Corrosion-resistant composite protective layer material for neodymium iron boron

A protective layer, neodymium-iron-boron technology, applied in the direction of anti-corrosion coatings, fire-proof coatings, coatings, etc., can solve the problems of weak bonding, poor wear resistance and weather resistance of coatings, and large environmental pollution, and achieve strong bonding, Effect of improving weather resistance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment is used for the corrosion-resistant composite protective layer material of neodymium iron boron, which includes:

[0036] A base layer, the base layer is spin-coated on neodymium iron boron; and

[0037] A protective layer, the protective layer is coated on the base layer;

[0038] The protective layer is composed of the following parts by weight of raw materials: 15 parts fluorine-containing methacrylate, 40 parts epoxy resin, 50 parts vinyl epoxy resin, 7 parts additives, 1 part curing agent, 1.5 parts filler and 30 parts. Parts of deionized water.

[0039] The base layer is composed of the following parts by weight of raw materials: 45 parts epoxy resin, 20 parts hydroxy epoxy resin, 3 parts additive, 2 parts triisocyanate compound, 1 part hexamethylene diisocyanate, 0.1 part organotin catalyst , 0.5 parts of nano titanium dioxide and 35 parts of deionized water.

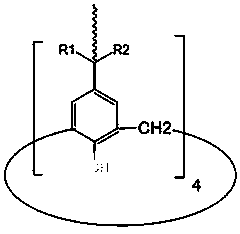

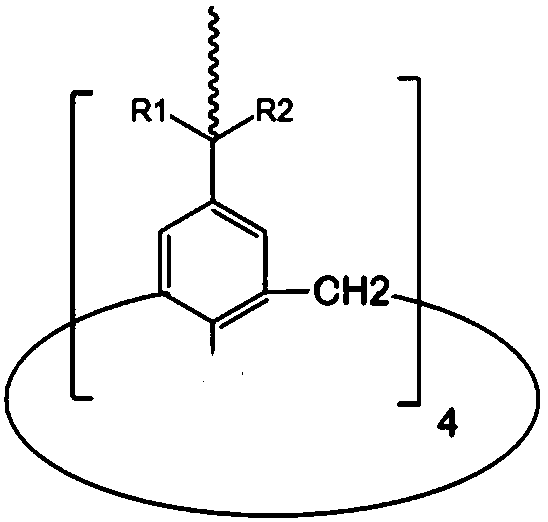

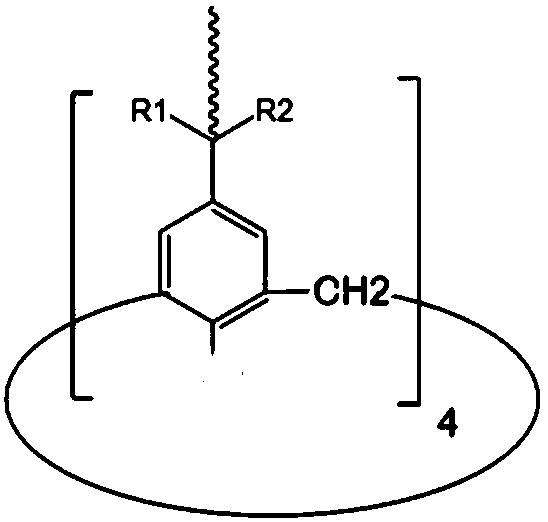

[0040] The additive is calix[4] arene.

[0041] The structural formula of the calix[4]arene is s...

Embodiment 2

[0054] This embodiment is used for the corrosion-resistant composite protective layer material of neodymium iron boron, which includes:

[0055] A base layer, the base layer is spin-coated on neodymium iron boron; and

[0056] A protective layer, the protective layer is coated on the base layer;

[0057] The protective layer is composed of the following parts by weight of raw materials: 10 parts of fluorine-containing methacrylate, 30 parts of epoxy resin, 40 parts of vinyl epoxy resin, 5 parts of additives, 0.5 parts of curing agent, 1 part of filler and 20 parts Parts of deionized water.

[0058] The base layer is composed of the following parts by weight of raw materials: 30 parts epoxy resin, 10 parts hydroxy epoxy resin, 1 part additive, 1 part triisocyanate compound, 0.5 part hexamethylene diisocyanate, 0.05 part organotin catalyst , 0.1 part of nano titanium dioxide and 20 parts of deionized water.

[0059] The additive is calix[4] arene.

[0060] The structural formula of the c...

Embodiment 3

[0073] This embodiment is used for the corrosion-resistant composite protective layer material of neodymium iron boron, which includes:

[0074] A base layer, the base layer is spin-coated on neodymium iron boron; and

[0075] A protective layer, the protective layer is coated on the base layer;

[0076] The protective layer is composed of the following parts by weight of raw materials: 20 parts fluorine-containing methacrylate, 50 parts epoxy resin, 60 parts vinyl epoxy resin, 10 parts additives, 1.5 parts curing agent, 2.5 parts filler and 50 parts Parts of deionized water.

[0077] The base layer is composed of the following parts by weight of raw materials: 60 parts epoxy resin, 30 parts hydroxy epoxy resin, 5 parts additive, 3 parts triisocyanate compound, 1.5 parts hexamethylene diisocyanate, 0.15 parts organotin catalyst , 1 part of nano titanium dioxide and 50 parts of deionized water.

[0078] The additive is calix[4] arene.

[0079] The structural formula of the calix[4]arene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com