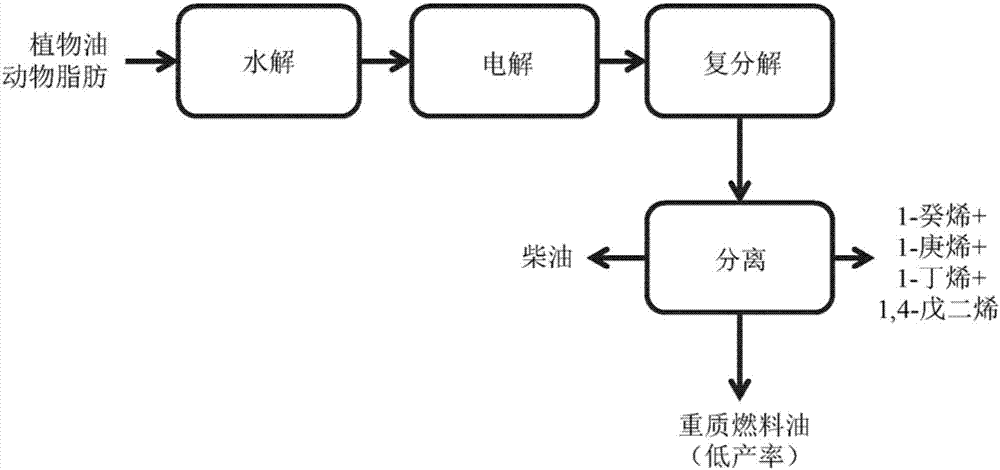

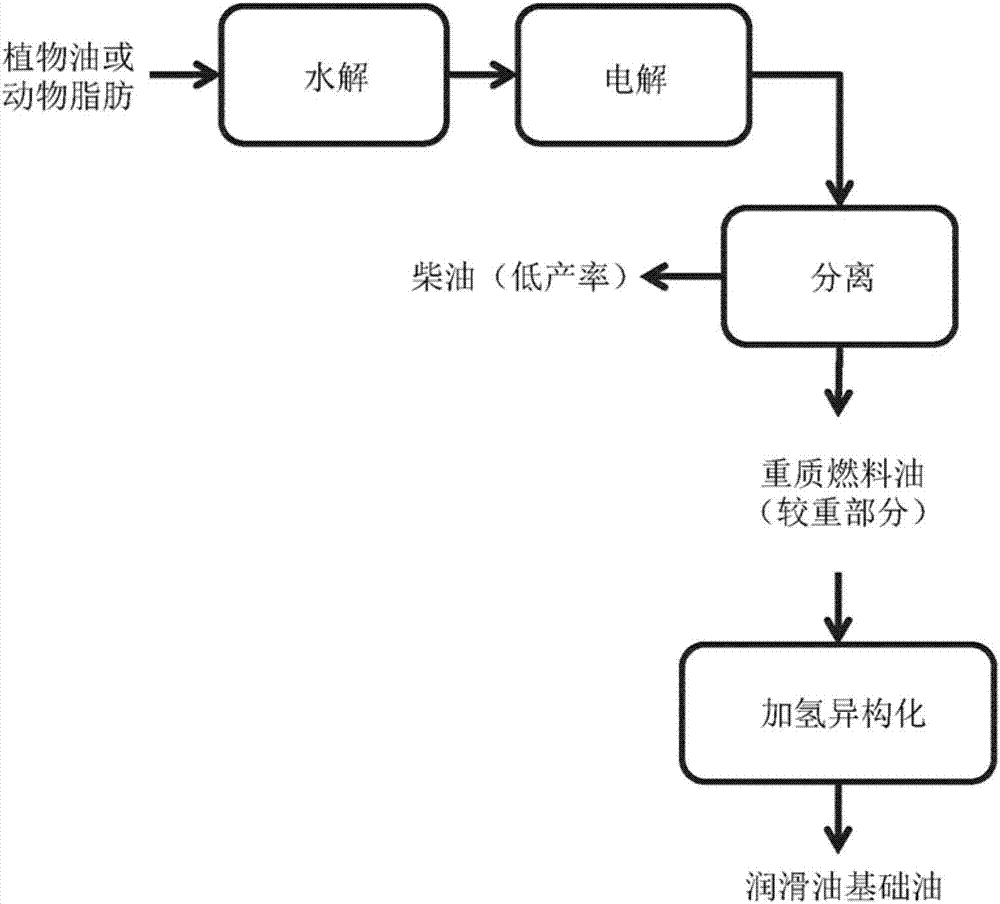

High productivity kolbe reaction process for transformation of fatty acids derived from plant oil and animal fat

Oils from plants and animal fats are hydrolyzed to fatty acids for a Kolbe reaction. The invention relates to a high productivity Kolbe reaction process for electrochemically decarboxylating C4-C28 fatty acids using small amounts of acetic acid to lower anodic passivation voltage and synthesizing C6-C54 hydrocarbons. The C6-C54 undergo olefin metathesis and / or hydroisomerization reaction process to synthesize heavy fuel oil, diesel fuel, kerosene fuel, lubricant base oil, and linear alpha olefin products useful as precursors for polymers, detergents, and other fine chemicals.

Owner:埃德沃克国际公司

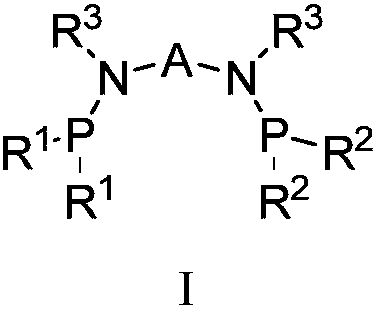

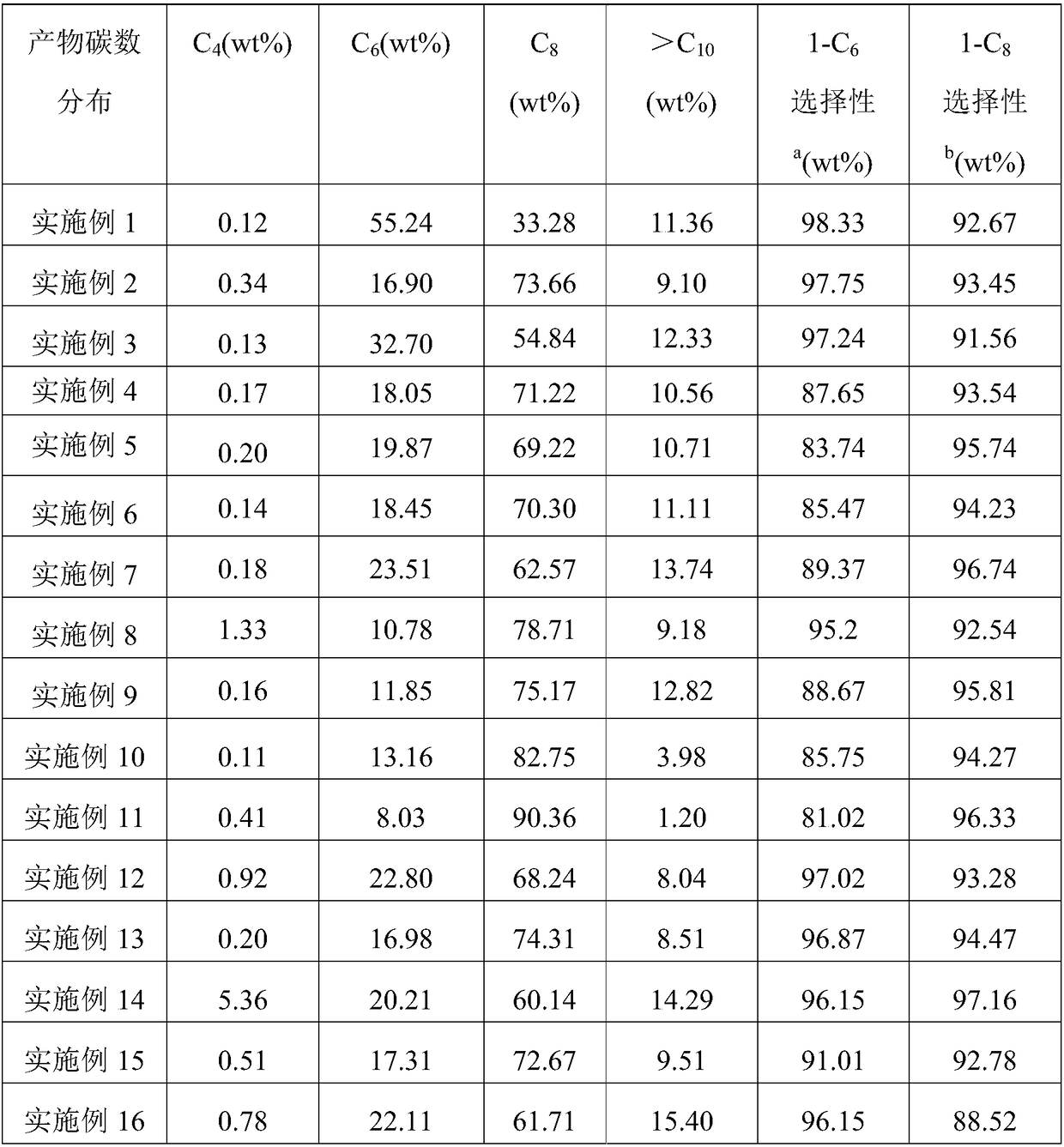

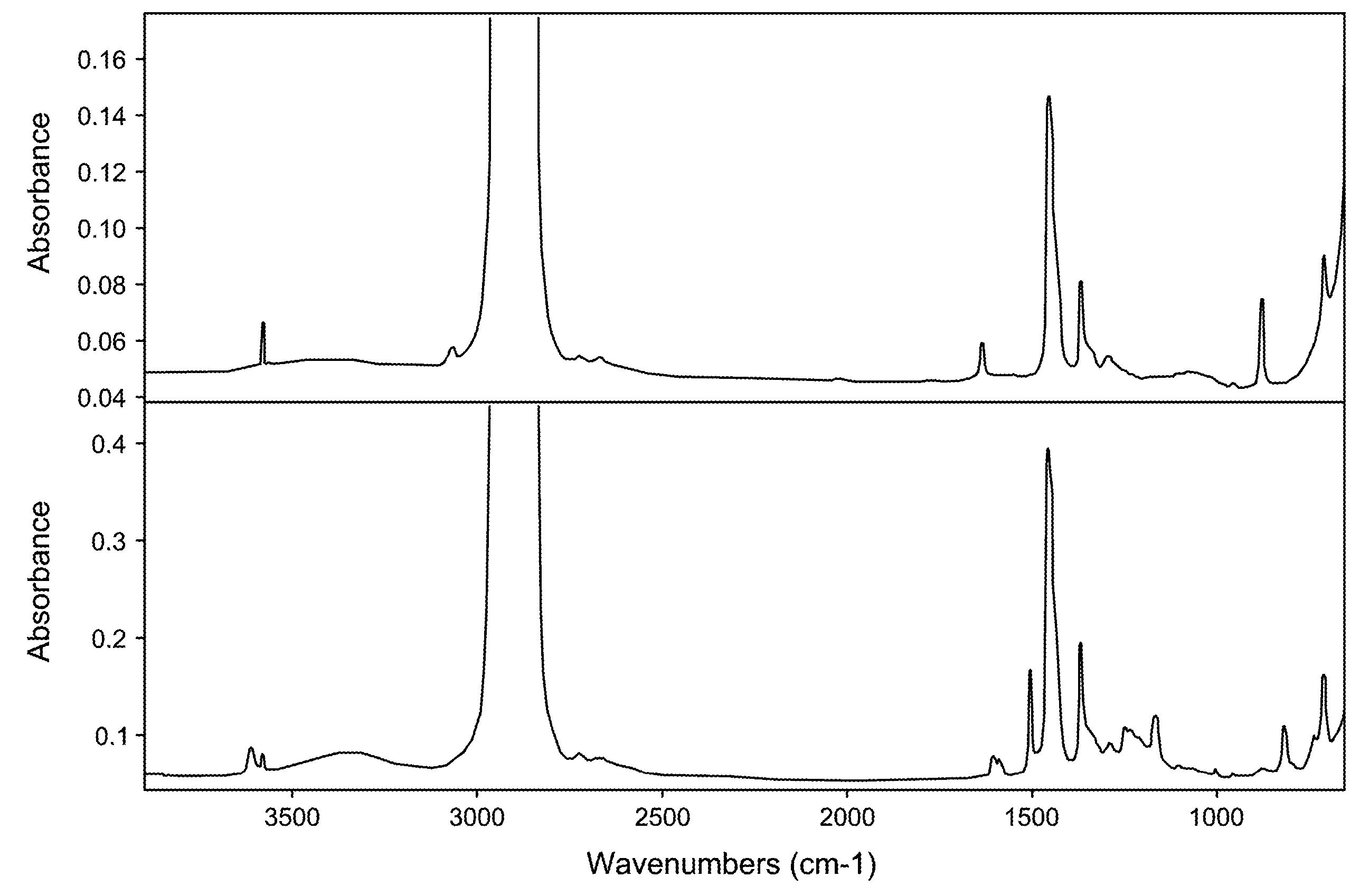

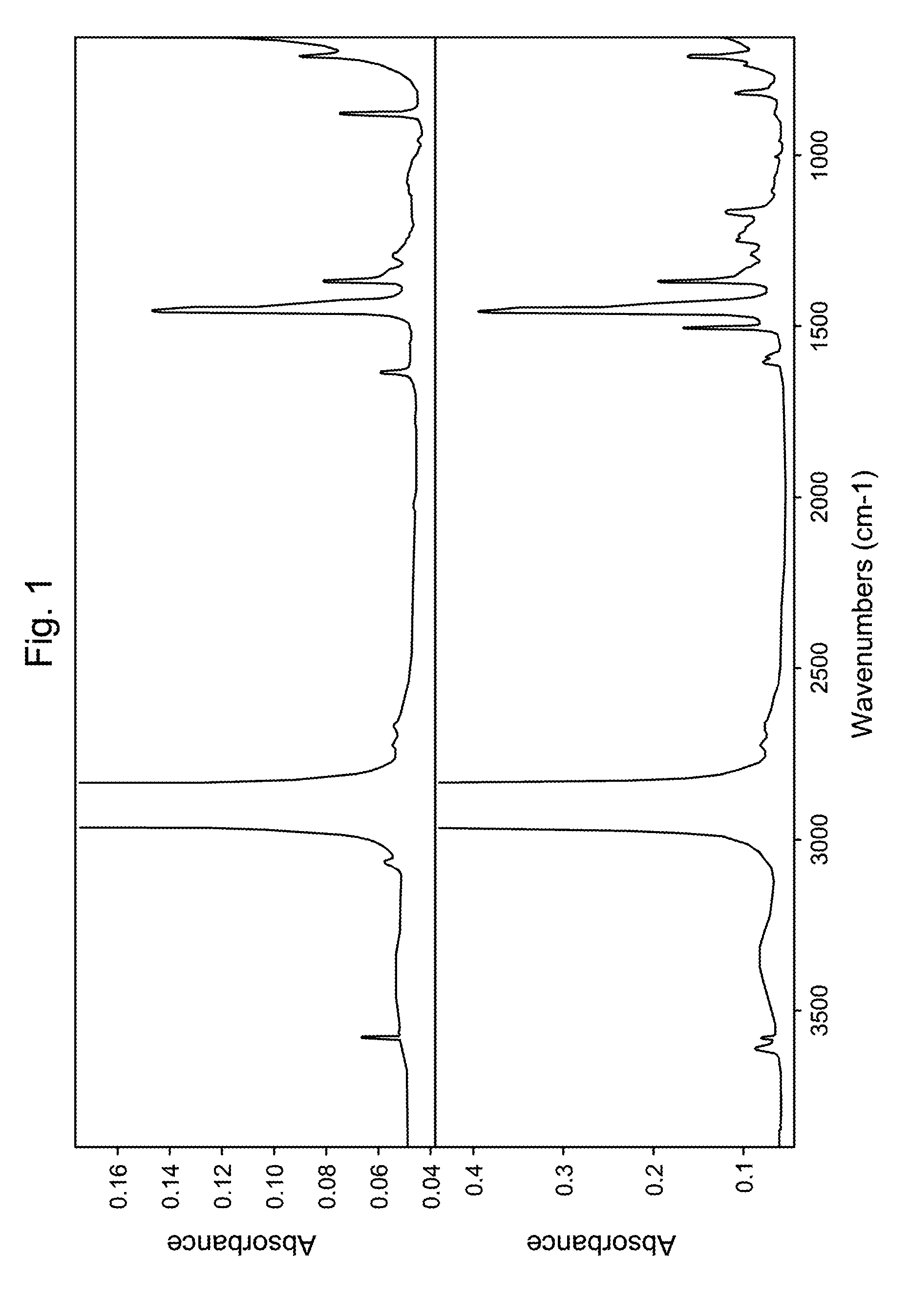

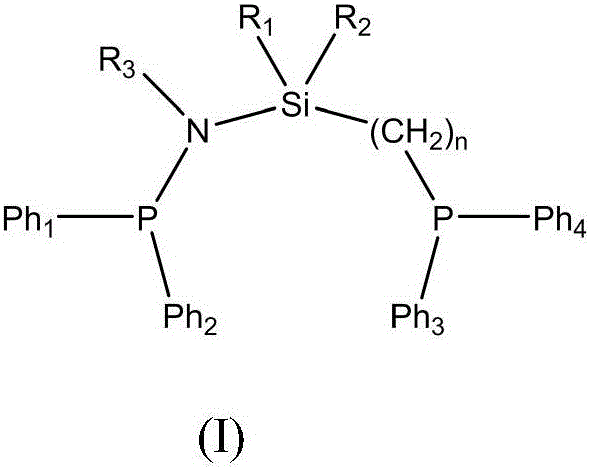

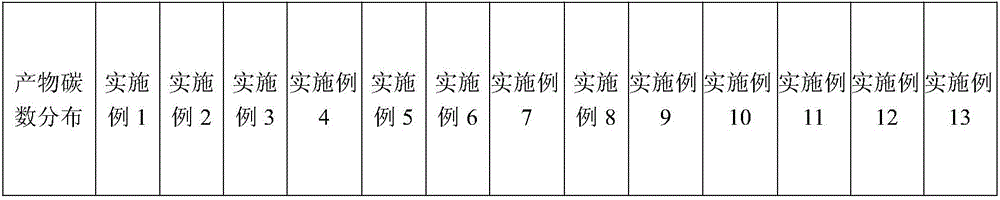

Catalyst component for selective oligomerization of ethylene and catalyst thereof

ActiveCN106582851AHigh activityEasy to synthesizeOrganic-compounds/hydrides/coordination-complexes catalystsGroup 5/15 element organic compounds1-Octene1-Hexene

ThThe invention relates to a catalyst component for selective oligomerization of ethylene and a catalyst thereof. The catalyst component is a compound which accords with a general formula (I) or a compound which is formed by connection of two or more constitutional units which accord with the general formula (I) by groups or chemical bonds; the structure of the general formula (I) is as follows: n is an integer, 0<=n<=4; Ph1, Ph2, Ph3 and Ph4 are selected from phenyl, substituted phenyl and derivatives thereof; R1, R2 and R3 are selected from phenyl, chain alkyl, annular alkyl and derivatives thereof. The catalyst has high activity, and high selectivity for the target product 1-hexene+1-octene; and 1-betene and 1-C10<+> are few. The catalyst has the characteristics of simple synthesis, low cost, long life, and the like; the mass percentage of C6-C8 linear alpha-olefins in the product is higher than 90%, and the mass percentage of C8 linear alpha-olefins is higher than 60%.

Owner:TIANJIN UNIV OF SCI & TECH

Linear alpha olefins from natural gas-derived synthesis gas over a nonshifting cobalt catalyst

InactiveUS6787576B2Hydrocarbon from carbon oxidesOrganic compound preparationWater vaporAlpha-olefin

Owner:EXXON RES & ENG CO

Drilling method using isomerized olefins and paraffin hydrocarbons as base oils for invert emulsion oil muds

Environmentally acceptable or regulatory compliant oil-based drilling fluids and methods of using same in drilling a wellbore in a subterranean formation are disclosed. The fluids are able to meet environmental regulations while maintaining acceptable oil mud rheology and overall oil mud performance. The fluids are comprised of an invert emulsion. The base or continuous phase of the emulsion is comprised of esters blended with isomerized olefins, and / or other hydrocarbons, such as paraffins, mineral oils or glyceride triesters or combinations thereof. Alternatively, the emulsion has as a base comprising isomerized olefins blended with other hydrocarbons such as linear alpha olefins, paraffins or naphthenes.

Owner:HALLIBURTON ENERGY SERVICES INC

Metathesis Catalyst and Process for Use Thereof

This invention relates to a catalyst compound comprising a combination of a cyclic alkyl amino carbene ligand and a benzylidene both attached to a Group 8 metal, preferably ruthenium atom.This invention also relates to a process to make linear alpha-olefins comprising contacting a feed material and an optional alkene (such as ethylene) with the catalyst described above, wherein the feed material is a triacylglyceride, fatty acid, fatty acid alkyl ester, and / or fatty acid ester, typically derived from seed oil (e.g., biodiesel).

Owner:EXXONMOBIL CHEM PAT INC

Metathesis catalyst and process for use thereof

This invention relates to a catalyst compound comprising a combination of a cyclic alkyl amino carbene ligand and a benzylidene both attached to a Group 8 metal, preferably ruthenium atom.This invention also relates to a process to make linear alpha-olefins comprising contacting a feed material and an optional alkene (such as ethylene) with the catalyst described above, wherein the feed material is a triacylglyceride, fatty acid, fatty acid alkyl ester, and / or fatty acid ester, typically derived from seed oil (e.g., biodiesel).

Owner:EXXONMOBIL CHEM PAT INC

Utilization Of Linear Alpha Olefins In The Production Of Metallocene Catalyzed Poly-Alpha Olefins

The invention is directed to a process for the preparation of lubricant base stocks by contacting alphaolefin feedstocks with single-site metallocene catalysts and recycling unconverted monomers, characterized by a purge step in the recycle.

Owner:EXXONMOBIL CHEM PAT INC

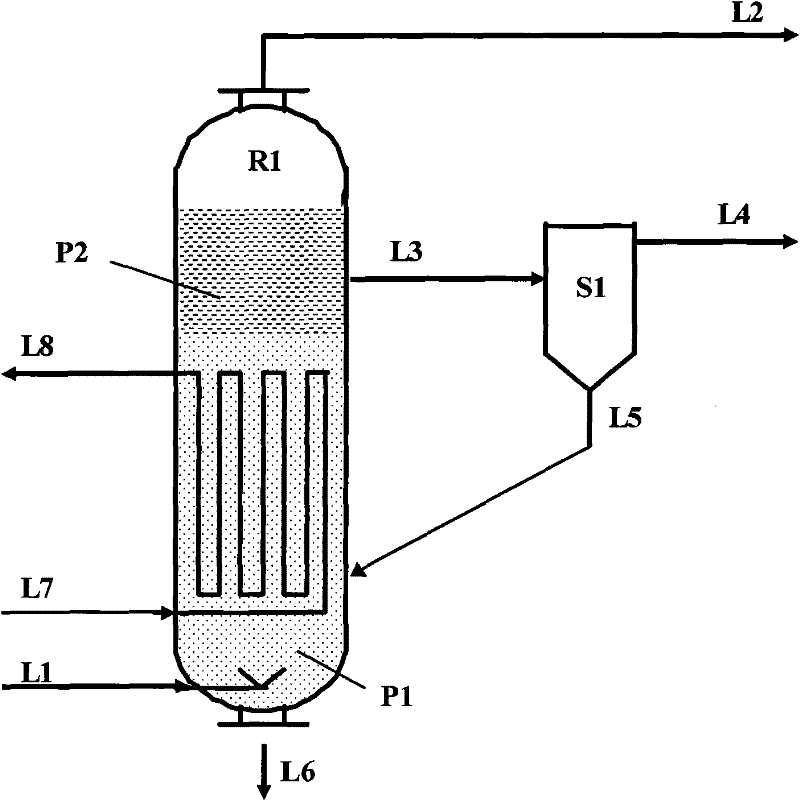

Method for oligomerization of ethylene

InactiveUS9896392B2Safe and stable operationImprove cooling effectOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionButeneAlpha-olefin

The present invention relates to a method for oligomerization of ethylene, comprising the steps:a) feeding ethylene, solvent and a catalyst composition comprising catalyst and cocatalyst into a reactor,b) oligomerizing ethylene in the reactor,c) discharging a reactor effluent comprising linear alpha-olefins including 1-butene, solvent, unconsumed ethylene dissolved in the reactor effluent, and catalyst composition from the reactor,d) separating ethylene and 1-butene collectively from the remaining reactor effluent, ande) recycling at least a part of the ethylene and the 1-butene separated in step d) into the reactor.

Owner:SABIC GLOBAL TECH BV +1

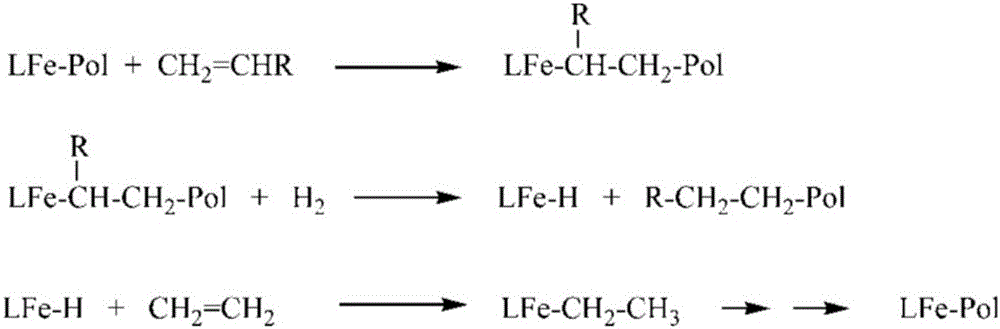

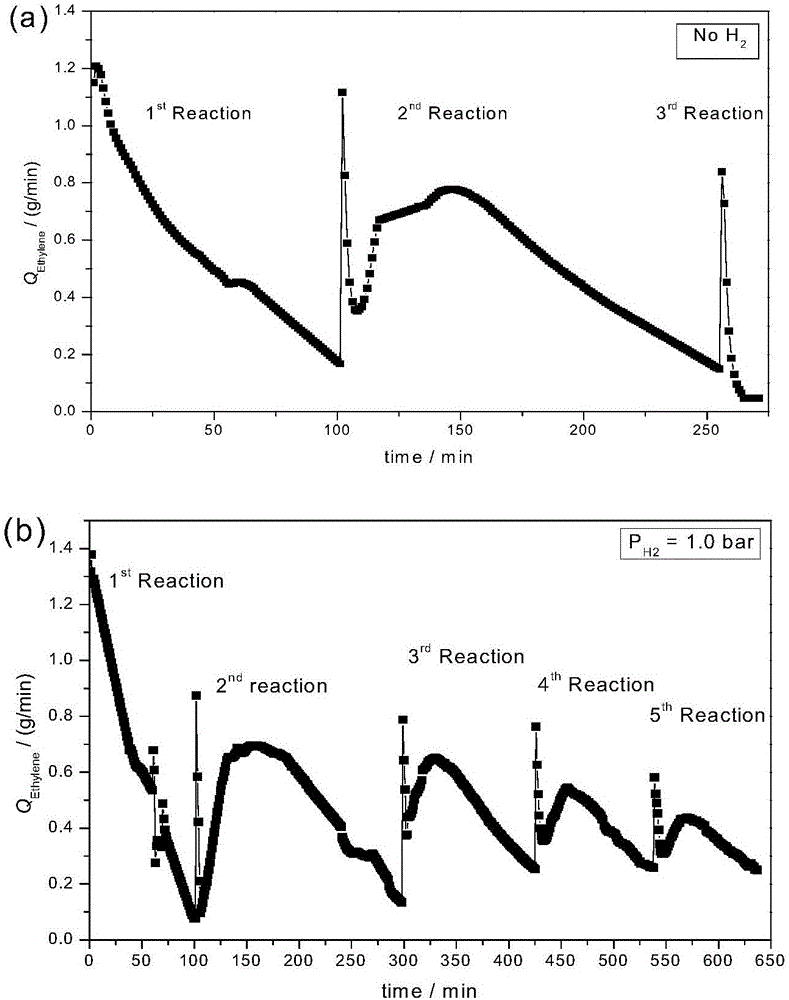

Method for enhancing yield of linear alpha-olefins

InactiveCN105884565AReduced inactivation rateHigh reactivityOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsOrganic solventHydrogen

The invention discloses a method for enhancing yield of linear alpha-olefins. The method comprises the following steps: introducing hydrogen into a catalytic-reaction-medium-containing oligomerization reactor as an activator, controlling at appropriate reaction temperature, introducing a vinyl monomer, keeping the reaction pressure, and carrying out oligomerization to prepare the high-grade linear alpha-olefins. The oligomerization reactor is selected from one or more of stirred tank reactors or tubular reactors, and can adopt series or parallel operation of single or multiple reactors. The hydrogen is added one or more of one-step addition, batch addition or sectionalized addition mode. The catalytic reaction medium is composed of a main catalyst, a cocatalyst and an organic solvent, wherein the main catalyst is selected from late-transition iron catalysts. The method is simple and feasible, is easy to implement, and can obviously enhance the yield of linear alpha-olefins, thereby greatly lowering the cocatalyst consumption of the unit product, and being beneficial to lowering the production cost and enhancing the economic benefits.

Owner:ZHEJIANG UNIV

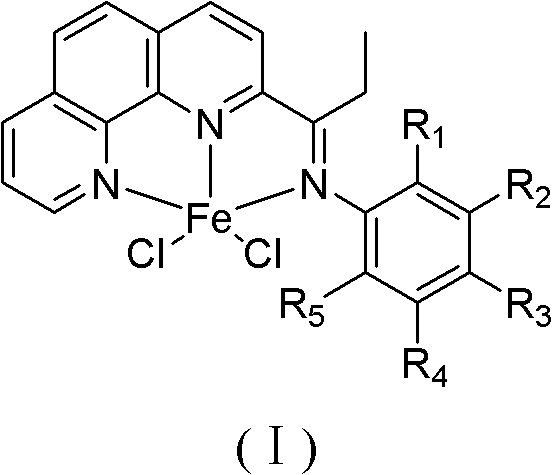

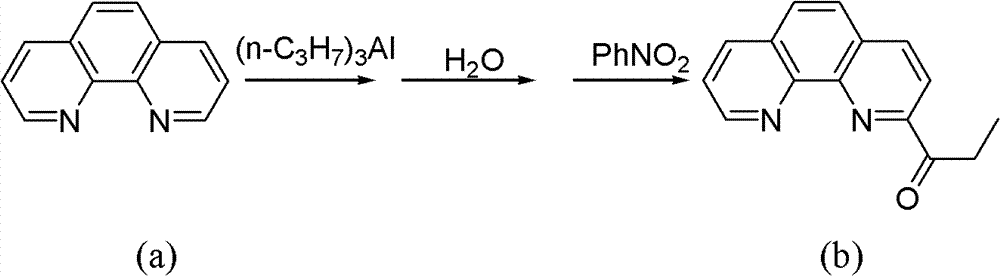

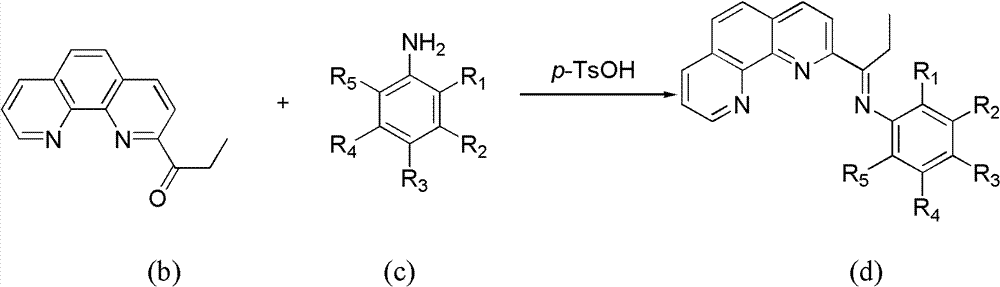

Ethylene oligomerization catalyst composition containing 1, 10-phenanthroline amino-iron (II) complex substituted by propionyl

InactiveCN103008010AReduce dosageHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsPhenanthrolineEthyl group

The invention provides an ethylene oligomerization catalyst composition. The ethylene oligomerization catalyst composition comprises a main catalyst of a 1, 10-phenanthroline amino-iron (II) complex which is substituted by propionyl in a formula (I) and a catalyst promoter of triethyl aluminum, wherein the molar ratio of the metallic aluminium of the catalyst promoter to the central metallic aluminium of the main catalyst is between 30 and 900. According to the ethylene oligomerization catalyst composition, the triethyl aluminum which is used as the catalyst promoter is low in price and only accounts for a small percentage of the price of methylaluminoxane, and the usage of the catalyst promoter is greatly reduced, the catalyst has good catalytic activity of catalyzing ethylene oligomerization, so that the ethylene oligomerization reaction cost is greatly lowered; the selectivity of linear alpha-olefin in an oligomerization product is high; the oligomerization product is distributed reasonably; polyvinyl cannot be generated; and thus, the ethylene oligomerization catalyst composition has a wide industrial prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com