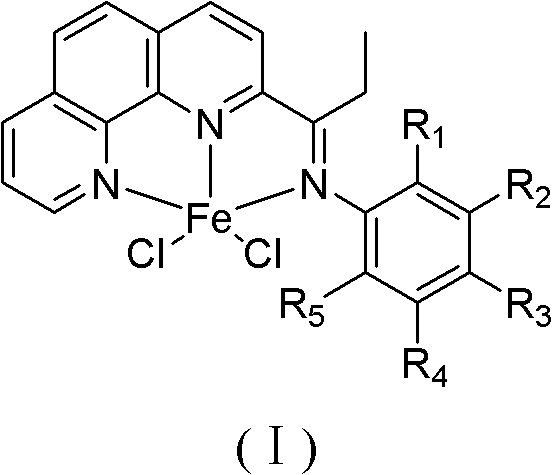

Ethylene oligomerization catalyst composition containing 1, 10-phenanthroline amino-iron (II) complex substituted by propionyl

A technology for the oligomerization of phenanthroline amines and ethylene, which is applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, hydrocarbons, etc., and can solve high cost, large consumption, and production costs Expensive and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

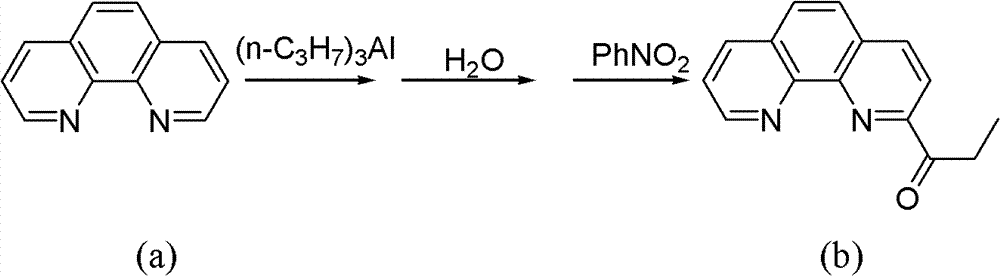

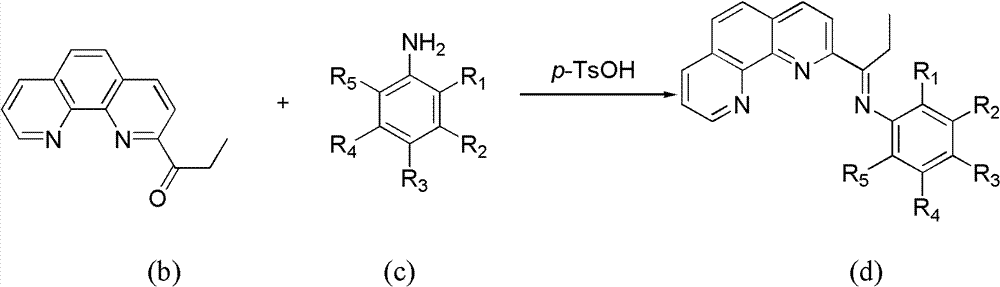

[0036] 1. Synthesis of Catalyst Chloride 2-n-propionyl-1,10-phenanthroline 2,6-diethylanilinate iron (II) complex

[0037] a. Synthesis of 2-n-propionyl-1,10-phenanthroline

[0038] Put 5.1 g (28.3 mmol) of 1,10-phenanthroline into a 250 ml three-necked flask, and dissolve it with 100 ml of toluene under nitrogen protection and magnetic stirring. Slowly add 13.5ml of tri-n-propylaluminum (d=0.82g / ml, 70.9mmol) dropwise to the three-necked flask under stirring at -60°C, the dropwise addition is completed in about 15 minutes, and continue stirring at this temperature for 18h. Afterwards, the temperature was raised to about 30° C., and stirring was continued for 10 h. Then the reaction mixture was cooled to about -30°C, 50ml of distilled water was slowly added thereto, and then heated to 30°C and stirred for 10h. Then separate the liquids, take out the organic phase, and extract the inorganic phase three times with dichloromethane, each time the consumption of dichloromethane i...

Embodiment 2

[0052] Using the main catalyst prepared in Example 1, the cocatalyst is triethylaluminum to carry out ethylene oligomerization, the difference from Example 1 is: the consumption of triethylaluminum toluene solution is 2.15ml (concentration is 0.74mol / l ), so that Al / Fe=796. At 30°C, the ethylene pressure was maintained at 1 MPa, and the reaction was stirred for 30 minutes. A small amount of reaction mixture was taken out with a syringe and neutralized with 5% dilute hydrochloric acid for GC analysis: the oligomerization activity was 2.45×10 6 g·mol -1 (Fe)·h -1 , the oligomer contents are C 4 16.3%, C 6 ~C 10 51.1%, C 6 ~C 18 77.5% (including 88.2% linear α-olefins), C 20 ~C 28 6.2%. The remaining reaction mixture was neutralized with 5% hydrochloric acid in ethanol, and no polymer was obtained. The analysis results are shown in Table 1.

Embodiment 3

[0054] Using the main catalyst prepared in Example 1, the cocatalyst is triethylaluminum to carry out ethylene oligomerization, the difference from Example 1 is: the consumption of triethylaluminum toluene solution is 1.88ml (concentration is 0.74mol / l ), so that Al / Fe=696. At 30°C, the ethylene pressure was maintained at 1 MPa, and the reaction was stirred for 30 minutes. A small amount of reaction mixture was taken out with a syringe and neutralized with 5% dilute hydrochloric acid for GC analysis: the oligomerization activity was 3.23×10 6 g·mol -1 (Fe)·h -1 , the oligomer contents are C 4 18.9%, C 6 ~C 10 55.8%, C 6 ~C 18 76.4% (including 88.4% linear α-olefins), C 20 ~C 28 4.7%. The remaining reaction mixture was neutralized with 5% hydrochloric acid in ethanol, and no polymer was obtained. The analysis results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com