Waterborne epoxy fireproof coating as well as preparation method and application thereof

A fire-resistant coating, water-based epoxy technology, applied in fire-resistant coatings, epoxy resin coatings, anti-corrosion coatings, etc., can solve the problems of high viscosity of epoxy fire-resistant coatings, unsuitable mixing, secondary environmental pollution, etc., and achieve excellent corrosion resistance , Excellent protective effect, high fire prevention efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

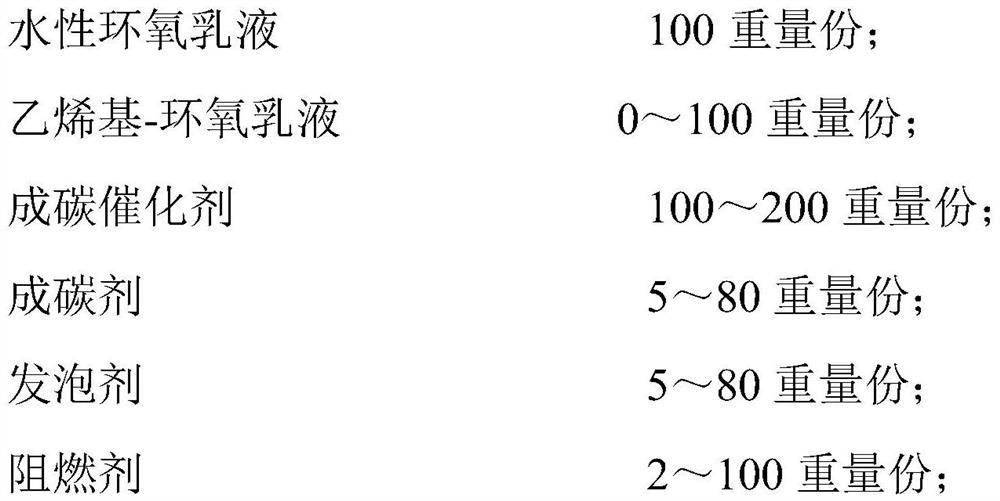

[0108] A component

[0109] The raw material and consumption that A component adopts in the embodiment 1 of table 1

[0110]

[0111] B component

[0112] Raw material and consumption that B component adopts among the table 2. embodiment 1

[0113]

[0114]

[0115] Synthesis of vinyl-epoxy emulsion in component A:

[0116] (1) Dissolve 220g of bisphenol F type epoxy resin in 86g of vinyl acetate and 198g of vinyl tertiary carbonate monomers, and completely dissolve the epoxy resin at a high speed of 600rad to form a premix

[0117] (2) Disperse 25g of emulsifier Calimulse AOS and 15g of emulsifier OP-15 in 400g of deionized water evenly under high-speed dispersion

[0118] (3) Slowly add the premix in (1) to (2) under high-speed dispersion to obtain a pre-emulsion

[0119] (4) prepare the aqueous solution of 5% ammonium persulfate of 20g

[0120] (5)N 2 Protection, under high-speed dispersion, add 25% of (3) into the reactor, after heating up to 50°C, add 20% o...

Embodiment 2

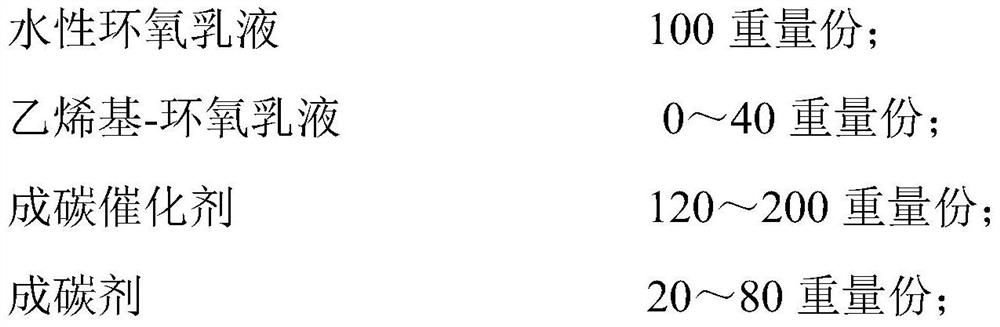

[0127] A component

[0128] Raw material and consumption that A component adopts in the embodiment 2 of table 4

[0129]

[0130]

[0131] B component

[0132] Raw material and consumption that B component adopts among the table 5. embodiment 2

[0133]

[0134] Synthesis of vinyl-epoxy emulsion in component A:

[0135] (1) Dissolve 235g of bisphenol A type epoxy resin in 112g of vinyl methacrylate and 196g of vinyl acrylate, under the high-speed dispersion of 2000rad, the epoxy resin is completely dissolved to form a premix

[0136] (2) Disperse 35g of emulsifier Calimulse PR and 40g of emulsifier TX-15 in 600g of deionized water evenly under high-speed dispersion

[0137] (3) Slowly add the premix in (1) to (2) under high-speed dispersion to obtain a pre-emulsion

[0138] (4) make the deionized aqueous solution of 7% tetrabutylammonium bromide of 24g

[0139] (5)N 2 protection, high-speed dispersion, add 40% of (3) into the reaction kettle, after heating to 40...

Embodiment 3

[0145] A component

[0146] Raw material and consumption that component A adopts in table 7. embodiment 3

[0147]

[0148] B component

[0149] Raw material and consumption that B component adopts among the table 7. embodiment 3

[0150] Polyamine modified curing agent 20 parts by weight homemade

[0151] Cellulose fiber 10 parts by weight Changzhou Zhuwei

[0152] Basalt fiber 10 parts by weight Changzhou Zhuwei

[0153] Synthesis of modified epoxy emulsion A in component A:

[0154] (1)N 2Protection, under high-speed stirring, gradually warming up to 80 ° C, completely dissolving 118g of 2,4-hexanediol in 212g of trimethylolethane triglycidyl ether, and then dropwise adding 12g of 5% tetrabutyl bromide Ammonium chloride N,N-dimethylformamide solution, keep the system temperature at 80-100°C, after 18 hours of polymerization, add 228g of bisphenol A and 110g of resorcinol, and continue to drop 10g of 5% four N,N-dimethylformamide solution of butylammonium bromide, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com