Preparation method for net-like methyl phenyl vinyl polysiloxane for LED packaging

A technology of methylphenylvinylpolysiloxane and tetramethyltetravinylcyclotetrasiloxane, applied in the direction of adhesives and the like, can solve the problems of wide product molecular weight distribution, large amount of waste acid, troublesome post-processing, etc., Achieve the effect of narrow molecular weight distribution, simple post-processing and environmental protection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

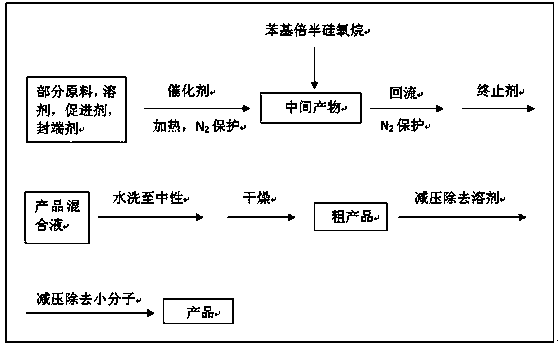

Method used

Image

Examples

Embodiment 1

[0042]The preparation method of the reticular methylphenylvinylpolysiloxane for LED encapsulation of preferred embodiment 1 of the present invention, its process is: under N protection, in 250ml, thermometer, reflux condensing tube, mechanical agitation four ports are equipped with Add 11.0g of tetramethyltetravinylcyclotetrasiloxane, 9.3g of octamethylcyclotetrasiloxane, 11.7g of hexamethyldisiloxane, 10.3g of diphenylsiloxane, and 25.0g of toluene into the bottle , DMSO 0.347g, KOH 0.037g, react at 75°C for 4h; after the reaction, add 40.0g of phenylsilsesquioxane, 29.0g of toluene, several grams of KOH, re-protect the nitrogen, and heat to toluene reflux, react After 5 h, the reaction was cooled to room temperature, and a sufficient amount of deionized water was added to terminate the reaction. After continuing to stir for 30min, the product was poured into a 500ml separatory funnel, washed with deionized water to neutrality (washed three times), and the upper toluene solut...

Embodiment 2

[0050] The preparation method of the reticular methylphenyl vinyl polysiloxane for LED encapsulation of preferred embodiment two of the present invention, its process is: 2 Under protection, add 5.33g of tetramethyltetravinylcyclotetrasiloxane, 13.8g of octamethylcyclotetrasiloxane, 13.8g of hexamethyldi Siloxane 10.2g, diphenylsiloxane 12.3g, toluene 28g, DMSO 0.452g, KOH 0.035g, react at 75°C for 4h; after the reaction, add phenylsilsesquioxane 40.0g, toluene 28g, KOH 0.107g, nitrogen protection again, and heated to toluene reflux, reacted for several hours, cooled to room temperature after the reaction, added enough deionized water to terminate the reaction, and continued to stir for 30min. Pour the product into a 500ml separatory funnel, wash it with deionized water to neutrality (wash three times), obtain the upper toluene solution layer, add anhydrous magnesium sulfate to dry, filter to remove the magnesium sulfate solid, evaporate under reduced pressure at 4000 Pa Afte...

Embodiment 3

[0057] The preparation method of the reticular methylphenyl vinyl polysiloxane for LED encapsulation of preferred embodiment three of the present invention, its process is: 2 Under protection, add 2.7g of tetramethyltetravinylcyclotetrasiloxane, 16.1g of octamethylcyclotetrasiloxane, 16.1g of hexamethyldi Siloxane 10.2g, diphenylsiloxane 12.3g, toluene 28g, DMSO 0.452g, KOH 0.044g, react at 75°C for 4h; after the reaction, add phenylsilsesquioxane 40.0g, toluene 28g, KOH 0.117g, nitrogen protection again, and heated to toluene reflux, reacted for 10 hours, cooled to room temperature after the reaction, added enough deionized water to terminate the reaction, continued to stir for 30min. Pour the product into a 500ml separatory funnel, wash it with deionized water to neutrality (wash three times), obtain the upper toluene solution layer, add anhydrous magnesium sulfate to dry, filter to remove the magnesium sulfate solid, evaporate under reduced pressure at 4000 Pa After toluen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com