Flame retardation type exterior coating capable of automatically cleaning

A kind of exterior wall coating, flame-retardant technology, applied in the direction of coating, etc., can solve the problems of potential safety hazards, insufficient antifouling ability, and affecting appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

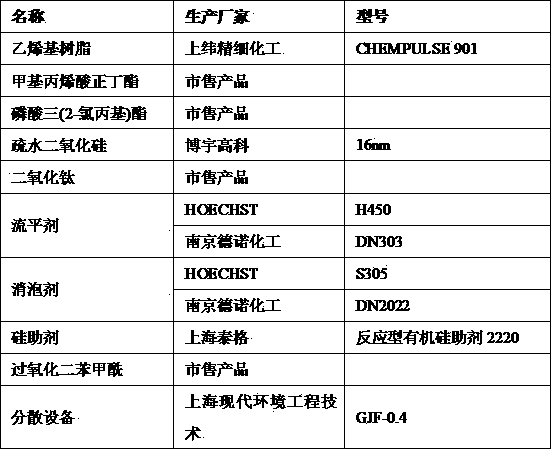

[0032] Add 200 grams of standard bisphenol A epoxy vinyl ester slurry (55% resin content, 45% styrene content), 200 grams of n-butyl methacrylate, and 25 grams of tris(2-chloropropyl) phosphate into the container. gram, 20 grams of hydrophobic silica, 10 grams of titanium dioxide, 4 grams of leveling agent, 4 grams of defoamer, 20 grams of silicon additives, use a high-speed disperser, disperse for 2 hours at a line speed of 10 meters per second, and then add 15 Gram dibenzoyl peroxide, continue to disperse for 30 minutes, dibenzoyl peroxide is completely dissolved without particle residue.

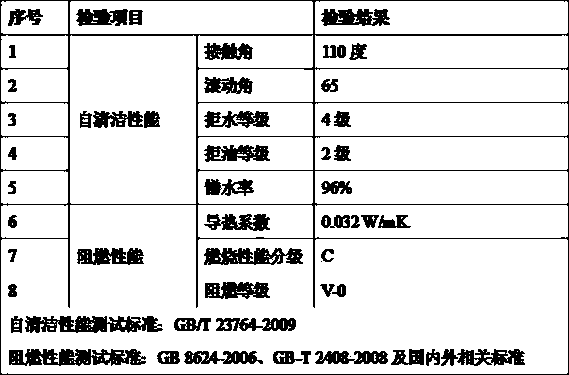

[0033] Evenly coat the mixed slurry on the surface of the glass plate, place the glass plate in an oven with a constant temperature of 70°C and bake for 60 minutes, then program the temperature to 90°C (1°C per minute, 30 minutes in total), and Hold at 90°C for 30 minutes. Naturally cooled to room temperature, after aging at room temperature for 3 days, the polymer texture of the surface...

Embodiment 2

[0036] Add 4 kg of standard bisphenol A epoxy vinyl ester slurry (resin content 55%, styrene content 45%), 4 kg of n-butyl methacrylate, 500 g of tris (2-chloropropyl) phosphate in the container grams, 400 grams of hydrophobic silica, 200 grams of titanium dioxide, 80 grams of leveling agent, 80 grams of defoamer, 400 grams of silicon additives, using a high-speed disperser, dispersing for 10 hours at a line speed of 10 meters per second, and then adding 300 Gram dibenzoyl peroxide, continue to disperse for 2 hours, dibenzoyl peroxide is completely dissolved without particle residue.

[0037] Evenly coat the mixed slurry on the surface of the glass plate, place the glass plate in an oven with a constant temperature of 70°C and bake for 60 minutes, then program the temperature to 90°C (1°C per minute, 30 minutes in total), and Hold at 90°C for 30 minutes. Naturally cooled to room temperature, after aging at room temperature for 3 days, the polymer texture of the surface layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com