Preparation method of neodymium iron boron with low cost and high corrosion resistance

A high corrosion resistance and corrosion resistance technology, used in inductor/transformer/magnet manufacturing, magnetic materials, anti-corrosion coatings, etc., can solve the heat resistance, wear resistance and weather resistance of the outer epoxy layer, surface protection Deal with problems such as high cost, poor wear resistance and weather resistance, and achieve the effect of low cost, enhanced bonding strength, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

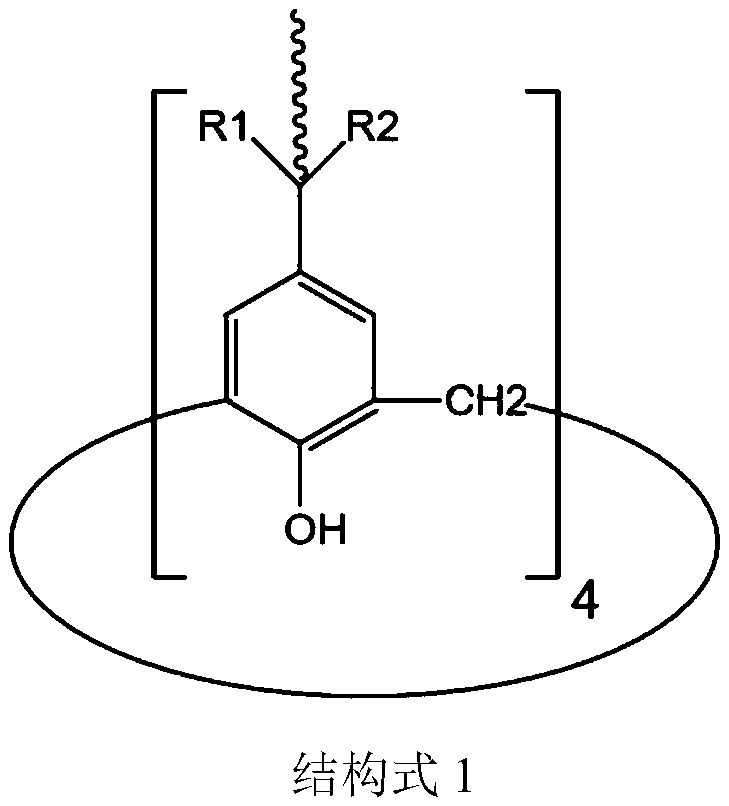

Method used

Image

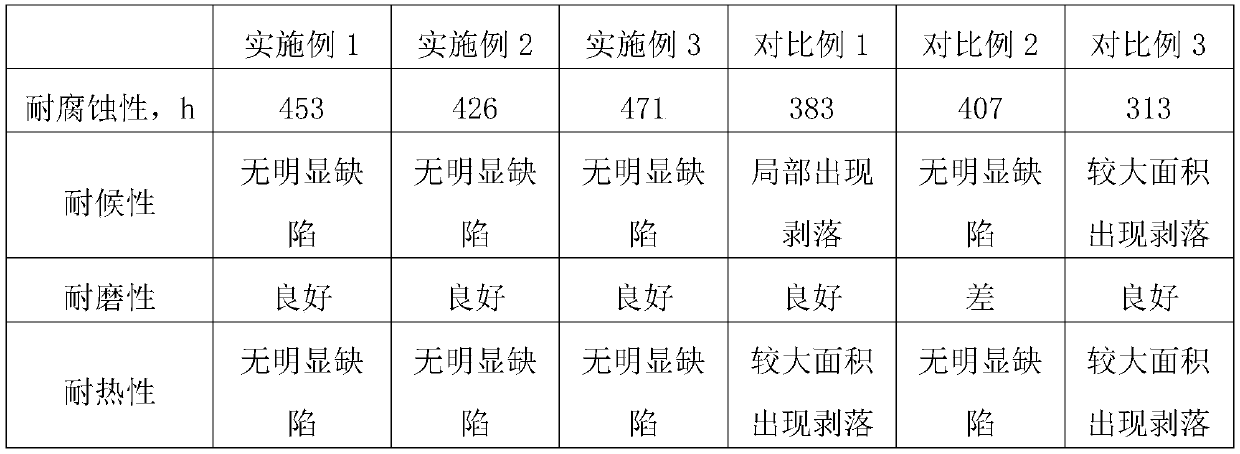

Examples

Embodiment 1

[0034] The preparation method of low-cost and high-corrosion-resistant NdFeB in this embodiment comprises the following steps:

[0035] S1 NdFeB pretreatment: use an initial impulse current of 70A to treat the sintered NdFeB magnet for 3 minutes in the titanium salt solution, and then reduce the current to 40A for 40 minutes;

[0036] Preparation of S2 modified coating mixture: Stir and mix fluorine-containing methacrylate, epoxy resin, and vinyl epoxy resin evenly to prepare the main raw material, put it in a ball mill tank, and then add 1 / 2 part of additives , titanium phosphate and deionized water, mixed uniformly by ball milling to obtain a modified coating mixture;

[0037] Preparation of S3 corrosion-resistant NdFeB: Add the curing agent, the remaining 1 / 2 part of additives and fillers to the modified coating mixture obtained in step S2, stir and mix evenly, and then spin-coat the NdFeB pretreated in step S1 For the surface of boron material, it takes 1 hour to raise th...

Embodiment 2

[0048] The preparation method of low-cost and high-corrosion-resistant NdFeB in this embodiment comprises the following steps:

[0049] S1 NdFeB pretreatment: use an initial impulse current of 60A to treat the sintered NdFeB magnet for 5 minutes in the titanium salt solution, and then reduce the current to 30A for 30 minutes;

[0050]Preparation of S2 modified coating mixture: Stir and mix fluorine-containing methacrylate, epoxy resin, and vinyl epoxy resin evenly to prepare the main raw material, put it in a ball mill tank, and then add 1 / 2 part of additives , titanium phosphate and deionized water, mixed uniformly by ball milling to obtain a modified coating mixture;

[0051] Preparation of S3 corrosion-resistant NdFeB: Add the curing agent, the remaining 1 / 2 part of additives and fillers to the modified coating mixture obtained in step S2, stir and mix evenly, and then spin-coat the NdFeB pretreated in step S1 For the surface of boron material, after coating, it takes 0.5h...

Embodiment 3

[0062] The preparation method of low-cost and high-corrosion-resistant NdFeB in this embodiment comprises the following steps:

[0063] S1 NdFeB pretreatment: use an initial impulse current of 80A to treat the sintered NdFeB magnet for 1min in the titanium salt solution, and then reduce the current to 50A for 30min;

[0064] Preparation of S2 modified coating mixture: Stir and mix fluorine-containing methacrylate, epoxy resin, and vinyl epoxy resin evenly to prepare the main raw material, put it in a ball mill tank, and then add 1 / 2 part of additives , titanium phosphate and deionized water, mixed uniformly by ball milling to obtain a modified coating mixture;

[0065] Preparation of S3 corrosion-resistant NdFeB: Add the curing agent, the remaining 1 / 2 part of additives and fillers to the modified coating mixture obtained in step S2, stir and mix evenly, and then spin-coat the NdFeB pretreated in step S1 For the surface of boron material, it takes 1 hour to raise the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com