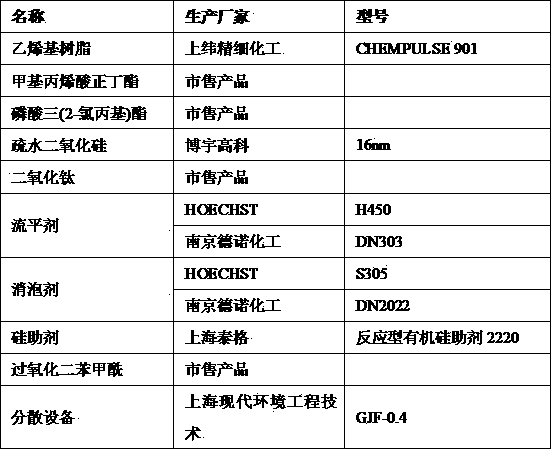

Patents

Literature

64 results about "Vinyloop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

VinyLoop is a proprietary physical plastic recycling process for polyvinyl chloride (PVC). It is based on dissolution in order to separate PVC from other materials or impurities.

Organosilicon sealant for LED (light-emitting diode) packaging

The invention relates to an organosilicon sealant for LED (light-emitting diode) packaging, belonging to the technical field of organosilicon sealants. The organosilicon sealant comprises a component A and a component B. The component A comprises 15-25 parts of divinyl polydimethylsiloxane silicon resin and 2-6 parts of platinum catalyst. The component B comprises 50-58 parts of divinyl polydimethylsiloxane silicon resin, 50-88 parts of methylhydropolysiloxane, 2-8 parts of reaction inhibitor, 30-40 parts of fumed silica, 2-10 parts of additive KH-560 and 20-25 parts of TiO2. The vinyl silicon resin, hydrogen-containing silicon oil and tetramethyltetravinylcyclosiloxane are subjected to addition reaction under the condition of the platinum catalyst to prepare the organosilicon electronic packaging adhesive with favorable comprehensive properties. The sealant is very suitable for LED packaging.

Owner:BLUESTAR CHENGDU NEW MATERIALS

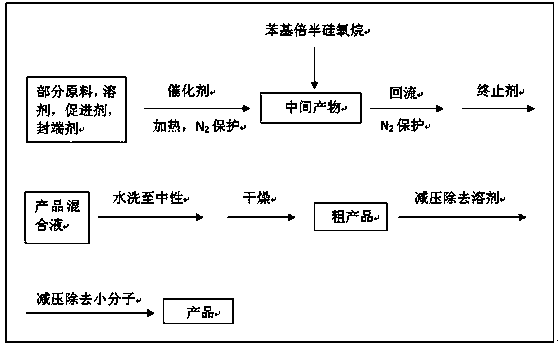

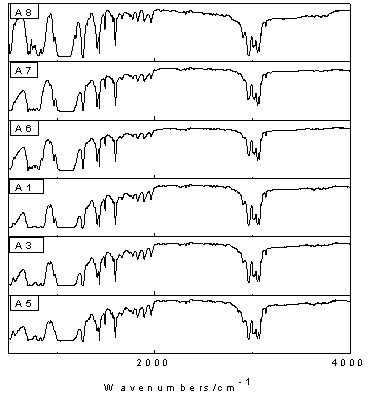

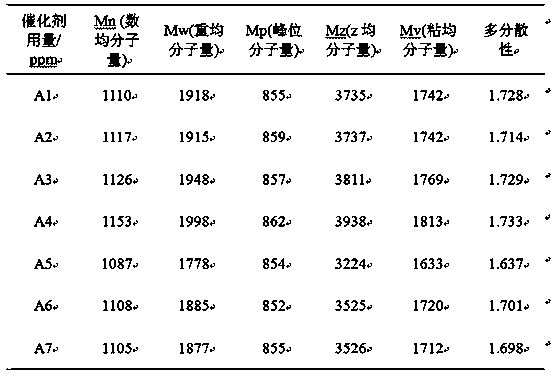

Preparation method for net-like methyl phenyl vinyl polysiloxane for LED packaging

InactiveCN104211965ANarrow molecular weight distributionSimple post-processingAdhesivesPolymer sciencePhenyl group

The invention discloses a preparation method for net-like methyl phenyl vinyl polysiloxane for LED packaging, and concretely relates to a preparation method for a vinyl polysiloxane prepolymer containing methyl and phenyl groups and possessing a net-like structure. According to the preparation method, phenyl silsesquioxane, diphenylsiloxane, octamethyl cyclotetrasiloxane, tetramethyl tetravinyl cyclotetrasiloxane and an end-capping reagent are subjected to a copolymerization reaction under an alkali catalytic condition according to a certain, so that the methyl phenyl vinyl polysiloxane prepolymer which possesses a net-like structure and is a liquid at room temperature is obtained. The prepolymer and an organic silicon monomer or prepolymer containing a silicon-hydrogen structure are subjected to addition polymerization, so that organic silicon resin with excellent performances for LED packaging is prepared. The method simultaneously overcomes the disadvantages that a chlorosilane hydrolysis method generates too much waste acids and is complex in post treatment, the molecular weight distribution is wide and the like, and is the method is an environment-friendly good-repeatability technology.

Owner:BEIJING UNIV OF CHEM TECH

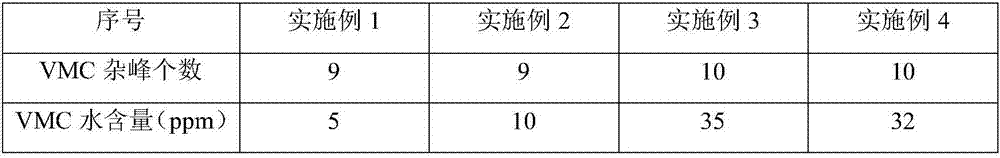

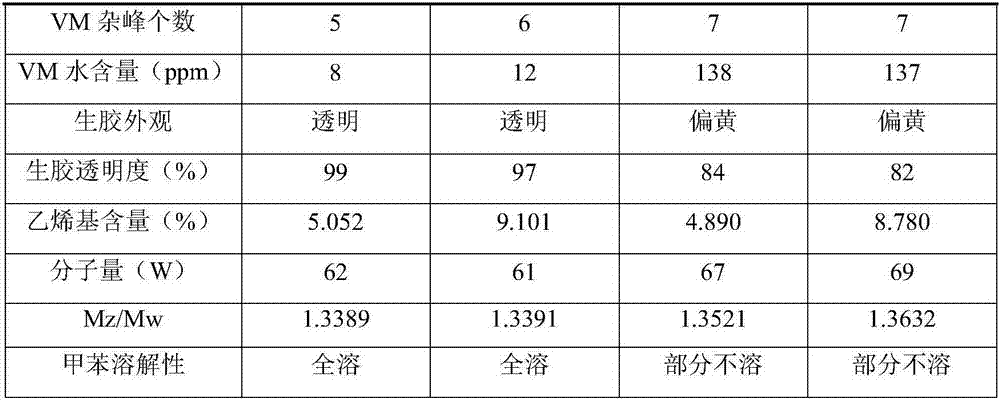

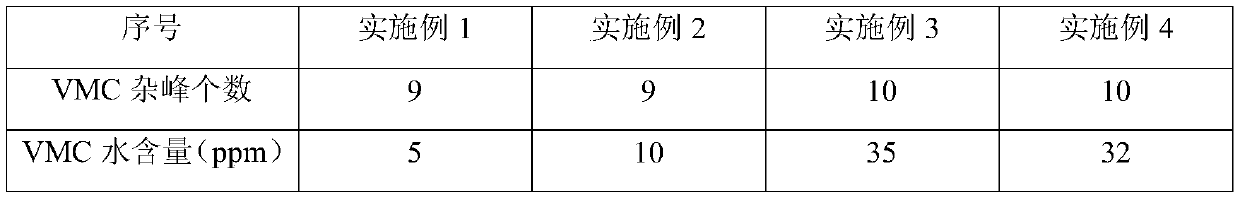

Production technology of methyl vinyl silicon rubber

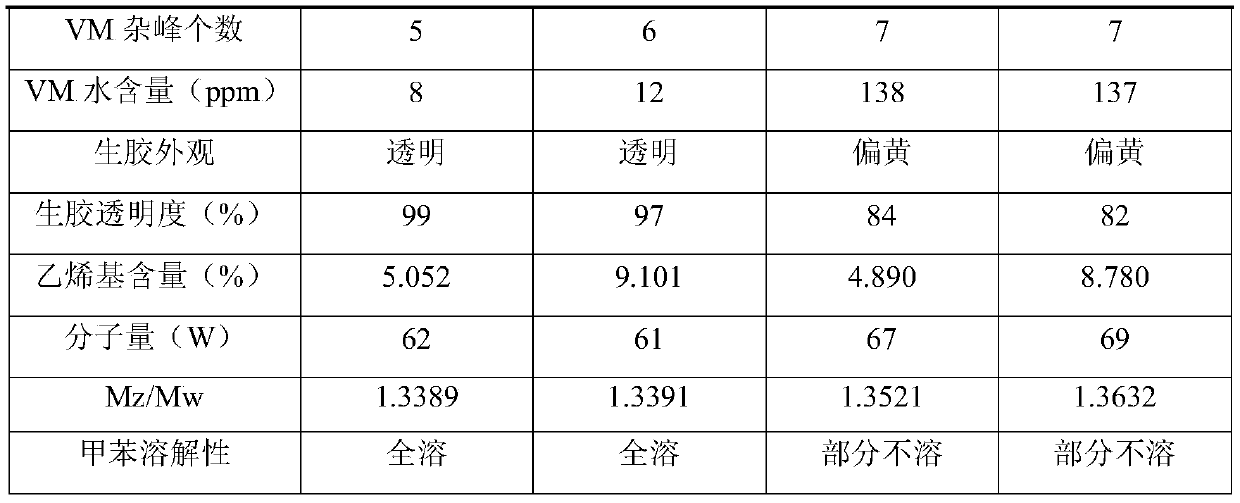

The invention relates to a production technology of high-transparency and high-vinyl methyl vinyl silicon rubber. The production technology comprises the following steps of performing primary filtering and fine filtering on DMC, so as to remove colored impurities including iron rust and the like; removing impurities from auxiliary materials, VMC and divinyltetramethyldisiloxane through vacuum bubble dehydration and physical dynamic adsorption; using a high-temperature and low-pressure dehydration technology, adding the dehydrated material into a polymerizing kettle, adding a catalyst, VMC and a termination sealing agent to polymerize, and balancing after the polymerizing is completed; preheating the balanced rubber material, and then sending into a low molecule removal device to remove low molecule and produce the rubber. The production technology has the advantages that the problems of easiness in crosslinking and broad distribution of molecular weight in the high-vinyl raw rubber are solved; in the low molecule removal process, the gradual heating manner is adopted, and the problems of falling and crosslinking of vinyl, instability of vinyl content, slight yellowing of a product and the like due to continuous high temperature of local part in the raw rubber production heating process are solved.

Owner:HUBEI XINGRUI SILICON MATERIAL CO LTD

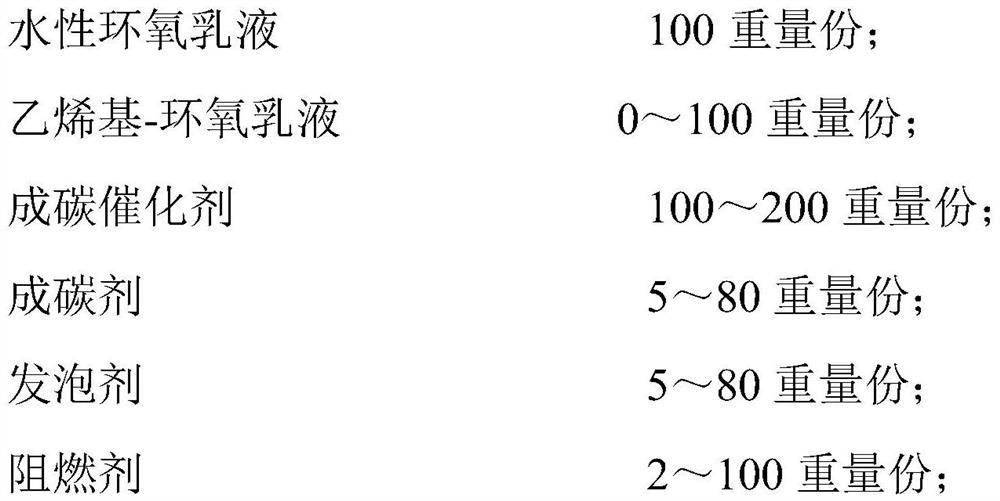

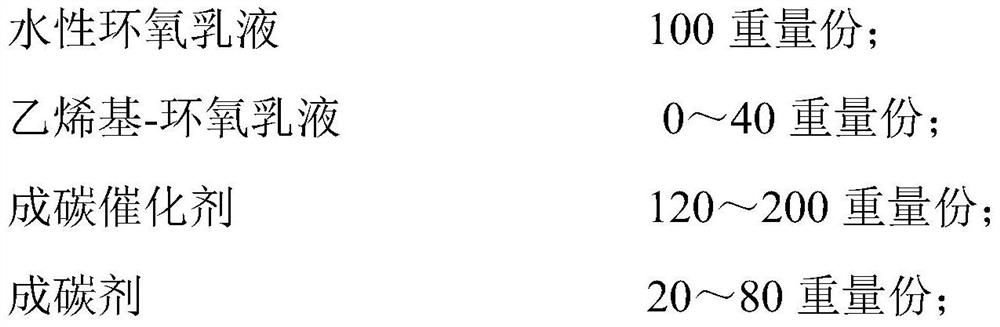

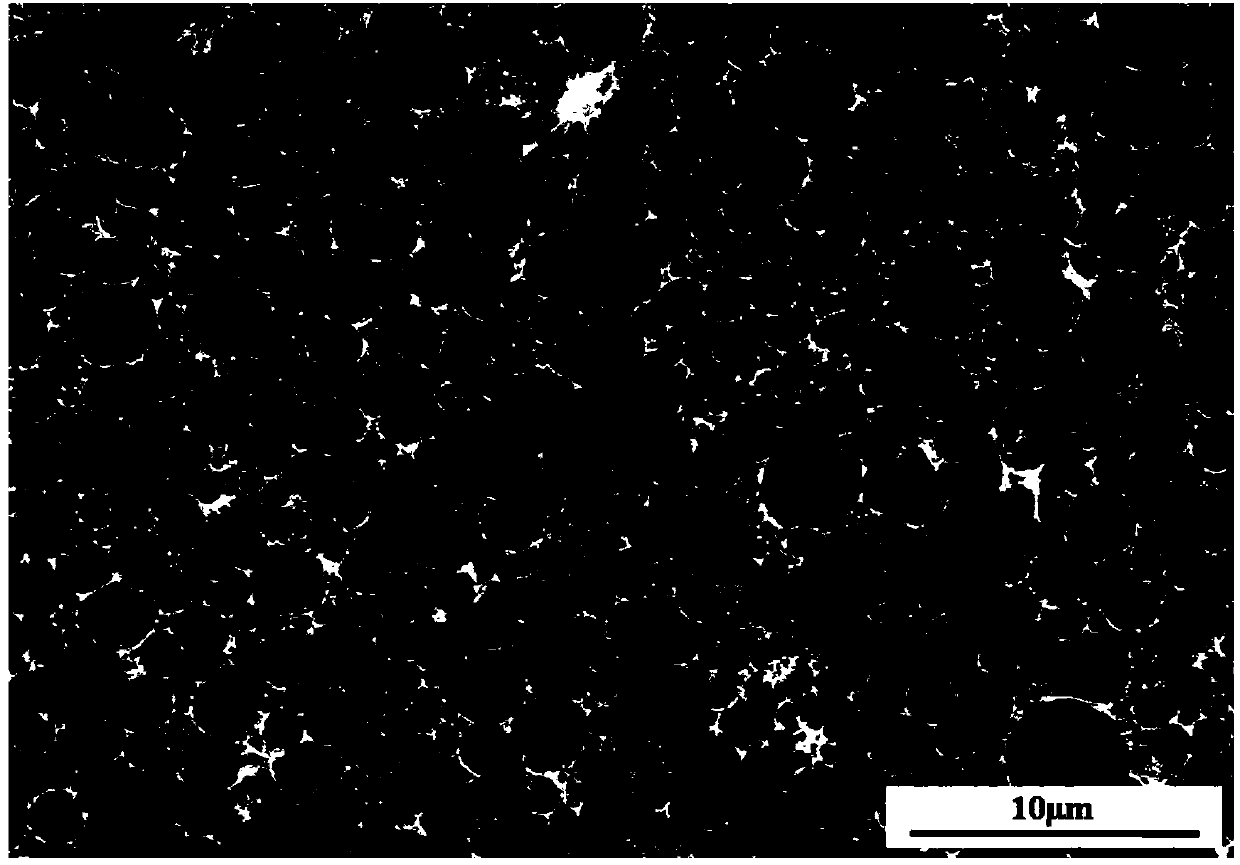

Waterborne epoxy fireproof coating as well as preparation method and application thereof

ActiveCN113444425ANo pollution in the processEasy to operateFireproof paintsAnti-corrosive paintsFiberPolymer science

The invention discloses a waterborne epoxy fireproof coating as well as a preparation method and application thereof. The waterborne epoxy fireproof coating is composed of a component A and a component B. The component A comprises a waterborne epoxy emulsion, a vinyl-epoxy emulsion, a carbon forming catalyst, a carbon forming agent, a foaming agent and a flame retardant; and the component B comprises a curing agent and refractory fibers. The water-based epoxy fireproof coating disclosed by the invention has the same excellent sealing performance as a solvent-free epoxy fireproof coating and a high-solid-content epoxy fireproof coating, has excellent corrosion resistance, UV irradiation resistance, water resistance and organic solvent resistance, and can be used in a severe outdoor environment. According to the fireproof coating, self-made emulsions are preferably selected, the structure of a film forming matter is optimized and adjusted, and fireproof efficiency is high. Meanwhile, water is selected as a diluent, so coating problems of an original epoxy fireproof coating are fundamentally solved, a water-based system is more environmentally friendly, and the coating belongs to a new-generation fireproof coating technology.

Owner:MARINE CHEM RES INST

Preparation method of fluorinated polysiloxane raw rubber with terminal groups containing vinyl

The invention relates to a preparation method of fluorinated polysiloxane raw rubber with terminal groups containing vinyl. The preparation method comprises the following steps: (1) carrying out heating dehydration on sodium hydroxide and divinyl tetramethyl disiloxane, carrying out heating reflux, cooling, filtrating, reducing pressure of filtrate so as to remove impurities so as to obtain solid powder, sealing and storing; (2) heating vinyl dimethyl silanol sodium salt in the step (1) and a fluorine-containing monomer (3,3,3-trifluoropropyl)methylcyclotrisiloxane, dewatering, continuously heating, and carrying out reduced pressure so as to remove low-boiling-point substances; (3) adding the fluorine-containing monomer (3,3,3-trifluoropropyl)methylcyclotrisiloxane and tetravinyl tetramethyl cyelo tetrasiloxane to a polymerization reactor, heating, dewatering, adding vinyl dimethyl silanol sodium salt alkali-gel, carrying out polymerization reaction, neutralizing by using a neutralizing agent, heating and removing low-boiling-point substances to obtain the fluorinated polysiloxane raw rubber with the terminal groups containing vinyl. The preparation method is used for producing the hot vulcanized fluorinated polysiloxane raw rubber with oil resistance and solvent resistance; the hot vulcanized fluorinated polysiloxane raw rubber serving as sealing materials, coating materials, gasket materials and the like is widely applied to the fields such as aviation, aerospace, automobiles, petrochemical engineering and artificial organs.

Owner:浙江恒业成有机硅有限公司

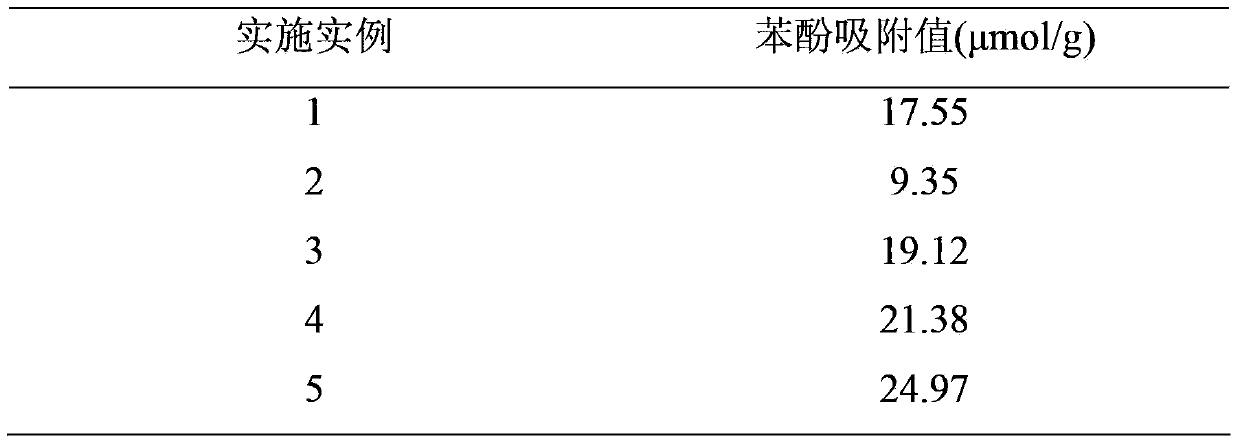

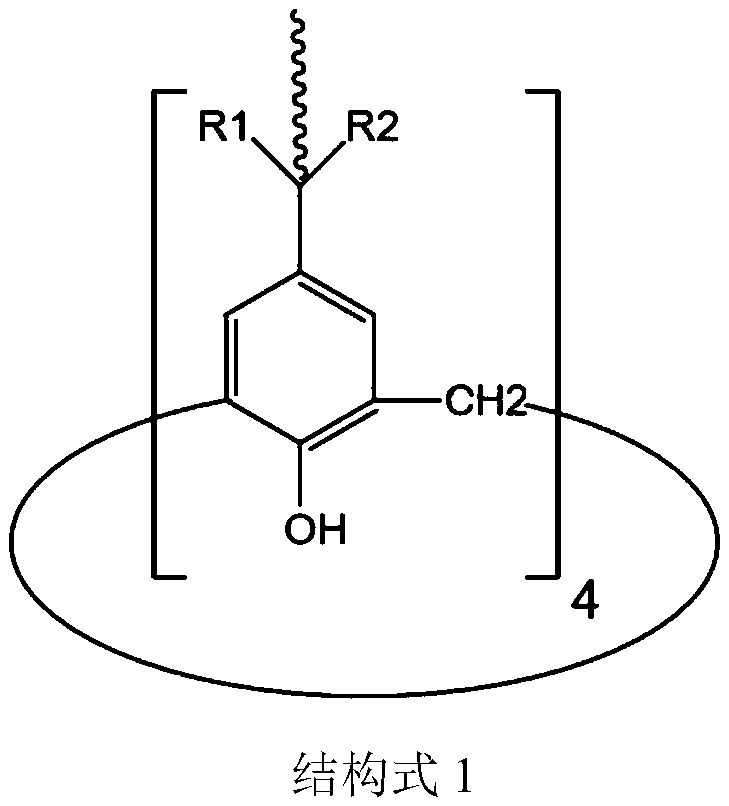

Copolymerization-immobilized beta-cyclodextrin porous separation material as well as preparation method and application thereof

The invention discloses a copolymerization-immobilized beta-cyclodextrin porous separation material as well as a preparation method and an application thereof belongs to a porous separation material technology. The preparation method comprises the following steps of: preparing vinyl beta-cyclodextrin; uniformly mixing vinyl beta-cyclodextrin with styrene, p-vinyltoluene and an emulsifier, and then adding an initiator and aqueous solution containing an electrolyte to prepare a stable concentrated emulsion; polymerizing for 6-48 hours at 50-80 DEG C to obtain the copolymerization-immobilized beta-cyclodextrin porous separation material, wherein the mixture of vinyl beta-CD, styrene, p-vinyltoluene and the emulsifier is continuous-phase, the aqueous solution containing the electrolyte is disperse-phase, and the volume fraction of the disperse phase occupying the concentrated emulsion is 74-95%; the dosages of the initiator and the electrolyte are 3-10% of the mass of the mixture of vinyl beta-CD, styrene and p-vinyltoluene. The porous separation material can be used for phenolic wastewater treatment, and can achieve certain separation efficiency.

Owner:BEIJING UNIV OF CHEM TECH

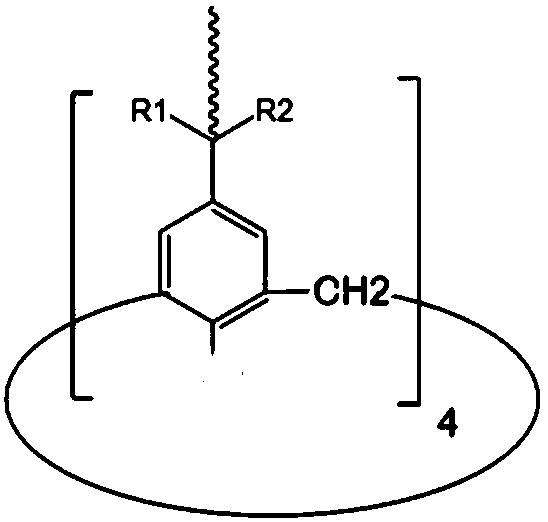

Preparation method of neodymium iron boron with low cost and high corrosion resistance

ActiveCN111073466AImprove corrosion resistanceHigh bonding strengthFireproof paintsAnti-corrosive paintsMethacrylateFirming agent

The invention discloses a preparation method of neodymium iron boron with low cost and high corrosion resistance. The preparation method comprises the following steps: S1, pretreating a sintered neodymium iron boron magnet by using an initial impact current in a titanium salt solution; S2, uniformly stirring and mixing fluorine-containing methacrylate, epoxy resin and vinyl epoxy resin to preparea main body raw material, putting the main body raw material into a ball-milling tank, adding 1 / 2 part of an additive and titanium phosphate, and performing ball-milling and uniform mixing to obtain amodified coating mixed solution; and S3, adding a curing agent, the remaining 1 / 2 part of additive and filler into the modified coating mixed solution obtained in the step S2, performing stirring andmixing uniformly, spin-coating the surface of the neodymium iron boron material pretreated in the step S1, and performing heating and drying after coating to obtain the corrosion-resistant neodymiumiron boron. According to the preparation method, after the neodymium iron boron is pretreated, the modified coating is subjected to spin coating and drying, the neodymium iron boron with high corrosion resistance is obtained, the preparation process is simple, and the cost is low.

Owner:ZHEJIANG ZHONGHANG NEW MATERIAL

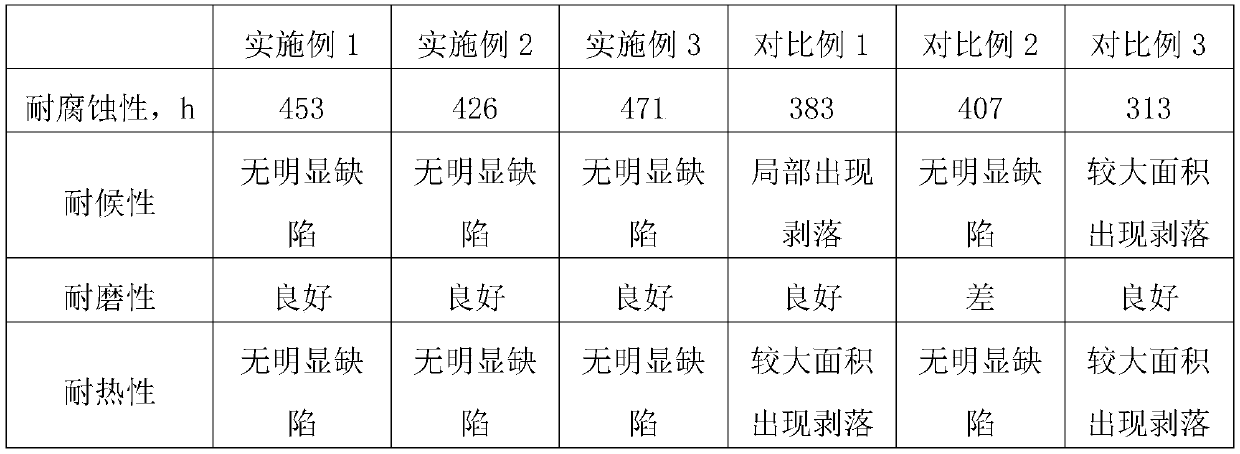

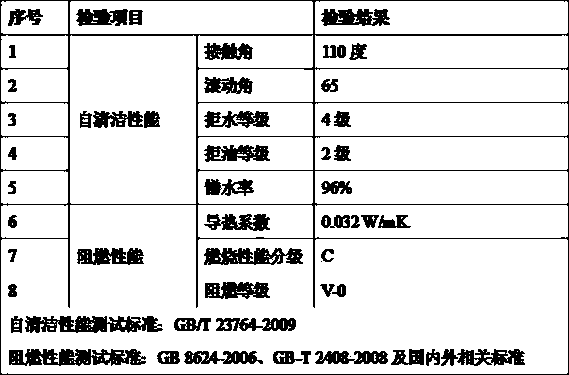

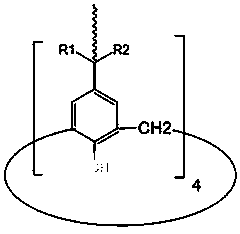

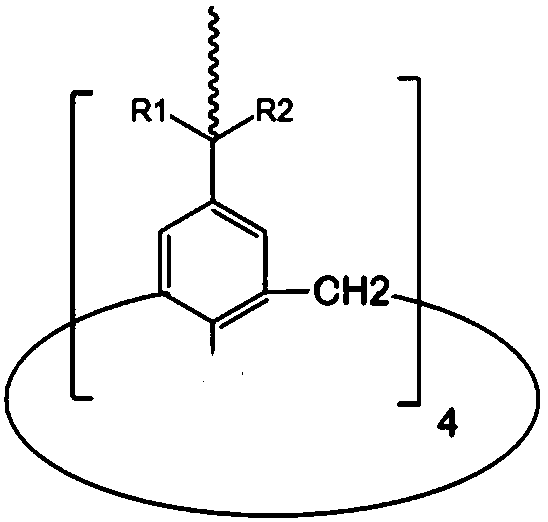

Flame retardation type exterior coating capable of automatically cleaning

The invention relates to relates to a flame retardation type exterior coating capable of automatically cleaning, the coating takes epoxy resin slurry and methacrylate as monomer. The exterior coating comprises the following raw materials by weight: 20-40 parts of vinyl epoxy resin slurry, 5-30 parts of n-butyl methacrylate, 0.5-2.5 parts of phosphate tri(2-chloropropyl)ester, 1-10 parts of hydrophobic silica, 0.1-5 parts of titanium dioxide, 0.1-2 parts of levelling agent, 0.1-2 parts of antifoaming agent, 0.5-5 parts of silicon auxiliary agent and 1-5 parts of initiator. When the coating is used, the monomer initiates a polymerization through a radical initiator to form a thermosetting polymer, a contact angle with water is greater than 110 DEG, and a roll angle is less than 65 DEG. The water-repellency grade is grade 4, and the oil-repellency grade is grade 2. The hydrophobicity can reach 96%, the heat conduction coefficient is 0.032W / mK, the combustion grading accords with a grade C, and all the indexes can reach an international relative standard.

Owner:浙江鸿浩科技有限公司

Corrosion-resistant composite protective layer material for neodymium iron boron

ActiveCN111073467AGood weather resistanceHydrophobicFireproof paintsAnti-corrosive paintsMethacrylateFirming agent

The invention discloses a corrosion-resistant composite protective layer material for neodymium iron boron, and the composite protective layer material comprises: a substrate layer which is spin-coated on the neodymium iron boron; a protective layer coated on the substrate layer, wherein the protective layer is prepared from the following raw materials in parts by weight: 10-20 parts of fluorine-containing methacrylate, 30-50 parts of epoxy resin, 40-60 parts of vinyl epoxy resin, 5-10 parts of an additive, 0.5-1.5 parts of a curing agent, 1-2.5 parts of a filler and 20-50 parts of deionized water. According to the composite protective layer material, through the arrangement of the double-layer structure of the base layer and the protective layer, the surface corrosion resistance of the neodymium-iron-boron permanent magnet can be improved, the wear resistance and the heat resistance of the neodymium-iron-boron permanent magnet can be improved, and the service life of the neodymium-iron-boron surface protective layer is prolonged.

Owner:ZHEJIANG ZHONGHANG NEW MATERIAL

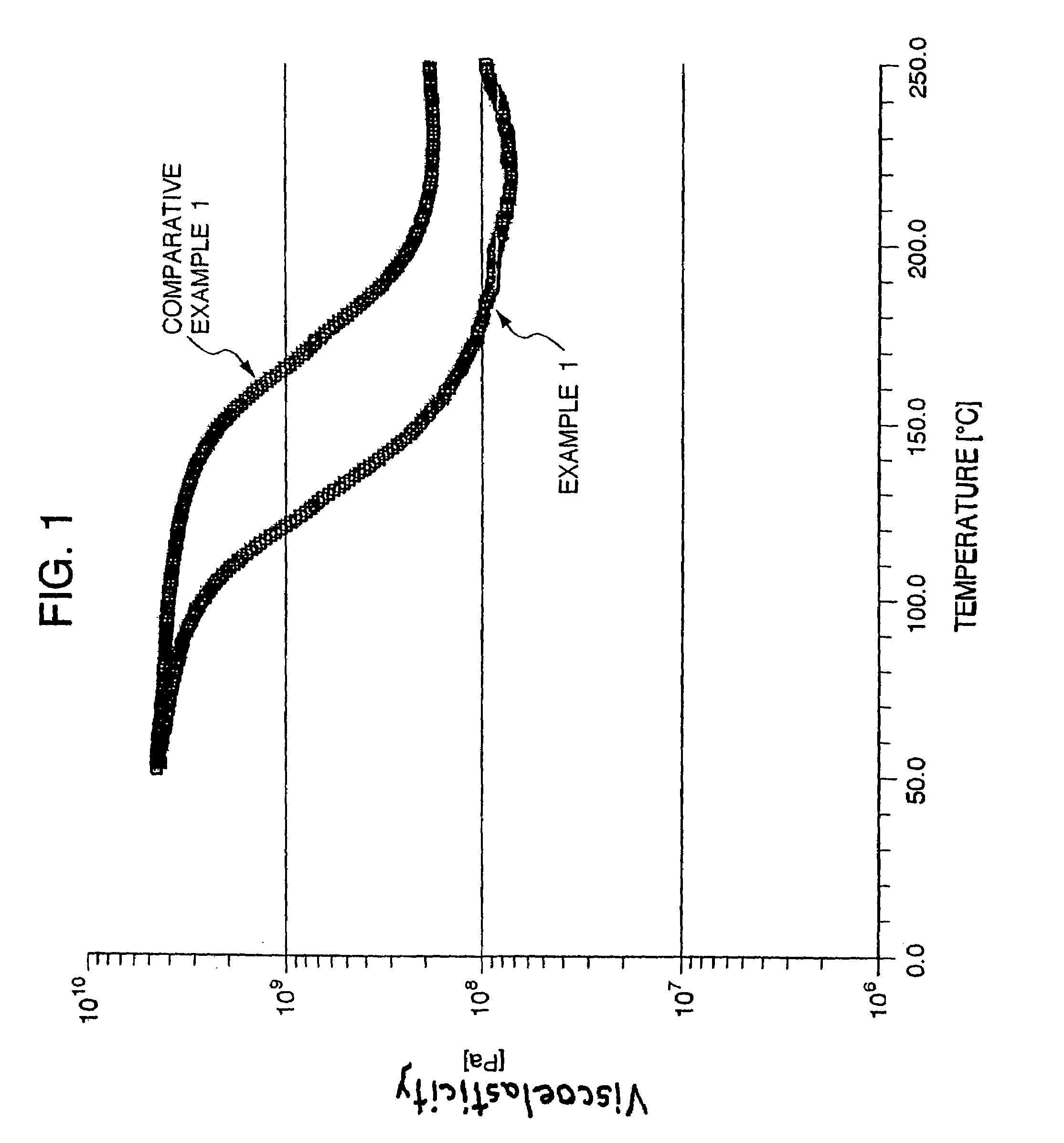

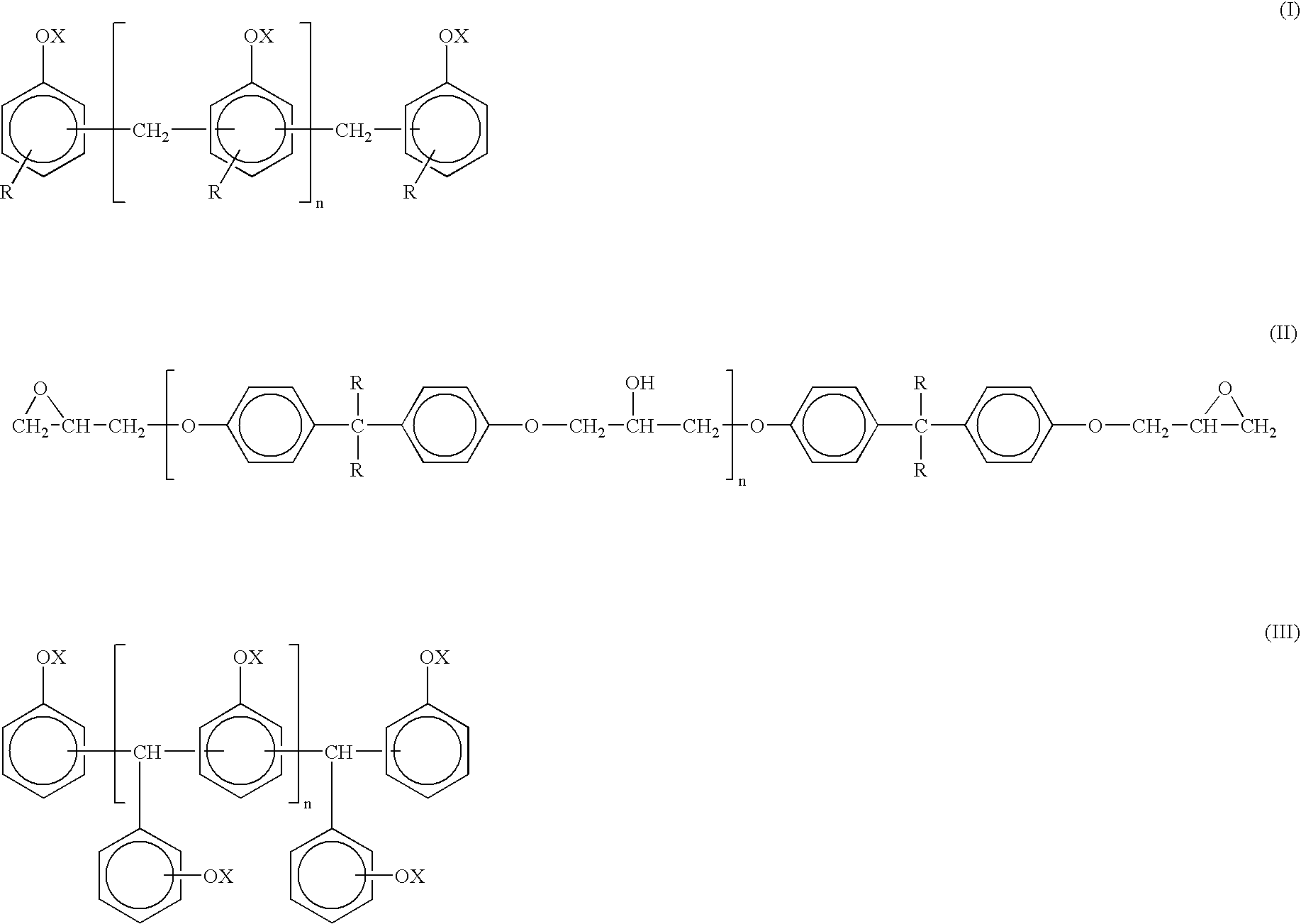

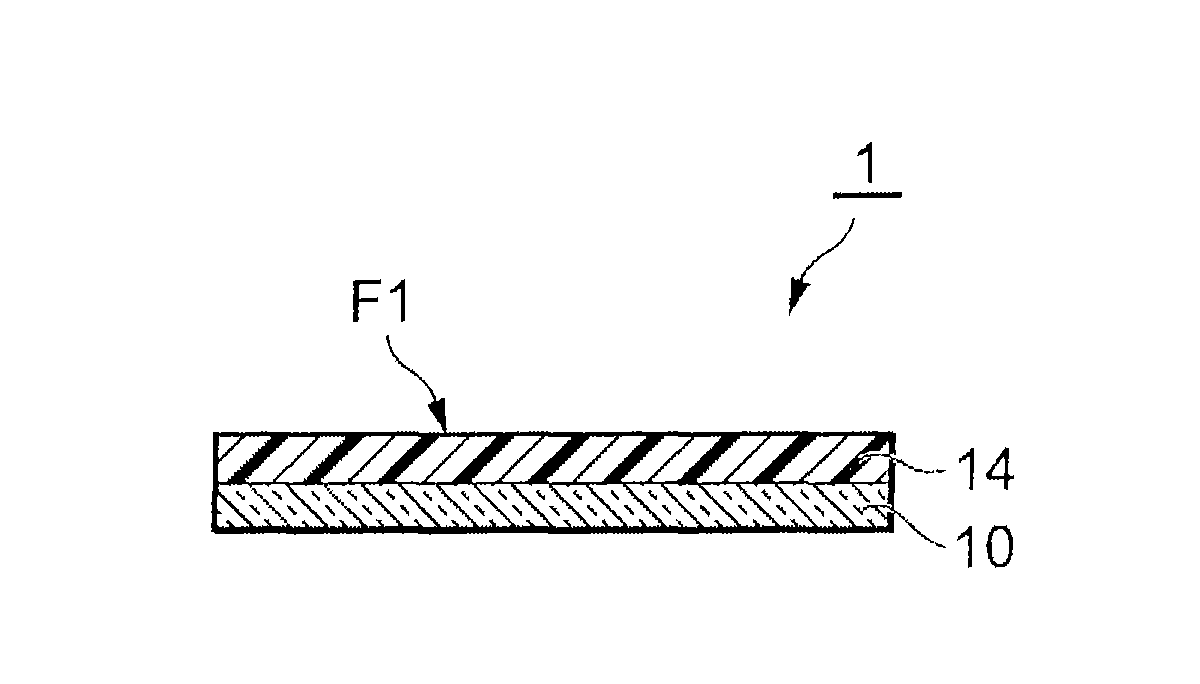

Photo-cured film, and photosensitive element, printed wiring board and semiconductor package using such film

InactiveUS7071243B2Improve performanceDistinguished heat resistancePhotosensitive materialsPhotomechanical apparatusEpoxyElectrical resistance and conductance

A photo curable resin composition, which comprises (A) an acid-modified, vinyl group-containing epoxy resin, (B) an elastomer, (C) a photopolymerization initiator, (D) a diluent and (E) a curing agent, can give a high performance cured film having distinguished heat resistance, humidity-heat resistance, adhesibility, mechanical characteristics and electrical characteristics, and a photosensitive element, which comprises a support and a layer of the photo curable resin composition laid on the support, has distinguished heat resistance, humidity-heat resistance, adhesibility, mechanical characteristics and electrical characteristics.

Owner:HITACHI CHEM CO LTD

Coating for coating plastic bottom shell of notebook computer

PendingCN113801567AHigh impact strengthImprove wear resistancePolyurea/polyurethane coatingsPolyester coatingsPolymer scienceMeth-

The invention discloses a coating for coating a plastic bottom shell of a notebook computer. The coating comprises a primer and a finish; the primer comprises a component A and a component B, and the mass ratio of the component A to the component B is 100: (2-5); the component A is prepared from 50 to 70 parts of carboxyl-containing hyperbranched poly (amine-ester) acrylate, 10 to 20 parts of carboxyl-terminated aromatic hyperbranched polyester, 2 to 4 parts of functional additive and 20 to 30 parts of solvent A; the component B is prepared from the following components in parts by weight: 60 to 80 parts of aziridine cross-linking agent XR-100 and 25 to 35 parts of butyl acetate; the finish paint is prepared from the following components in parts by weight: 60 to 75 parts of hyperbranched perfluorinated polyurethane acrylate oligomer, 3 to 5 parts of 4-vinyl-2, 8-bis (trifluoromethyl) quinoline, 2 to 4 parts of 2, 4, 6-trivinyl boroxane, 0.1 to 0.3 part of 1-allyl-3-vinyl imidazole chlorine salt, 4 to 6 parts of matting powder, 0.8 to 1.2 parts of a flatting agent, 1 to 2 parts of a dispersing agent, 0.8 to 1.2 parts of an initiator and 40 to 50 parts of a solvent B. The coating for coating the plastic bottom shell of the notebook computer, disclosed by the invention, is good in impact strength, excellent in wear resistance, heat and humidity resistance, cold and hot cycle resistance and heat-resistant stability, and sufficient in environmental protection property and adhesive force.

Owner:安徽英力电子科技股份有限公司

Vinyl silicon resin for moderate-refractive-index LED and preparation method thereof

The invention discloses vinyl silicon resin for a moderate-refractive-index LED. The vinyl silicon resin is prepared from, by weight, 100-105 parts of phenyl trimethoxysilane, 10-20 parts of tetravinyl tetramethyl cyelo tetrasiloxane, 20-60 parts of distilled water, 30-50 parts of divinyl tetramethyl disiloxane, 100-200 parts of solvent and 3-5 parts of catalyst. The invention further provides a preparation method of the vinyl silicon resin. The phenyl trimethoxysilane, the tetravinyl tetramethyl cyelo tetrasiloxane, the distilled water, the divinyl tetramethyl disiloxane, the solvent and the catalyst are added into a container, the temperature is improved to be 40-60 DEG C, the constant temperature is kept for 4-8 hours while stirring, the temperature is improved to be 100-130 DEG C, constant-temperature reaction is performed for 4-8 hours while stirring, reaction liquid is subjected to washing with the distilled water till the reaction liquid is neutral, and then reduced-pressure distillation is performed under the condition that the temperature is controlled to be 200 DEG C and the pressure is controlled to be -0.096 MPa to obtain the vinyl silicon resin for the high-light-transmittance moderate-refractive-index LED. The vinyl silicon resin prepared by means of the preparation method is better in stability.

Owner:SHANGHAI INST OF TECH

High-hardness addition type liquid silica gel and preparation method thereof

The invention relates to a silicone rubber product, in particular to high-hardness addition type liquid silicone rubber and a preparation method thereof. The high-hardness addition type liquid silicone rubber comprises a component A and a component B. The component A comprises a basic rubber material, vinyl MQ resin and a platinum complex catalyst; and the component B comprises first vinyl MQ resin, silicone oil containing hydrogen in the end and tetramethyl tetravinyl cyclotetrasiloxane. According to the preparation method, the affinity of a reinforcing filler to oil is improved by performing surface pretreatment on the reinforcing filler, the content of the reinforcing filler in the silica gel can be further increased, and meanwhile, two different vinyl MQ resins are compounded to serve as a reinforcing agent of a silica gel system, so that the hardness of the prepared silica gel is greatly improved.

Owner:惠州市永卓科技有限公司

Environment-friendly plastic and preparation method thereof

The invention discloses an environment-friendly plastic which is characterized by being prepared from the following raw materials in parts by weight: 15-25 parts of cinnamic acid modified plant fibers, 30-40 parts of vinyl beta cyclodextrin quaternary ammonium salt, 45-55 parts of 2-vinylpyrazine / methylvinylsilicate Fluorene / 1,3-adamantanediol monoacrylate copolymers, 1-2 parts of initiators, 4-6parts of epoxysuccinic acid and 5-8 parts of epoxy-terminated hyperbranched polyphosphate. The invention also provides a preparation method thereof. The environment-friendly plastic disclosed by the invention is excellent in comprehensive performance, good in mechanical property, water resistance, flame retardance and oxidation resistance, capable of being completely degraded after being discarded, and small in environmental influence.

Owner:崔凤金

Heavy release film for OCA optical adhesive

PendingCN112574452AStrong release forceImprove adhesionSynthetic resin layered productsPolyurea/polyurethane coatingsMethacrylatePolymer science

The invention discloses a heavy release film for an OCA optical adhesive, wherein the heavy release film is used for being attached to one side of an OCA optical adhesive layer and clamping the OCA heavy release film layer in the middle together with a light release film on the other side, and comprises a release film base material and a release agent layer coated on the surface of the release film base material, wherein the release agent layer is prepared from an ultraviolet light curing release agent prepared from the following raw materials in parts by weight: 50-150 parts of polybutadienepolyurethane, 50-90 parts of polyacrylate resin, 20-40 parts of 1,3-dioxolane, 20-50 parts of tetramethyl tetravinyl cyclotetrasiloxane, 25-55 parts of an octadecyl methacrylate active monomer diluent, 20-40 parts of tetrahydrofuran and 1-5 parts of an initiator, namely 2-hydroxy-2-methyl-1-phenyl-1-acetone. The ultraviolet curing release agent of the heavy release film does not need high-temperature baking and can bear high-temperature treatment during OCA optical adhesive curing.

Owner:JIANGSU SHUANGXING COLOR PLASTIC NEW MATERIALS

Light release film for OCA

ActiveCN112937043APrevent disengagementSmall adhesionLamination ancillary operationsSynthetic resin layered productsPolymer scienceFilm base

The invention discloses a light release film for an OCA (optical clear adhesive). The light release film is used for being attached to one side of an OCA layer, the light release film and a heavy release film on the other side clamp the OCA layer in the middle, the light release film comprises a release film base material and a release agent layer which coats the surface of the release film base material, the release agent layer is prepared from a release agent, and the release agent is prepared from, by weight, 50 to 80 parts of polydimethylsiloxane, 100 to 200 parts of ethyl acetate, 10 to 20 parts of polyurethane resin, 10 to 20 parts of ethylene-vinyl acetate copolymer, 10 to 20 parts of tetramethyl tetravinyl cyclotetrasiloxane, 20 to 40 parts of tetrahydrofuran, and 10 to 20 parts by weight of a terpene resin tackifier. The release agent layer provided by the invention can obtain continuous release property by slowing down and controlling the seepage speed of the release component.

Owner:JIANGSU SHUANGXING COLOR PLASTIC NEW MATERIALS

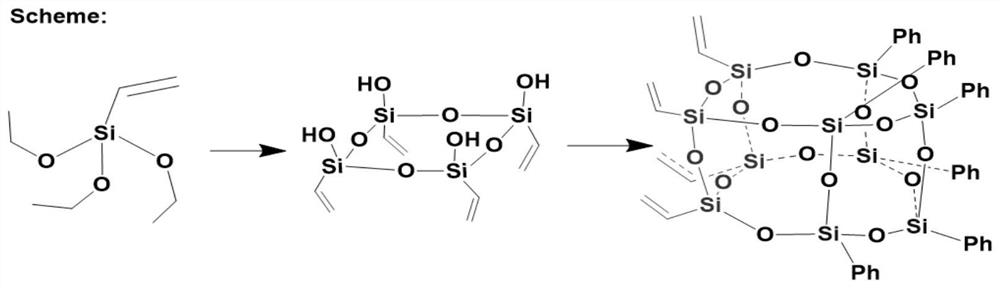

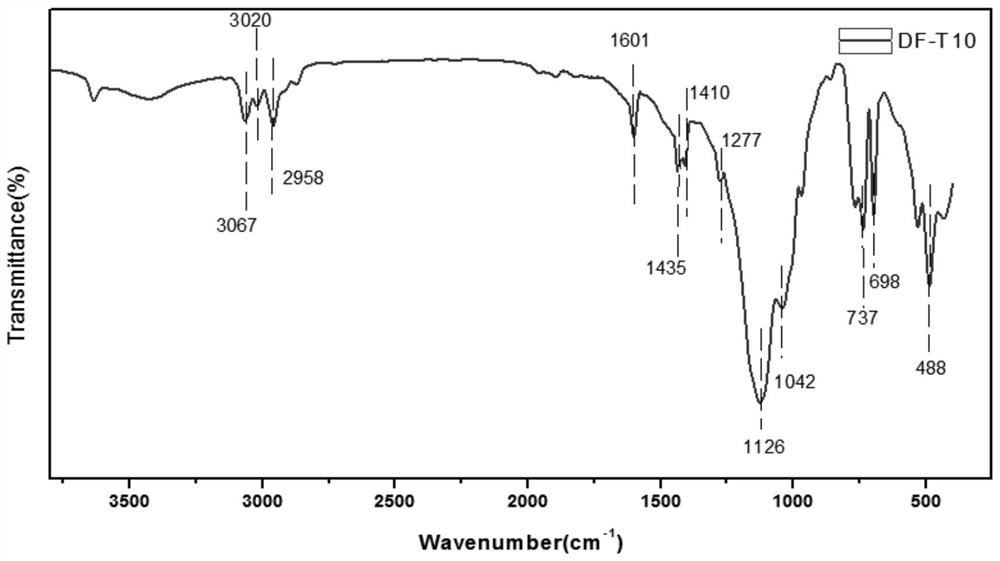

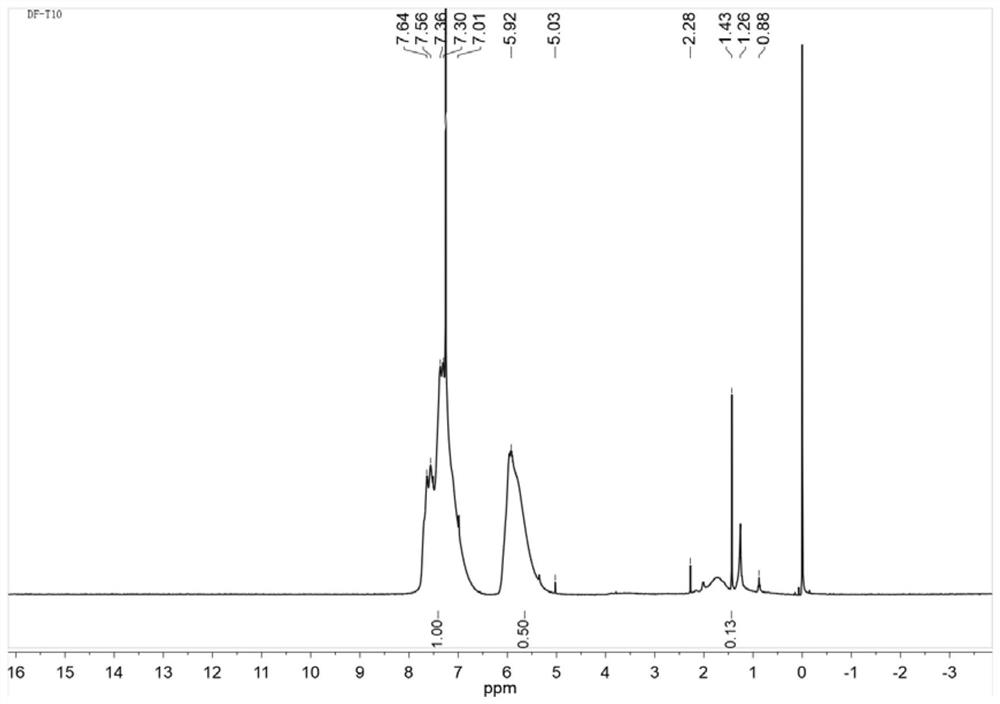

Tetraethylene hexaphenyl bifunctional group-containing T10 polyhedral oligomeric silsesquioxane and preparation method thereof

The invention belongs to the technical field of organic and inorganic nano hybrid materials, and discloses T10 polyhedral oligomeric silsesquioxane containing tetraethylene hexaphenyl bifunctional groups and a preparation method of the T10 polyhedral oligomeric silsesquioxane. The preparation method comprises the following steps: dissolving vinyltriethoxysilane in isopropanol, and then adding into a mixed solution containing potassium methoxide and water to obtain tetrahydroxy tetravinyl cyclotetrasiloxane; the preparation method comprises the following steps: dissolving tetraethylene hexaphenyl bifunctional group T10 polyhedral oligomeric silsesquioxane in 1, 4-dioxane, adding phenylsilane and a catalyst, and reacting under the protection of inert gas to obtain the tetraethylene hexaphenyl bifunctional group T10 polyhedral oligomeric silsesquioxane. The method has the advantages of simple reaction process, definite product structure and excellent solubility in common solvents, and can be applied to intercalation modified montmorillonite, hydrotalcite and other inorganic materials to increase the interlayer spacing of the inorganic materials and the like.

Owner:国科广化精细化工孵化器(南雄)有限公司 +3

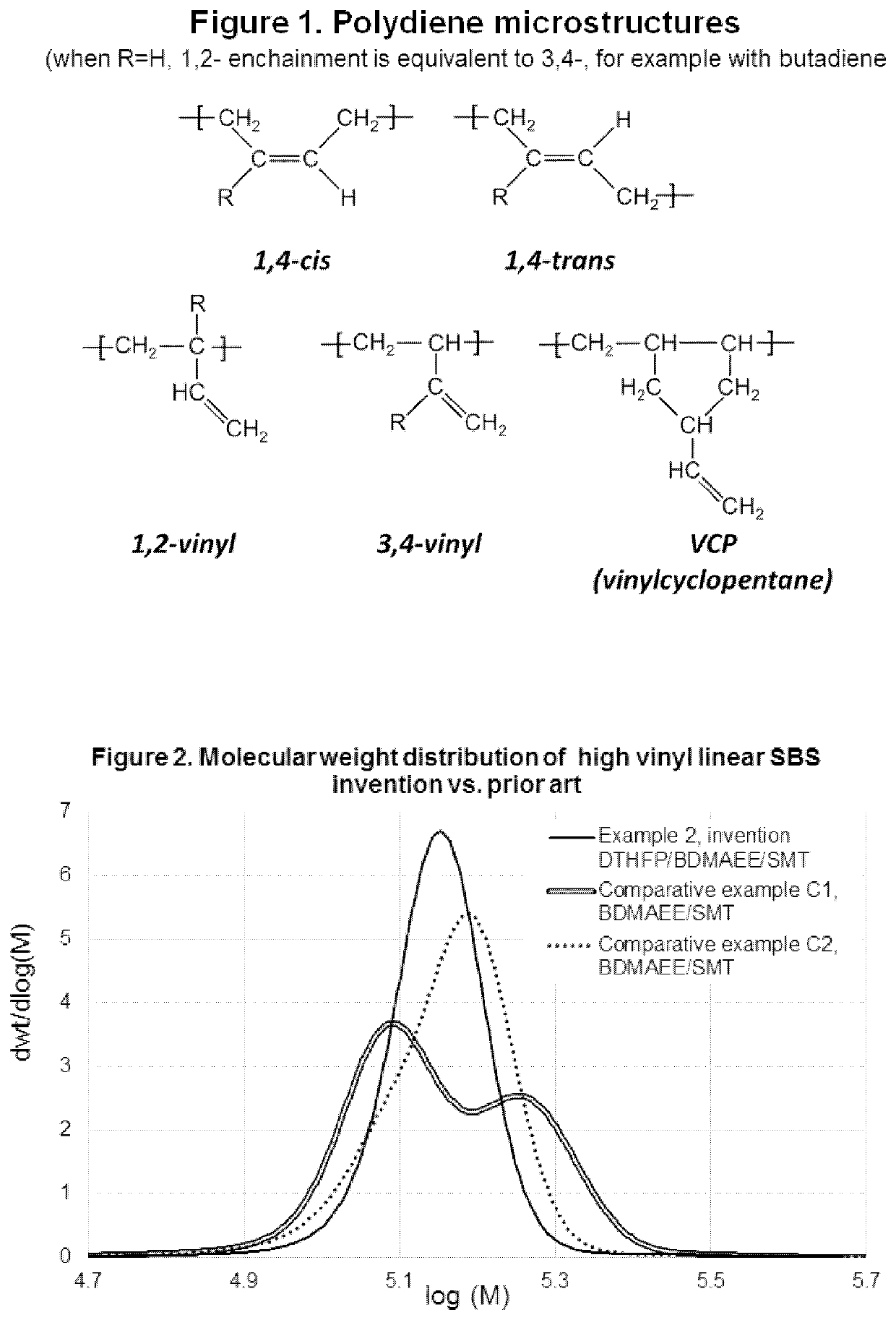

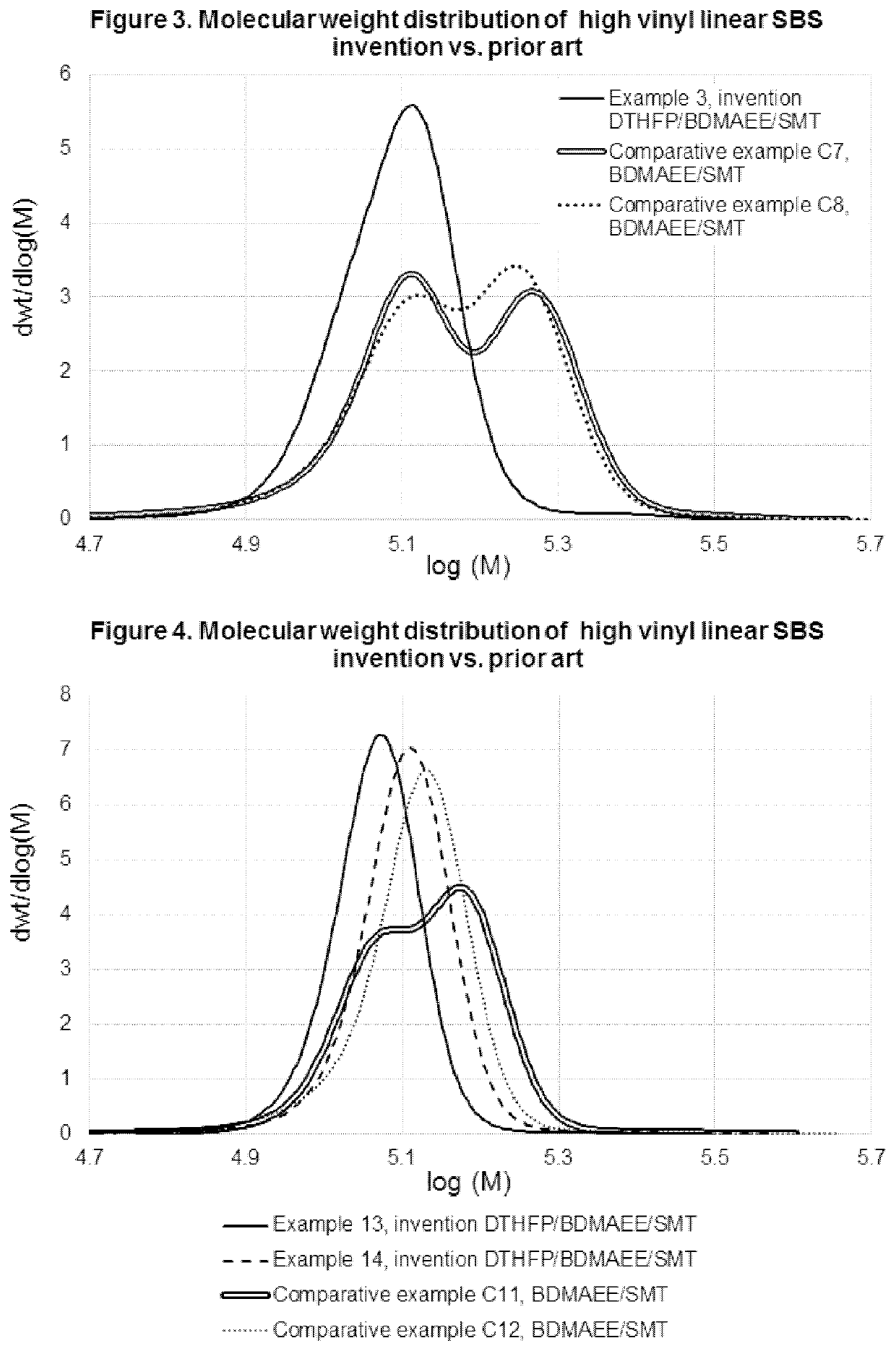

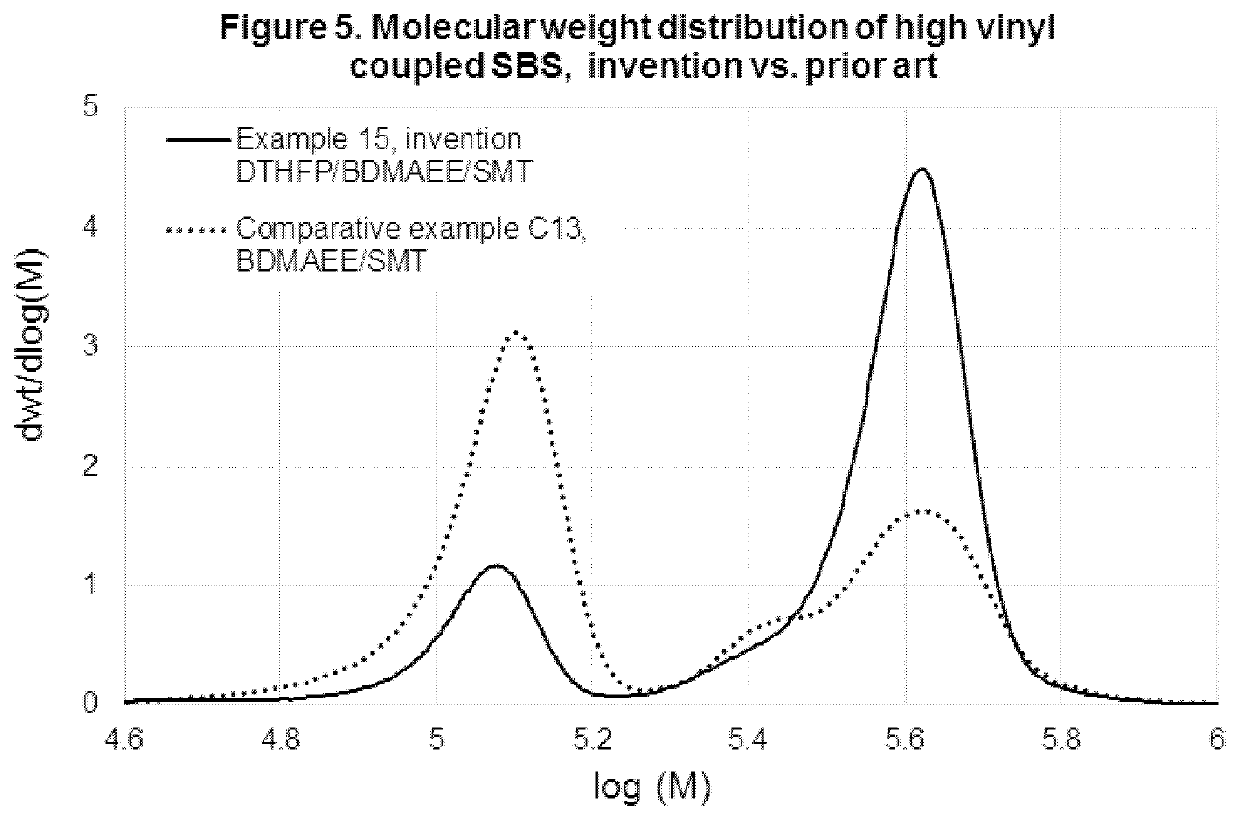

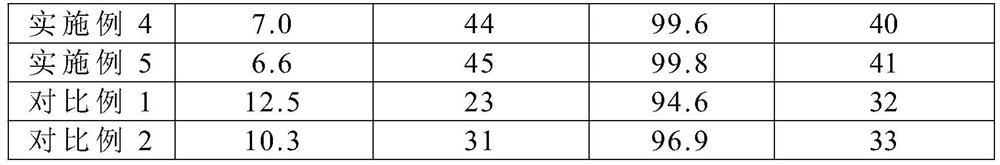

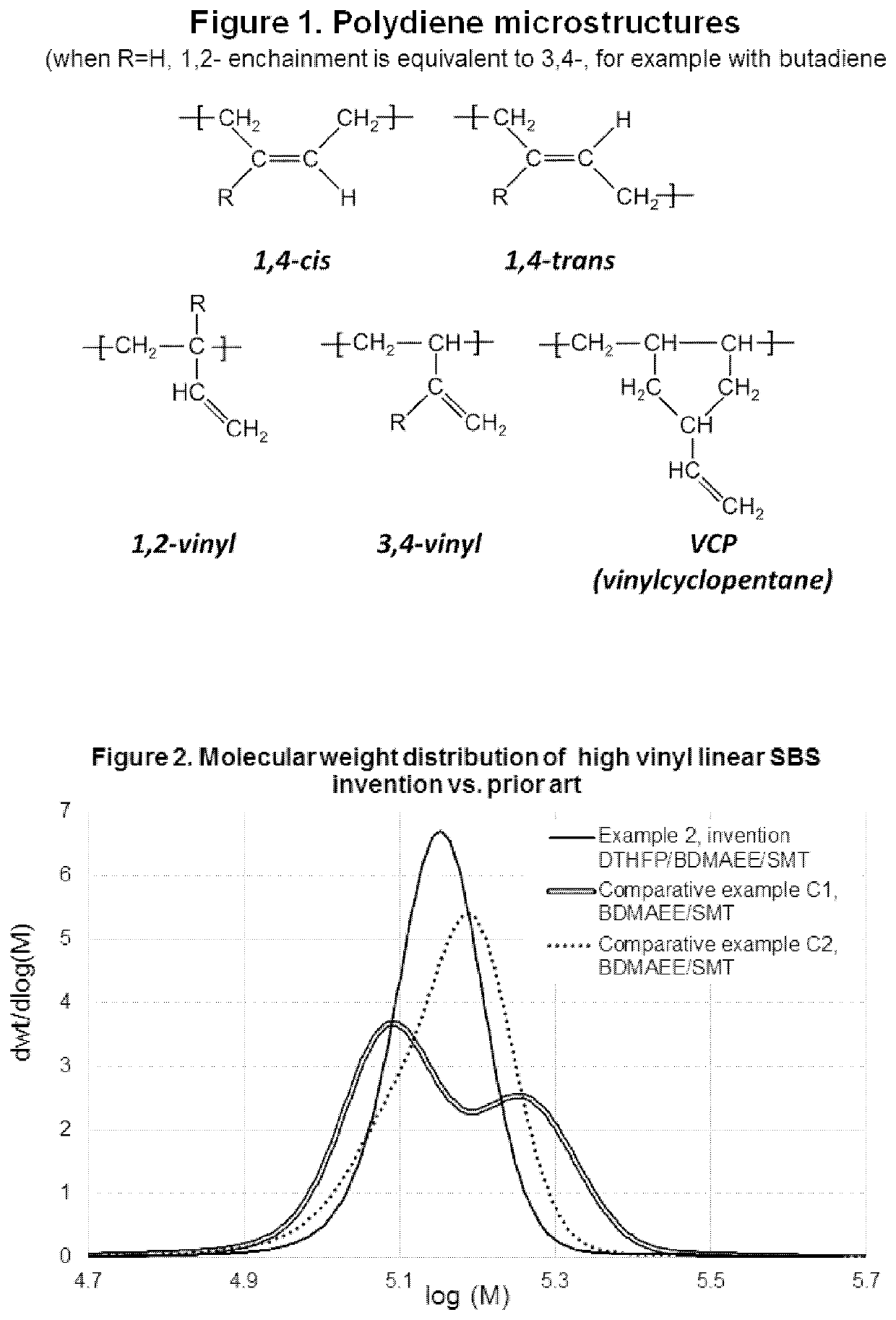

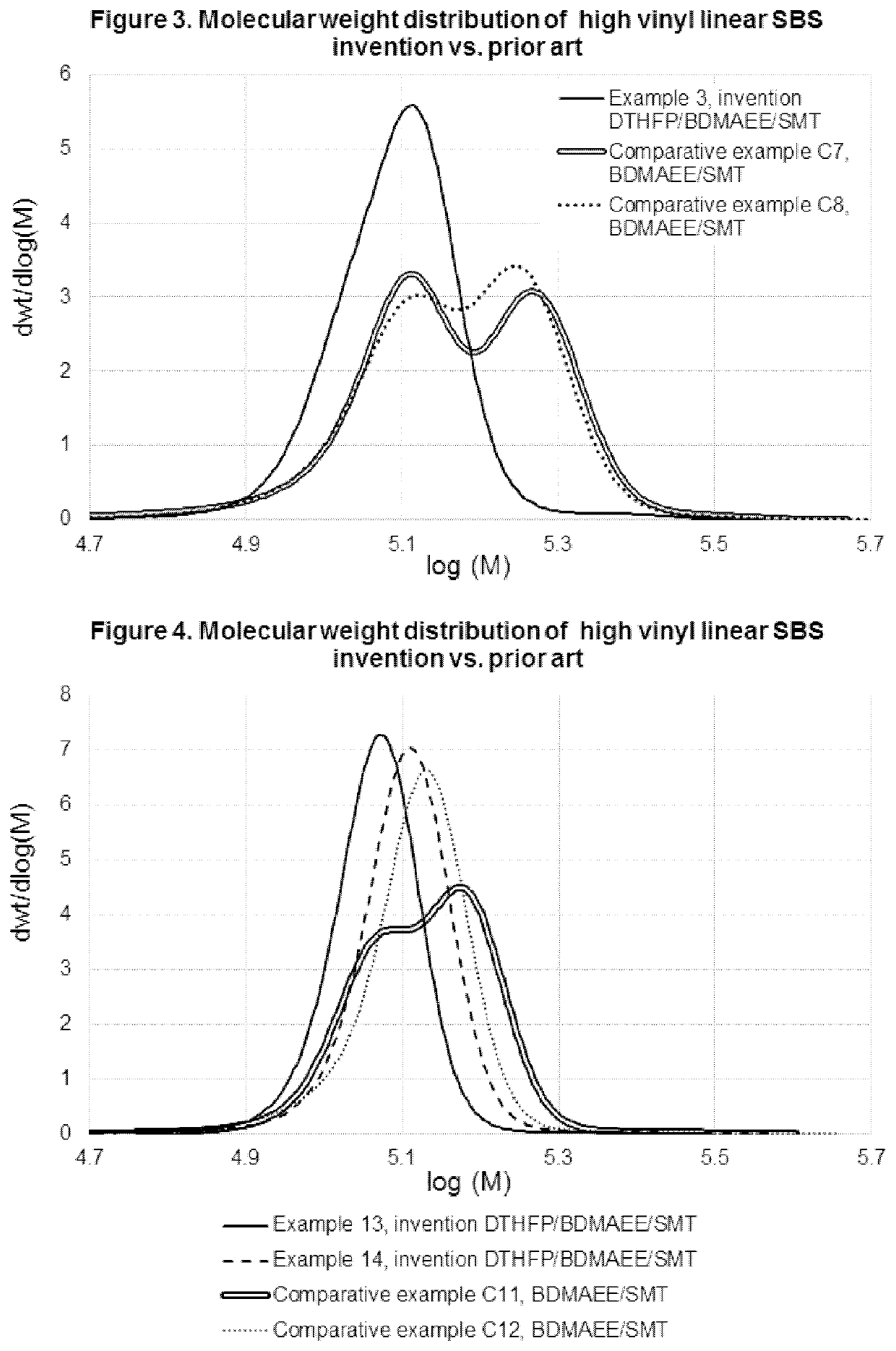

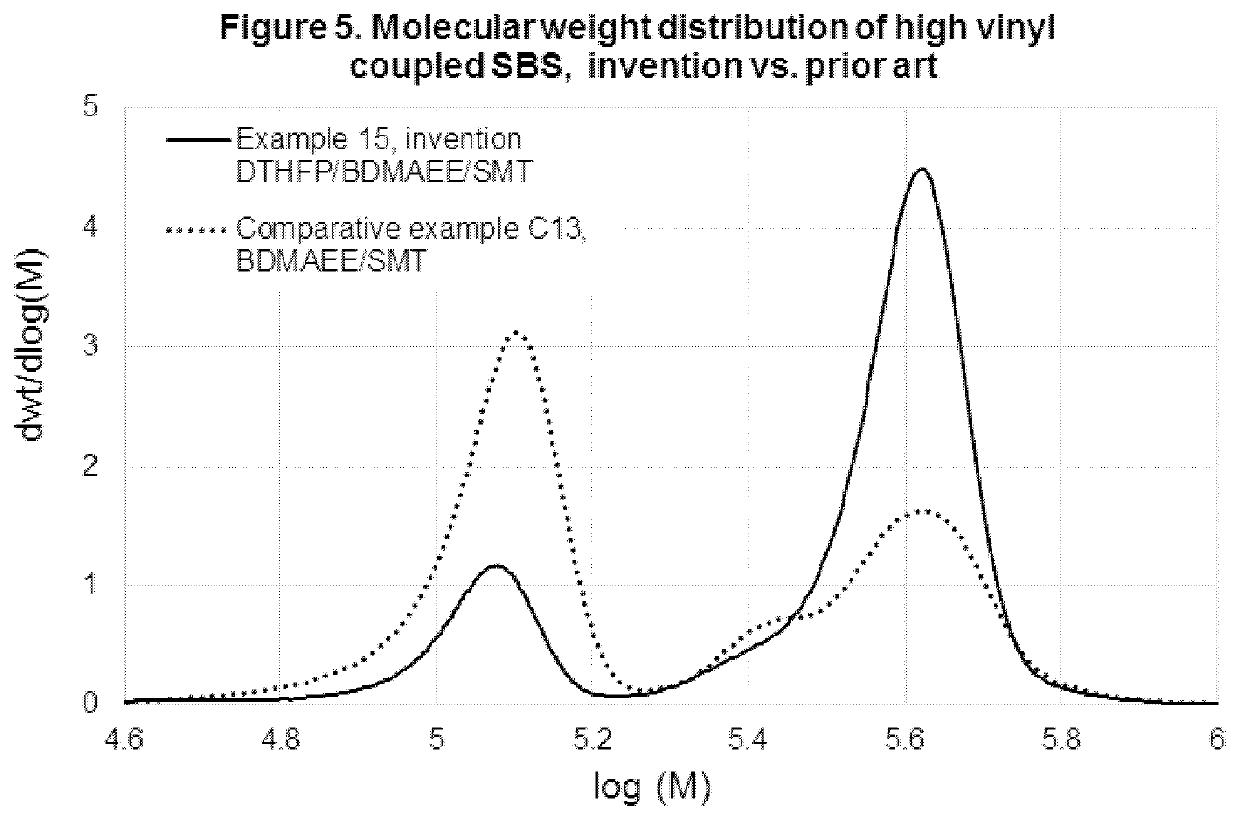

Polar modifier systems for high vinyl block copolymerization

Polar modifier systems based on a blend of DTHFP, ETE, TMEDA, DMTHFMA and / or functionally similar compounds with BDMAEE and SMT are used to make block copolymers having high levels of pendant vinyl double bond repeat units, which is through highly selective 1,2-bond butadiene addition, low vinylcyclopentane formation, unimodal narrow molecular weight distribution, and a low level of randomized co-monomer repeat units. The block copolymers have very high levels of 1,2-vinyl content and high 3,4-vinyl bond addition of the conjugated diene monomer and low vinylcyclopentane content. The polar modifier systems provide a fast polymerization rate, with a unimodal narrow molecular weight distribution. The polar modifier systems allow operation at a higher temperature than in prior art systems, which reduces cooling requirements.

Owner:DYNASOL ELASTOMEROS S A DE

Wear-resistant and aging-resistant decorative material and preparation method thereof

PendingCN114250037AReduce investmentImprove pass rateFilm/foil adhesivesPolymer scienceVinyl carbazole

The invention discloses a wear-resistant and aging-resistant decorative material which is characterized by sequentially comprising a release film layer, a pressure-sensitive adhesive layer and a functional film layer from top to bottom, the functional film layer is prepared from the following components in parts by weight: 50 to 60 parts of hyperbranched polypropylene, 20 to 30 parts of 4-vinyl-2, 8-bis (trifluoromethyl) quinoline / N-vinylcarbazole / 1, 3-bis (oxiranyl methyl)-5-(2-allyl)-1, 3, 5-triazine-2, 4, 6 (1H, 3H, 5H)-triketone / vinyl trimethoxy silane copolymer, 2 to 4 parts of poly 4-methylpentene, 2 to 4 parts of 2, 4, 6-trimethyl-1, 3, 5-trimethyl-1, 3, 5-trimethyl-1, 3, 5-trimethyl-1, 3, 5-trimethyl-1, 3, 5-trimethyl-1, 3, 5-trimethyl-1, 3, 5-trimethyl-1, 3, 5-trimethyl-1, 3, 5- 3-5 parts of 2, 6-trivinyl boroxane, 8-12 parts of a wear-resistant auxiliary agent and 0.8-1.2 parts of an initiator. The invention also discloses a preparation method of the wear-resistant and aging-resistant decorative material. The wear-resistant and aging-resistant decorative material disclosed by the invention is sufficient in wear resistance and aging resistance, good in flame retardance and mechanical property, good in weather resistance and good in decorative effect.

Owner:田祝英

Polar Modifier Systems for High Vinyl Block Copolymerization

Polar modifier systems based on a blend of DTHFP, ETE, TMEDA, DMTHFMA and / or functionally similar compounds with BDMAEE and SMT are used to make block copolymers having high levels of pendant vinyl double bond repeat units, which is through highly selective 1,2-bond butadiene addition, low vinylcyclopentane formation, unimodal narrow molecular weight distribution, and a low level of randomized co-monomer repeat units. The block copolymers have very high levels of 1,2-vinyl content and high 3,4-vinyl bond addition of the conjugated diene monomer and low vinylcyclopentane content. The polar modifier systems provide a fast polymerization rate, with a unimodal narrow molecular weight distribution. The polar modifier systems allow operation at a higher temperature than in prior art systems, which reduces cooling requirements.

Owner:DYNASOL ELASTOMEROS S A DE

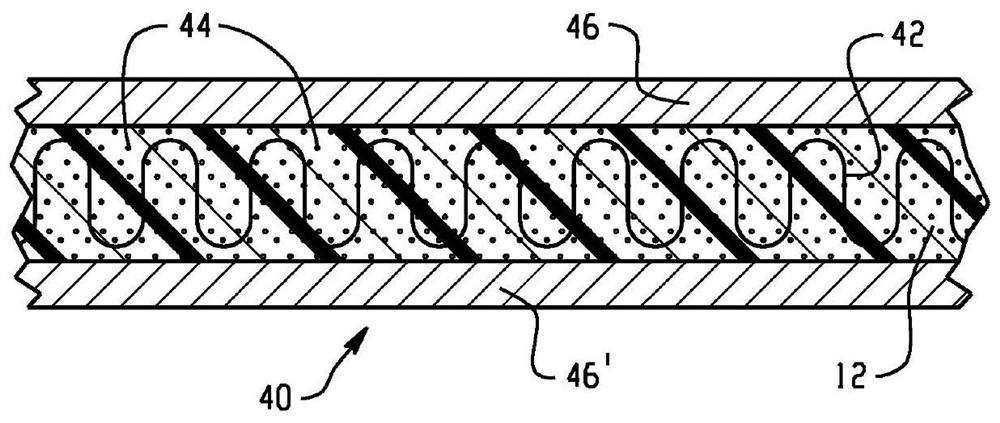

Printed circuit board substrate comprising a coated boron nitride

In an embodiment, a printed circuit board substrate (12) comprises a polymer matrix; a reinforcing layer (42); and a plurality of coated boron nitride particles (44); wherein the plurality of coated boron nitride particles comprise a coating having an average coating thickness of 1 to 100 nanometers. The polymer matrix can comprise at least one of an epoxy, a polyphenylene ether, polystyrene, an ethylene-propylene dicyclopentadiene copolymer, a polybutadiene, a polyisoprene, a fluoropolymer, or a crosslinked matrix comprising at least one of triallyl cyanurate, triallyl isocyanurate, 1,2,4-trivinyl cyclohexane, trimethylolpropane triacrylate, or trimethylolpropane trimethacrylate.

Owner:ROGERS CORP

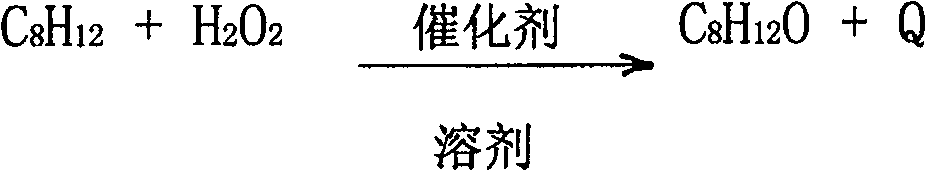

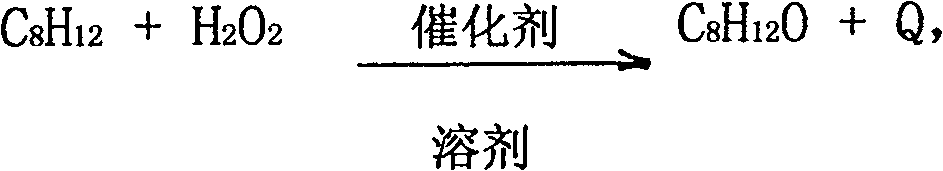

Process for preparing 4-vinyl epoxycyclohexane

The invention relates to a preparation method of 4-vinyl epoxy cyclohexane, the main raw materials are 4-vinyl cyclohexene and hydrogen peroxide, and the raw material for preparing 4-vinyl epoxy cyclohexane is 4-vinyl cyclohexane Hexene 20%-28%, H2O2 11%-19%, Catalyst 0.52%-1.10%, Solvent 54%-65%, measured in proportion Put 4-vinylcyclohexene, catalyst, solvent in the reactor , and stir, slowly add hydrogen peroxide, and control the reaction temperature at 45-70°C. After the hydrogen peroxide has completely reacted, cool the solution to below 25°C, filter the cooled solution, separate the catalyst, and perform a polishing process on the filtered solution. Distillation to separate the incompletely reacted 4-vinyl cyclohexene and the solvent, the solution that has been rectified once is subjected to secondary rectification, and the reaction by-products and other impurities are separated to obtain the finished product 4-vinyl epoxy cyclohexene Alkanes, through the test, the product yield of this production method can reach about 90%, the selectivity is 86-98%, the product content is ≥ 98.5%, and no pollutants are produced. It is a green and environmentally friendly production technology.

Owner:高密市友鹏木工机械有限公司

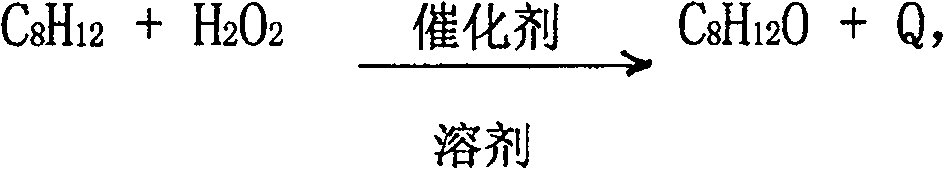

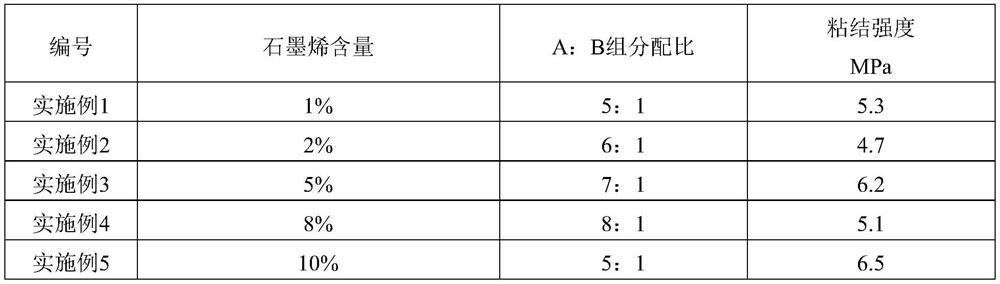

Graphene bottom sealing adhesive and preparation method thereof

PendingCN113999648AFast curingImprove mechanical propertiesNon-macromolecular adhesive additivesTetramethylammonium hydroxideDisiloxane

The invention discloses a graphene bottom sealing adhesive and a preparation method thereof. The method comprises the following steps: step 1, weighing of raw materials in proportion; step 2, preparation of a component A: adding octamethylcyclotetrasiloxane, tetramethyltetravinyl cyclotetrasiloxane and tetramethyldivinyl disiloxane into a reaction furnace, carrying out heating, performing vacuumizing for reaction, then conducting adjusting to normal pressure, adding tetramethylammonium hydroxide, and continuing heating for reaction; step 3, preparation of a component B: mixing and stirring a part of the component A with hydrogen-containing silicone oil, graphene powder, an additive and MQ resin, and carrying out vacuumizing to obtain the component B; and step 4, matching the remaining component A with the remaining component B according to a ratio so as to obtain obtain a mixture serving as the bottom sealing adhesive. The invention also provides the graphene bottom sealing adhesive prepared by using the method. The bottom sealing adhesive prepared by the invention can be rapidly cured, has better mechanical properties and aging resistance, also has better hydrophobicity, and is suitable for photovoltaic bottom sealing.

Owner:NANTONG QIANGSHENG PHOTOVOLATIC TECH

A light release film for oca optical glue

ActiveCN112937043BPrevent disengagementSmall adhesionLamination ancillary operationsSynthetic resin layered productsPolymer scienceEthyl acetate

The invention discloses a light release film used for OCA optical glue, which is used to be attached to one side of the OCA optical glue layer, and together with the heavy release film on the other side to clamp the OCA optical glue layer in the middle, The light release film includes a release film substrate and a release agent layer coated on the surface of the release film substrate, wherein the release agent layer is a release agent prepared from the following raw materials in parts by weight Preparation: 50-80 parts by weight of polydimethylsiloxane, 100-200 parts by weight of ethyl acetate, 10-20 parts by weight of polyurethane resin, 10-20 parts by weight of ethylene-vinyl acetate copolymer, 10-20 parts by weight of tetramethyl tetravinyl cyclotetrasiloxane, 20-40 parts by weight of tetrahydrofuran, and 10-20 parts by weight of terpene resin tackifier. The release agent layer of the present invention can obtain continuous release properties by slowing down and controlling the oozing speed of the release components.

Owner:JIANGSU SHUANGXING COLOR PLASTIC NEW MATERIALS

A kind of production technology of methyl vinyl silicone rubber

The invention relates to a production technology of high-transparency and high-vinyl methyl vinyl silicon rubber. The production technology comprises the following steps of performing primary filtering and fine filtering on DMC, so as to remove colored impurities including iron rust and the like; removing impurities from auxiliary materials, VMC and divinyltetramethyldisiloxane through vacuum bubble dehydration and physical dynamic adsorption; using a high-temperature and low-pressure dehydration technology, adding the dehydrated material into a polymerizing kettle, adding a catalyst, VMC and a termination sealing agent to polymerize, and balancing after the polymerizing is completed; preheating the balanced rubber material, and then sending into a low molecule removal device to remove low molecule and produce the rubber. The production technology has the advantages that the problems of easiness in crosslinking and broad distribution of molecular weight in the high-vinyl raw rubber are solved; in the low molecule removal process, the gradual heating manner is adopted, and the problems of falling and crosslinking of vinyl, instability of vinyl content, slight yellowing of a product and the like due to continuous high temperature of local part in the raw rubber production heating process are solved.

Owner:HUBEI XINGRUI SILICON MATERIAL CO LTD

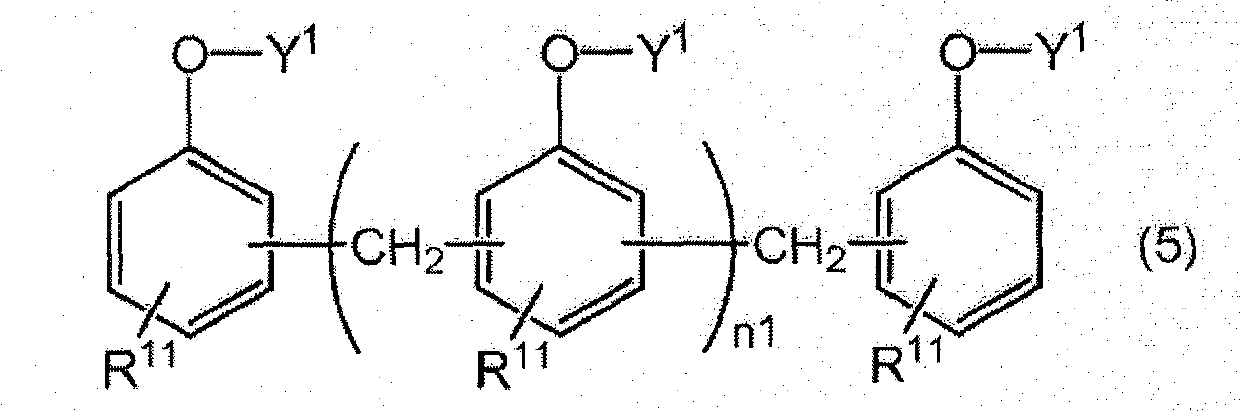

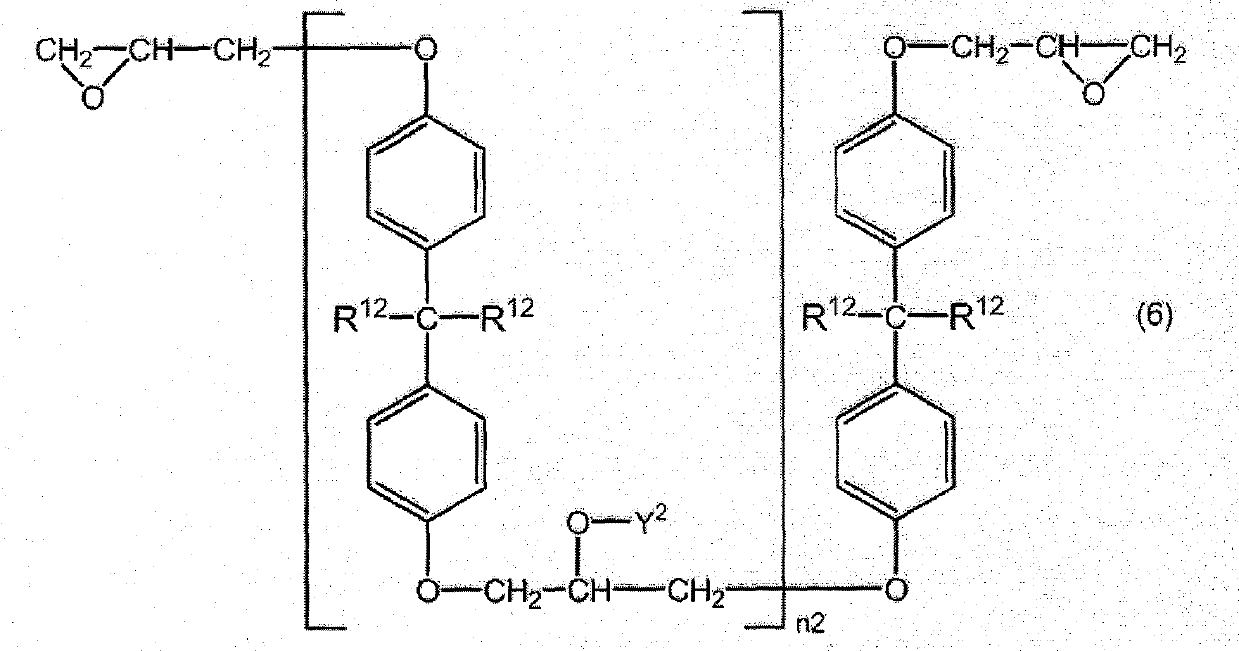

Photosensitive resin composition, photosensitive element, method of forming resist pattern, and process for producing printed wiring board

ActiveCN101675388BHigh light sensitivityImprove heat resistanceConductive material chemical/electrolytical removalPhotosensitive materials for photomechanical apparatusEpoxyPolymer science

A photosensitive resin composition comprising (A) an acid-modified vinyl-containing epoxy resin, (B) a photopolymerization initiator containing a compound having an oxime ester bond and (C) a sensitizer containing any of coumarin compounds of the following general formula (1).

Owner:RESONAC CORPORATION

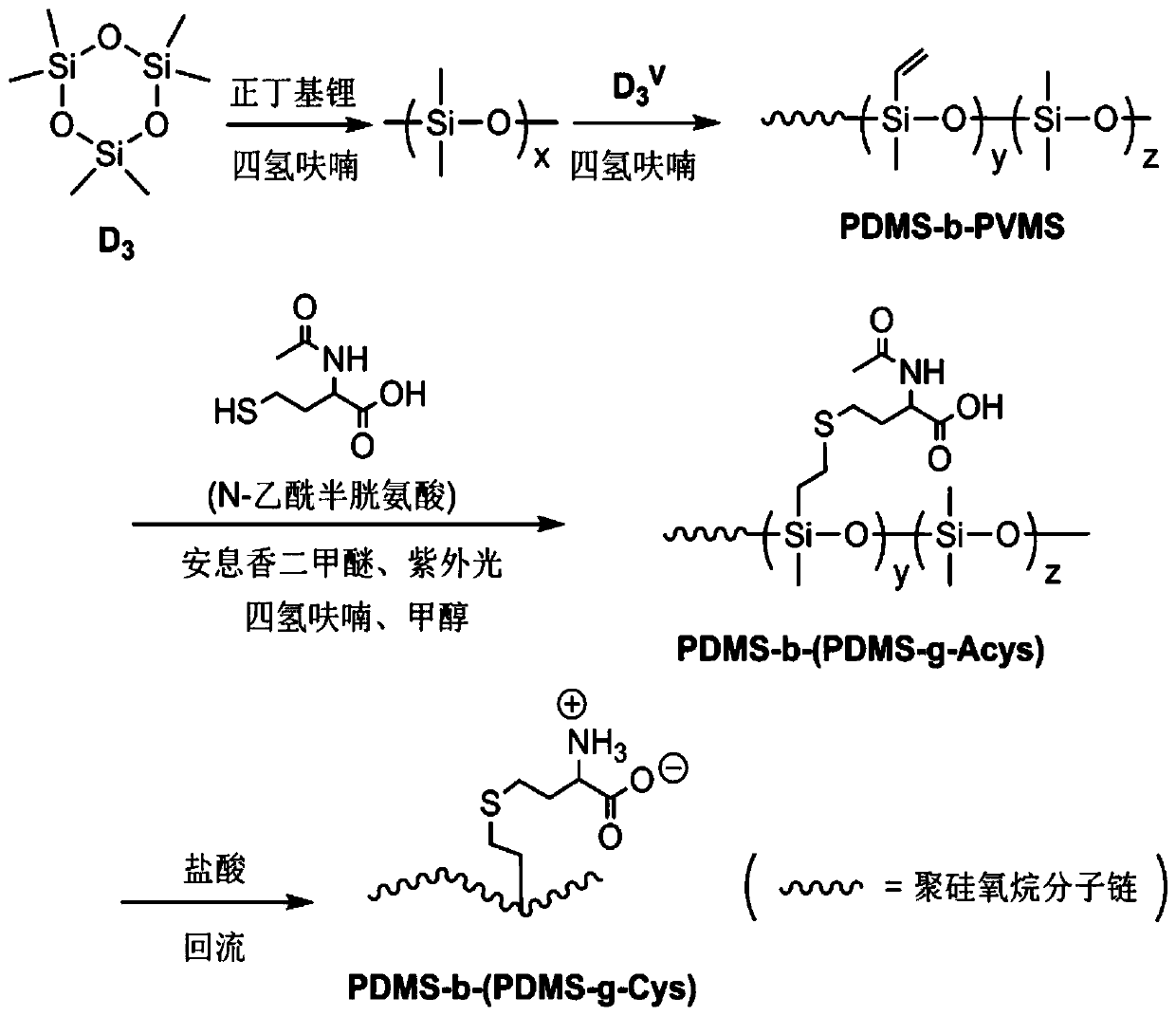

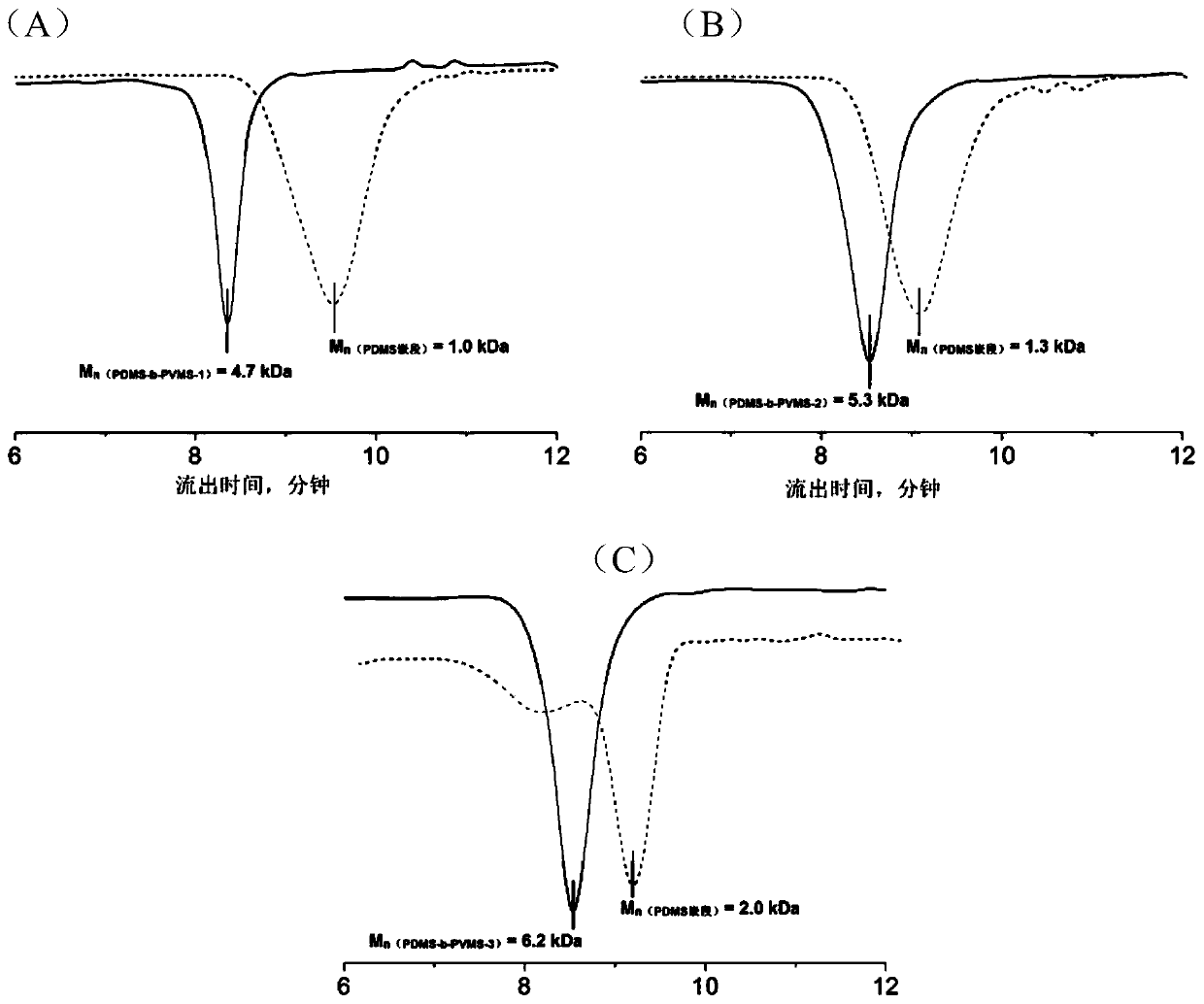

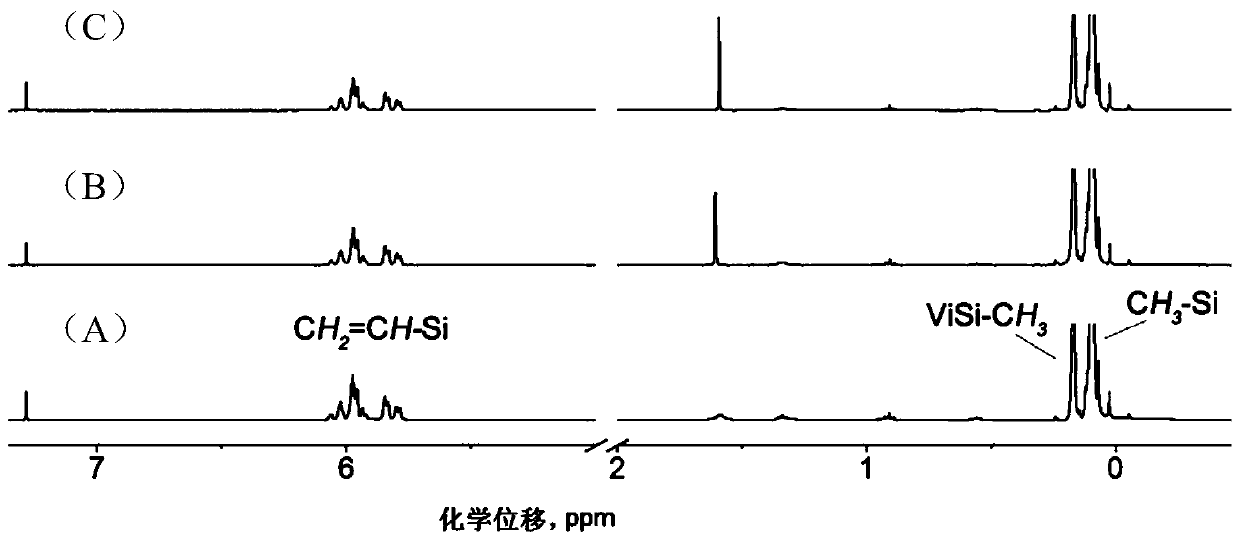

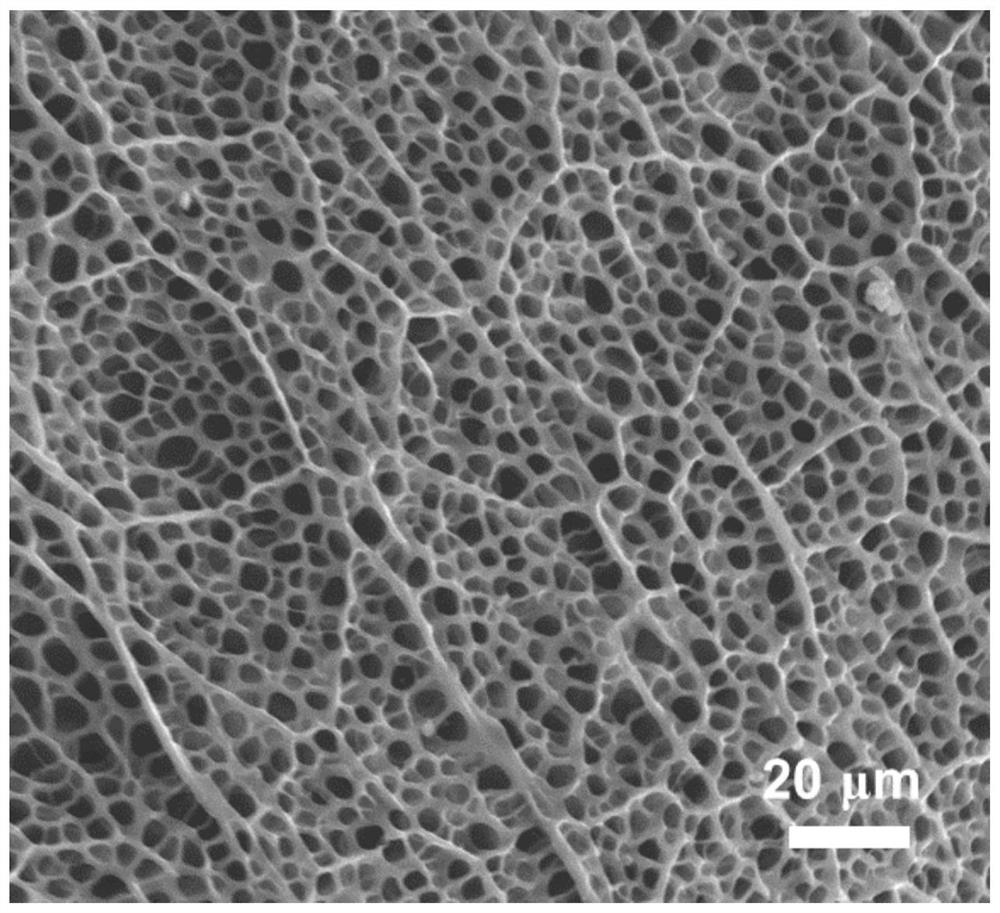

Polysiloxane block copolymer grafted with cysteine and its preparation method and application

The invention discloses a polysiloxane block copolymer of grafted cysteine and a preparation method and application of the polysiloxane block copolymer. The method includes: through ring opening polymerization of active anions, triggering cyclic monomers of hexamethyl cyclotrisiloxane, trimethyl triethylene trioxide and the like to perform ring opening polymerization through n-butyllithium to obtain PDMS (polydimethylsiloxane)-b-PVMS; through radical addition reaction of sulfydryl-vinyl, leading N-acetylcysteine groups to vinyl containing blocks to obtain PDMS-b-(PDMS-g-Acys); finally, subjecting acetyl to hydrolysis under acidic condition to obtain PDMS-b-(PDMS-g-Cys). Solid materials are soaked in a PDMS-b-(PDMS-g-Cys) water solution, an adsorption layer of the block copolymer can be formed on the surface of the materials, and the effect that surface adsorption of protein is reduced is achieved.

Owner:SOUTH CHINA UNIV OF TECH

Three-functional-group hyperbranched polysiloxane cross-linked high-strength and high-toughness composite hydrogel and preparation method thereof

The invention discloses a three-functional-group hyperbranched polysiloxane crosslinked high-strength and high-toughness composite hydrogel and a preparation method thereof. The preparation method comprises the following steps: 1) adding 1 part by weight of cellulose nanofibril and 1-30 parts by weight of acrylamide and / or acrylate monomers into a container, adding 60-300 parts by weight of water, and conducting mixing to form a uniform solution; 2) under the condition of ice-water bath, adding 0.1-1 part by weight of hyperbranched polysiloxane with three functional groups simultaneously containing vinyl, epoxy group and alkyl and 0.0005-0.002 part by weight of initiator into the solution obtained in the step 1), uniformly conducting stirring, and conducting reacting at 25-60 DEG C for 4-48 hours to obtain high-strength and high-toughness composite hydrogel. The molar ratio of vinyl, epoxy group and alkyl in the three-functional-group hyperbranched polysiloxane is 10:(1-6):(1-6).

Owner:ZHEJIANG FORESTRY UNIVERSITY

A kind of frost-resistant hard epoxy asphalt pavement material and preparation method thereof

InactiveCN103773037BImprove frost resistanceHigh hardnessBuilding insulationsPolymer scienceRoad surface

The invention relates to an antifreeze hard epoxy asphalt pavement material and a preparation method thereof. The antifreeze hard epoxy asphalt pavement material is composed of the following components according to the weight ratio: 28-30 parts of petroleum asphalt, calcium stearate 5-9 parts for vinyl epoxy resin, 18-22 parts for vinyl epoxy resin, 9-13 parts for trimellitic anhydride, 5-6 parts for butyric acid, 4-6 parts for 1-hexene, and 3-5 parts for magnesium chloride. The pavement material is prepared by heating, melting, stirring, pulverizing, heat preservation and other steps of each material component. The prepared pavement material has good frost resistance and high hardness, which can prevent cracking due to cold weather as a road material. phenomenon occurs.

Owner:NANTONG SOUTHEAST HIGHWAY ENG

A viscous material dedicated to substation sites

ActiveCN109321200BInsulationImprove temperature resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross linkerStearic acid

The invention belongs to the technical field of organic silicon rubber viscous materials, and in particular relates to a viscous material specially used in substation sites. Said viscous material specially used on the substation site, its raw material components include: by weight, 70-88 parts of raw silicone rubber, 5-8 parts of shell powder, 13-15 parts of stearic acid, diethylene 6~8 parts of base silicone oil, 8~12 parts of tetramethyltetravinyl cyclotetrasiloxane, 3~5 parts of indium tin oxide, 3~5 parts of silane coupling agent, and 1~3 parts of crosslinking agent. The material of the invention has insulation, high temperature resistance, high weather resistance, good ductility, excellent viscous effect, wide applicable temperature range, and is suitable for on-site application in substations.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com