Supported catalytic filler and preparation method and application thereof

A catalytic packing and supported technology, which is applied in the field of supported catalytic packing and its preparation, can solve the problems of low catalytic efficiency, achieve excellent acid resistance, avoid abnormal operating conditions, and firmly bond

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the supported catalytic filler includes the following steps:

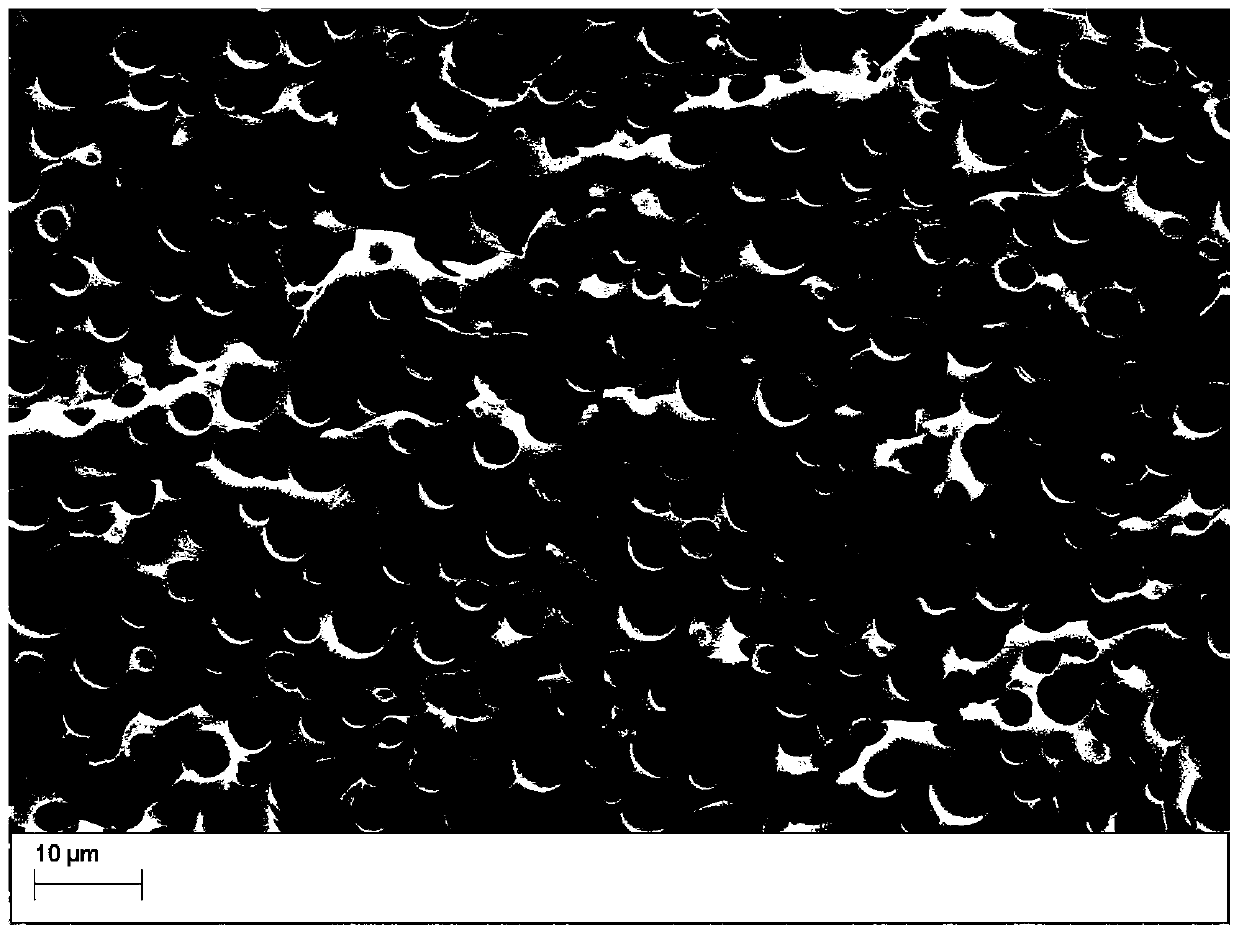

[0024] 1) Dissolve the epoxy resin in the pore forming agent and add the crosslinking agent to form a viscous liquid. Take a certain amount of 3mm×3mm θ-ring filler and place it in the above solution to fully wet the surface of the filler carrier and take it out. After the carrier surface has no obvious liquid retention, it is placed in a drum for curing at a constant temperature of 60-130°C for 5-24 hours to obtain a filler carrier containing a cured adhesive layer; after curing, the filler carrier is extracted with ethanol or washed with water to remove holes in the adhesive layer. Agent to obtain a porous adhesive layer filler carrier;

[0025] 2) The porous layer filler carrier is placed in a coupling agent solution of 1 to 5 wt% for 12 to 24 hours, and then vacuum dried for 24 hours. The porous filler carrier is placed in the PSS-Na aqueous solution, so that PSS-Na is immersed in t...

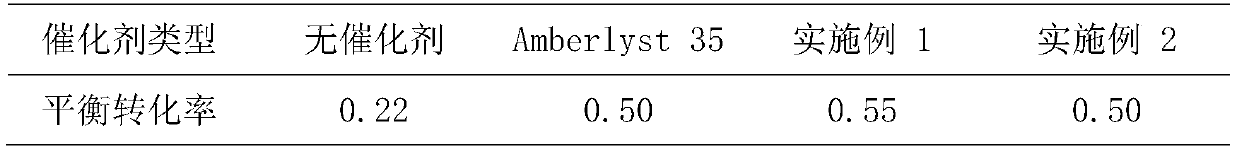

Embodiment 1

[0032] Dissolve 1 part of epoxy resin E44 in 0.3 part of polyethylene glycol (molecular weight 400) and add 0.25 part of tetraethylenepentamine to form an adhesive. Put a certain amount of theta ring filler in the adhesive, immerse it twice to fully wet the surface of the filler carrier, and then take it out. After the filler carrier surface has no obvious liquid retention, place it in a drum for curing at 60°C for 10 hours to obtain a solidification The filler carrier of the adhesive layer; the cured filler carrier is subjected to ethanol extraction to remove the pore-forming agent in the adhesive layer to obtain a porous adhesive layer filler carrier.

[0033] Place the above porous layer filler carrier in a 1wt% coupling agent solution for 24 hours and then dry it, then place it in an aqueous solution of sodium polystyrene sulfonate for 12 hours, so that the sodium polystyrene sulfonate is immersed in the micropores of the adhesive layer After drying, use dilute sulfuric acid ...

Embodiment 2

[0035] Dissolve 1 part of epoxy resin E51 in 0.5 part of polyethylene glycol / N,N'-dimethylformamide mixed solution and add 0.5 part of 4,4'-diaminodicyclohexylmethane to form an adhesive. Put a certain amount of θ-ring filler in the glue, immerse it twice to fully wet the surface of the filler carrier, and then take it out. After the filler carrier surface has no obvious liquid retention, place it in a drum for curing at 100°C for 5 hours to obtain a solid The filler carrier of the adhesive layer; the cured filler carrier is subjected to ethanol extraction to remove the pore-forming agent in the adhesive layer to obtain a porous adhesive layer filler carrier.

[0036] Place the above porous layer filler carrier in a 3wt% coupling agent solution for 24 hours and then dry it, and then place it in an aqueous solution of sodium polystyrene sulfonate for 12 hours to immerse the sodium polystyrene sulfonate into the micropores of the adhesive layer After drying, use dilute sulfuric aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com