Patents

Literature

160 results about "Reactive separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

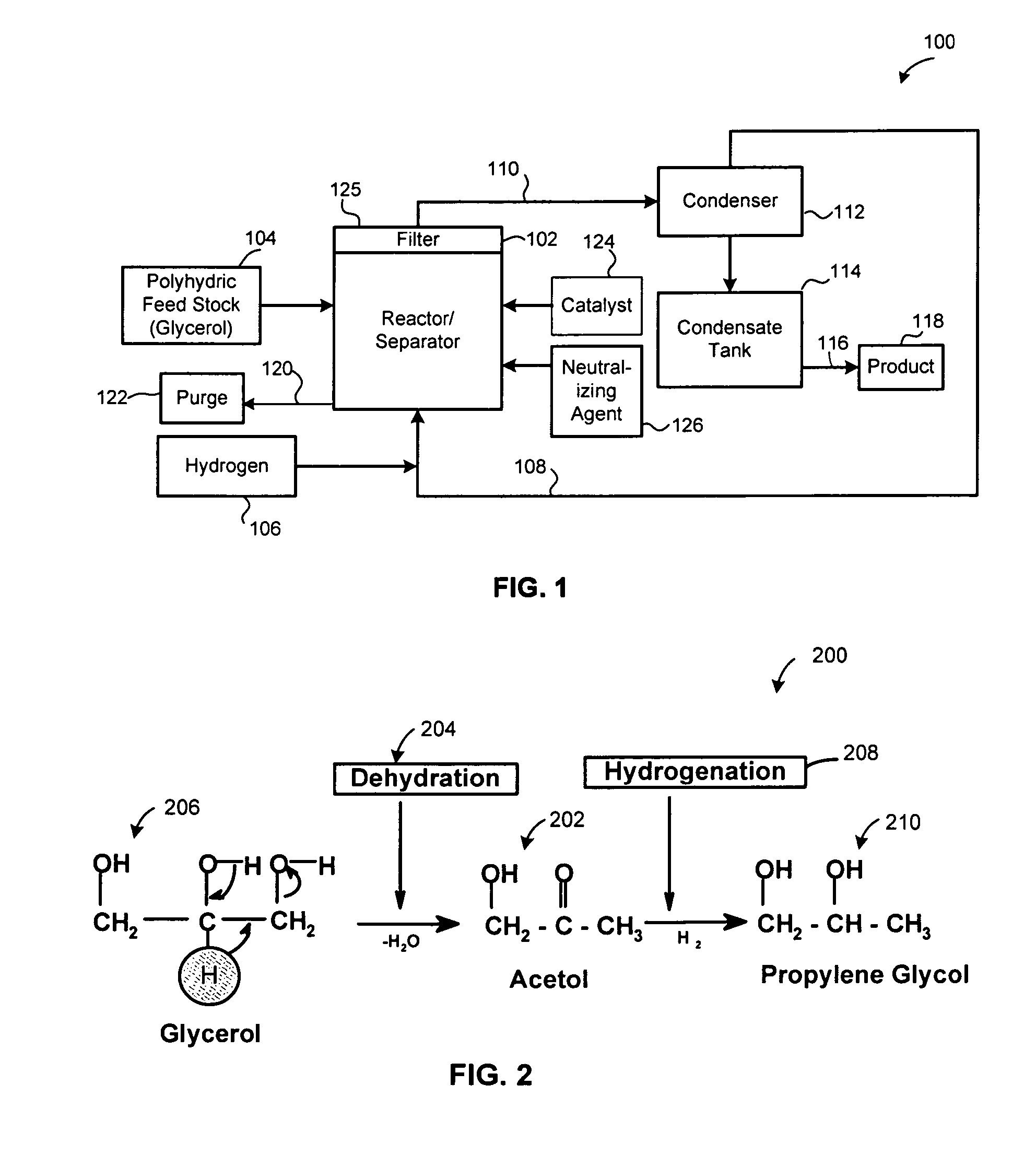

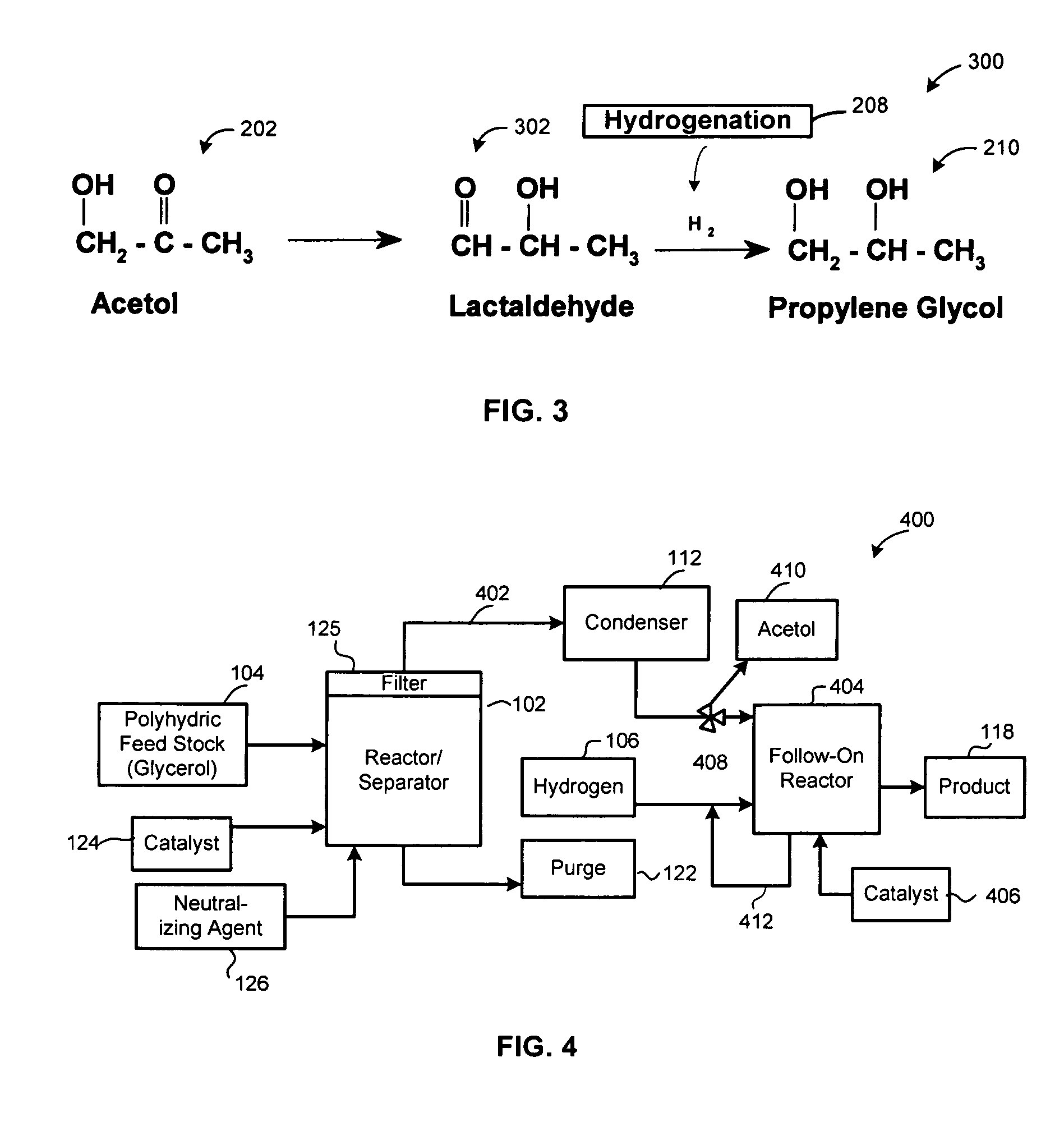

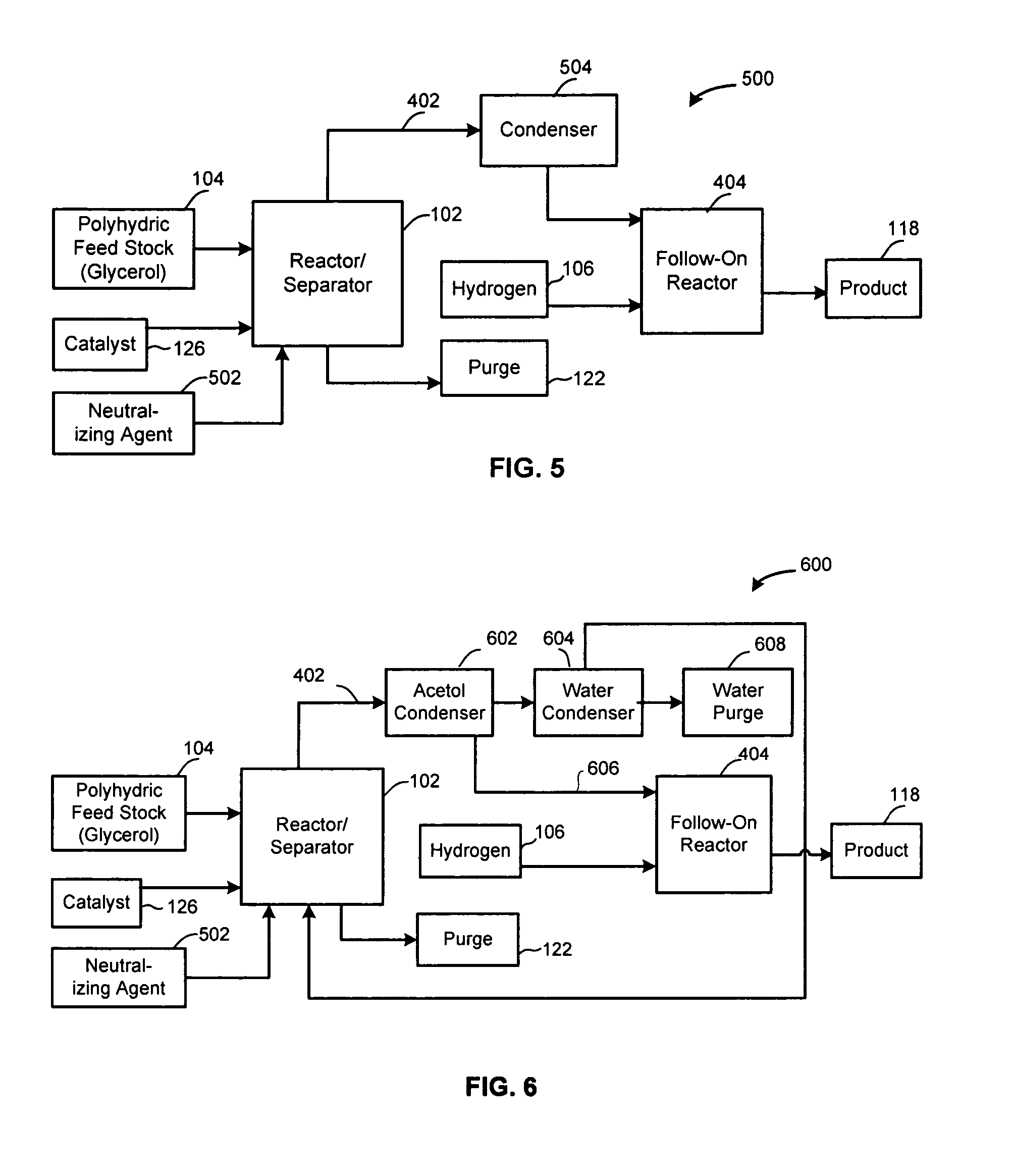

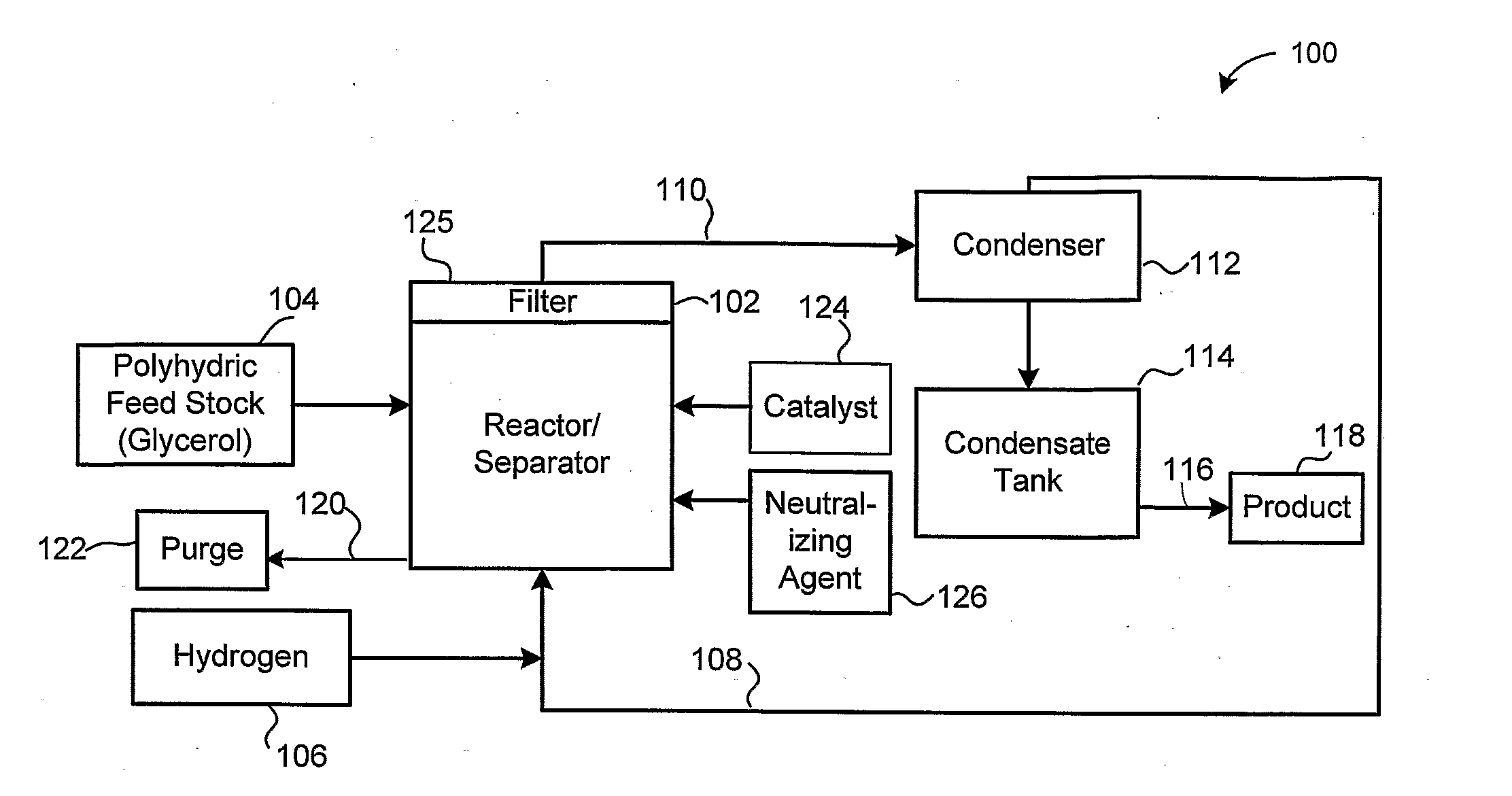

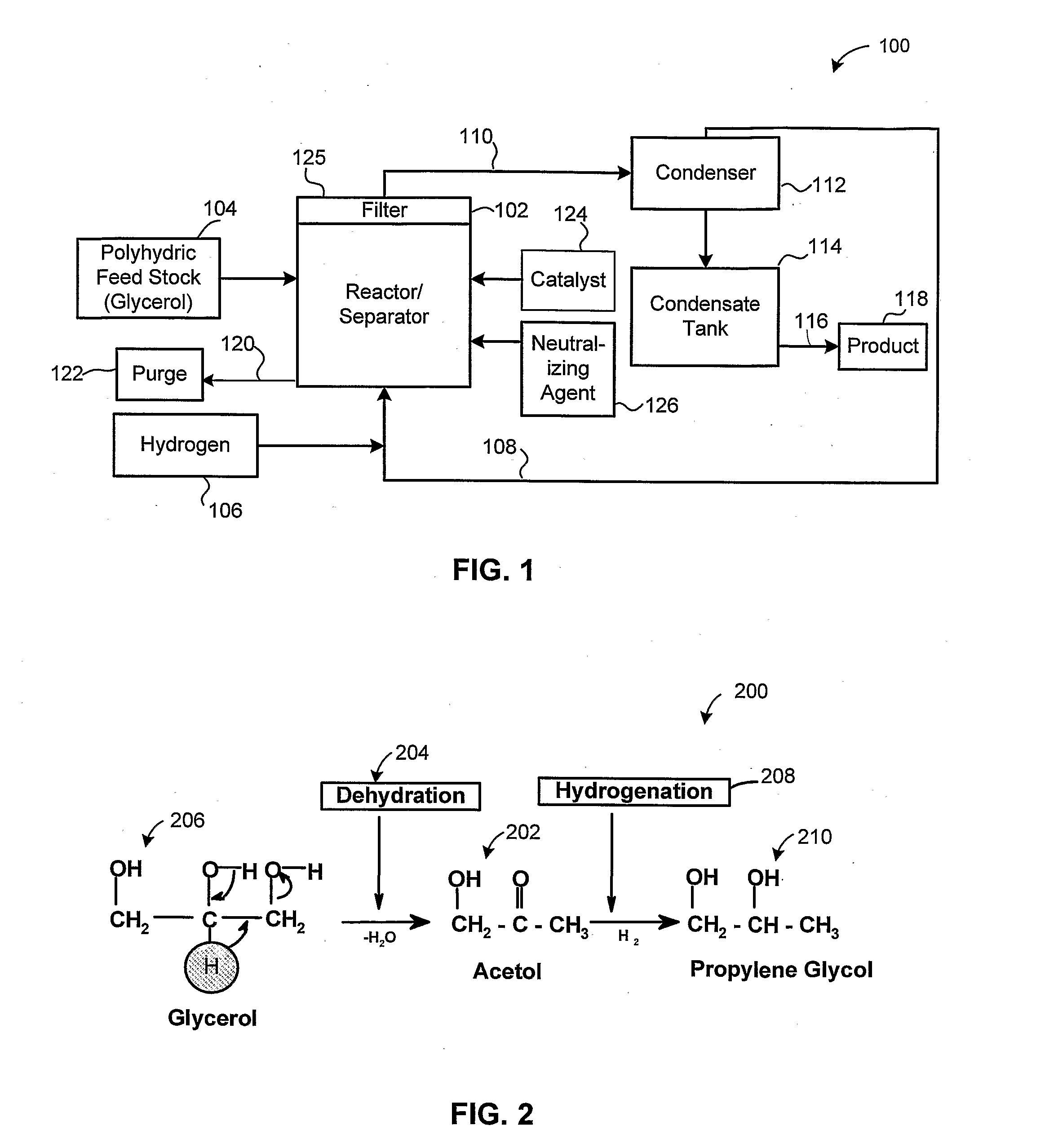

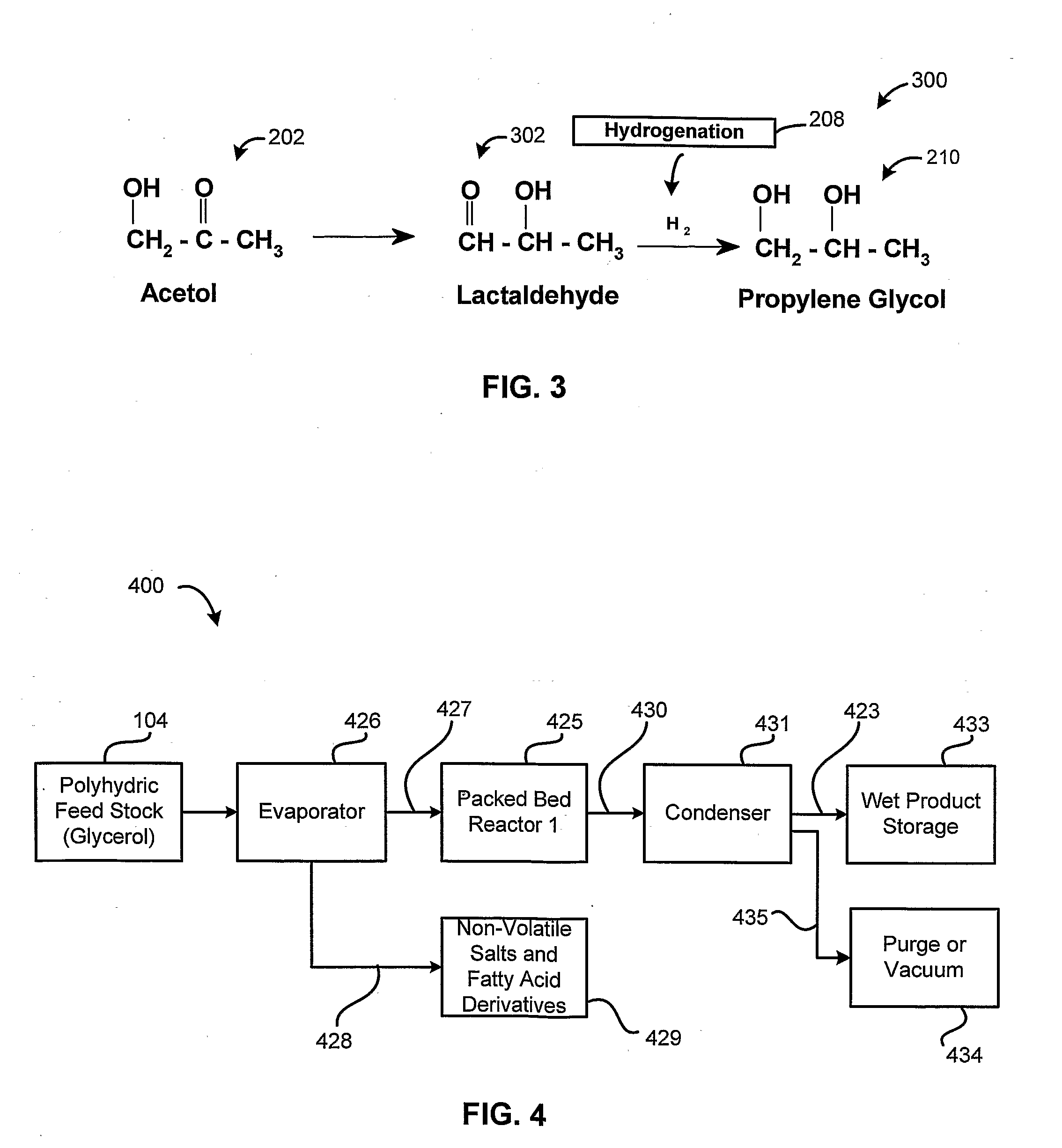

Method of producing lower alcohols from glycerol

ActiveUS20050244312A1High selectivityOrganic compound preparationOxygen compounds preparation by reductionAlcoholBoiling point

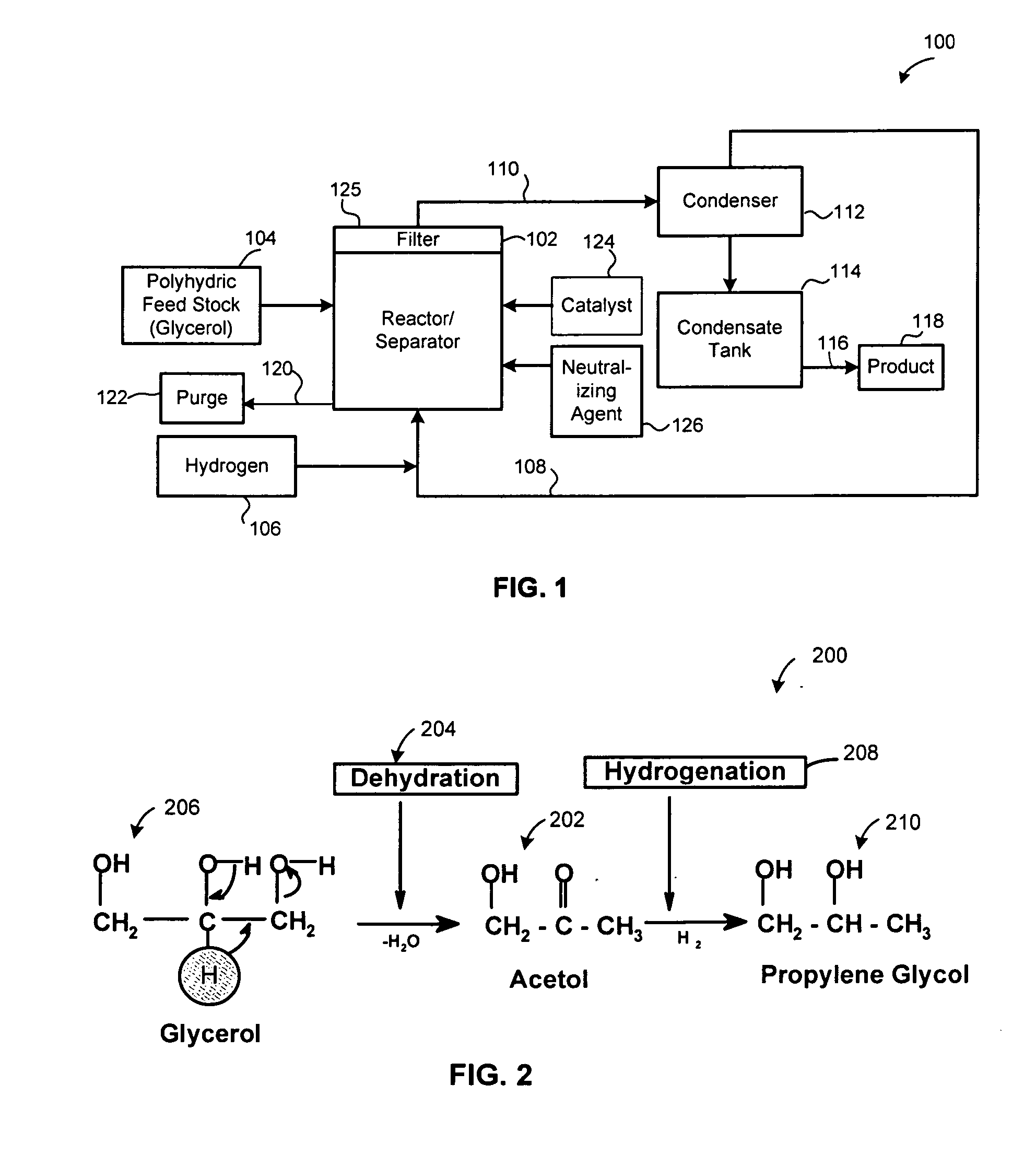

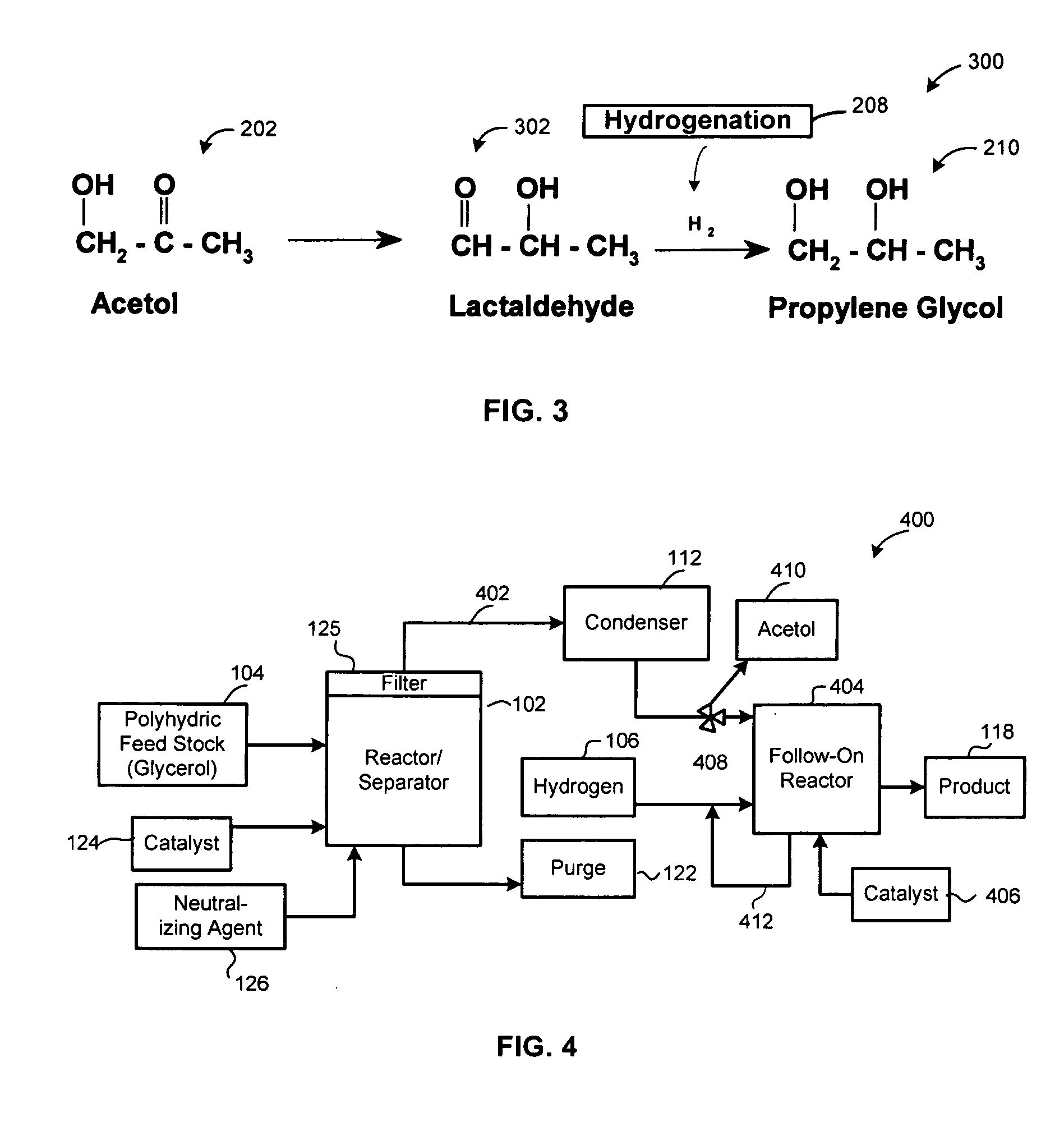

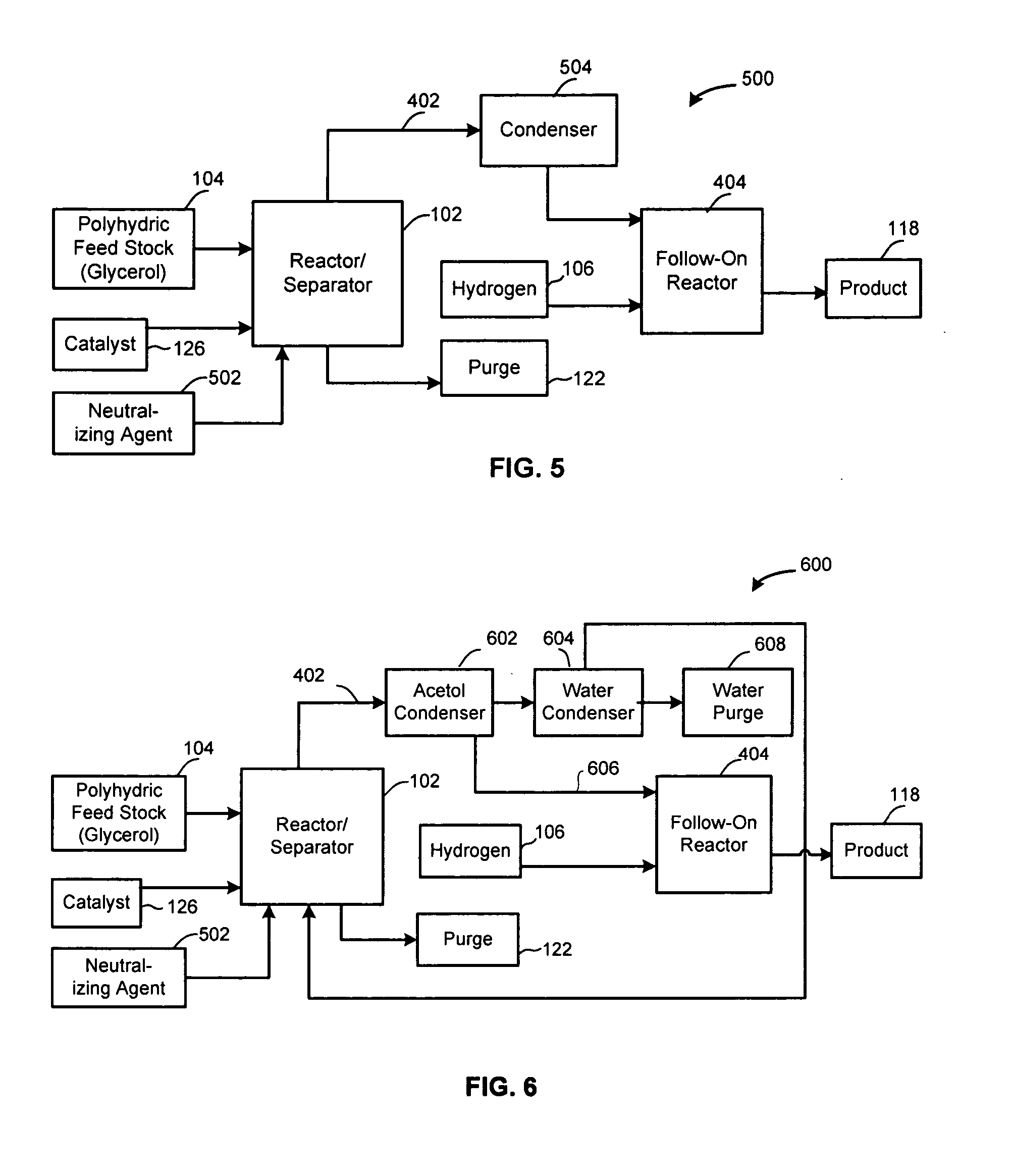

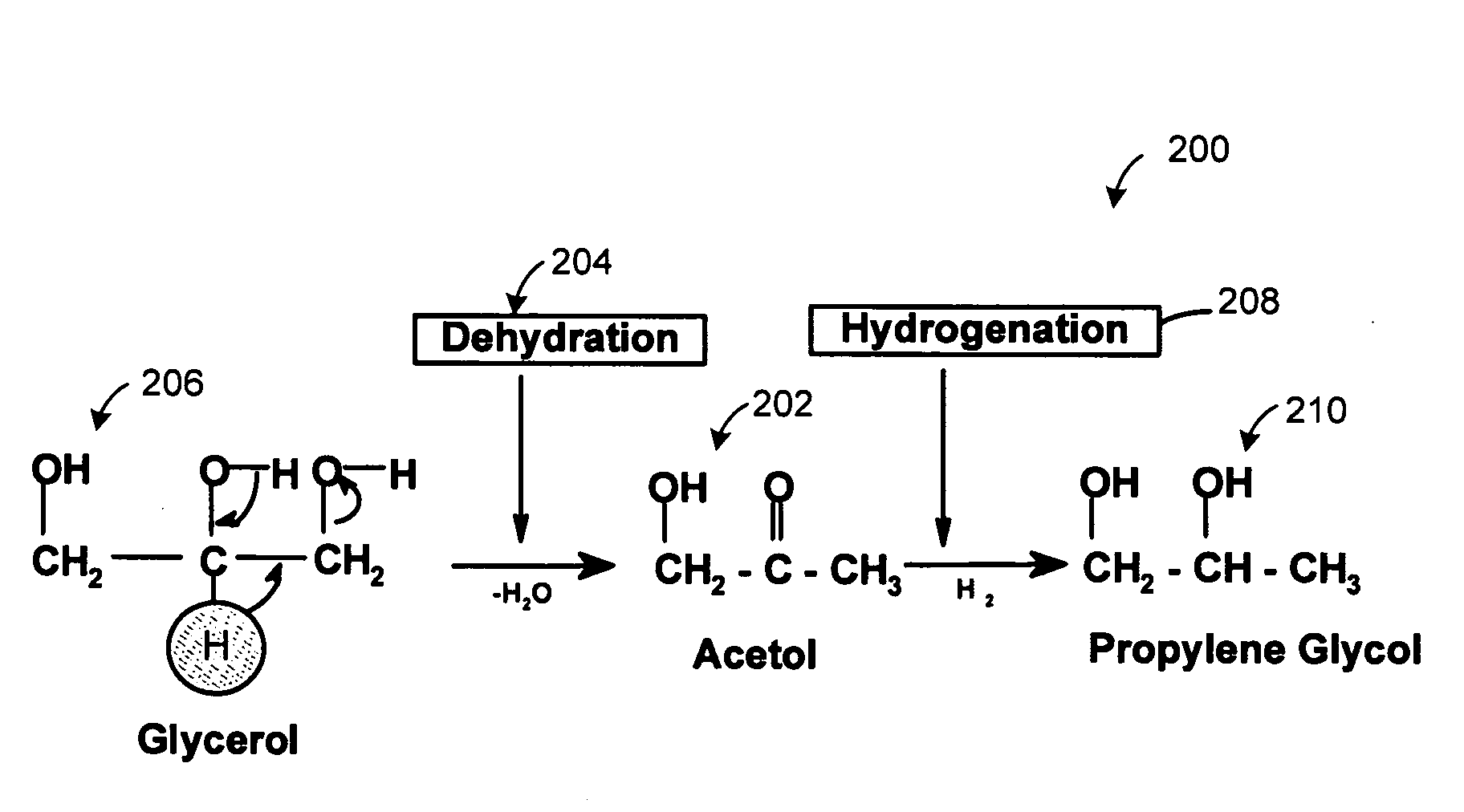

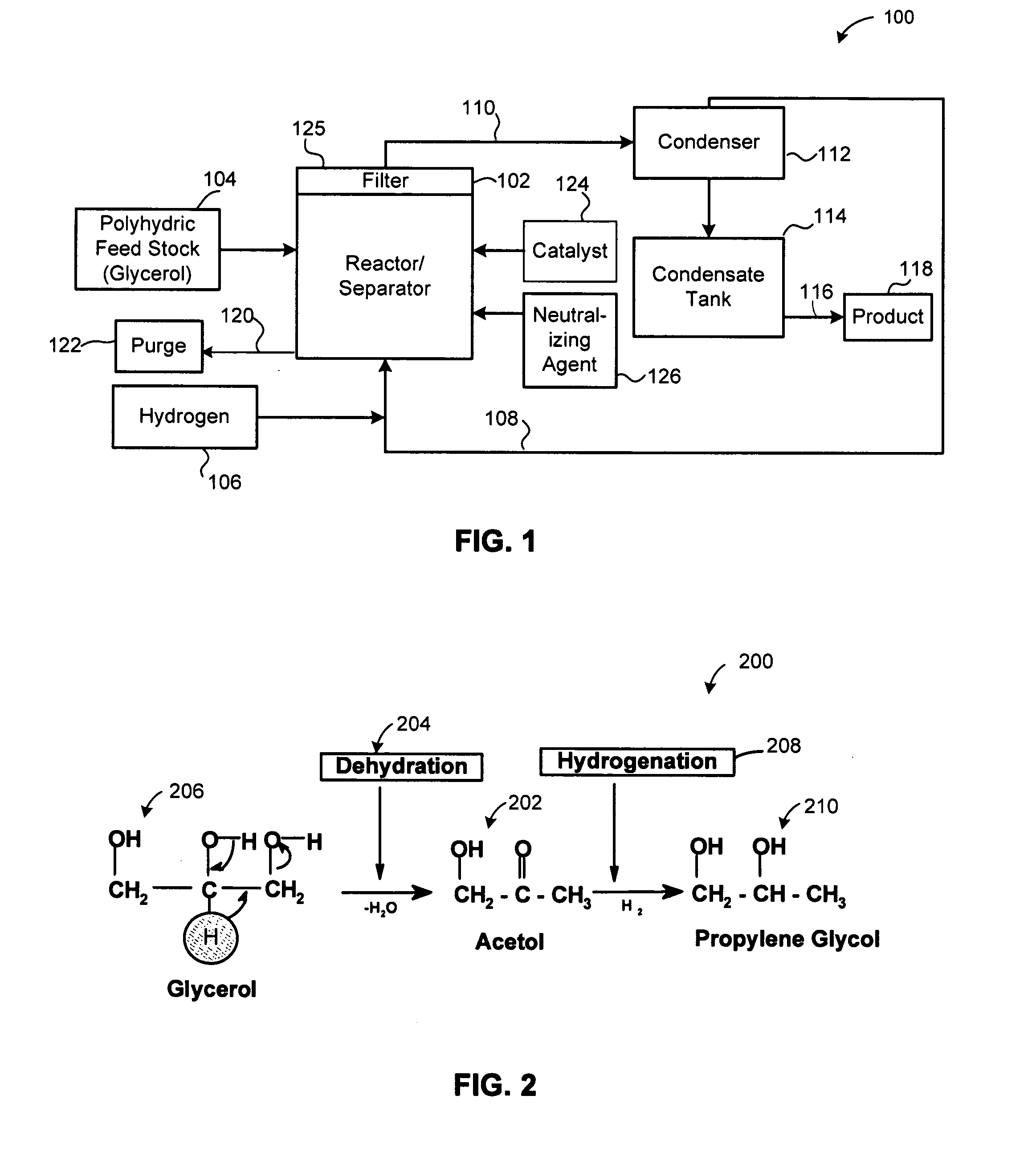

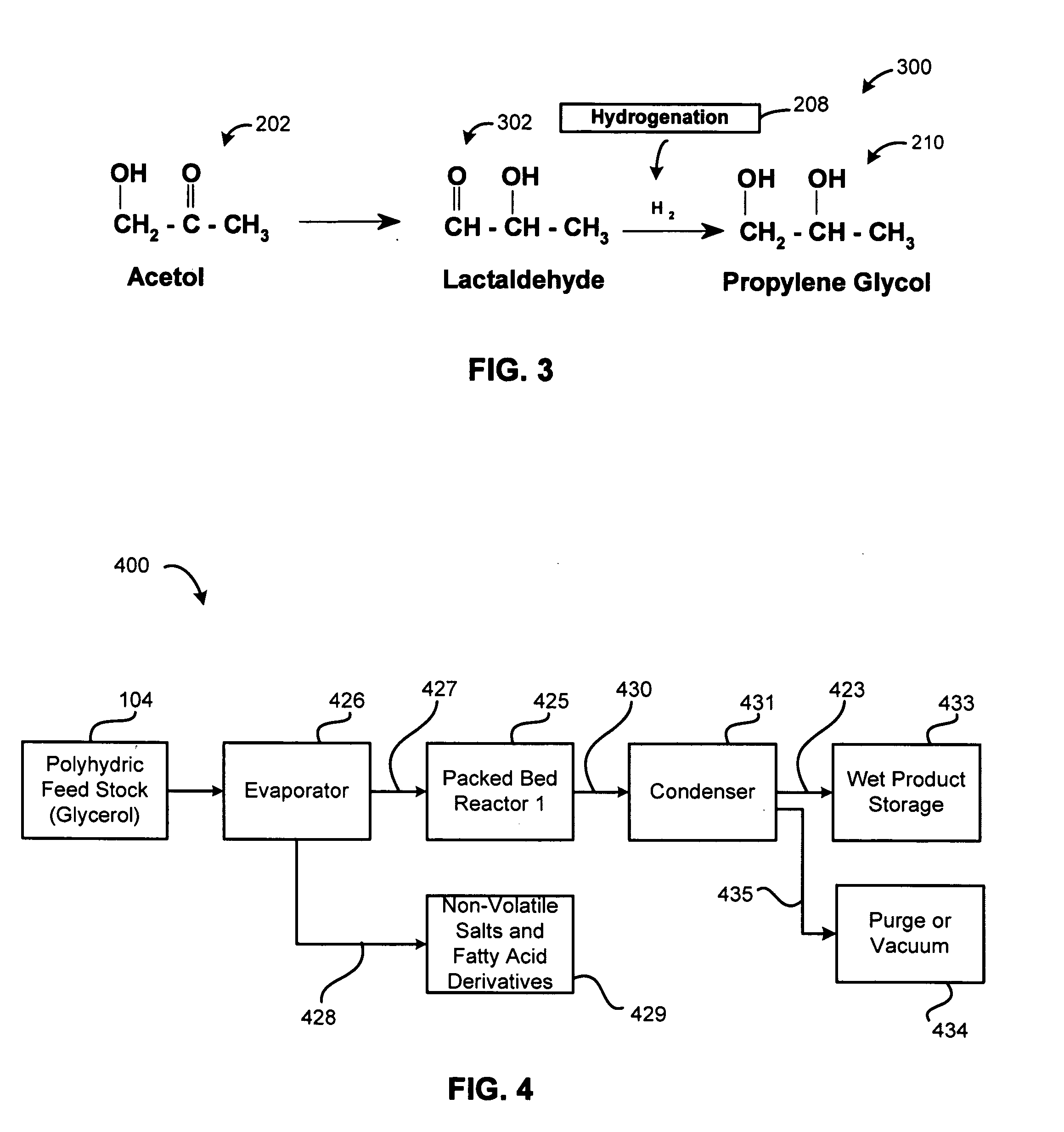

A reactive-separation process converts glycerin into lower alcohols, having boiling points less than 200° C., at high yields. Conversion of natural glycerin to propylene glycol through an acetol intermediate is achieved at temperatures from 150° to 250° C. at a pressure ranging from 1 and 25 bar. The preferred applications of the propylene glycol are as an antifreeze, deicing compound, or anti-icing compound. The preferred catalyst for this process in a copper-chromium powder.

Owner:RENEWABLE ALTERNATIVES LLC +1

Separation of carbon dioxide (CO2) from gas mixtures by calcium based reaction separation (CaRS-CO2) process

ActiveUS20060093540A1Good repeatabilityMaterial nanotechnologyCombustible gas catalytic treatmentReactive separationCarbonation

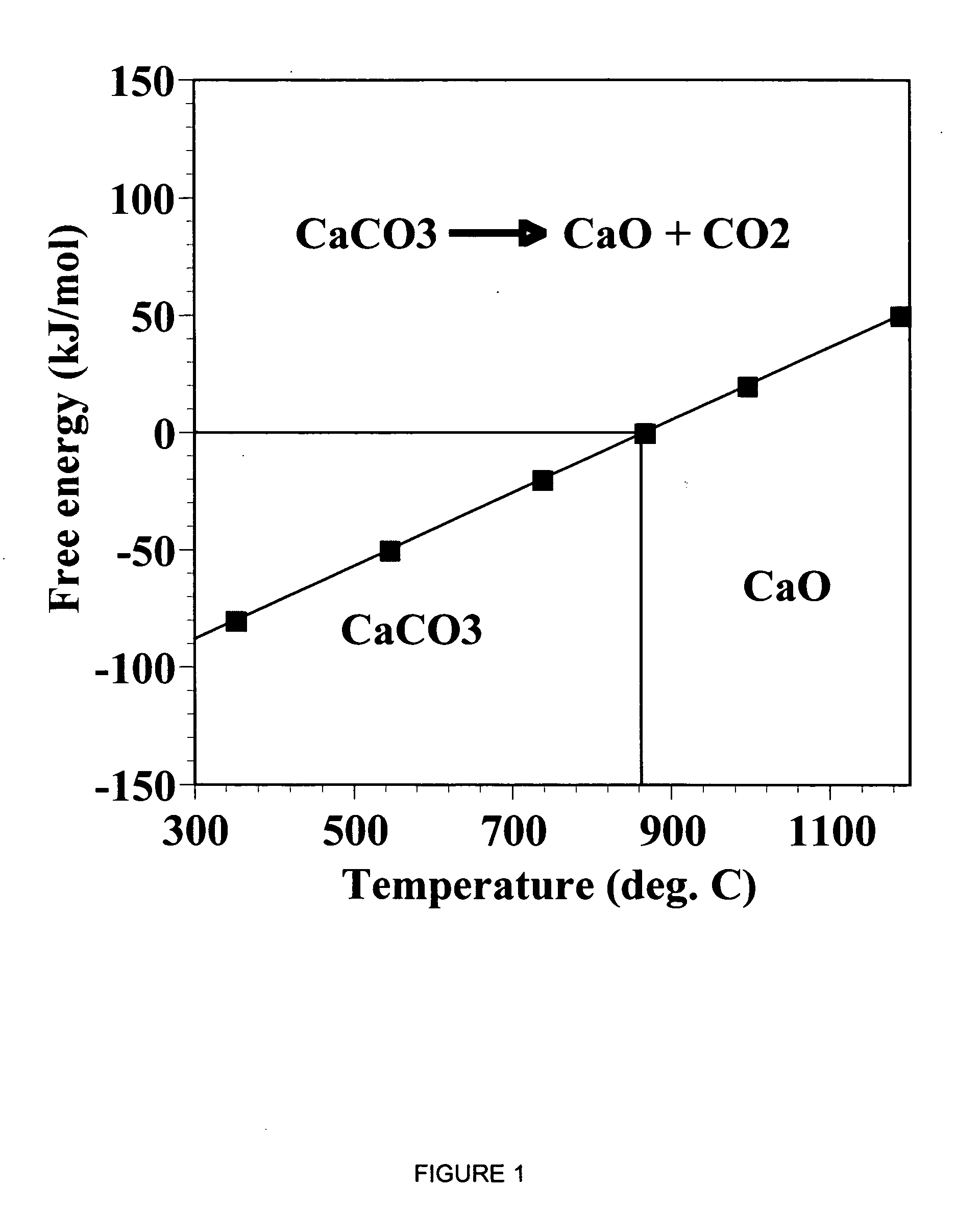

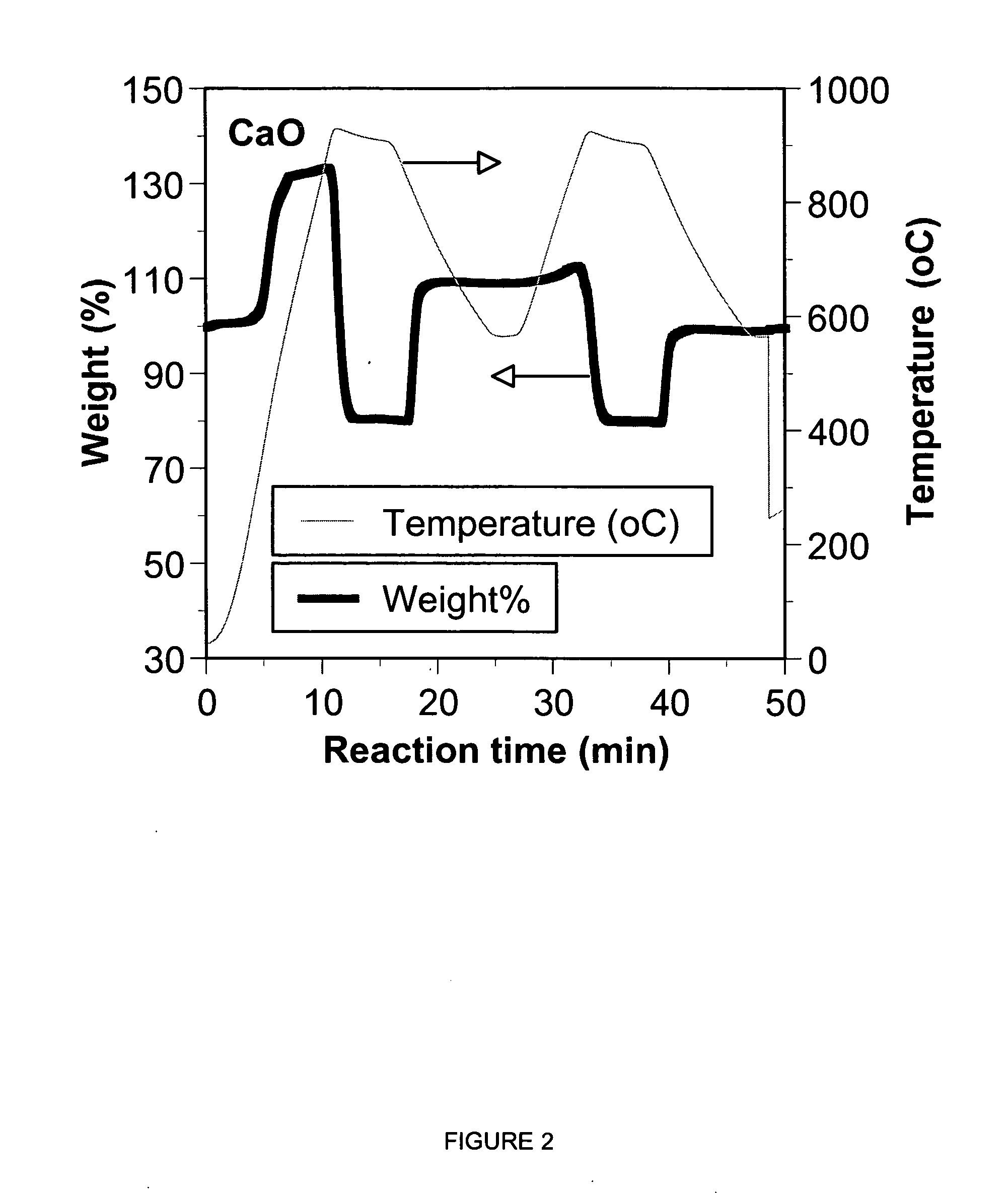

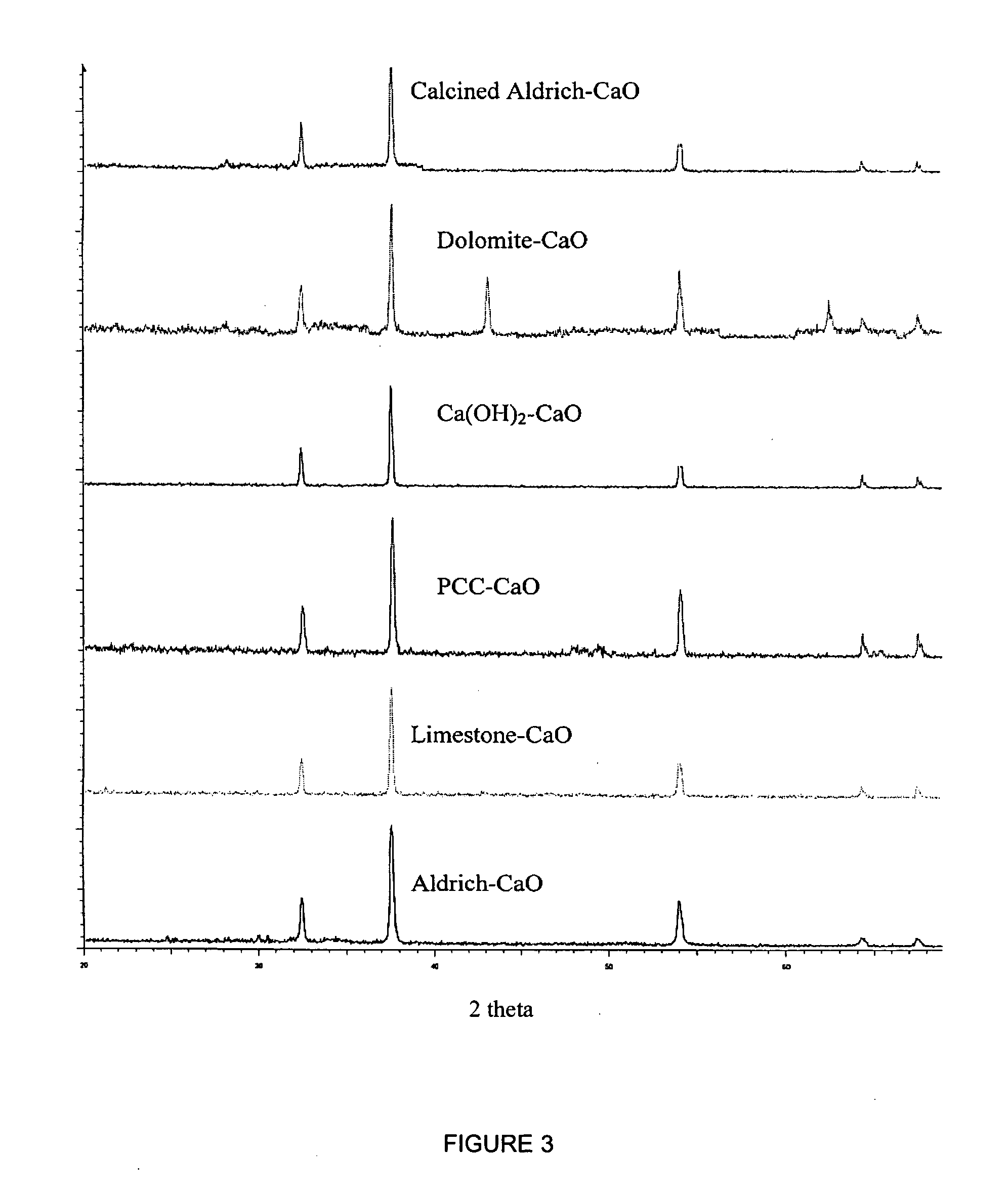

A reaction-based process has been developed for the selective removal of carbon dioxide (CO2) from a multicomponent gas mixture to provide a gaseous stream depleted in CO2 compared to the inlet CO2 concentration in the stream. The proposed process effects the separation of CO2 from a mixture of gases (such as flue gas / fuel gas) by its reaction with metal oxides (such as calcium oxide). The Calcium based Reaction Separation for CO2 (CaRS—CO2) process consists of contacting a CO2 laden gas with calcium oxide (CaO) in a reactor such that CaO captures the CO2 by the formation of calcium carbonate (CaCO3). Once “spent”, CaCO3 is regenerated by its calcination leading to the formation of fresh CaO sorbent and the evolution of a concentrated stream of CO2. The “regenerated” CaO is then recycled for the further capture of more CO2. This carbonation-calcination cycle forms the basis of the CaRS—CO2 process. This process also identifies the application of a mesoporous CaCO3 structure, developed by a process detailed elsewhere, that attains >90% conversion over multiple carbonation and calcination cycles. Lastly, thermal regeneration (calcination) under vacuum provided a better sorbent structure that maintained reproducible reactivity levels over multiple cycles.

Owner:THE OHIO STATES UNIV

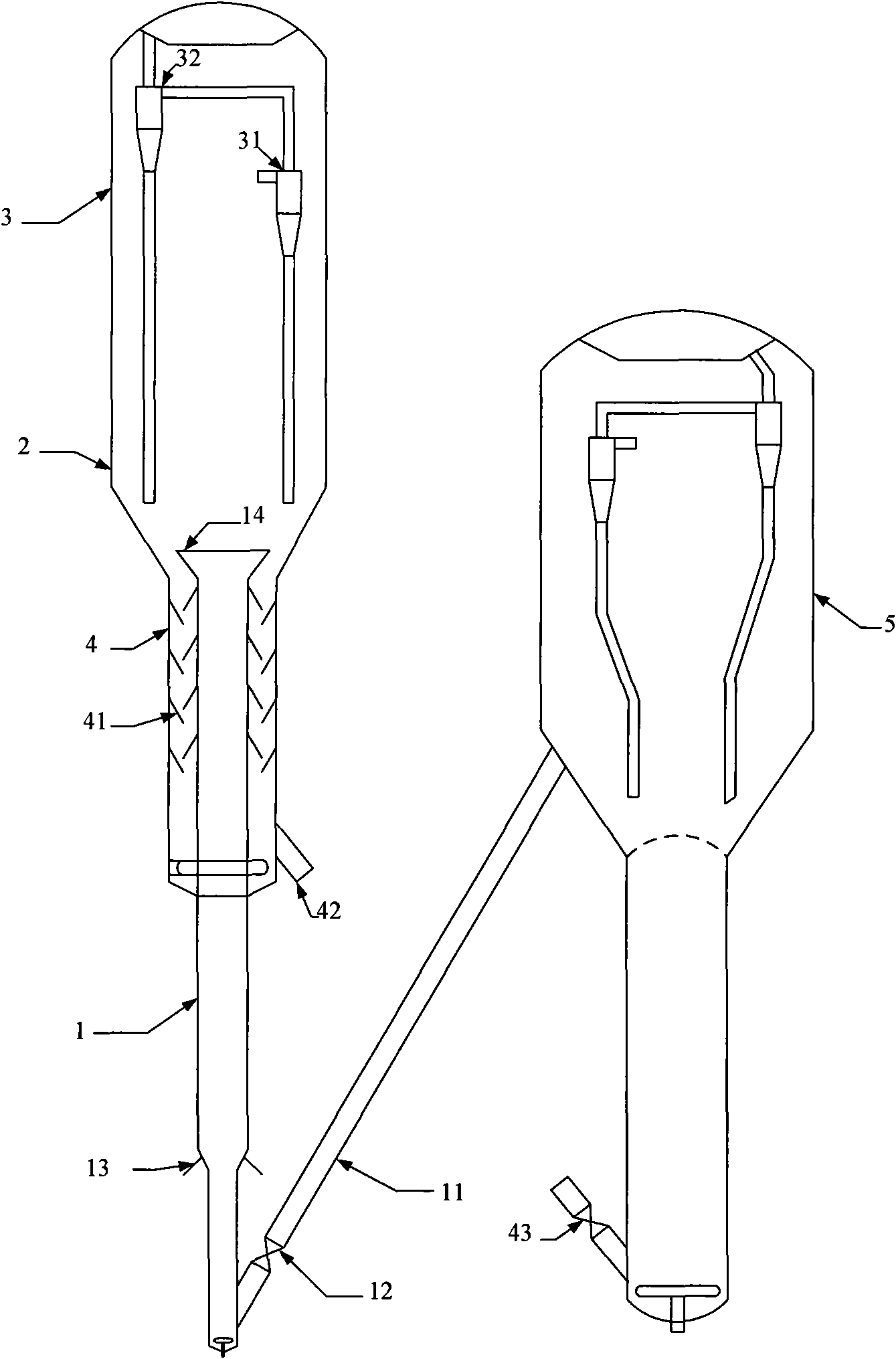

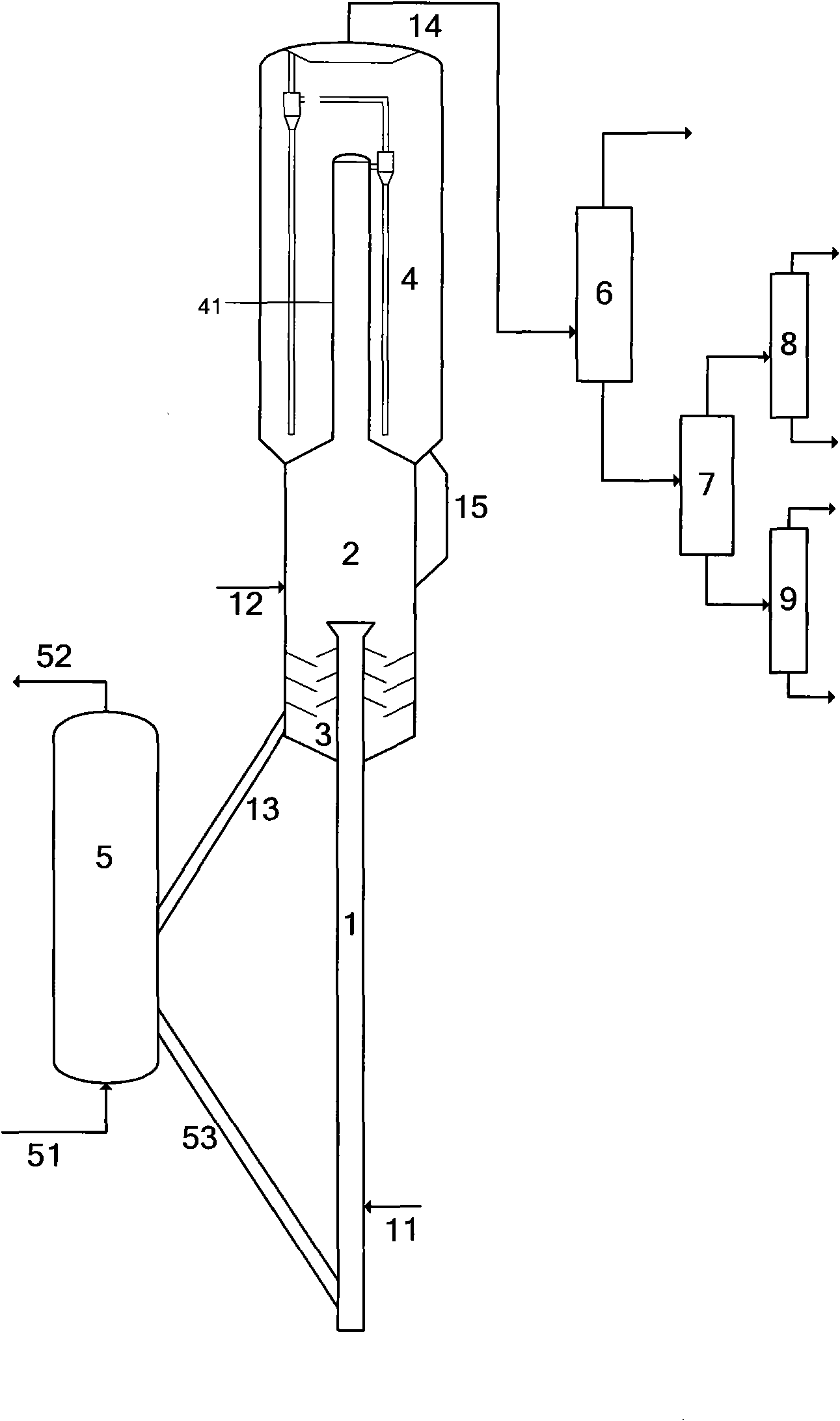

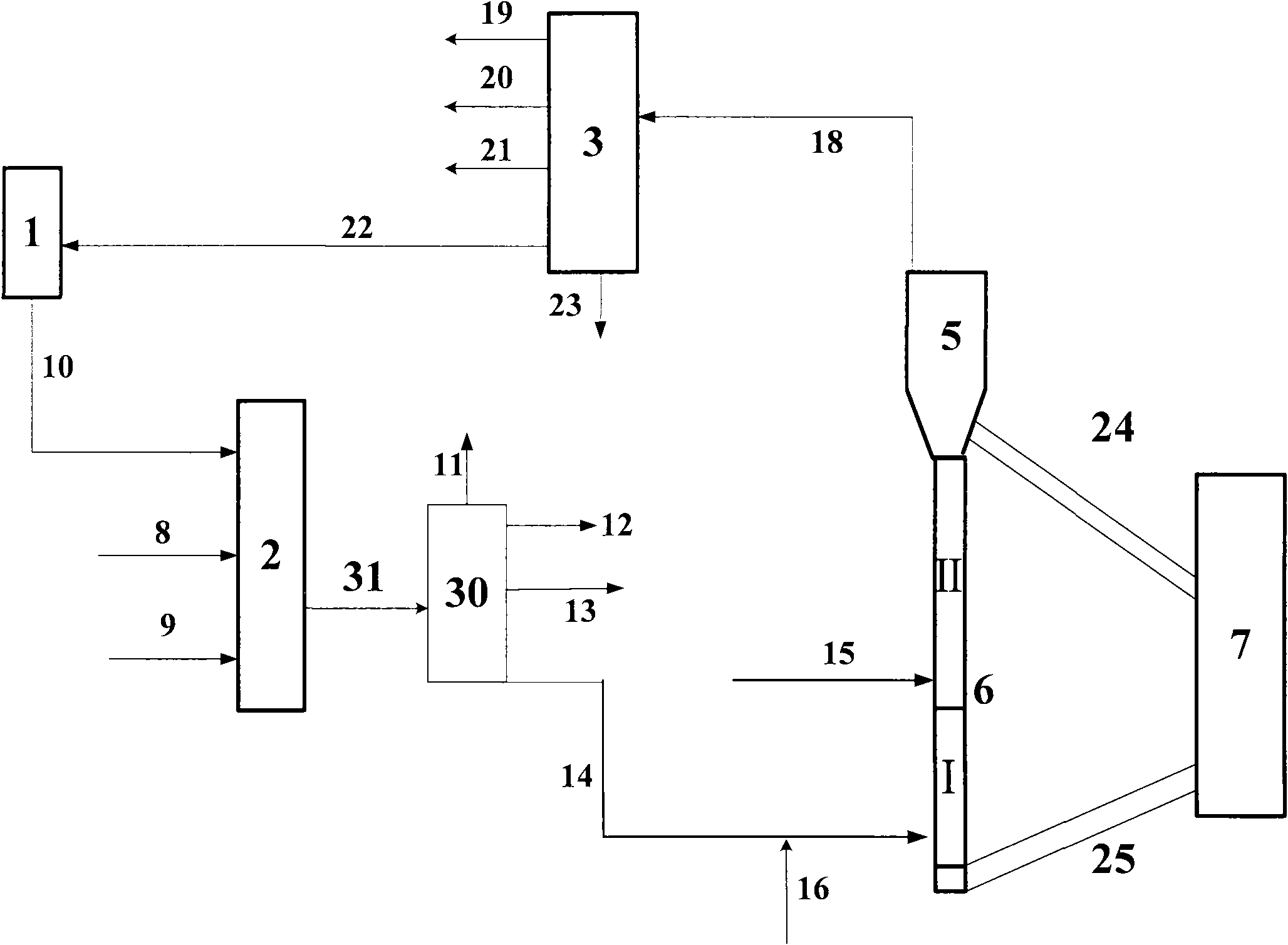

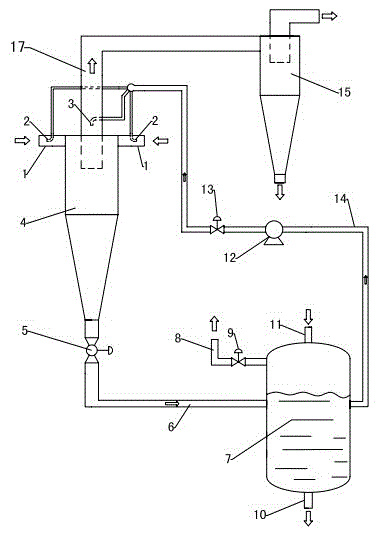

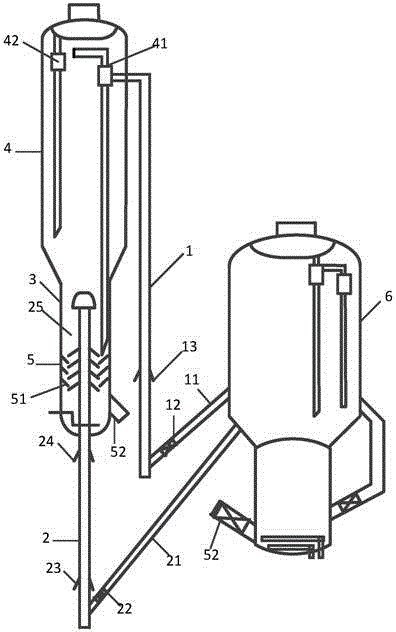

Method for combination processing heavy oil by pyrolysis and gasification

ActiveCN101451073AReasonable useImprove gasification efficiencyThermal non-catalytic crackingCoke ovensOil processingThermal energy

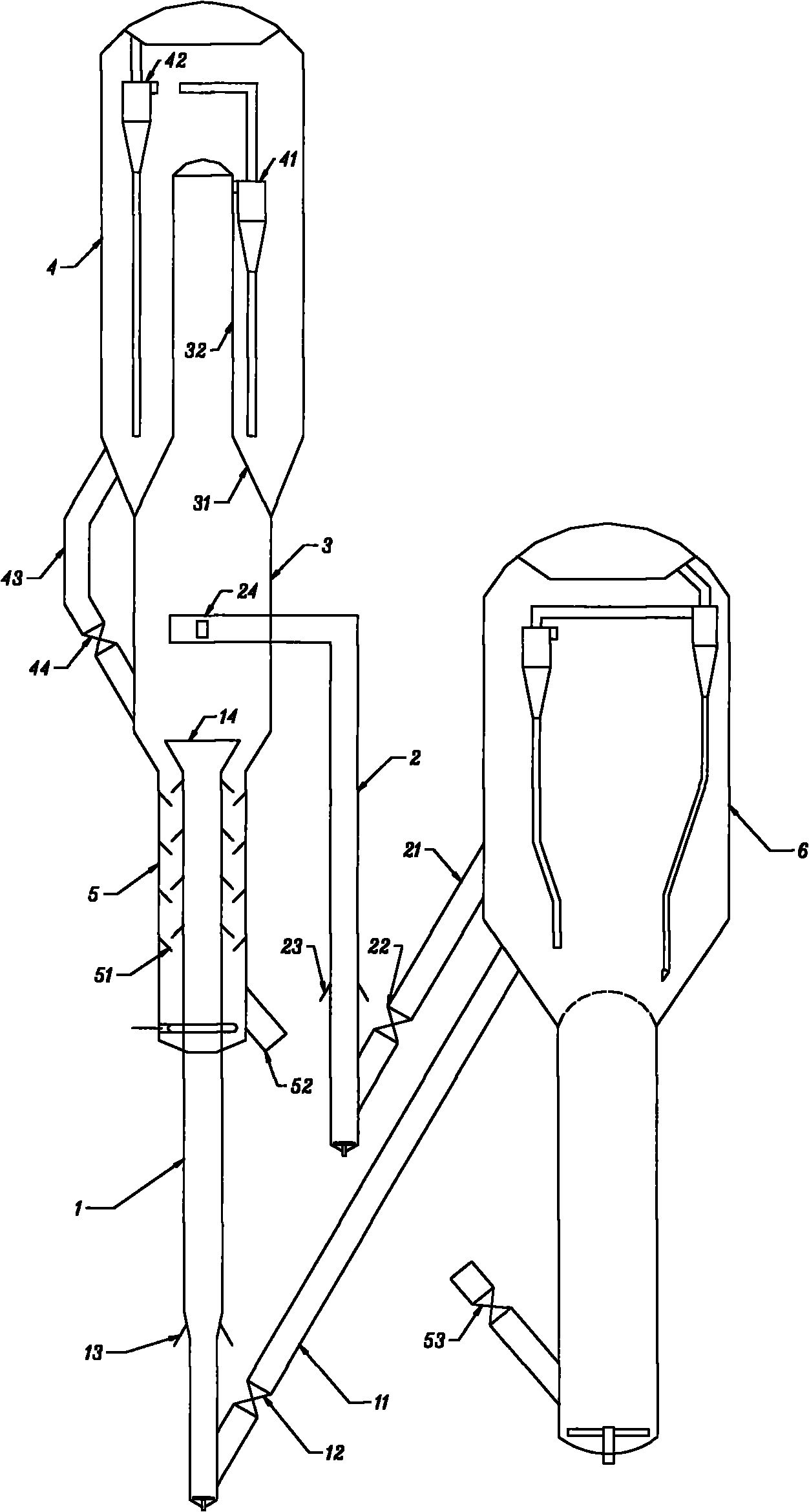

The invention relates to a heavy oil processing method by combining thermal cracking and gasification. A raw material is conducted to a reactor from the bottom of a gas-solid separation region, is dispersed into oil drops through an atomizer; a lightweight component of the oil drop is volatilized to form oil gas in the falling process of the oil drops in a thermal cracking region; a heavy component is condensed to form coke, wherein the oil gas carries out thermal cracking reaction; coke particles drop into a gasification region and carry out gasification reaction at a temperature of between 800 and 1,600 DEG C to generate synthetic gas; one part of residual fine coke particles drop into an ash hopper to form clinker; the other part of the residual fine coke particles and the generated gas flow upwards together, are contacted with the descending liquid drops and carry out heat exchange; gas phase and coke in the gas-solid separation region of the upper part of the rector are separated; the separated fine coke particles re-drop into the thermal cracking region and the gasification region and continuously react; and the separated gas phase flows out of the rector, enters a subsequent separation system and is separated into synthetic gas, dry gas, liquid gas, gasoline, diesel, oil slurry and other products. The method has high gasification efficiency and reasonable utilization of heat energy and reduces energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

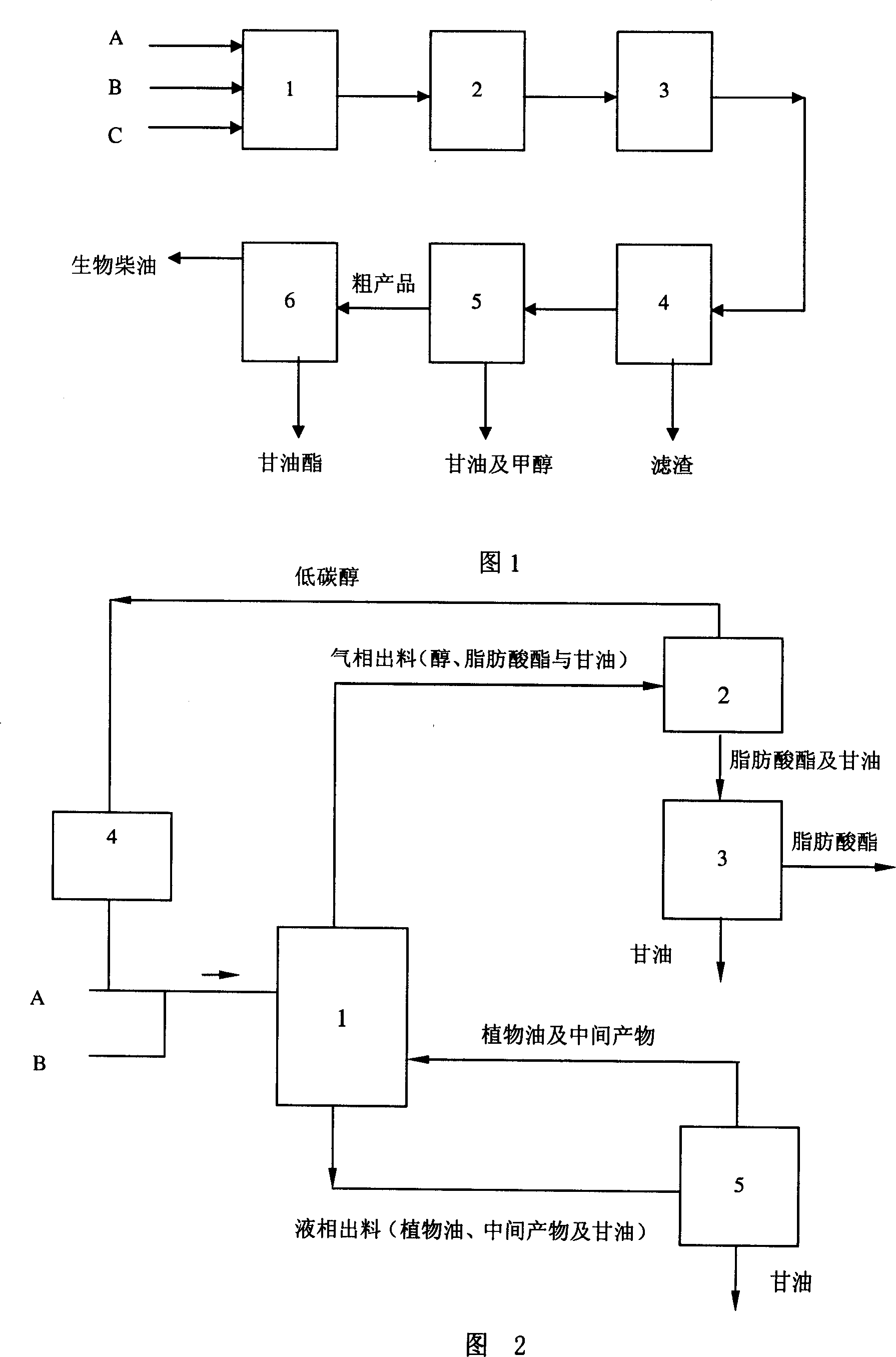

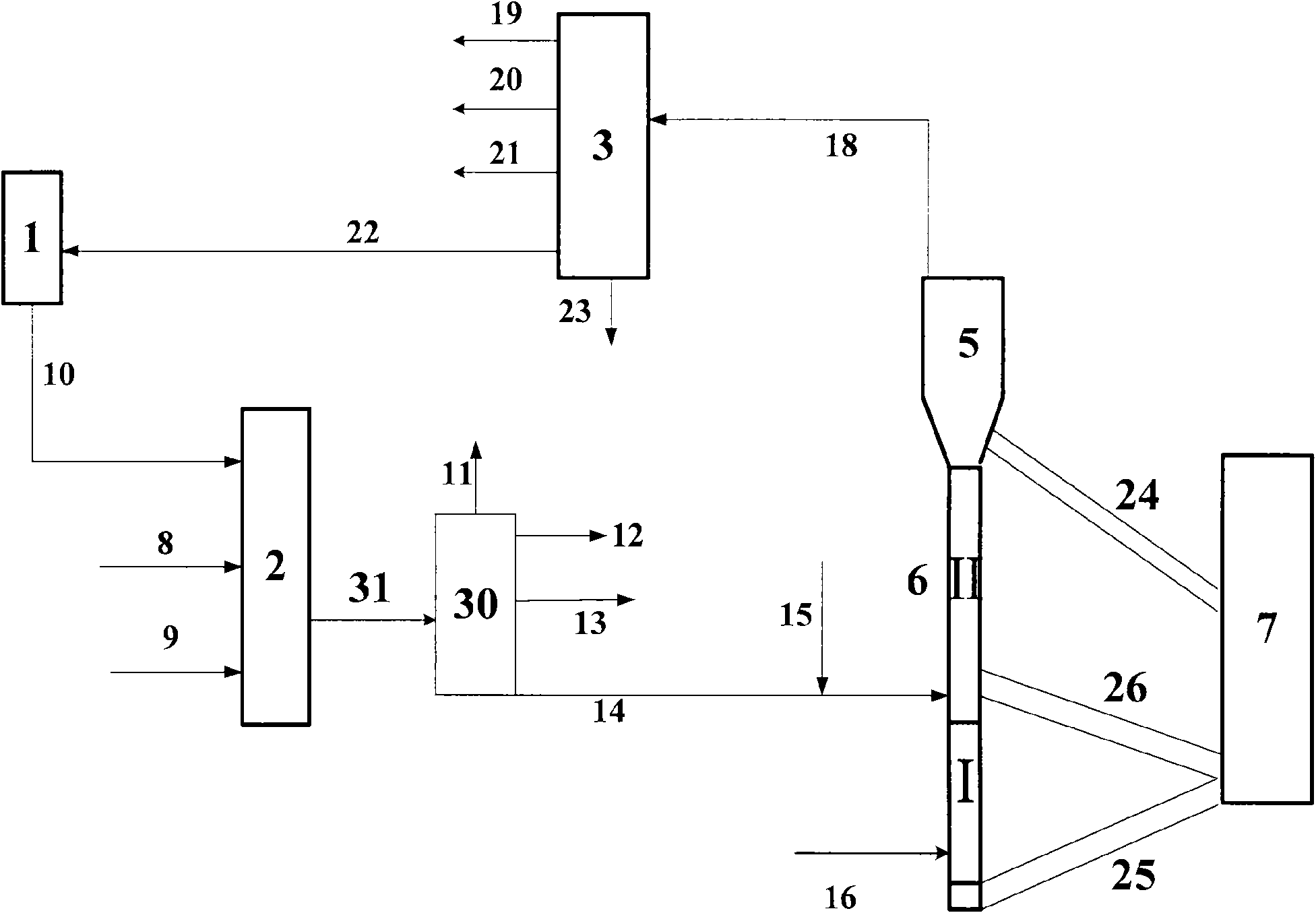

Method for catalytic conversion production of propylene and light aromatics

ActiveCN102337154AIncreased processing flexibilityImprove conversion rateTreatment with hydrotreatment processesChemical recyclingCatalytic transformationPtru catalyst

The invention provides a method for catalytic conversion production of propylene and light aromatics, which is characterized in that a hydrocarbon raw material and a catalytic cracking catalyst are contacted in a composite reactor for reacting under the catalytic cracking condition, the reaction products and the to-be-regenerated catalyst are separated, the separated to-be-regenerated catalyst is circularly used through stripping and performing coke burn-off regeneration, the separated reaction products is fractionated to obtain low carbon olefin, gasoline containing light aromatics and the like, and separated to obtain the light aromatics further; the composite reactor comprises a riser reactor and a fluidized bed reactor, an outlet of the riser reactor is communicated with a lower part of the fluidized bed reactor, a stripper is positioned at the lower part of the fluidized bed reactor, an upper part of the stripper is communicated with the bottom of the fluidized bed reactor, and the outlet of the fluidized bed reactor is communicated with the inlet of a gas solid separation device in a settler though a conveying pathway, a catalyst outlet of the settler is communicated with the lower part of the fluidized bed reactor. According to the invention, propylene and light aromatics enable high yield by using the method.

Owner:CHINA PETROLEUM & CHEM CORP +1

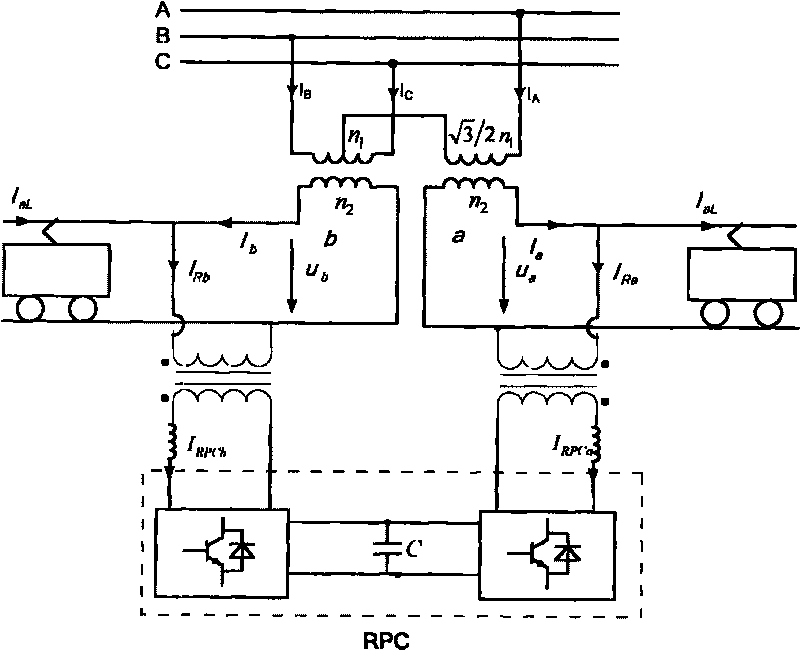

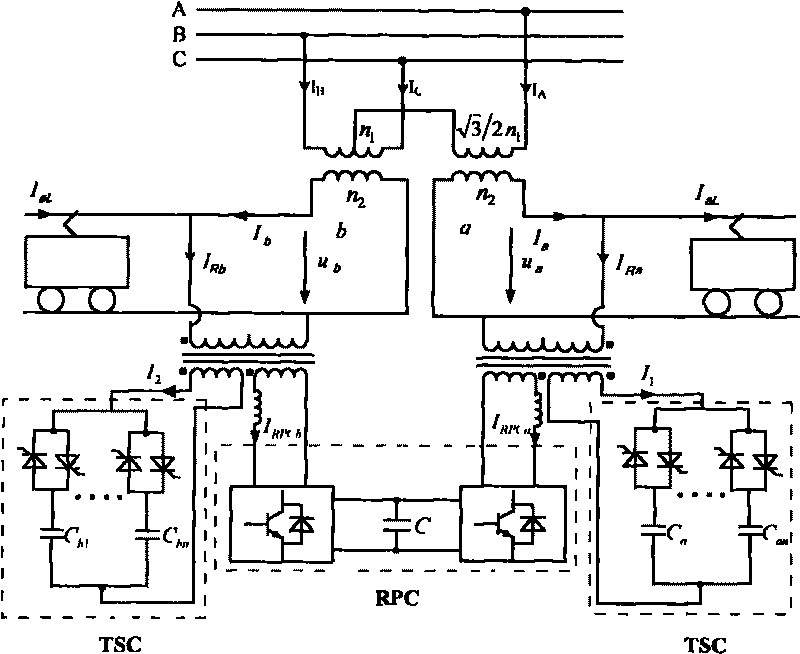

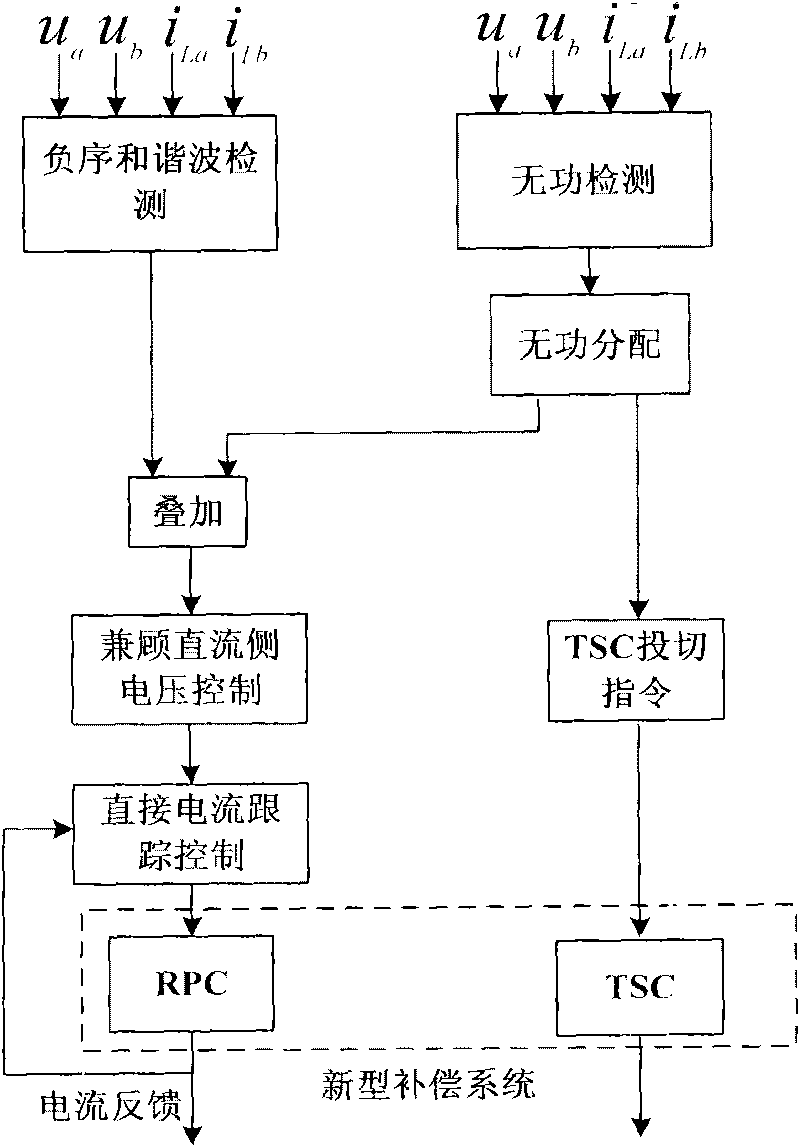

Power quality comprehensive compensation system of electric railway and control method thereof

InactiveCN101710707AQuick responseReduce capacityPolyphase network asymmetry elimination/reductionReactive power adjustment/elimination/compensationPower qualityReference current

The invention discloses a power quality comprehensive compensation system of an electric railway and a control method thereof. The system comprises a railway static power controller RPC and two sets of thyristor switched capacitors TSC. The thyristor switched capacitors bear a large proportion of reactive power compensation, RPC performs active power compensation, harmonic suppression and a remained small proportion of reactive power compensation for two power supply arms, therefore, the capacity of RPC is effectively reduced, and negative sequence, harmonic and reactive comprehensive compensation are realized. The control method comprises a cooperative control policy of RPC and TSC, reference current detection based on reactive separation, a reactive power distribution method and an RPC control method. The power quality comprehensive compensation system of the electric railway greatly improves the power quality of the electric railway with low cost, and the corresponding control method effectively coordinates the operation of RPC and TSC and ensures that the system has good compensation performance and favorable application prospect.

Owner:HUNAN UNIV

Catalytic pyrolysis process for producing petroleum hydrocarbon of ethylene and propylene

InactiveCN1566267AHigh yieldRaise the reaction temperatureCatalytic crackingCatalytic pyrolysisPetroleum

The invention discloses a catalytic pyrolysis process for producing petroleum hydrocarbon of ethylene and propylene which comprises, feeding preheated petroleum hydrocarbon raw material into lift tubes, contacting phosphor modified five-membered ring high silicon zeolite catalyst for reaction under the condition of catalytic thermal cracking, thus separating the reaction product and catalyst to be produced, then loading the reaction product into subsequent separation system for product separation, stripping and regenerating the catalyst, returning to reactor for circulation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of producing lower alcohols from glycerol

ActiveUS7663004B2Organic compound preparationOxygen compounds preparation by reductionAlcoholBoiling point

A reactive-separation process converts glycerin into lower alcohols, having boiling points less than 200° C., at high yields. Conversion of natural glycerin to propylene glycol through an acetol intermediate is achieved at temperatures from 150° to 250° C. at a pressure ranging from 1 and 25 bar. The preferred applications of the propylene glycol are as an antifreeze, deicing compound, or anti-icing compound. The preferred catalyst for this process in a copper-chromium powder.

Owner:RENEWABLE ALTERNATIVES LLC +1

Method for preparing propylene through catalytic conversion of olefin raw material

ActiveCN102337148AHigh densityLower contact temperatureCatalytic crackingBulk chemical productionCatalytic transformationPtru catalyst

Owner:CHINA PETROLEUM & CHEM CORP +1

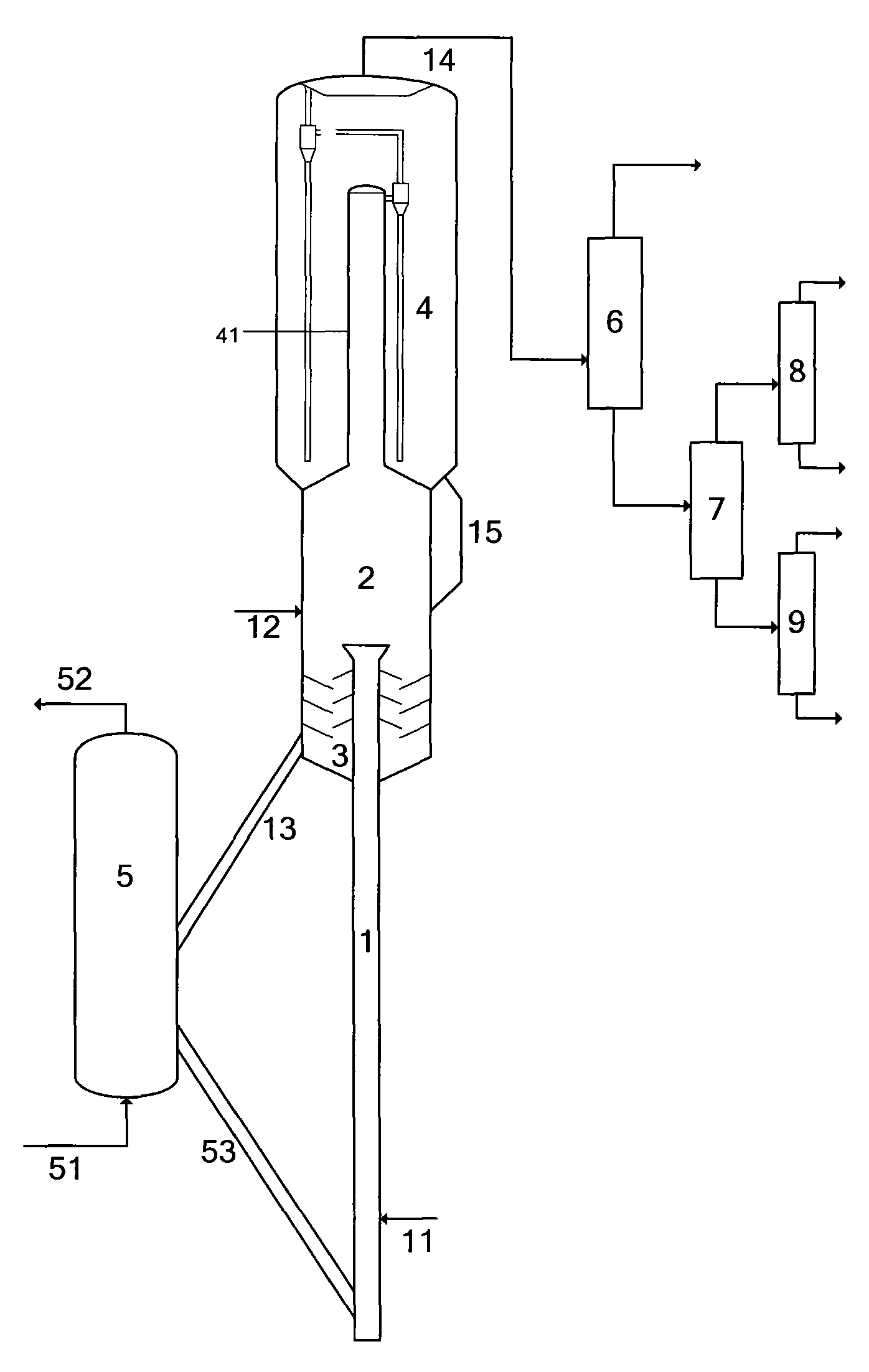

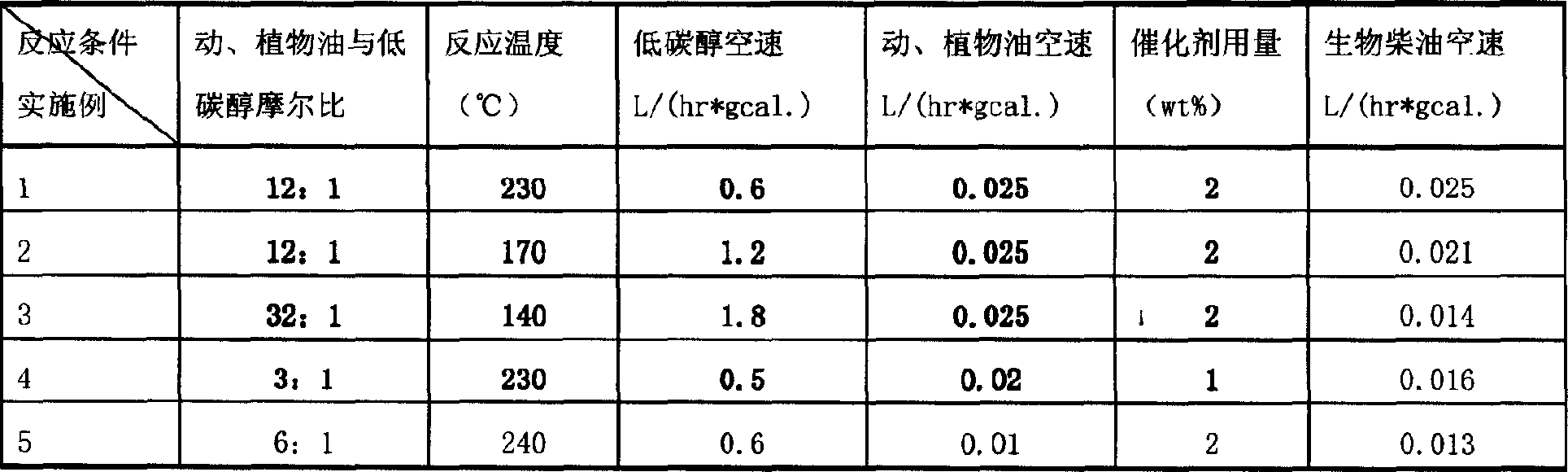

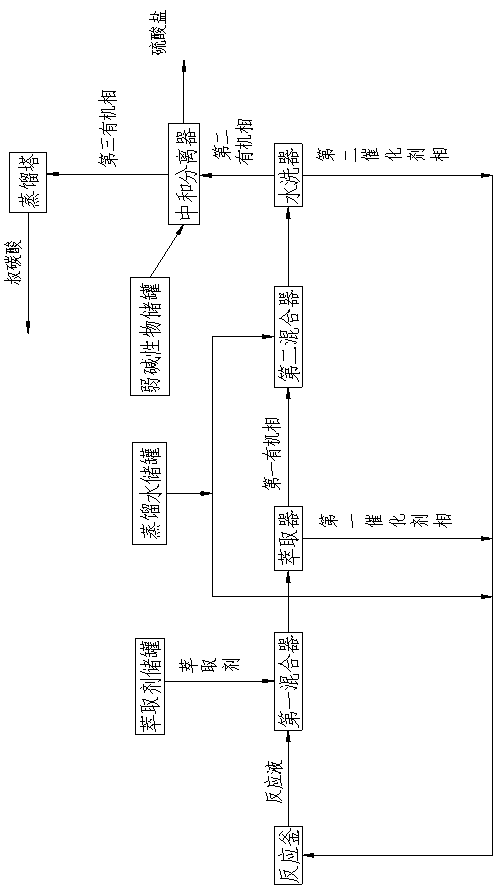

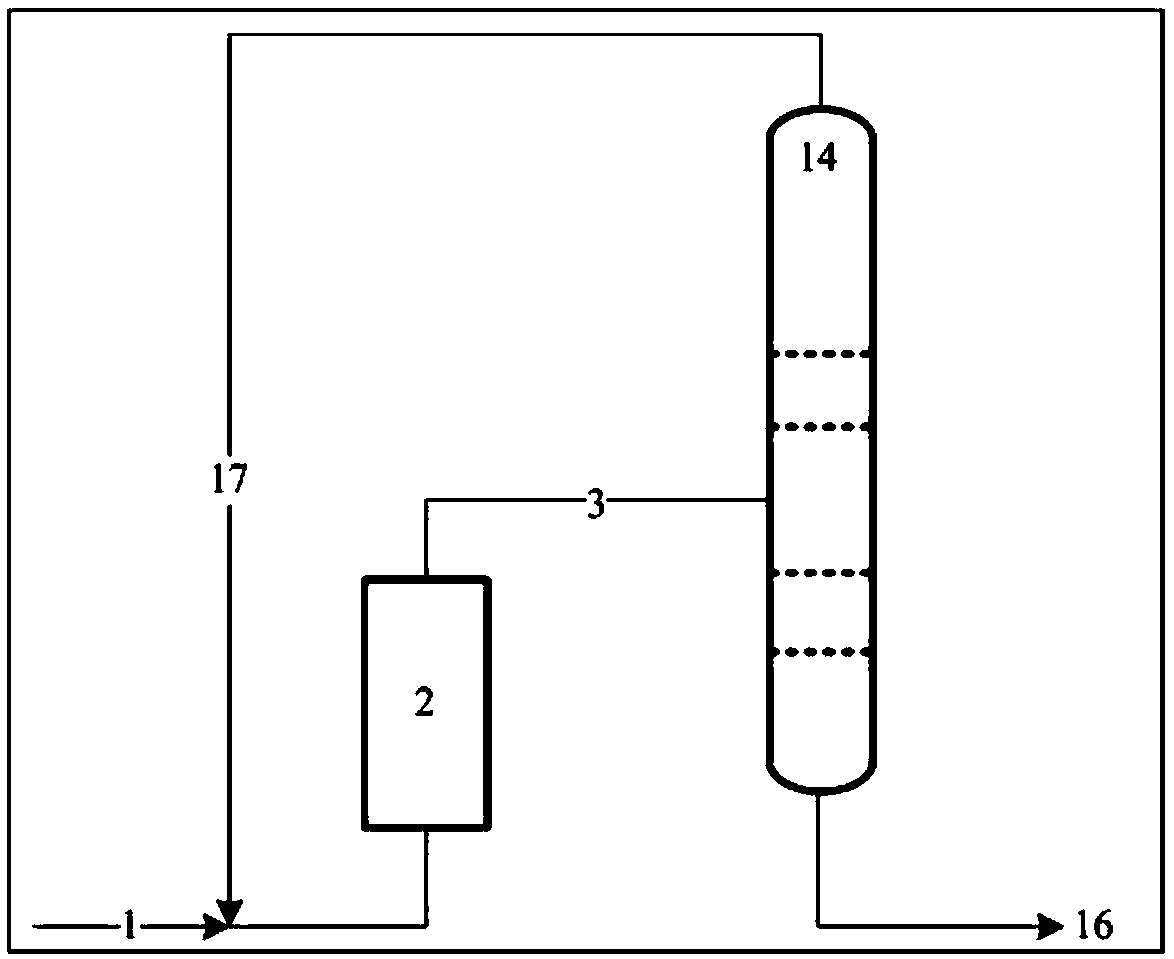

Technical method for preparing biodiesel using reactive separation process coupling technique

InactiveCN1710026ANo further processing requiredAchieve couplingBiofuelsLiquid hydrocarbon mixture productionChemical industryVegetable oil

This is the craft method of preparing biological diesel oil by using the coupling technology in reaction separating course. It relates to the new craft of preparing biology diesel oil (fatty diethylene glycol dinitrate) through the ester exchange reaction of vegetable oil and higher alcohols, and belongs to chemical industry craft technology field. It includes: the ester exchange reaction of vegetable oil and higher alcohols; the separation of product fatty diethylene glycol dinitrate, glycerol and reaction mixed liquid; the separation of product fatty diethylene glycol dinitrate, glycerol and higher alcohols; the separation of fat diethylene glycol dinitrate and glycerol; the condensation backflow of fatty alcohol; and the separation of glycerol. It makes the circumvolving higher alcohols carry out the product fatty diethylene glycol dinitrate and glycerol through higher reaction temperature, and realizes the separation of outcome and reactant; the non-homogeneous phase catalyst stays in the actor, and don't need to have following process to the catalyst. The invention realizes the coupling of reaction and separation courses, speeds up the speed of non-homogeneous phase reaction, and avoids the problem of the following process to catalyst in the homogeneous phase process. Besides it can save production cost, and improves the producing performance of biology diesel oil.

Owner:TSINGHUA UNIV

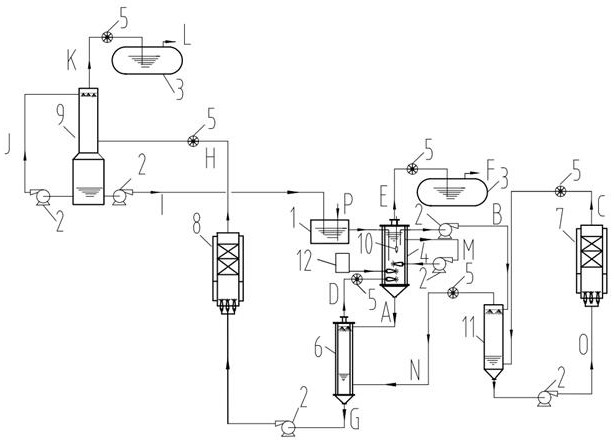

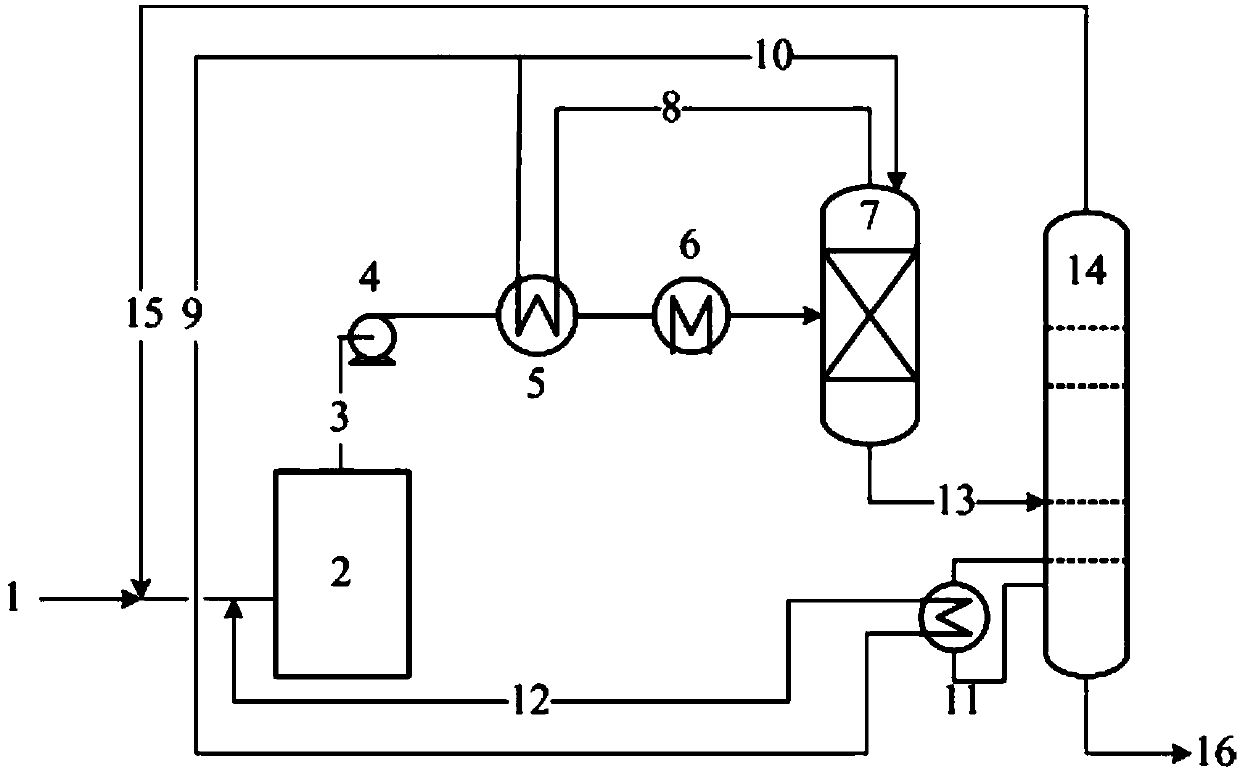

Technique for using methylbenzene to prepare benzaldehyde and benzene methanol by multistage oxidation and equipment

InactiveCN101607867APreparation by oxidation reactionsOrganic compound preparationBenzaldehydeFractionating column

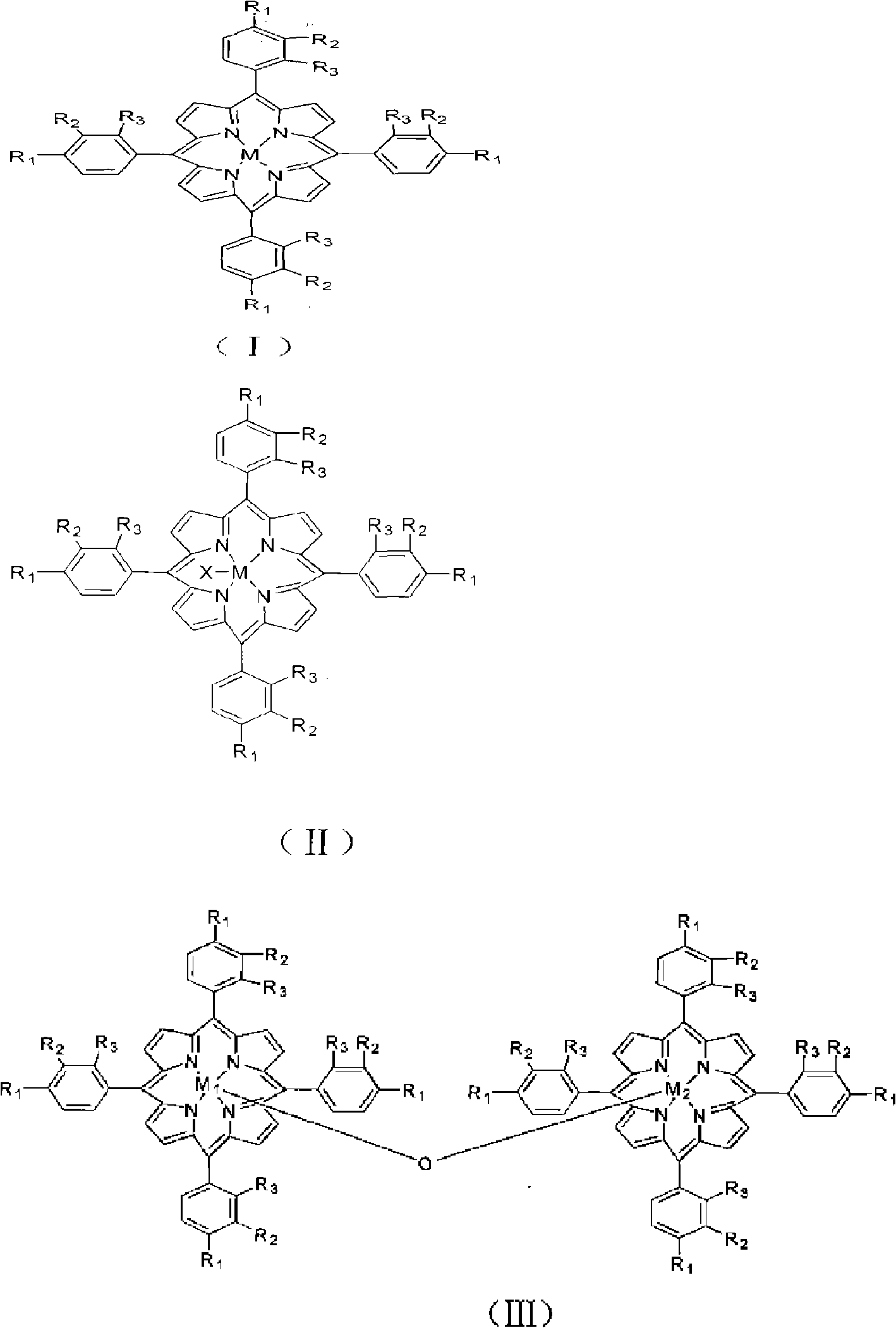

The invention discloses a technique for using methylbenzene to prepare benzaldehyde and benzene methanol by air oxidation and equipment. In a reaction separating system consisting of a multistage oxidation reactor as well as a gas-liquid separator, a lateral line fractionating column or a fractionating column system, 0.1 to 50ppm of monometallic porphyrin or u-oxygen bimetallic porphyrin is separately used as a catalyst, or metallic porphyrin and phthalimide (or salt) are used as a mixed catalyst according to the weight ratio of 1:20 to 100; when the reaction temperature is 80 to 200 DEG C, the methylbenzene is maintained in a multistage oxidizer for 60 to 180 minutes and prepared into the benzaldehyde and benzene methanol by catalytic oxidation; and the gas-liquid separation and purification are carried out. Compared with the prior art, the technique and equipment can obviously improve the conversion rate of the methylbenzene, and the conversion rate of the methylbenzene can reach to be more than 95% by experiments; in addition, the technique and equipment also can improve the selection of the benzaldehyde and benzene methanol, and the selection of the benzaldehyde and benzene methanol can reach to be more than 50%.

Owner:HUNAN UNIV

Method of producing lower alcohols from glycerol

A reactive-separation process converts glycerin into lower alcohols, having boiling points less than 200° C., at high yields. Conversion of natural glycerin to propylene glycol through an acetol intermediate is achieved at temperatures from 150° to 250° C. at pressures from 1 and 25 bar. The preferred applications of the propylene glycol are as an antifreeze, deicing compound, or anti-icing compound. The preferred catalyst for this process in a copper-chromium.

Owner:UNIVERSITY OF MISSOURI +1

Method for producing tertiary carboxylic acid

ActiveCN102718646AEasy separationReduce lossChemical recyclingCarboxylic preparation from carbon monoxide reactionCarboxylic acidCopper

The invention provides a method for producing a tertiary carboxylic acid. The method is a simple and efficient technology for producing a tertiary carboxylic acid. The method solves the problem that the existing production technology has the defects of difficult separation of a catalyst and a product, large discharge quantity of dilute sulfuric acid and severe environmental pollution. An olefin, water and carbon monoxide as raw materials undergo a synthesis reaction in the presence of a concentrated acid-carbonyl copper catalyst to produce a tertiary carboxylic acid. An improved reaction separation method is adopted and thus a catalyst loss is low and discharged three wastes are reduced. A product tertiary carboxylic acid and the catalyst can be separated only through utilization of water of which an amount is less than or equal to an amount of water needed by a reaction and thus the catalyst can be directly recycled and the problem that the prior art has the defects of poor separation effects, large dilute sulfuric acid discharge quality and serious dilute sulfuric acid pollution is solved.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND +1

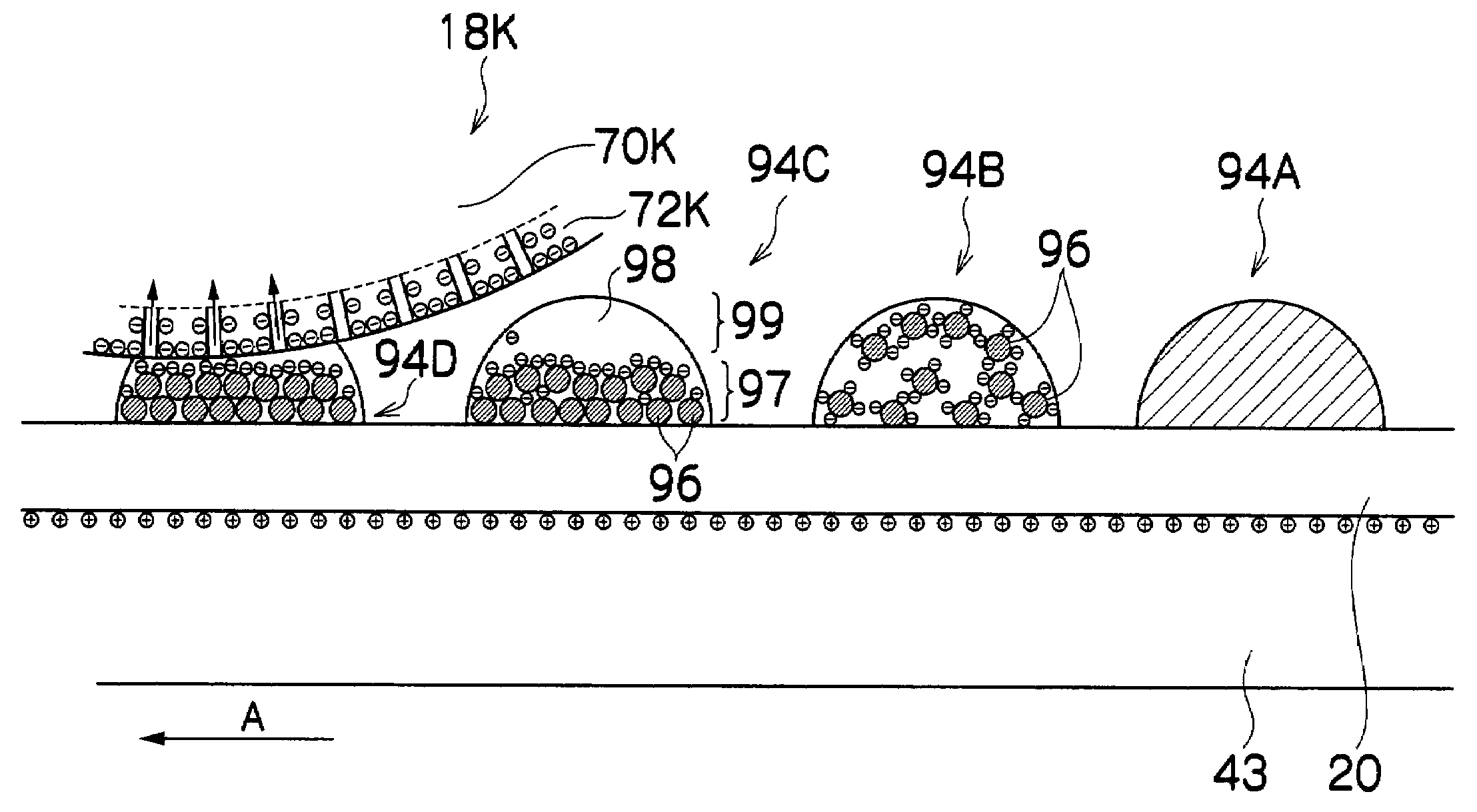

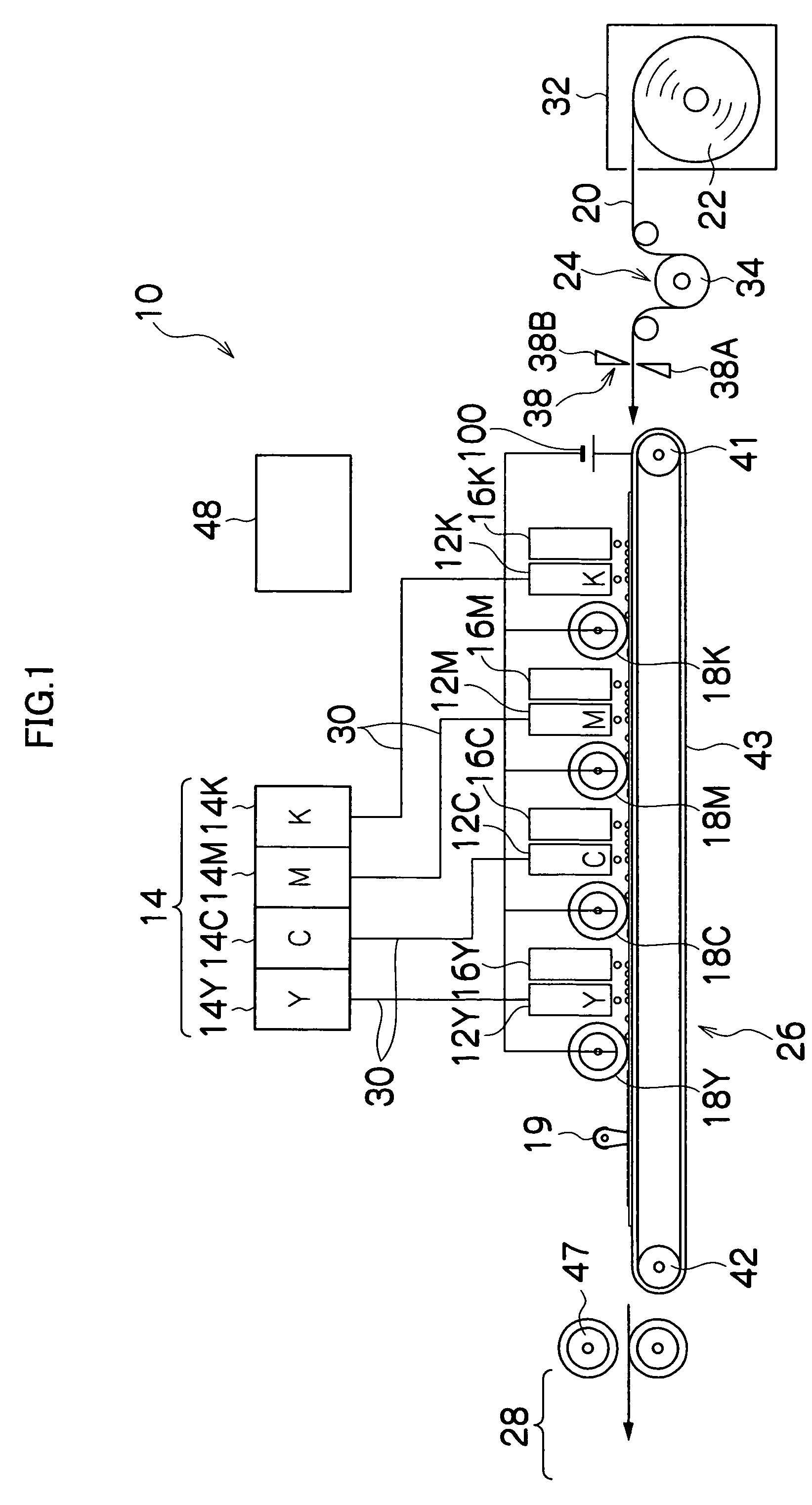

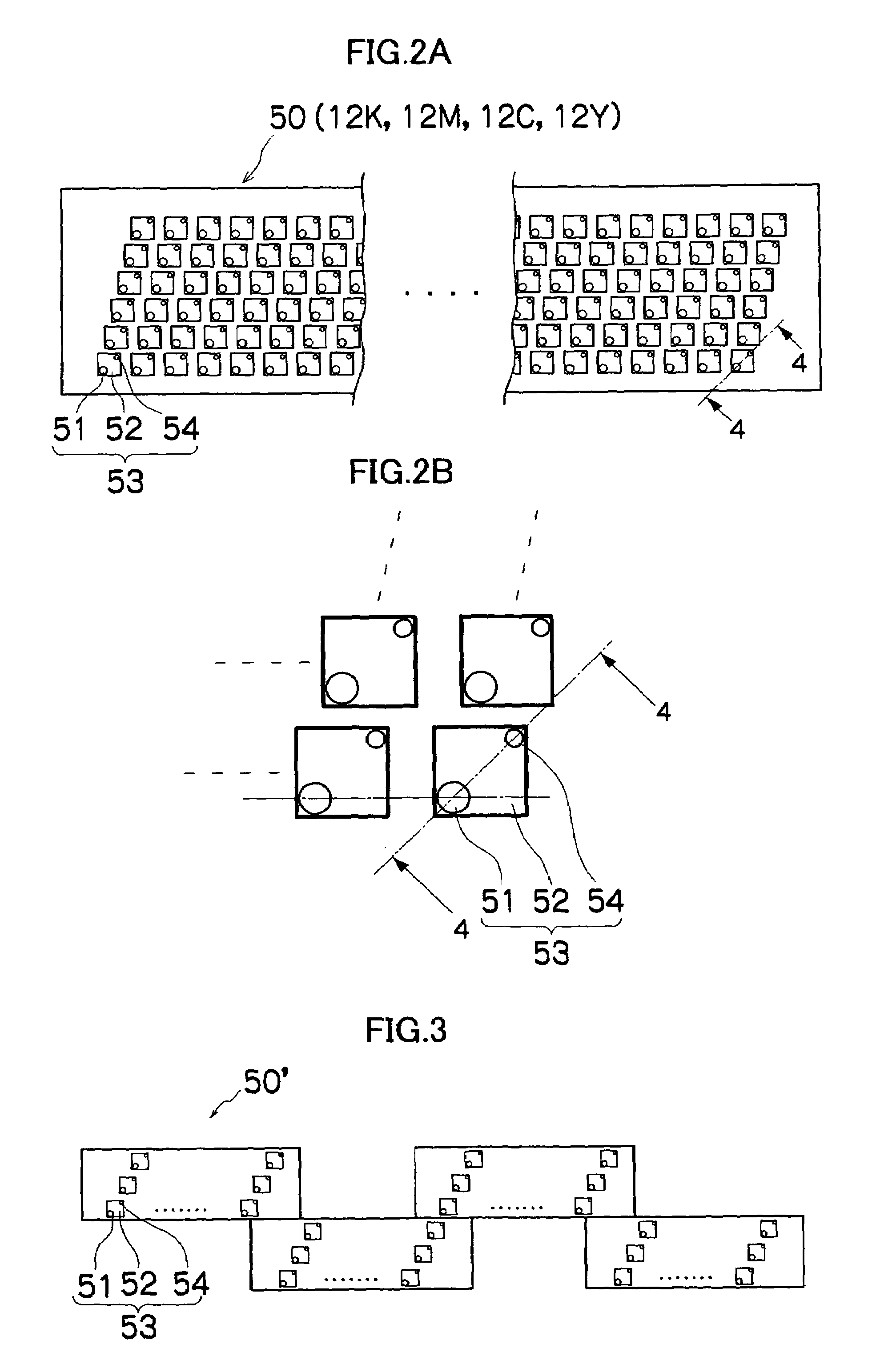

Image forming apparatus

InactiveUS7422318B2Remove swiftly and reliablyInking apparatusOther printing apparatusReactive separationImage formation

The image forming apparatus comprises: an ink ejection device which ejects ink comprising a coloring material dispersed or dissolved in a solvent onto a recording medium; a treatment liquid application device which applies a treatment liquid which produces a charged aggregate of the coloring material by reaction with the ink onto the recording medium, in such a manner that two liquids of the ink and the treatment liquid combine on the recording medium; a conveyance device which causes the ink ejection device and the recording medium to move relatively to each other by conveying at least one of the ink ejection device and the recording medium in a direction substantially perpendicular to a breadthways direction of the recording medium; and a solvent absorbing device which is charged to a same polarity as the aggregate of the coloring material and absorbs the solvent in the ink on the recording medium, wherein: the coloring material and the solvent are separated by reaction of the two liquids which have combined on the recording medium; the solvent is then absorbed by the solvent absorbing device; and the coloring material is then fixed onto the recording medium.

Owner:FUJIFILM CORP

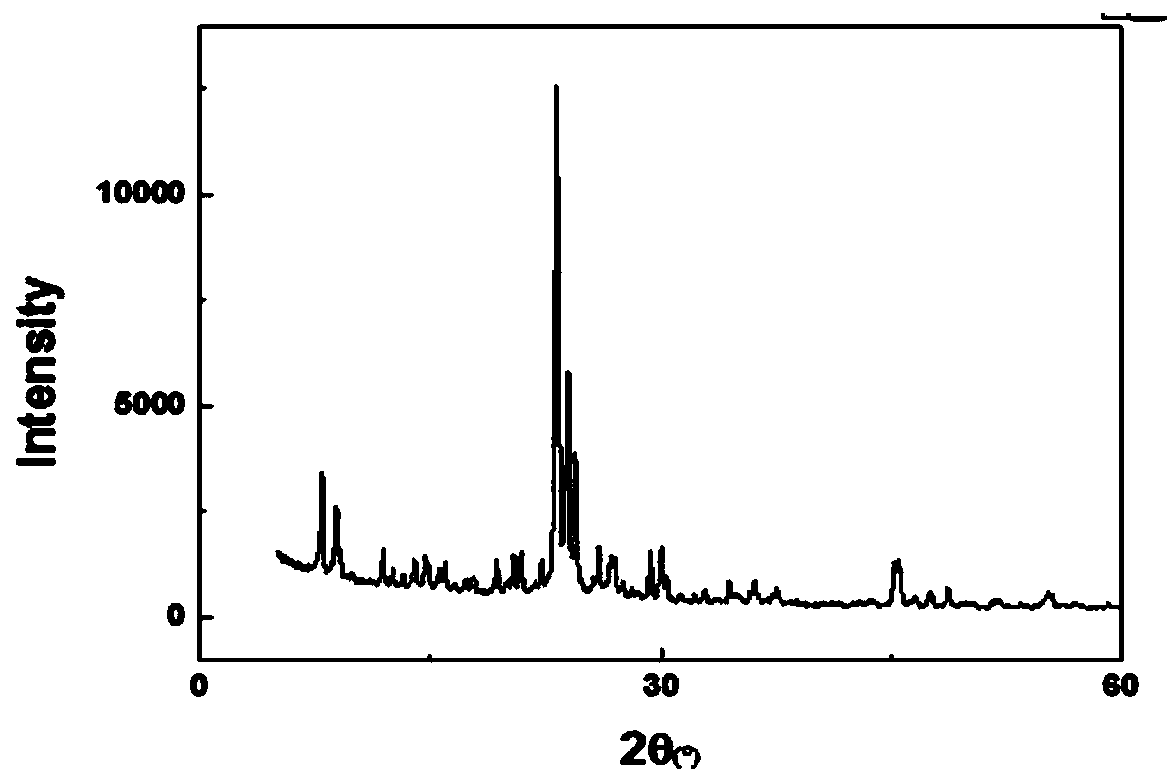

Multifunctional catalyst having nano/micro-scale reaction and separation coupling function and preparation method thereof

ActiveCN104258896AAvoid pollutionImprove stabilityMolecular sieve catalystsHydrocarbon by hydrogenationMolecular sievePtru catalyst

The invention relates to a multifunctional catalyst having a nano / micro-scale reaction and separation coupling function. The multifunctional catalyst comprises a core carrier containing a catalytic hydrogenation active component, wherein a molecular sieve shell layer having shape selection or isomerization capability is formed on the core carrier; the molecular sieve shell layer is one or two of ZSM-5, Silicalite-1 or a mordenite type molecular sieve; the molecular sieve shell layer is of a cylindrical staggered intergrowth structure; and the staggered intergrowth structure grows vertically to the outer surface of the core carrier. Through adoption of the catalyst disclosed by the invention, nano / micro-scale reaction and separation coupling can be realized; the process flow of a current hydroisomerization reaction is improved; the operation cost is reduced; the production efficiency is increased, and efficient coupling of reaction and separation processes is realized. The catalyst can be applied to various hydrogenation and isomerization processes.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

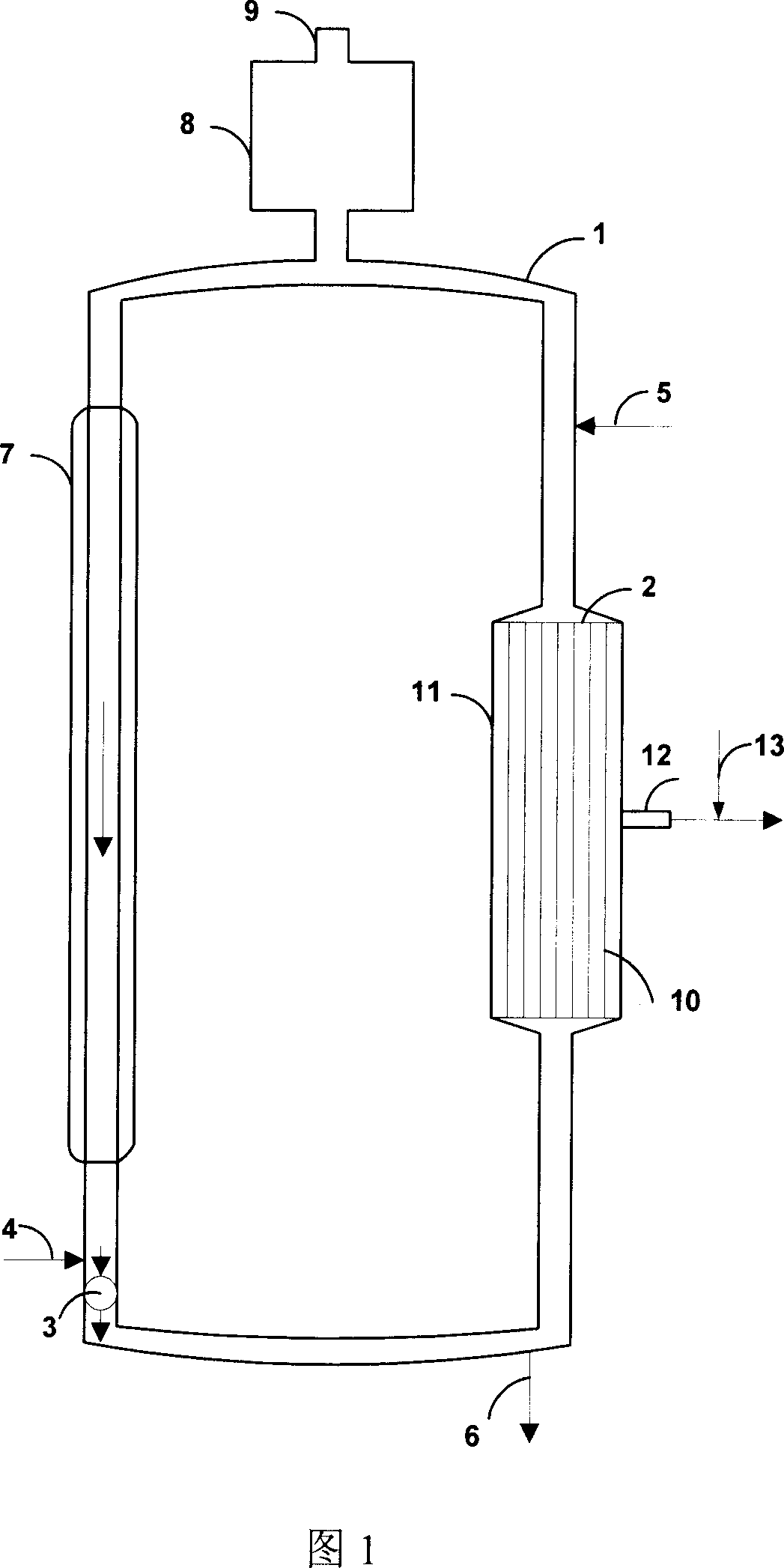

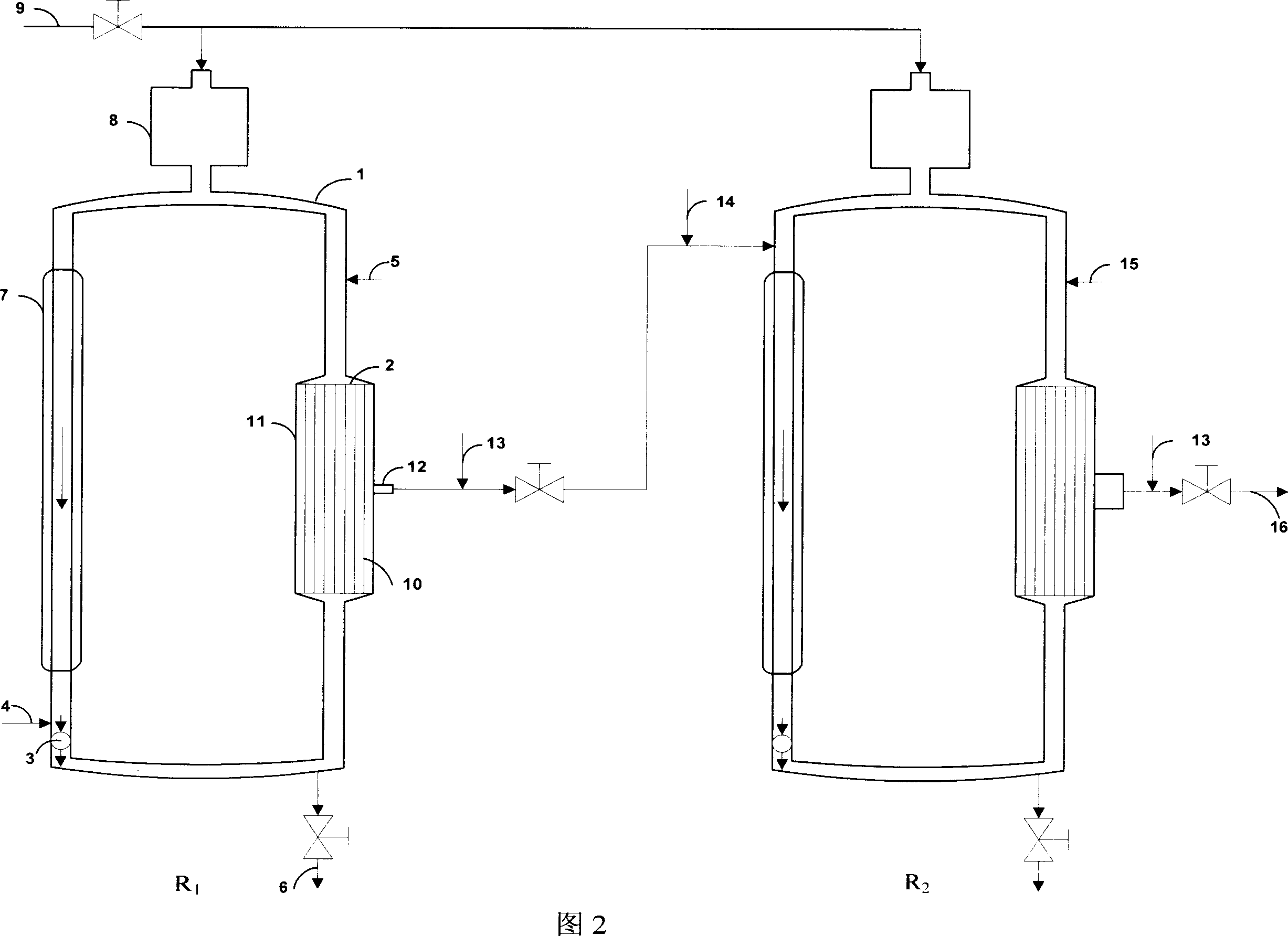

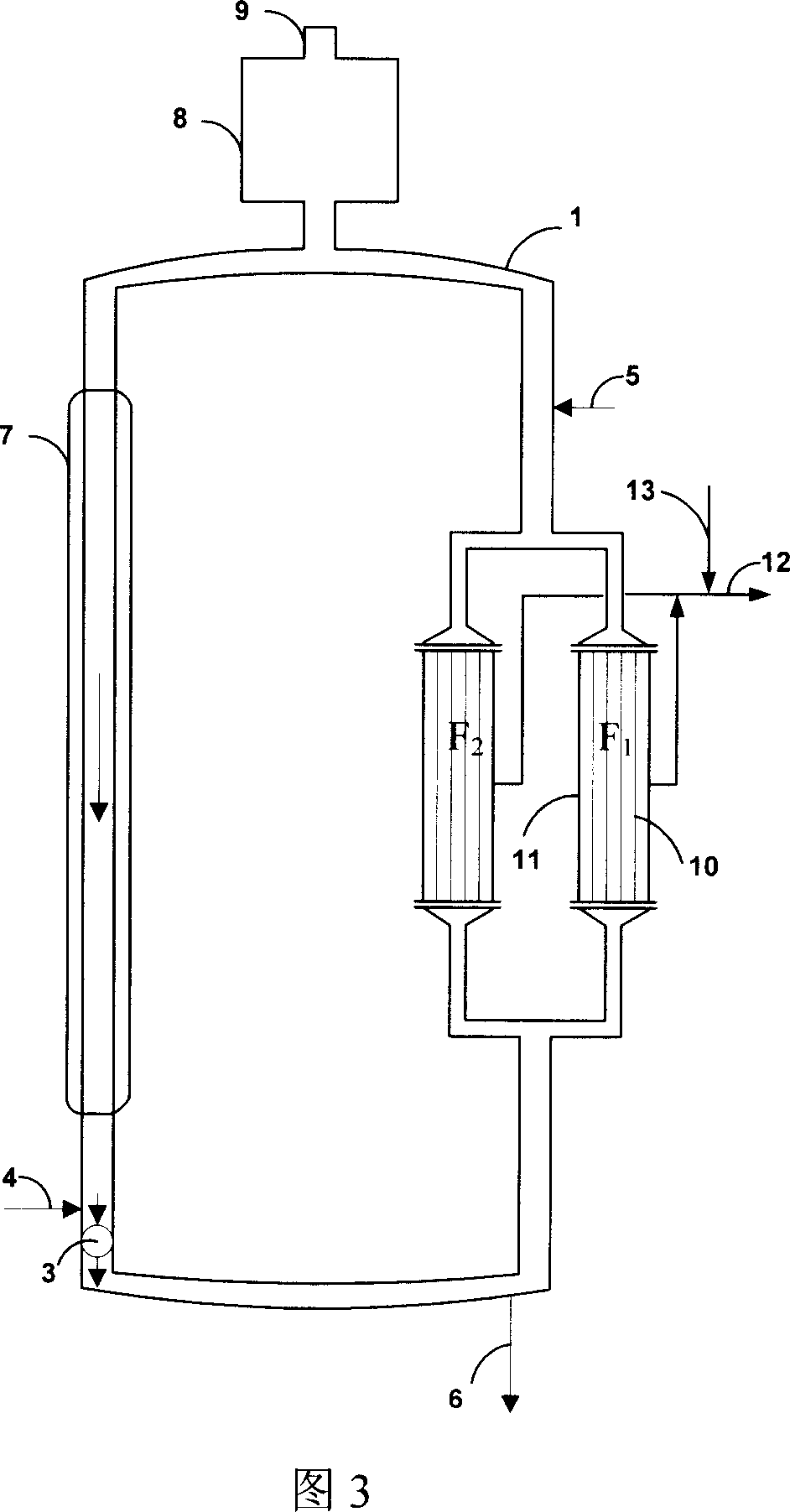

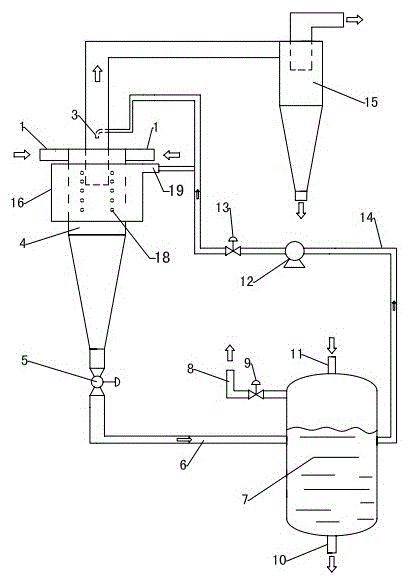

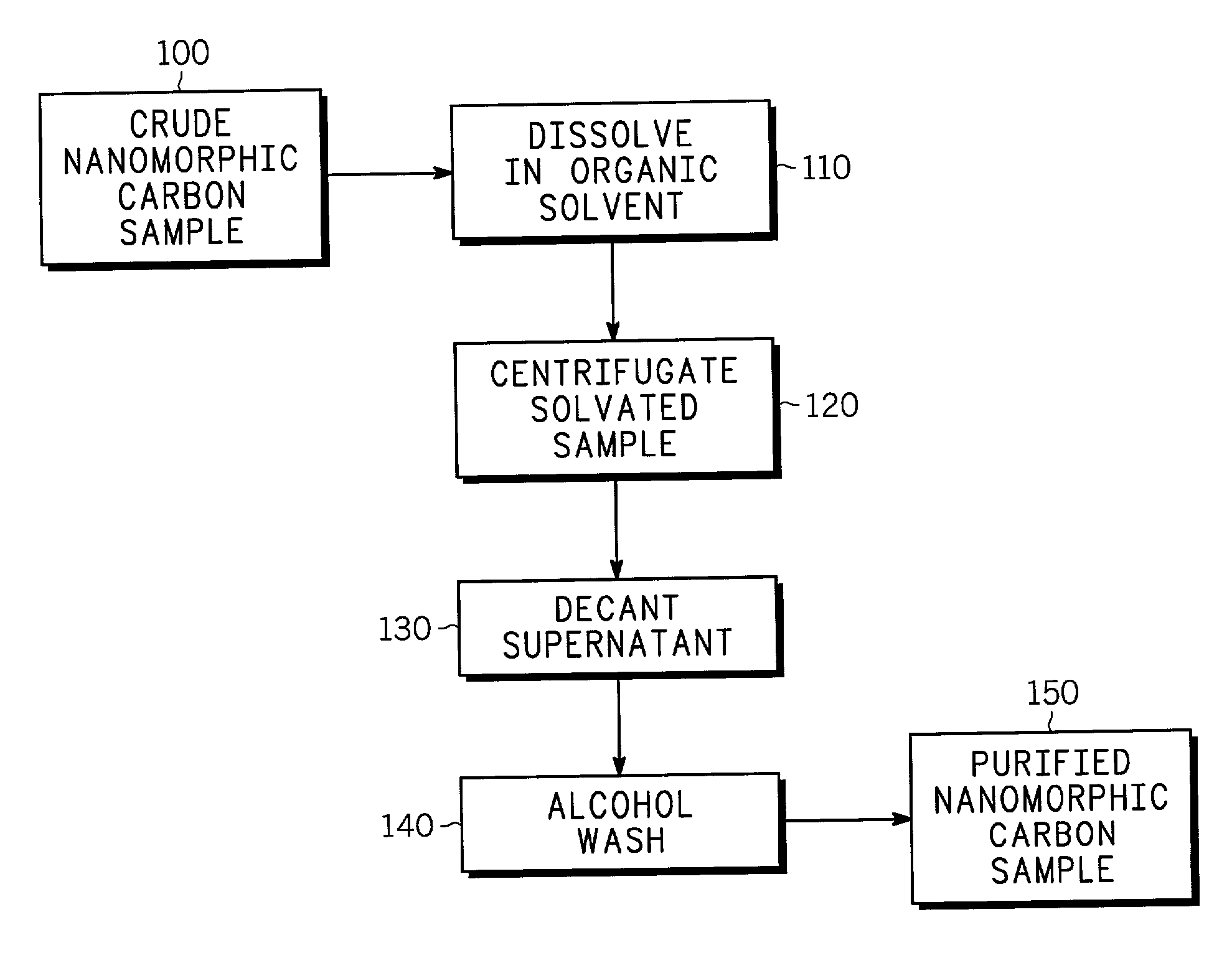

Integrated reacting and separating device

ActiveCN101116804AWell mixedImprove heat transfer effectPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesUltrafiltrationEngineeringReaction system

The present invention provides an integral reaction-separation equipment, mainly comprising a ring pipe and a separation component, wherein a circular reaction circuit is formed by the ring pipe and the separation component. The equipment is compact in structure, integrates catalytic reaction with catalyst separation and material heat transfer, especially can guarantee the high efficiency separation and the recycling use of fine particles such as nanometer or micron catalyst with reacting materials, and has good material mixing and heat transferring effects, which is suitable for strong heat absorbing or releasing solid-liquid, solid-liquid-liquid and partial gas-liquid-solid multiphase reaction system.

Owner:CHINA PETROLEUM & CHEM CORP +1

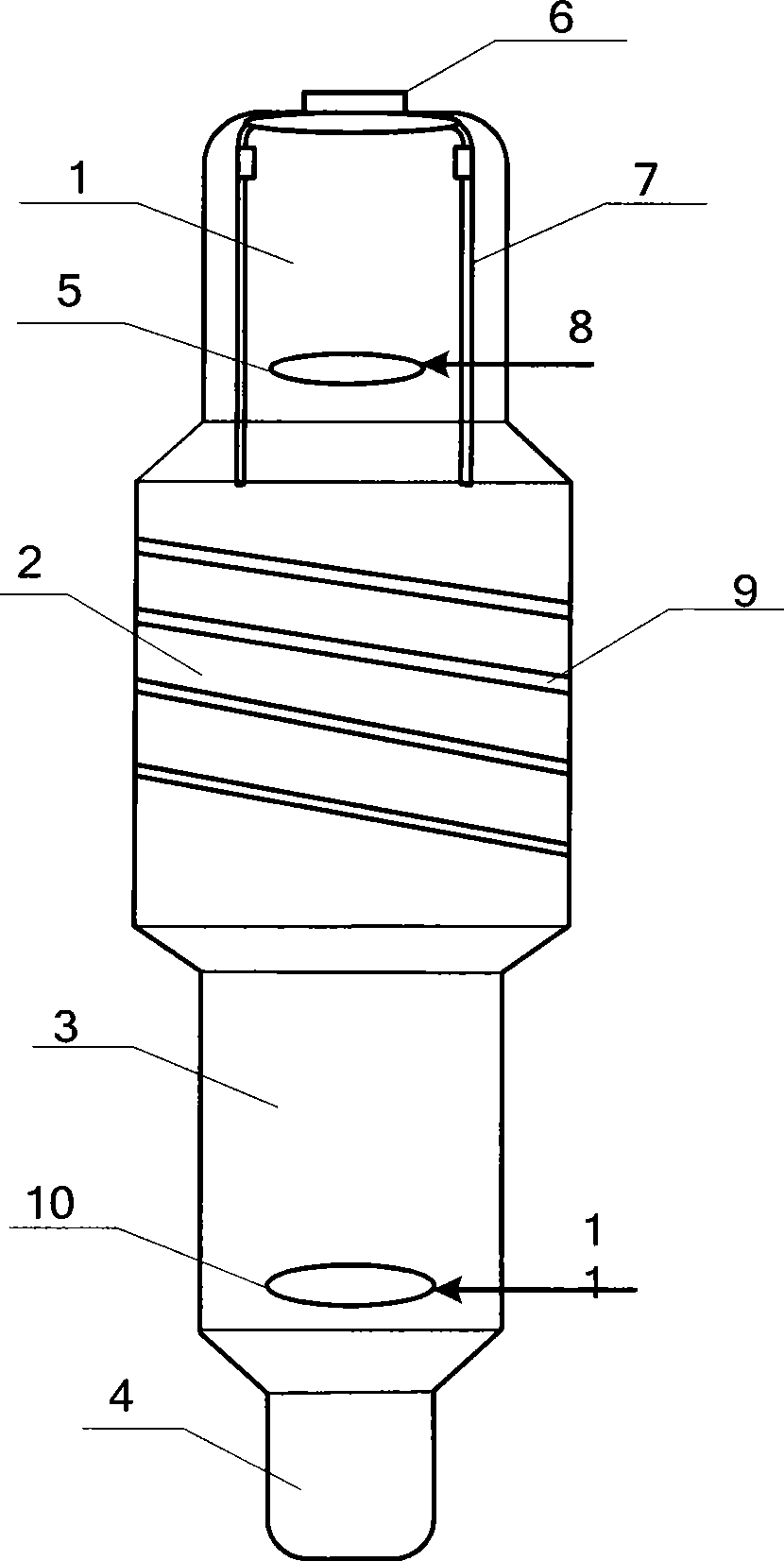

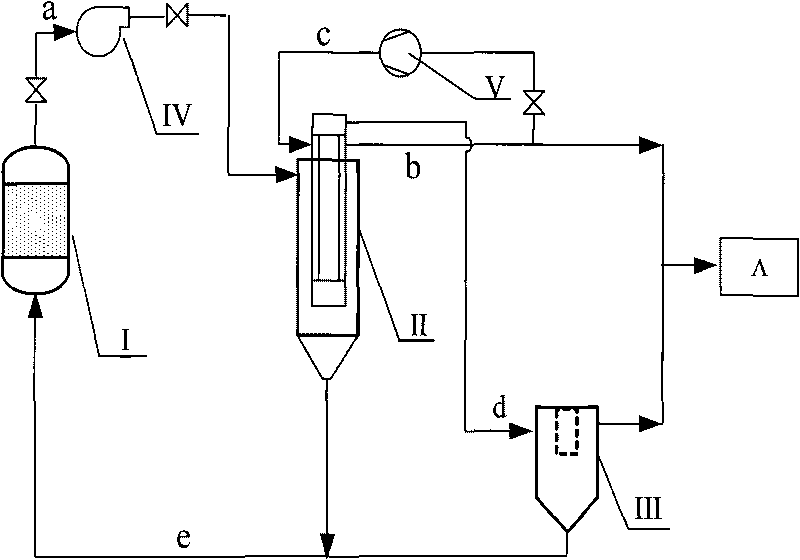

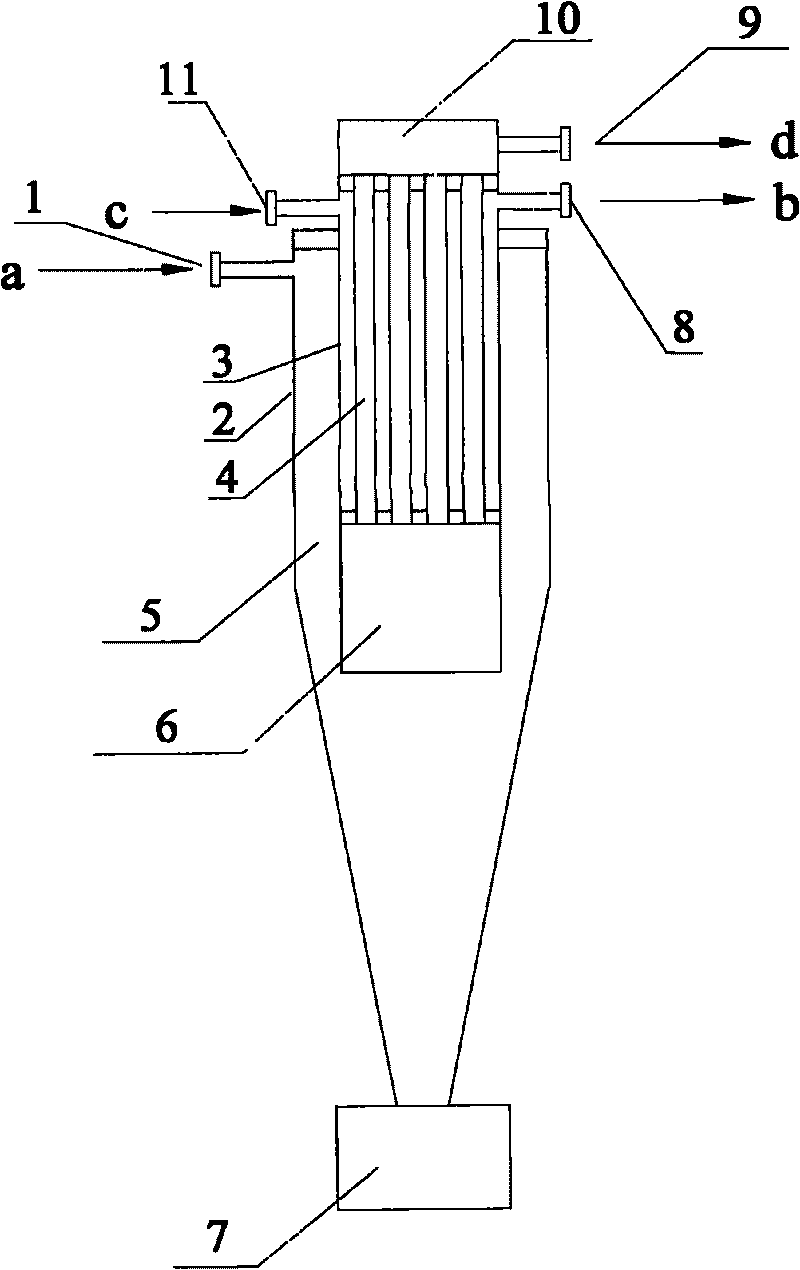

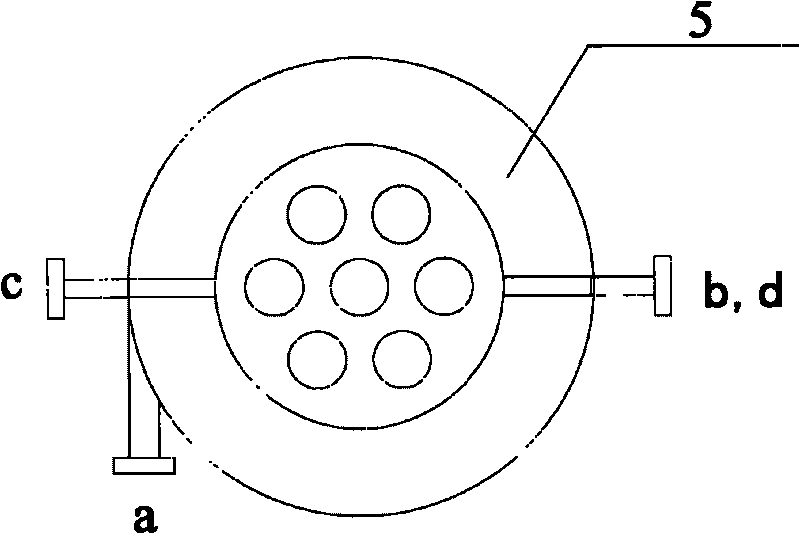

Gas-solid phase reaction separation system and separation method thereof

ActiveCN101757827AAvoid pollutionEfficient removalCombination devicesDispersed particle filtrationReactive separationCross-flow filtration

The invention relates to a gas-solid phase reaction separation system and a separation method thereof. The separation method comprises the following steps that: high-temperature flue gas (a) enters an inorganic membrane cross flow filter (II), airflow makes the circular rotation movement from the upper part to the lower part along a rotation channel (5) in a filter (II), partial particles in the airflow are thrown to the filter wall by inertial centrifugal force and collected in a dust collecting chamber (7) at the bottom of the filter, and the gas enters a membrane component (3) from the bottom to the upper part along a central exhaust passage (6) and is subjected to gas-solid separation through the sieving action of an inorganic membrane; the purified clean gas (b) enters an after-treatment (A) section; concentrated dust gas (d) intercepted by the inorganic membrane filter enters a bag-type filter (III) for collecting solid dust; the gas permeating the cloth bag filter enters the after-treatment (A) section; and the dust (e) intercepted by the inorganic membrane filter (II) and the bag-type filter (III) returns to a reactor (I) to take part in reaction.

Owner:NANJING UNIV OF TECH

Thermal chemical sulfur-iodine circulating hydrogen production full-process method and device

ActiveCN114195094AWell mixedPrevent precipitationHydrogen productionReactive separationPhysical chemistry

The invention discloses a thermochemical sulfur-iodine circulating hydrogen production whole-process method and device. According to the invention, a Bunsen reaction section is coupled with an HIx and H2SO4 two-phase separation section, and an HIx purification section is coupled with a concentration section. High-temperature mixed gas of the H2SO4 decomposition tower is directly introduced into the H2SO4 concentration tower, and a large amount of water in the H2SO4 solution is quickly vaporized under the condition of no external heat source, so that the purpose of concentrating the H2SO4 solution is achieved; the high-temperature mixed gas continues to enter a downstream HIx purification and concentration tower, a large amount of water in an HIx system is vaporized and taken away, and the purpose of concentrating the HI solution is achieved. H2SO4 mingled in an HIx system is converted into SO2 in an oxygen-enriched environment and is taken away, so that the purpose of purifying the HI solution is achieved. After hydrogen in the condensing tower is separated, the residual iodine-containing liquid is recycled and returns to the Bunsen reaction separation tower, and the investment and the energy consumption can be reduced by more than 40% compared with the traditional sulfur-iodine hydrogen preparation method.

Owner:浙江百能科技有限公司

Method of producing lower alcohols from glycerol

InactiveUS20100019192A1High yieldHigh selectivityOxygen-containing compound preparationOrganic compound preparationAlcoholBoiling point

A reactive-separation process converts glycerin into lower alcohols, having boiling points less than 2000 C, at high yields. Conversion of natural glycerin to propylene glycol through an acetol intermediate is achieved at temperatures from 150° to 2500 C at pressures from 1 and 25 bar. The preferred applications of the propylene glycol are as an antifreeze, deicing compound, or anti-icing compound. The preferred catalyst for this process in a copper-chromium.

Owner:UNIVERSITY OF MISSOURI +1

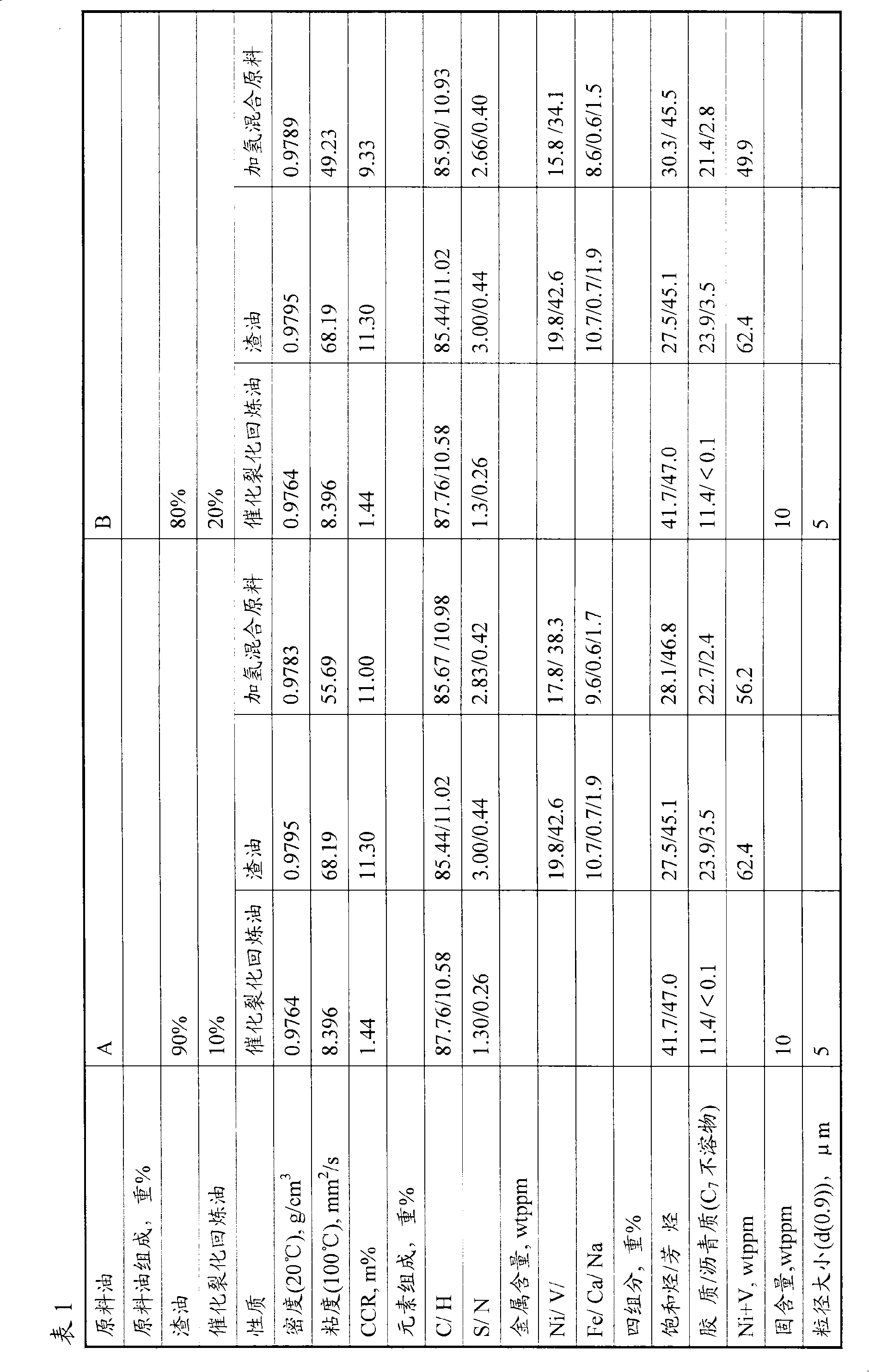

Improved hydrotreatment and catalytic cracking combination method for hydrocarbon oil

ActiveCN101538481AEnhanced dissociationImprove efficiencyTreatment with hydrotreatment processesCycle oilChemistry

The invention discloses an improved hydrotreatment and catalytic cracking combination method for hydrocarbon oil, which comprises the following steps that: under reaction conditions of the presence of hydrogen and the hydrotreatment, the contact reaction of residual oil, catalytic cracking cycle oil, optional distillate oil and a hydrotreating catalyst is performed, and gas, hydrogenerated naphtha, hydrogenerated diesel oil and hydrogenerated tail oil are obtained after a reaction product is separated; under catalytic cracking reaction conditions, the contact reaction of the optional conventional catalytic cracking raw oil, the hydrogenerated tail oil and a catalytic cracking catalyst is performed, and dry gas, liquefied gas, catalytic cracking gasoline, catalytic cracking diesel oil and catalytic cracking cycle oil are obtained after a reaction product is separated; and the conventional catalytic cracking raw oil is light or heavy distillate oil, and the contact reaction with the catalytic cracking catalyst is that the heavy raw oil and light raw oil are optionally and orderly performed along with the hydrogenerated tail oil in a reactor comprising at least two reaction regions (I and II) along the flowing direction of reaction materials respectively. The method is suitable for hydrocarbon oil conversion to produce more gasoline and diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

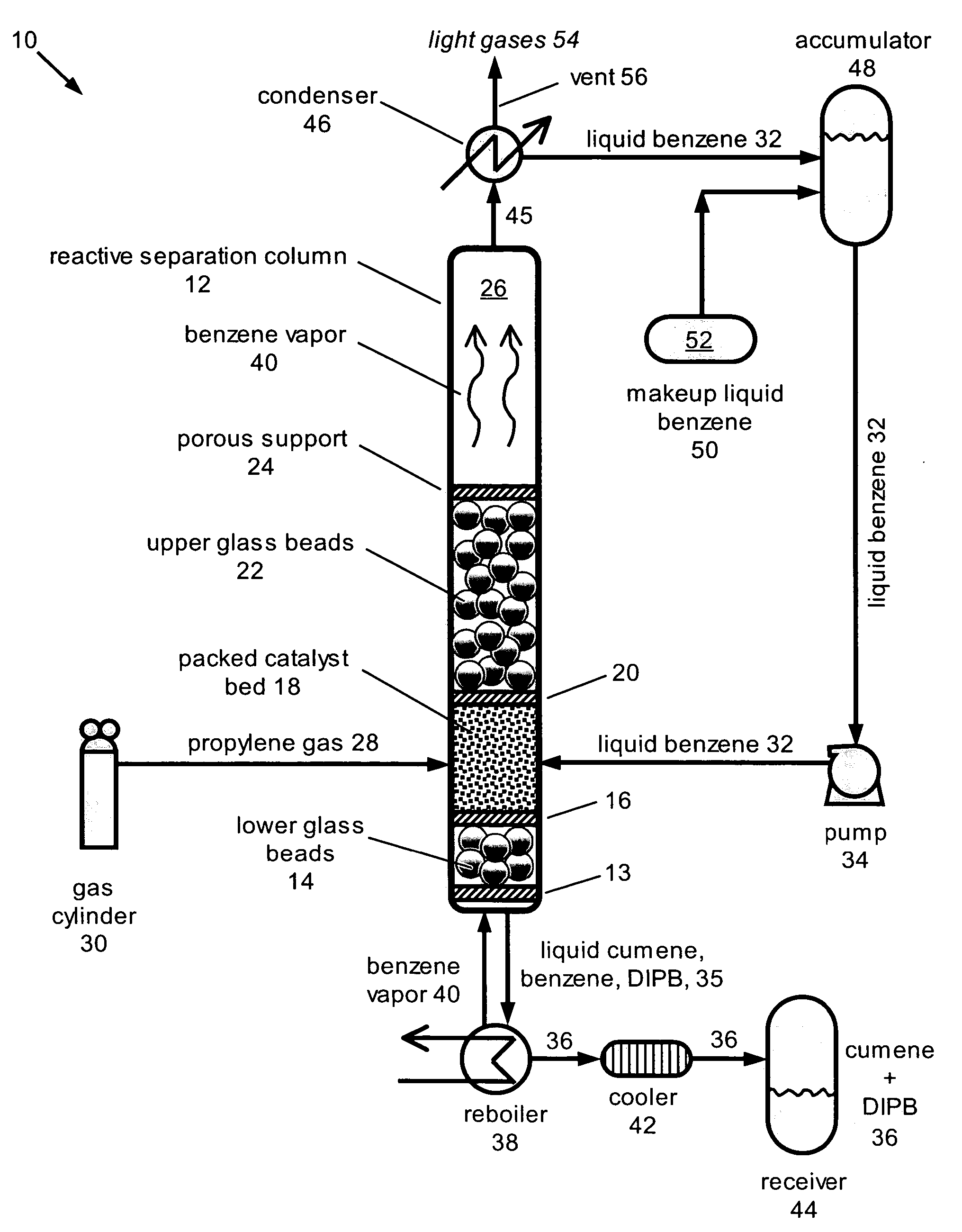

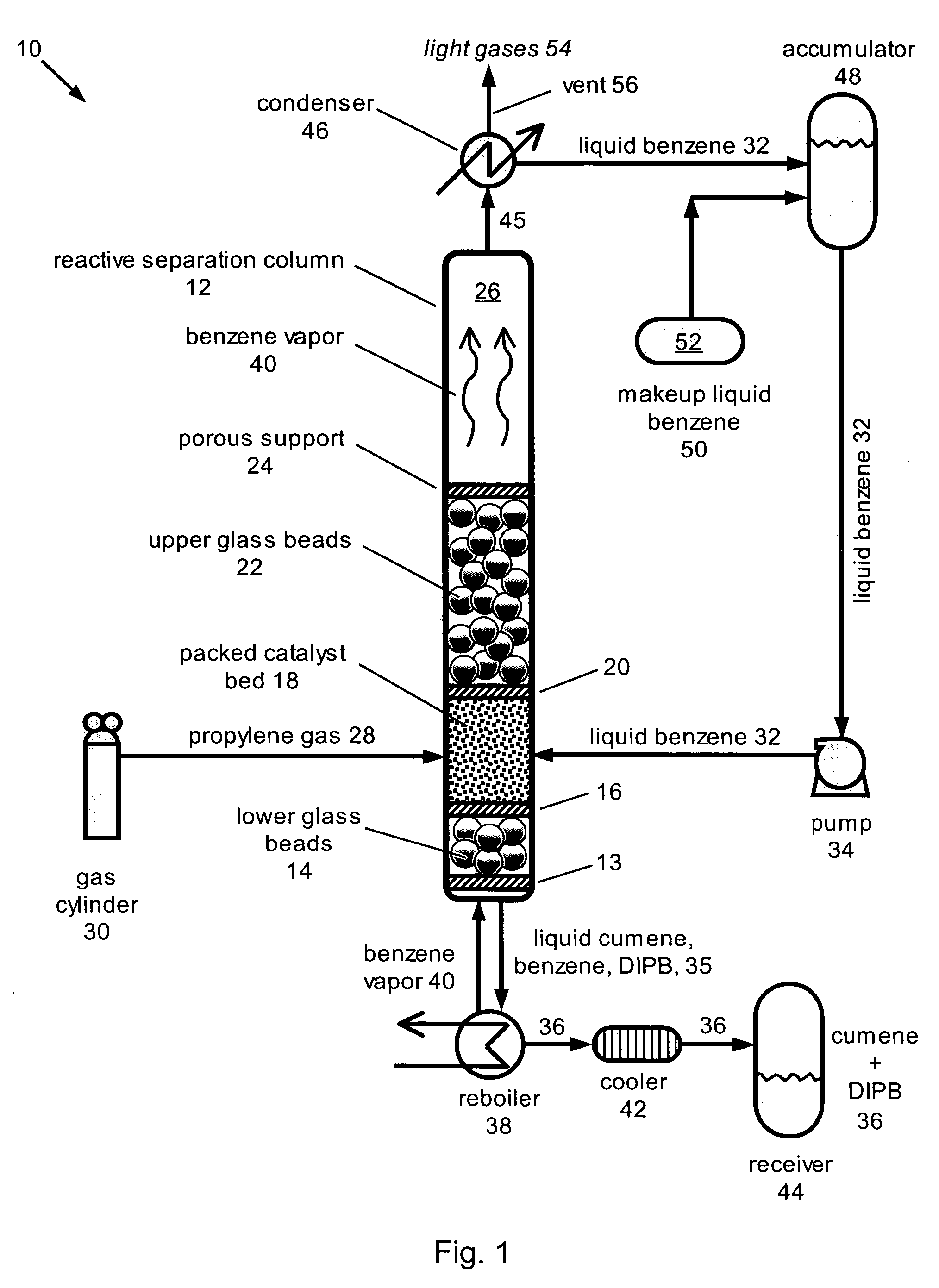

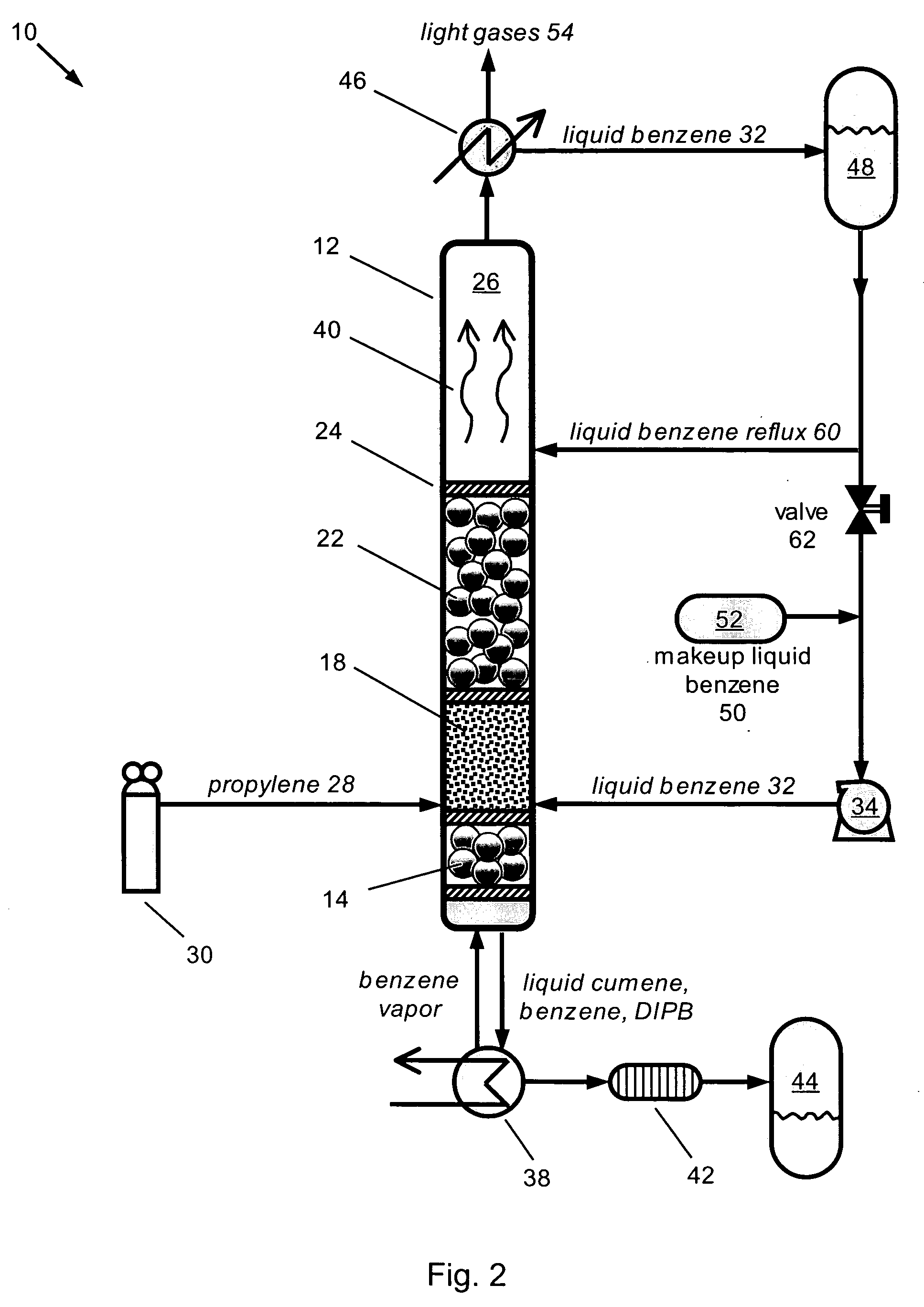

Catalytic reactive separation system for energy-efficient production of cumene

InactiveUS20060281958A1Reduce needPhysical/chemical process catalystsIndirect heat exchangersReactive separationChemistry

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

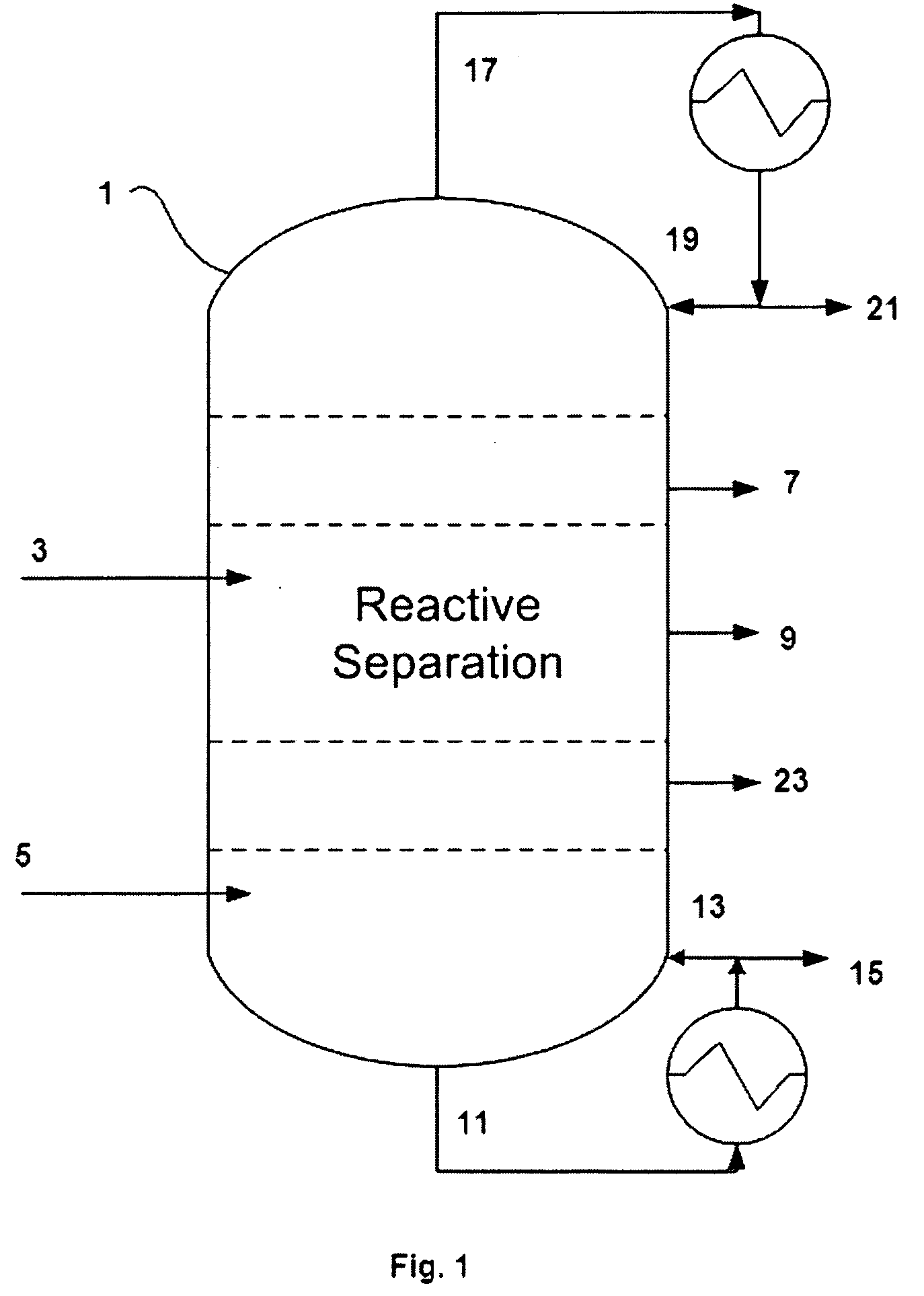

Reactive Separation To Upgrade Bioprocess Intermediates To Higher Value Liquid Fuels or Chemicals

InactiveUS20090182064A1Reduce resource utilizationImproves energy paybackOrganic compound preparationChemical industryUnit operationReactive separation

The process and system of the embodiments utilize a reactive separation unit to upgrade a bioprocess intermediate stream to higher value liquid fuels or chemicals. The reactive separation unit simultaneously enables molecular weight and density increases, oxygen content reduction, efficient process energy integration, optional water separation for potential reuse, and incorporation of additional hydrocarbons or oxygenated hydrocarbons as co-feed(s). The use and selection of particular co-feed(s) for this purpose enables tailoring of the intended product composition. The process and system yields a product of higher alcohols, liquid hydrocarbons, or a combination of these. These can be split into two (or more) boiling point fractions by the same reactive separations unit operation resulting in product(s) that can be used as chemicals, chemical intermediates, or alternative (non-fossil-based) liquid transportation fuels.

Owner:LOGOS TECH

Integrated spiral-flow reaction and separation system and process for sulfur containing gas desulfuration

ActiveCN105107356ASimplify structural complexityIncrease mass transfer rateDispersed particle separationRelative VolumeLiquid storage tank

An integrated spiral-flow reaction and separation system and process for sulfur containing gas desulfuration and belongs to the field of a gas desulfuration purifcation process. The system comprises a spiral-flow reactor (4) which is characterized in that the lower part of the spiral-flow reactor (4) is connected with one side of an amine liquid storage tank (7) through a liquid-enriching and liquid-draining pipeline (6) while the other side of the liquid storage tank (7) is connected with the liquid inlet end in the upper part of the spiral-flow reactor (4) through an absorption liquid circulating pipeline (14); the upper part of the spiral-flow reactor (4) is connected with a gas-liquid spiral-flow separator (15) through an exhaust device. The system provided by the invention integrates gas-liquid mixing, reaction and separation and solves the problem that a conventional desulfurizing absorption tower is large in occupied space and great in overall pressure drop. The overall height of the spiral-flow reactor does not exceed 8m. Compared to the height which is tens of meters of a platy tower and a filler tower, the space occupied by the device and the initial investment of the device are extremely saved. The spiral-flow reactor is strong in internal adaptability, agile to operate and free of moving parts. The system is hard to malfunction, relatively small in relative volume and convenient to overhaul.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

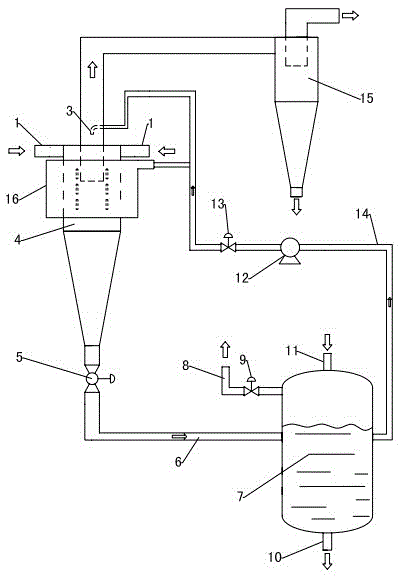

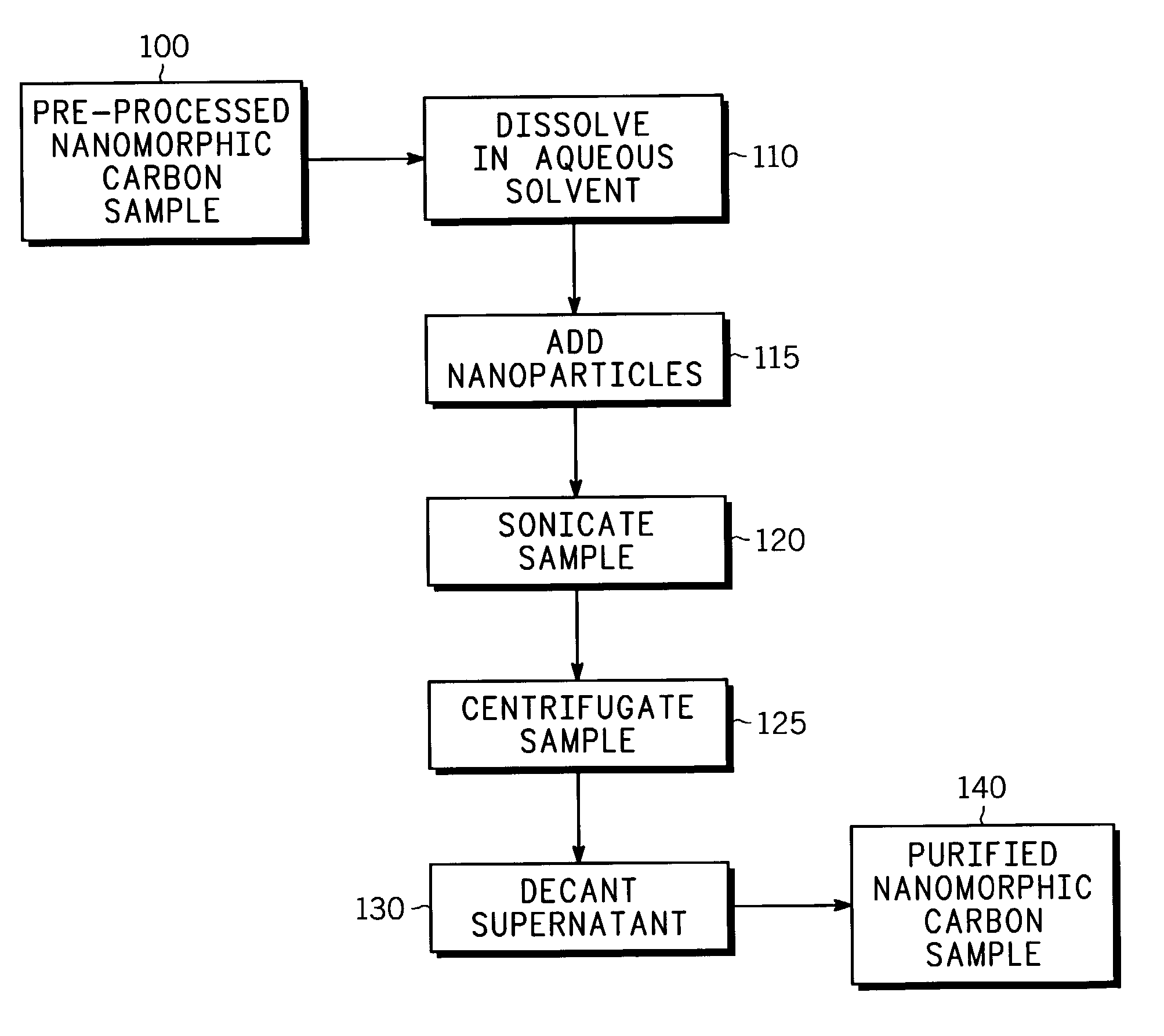

Method for non-reactive separation of nanomorphic carbon species

An exemplary method for substantially non-chemically-reactive separation of nanomorphic carbon species (150) comprises inter alia the steps of dissolving a crude nanomorphic carbon sample (100) in an organic solvent (110), centrifugation of the solvated sample (120) and decantation of the resulting supernatant (130). Disclosed features and specifications may be variously controlled, adapted or otherwise optionally modified to improve carbon nanospecies purification. An exemplary embodiment of the present invention representatively provides for non-oxidative cleaning of carbon nanotubes.

Owner:MOTOROLA INC

Catalytic conversion method for production of propylene

ActiveCN104557395AHigh selectivityHigh yieldTreatment with plural serial stages onlyHydrocarbon from oxygen organic compoundsCatalytic transformationPtru catalyst

A catalytic conversion method for production of propylene, a petroleum hydrocarbon raw material and methanol are respectively contacted with a catalytic cracking catalyst in a petroleum hydrocarbon catalytic cracking reaction zone and a micropore modified catalytic cracking catalyst in a methanol catalytic conversion reaction zone to react, and separation is then carried out to obtain a propylene-rich product. a coked catalyst undergoes steam stripping and regeneration and then is divided into two parts: one part is directly sent into the catalytic cracking reaction zone to be recycled; and the other part is firstly sent into a catalyst micropore modification zone to be contacted with and react with a modifier, and then the other part is sent into the methanol catalytic conversion reaction zone to be recycled. By micropore modification of a catalyst, the catalytic cracking catalyst containing double active components macroporous zeolite and mesoporous zeolite has high heavy oil conversion ability and high propylene selectivity for catalytic cracking of a petroleum hydrocarbon raw material and also has high propylene selectivity for methanol catalytic conversion.

Owner:CHINA PETROLEUM & CHEM CORP +1

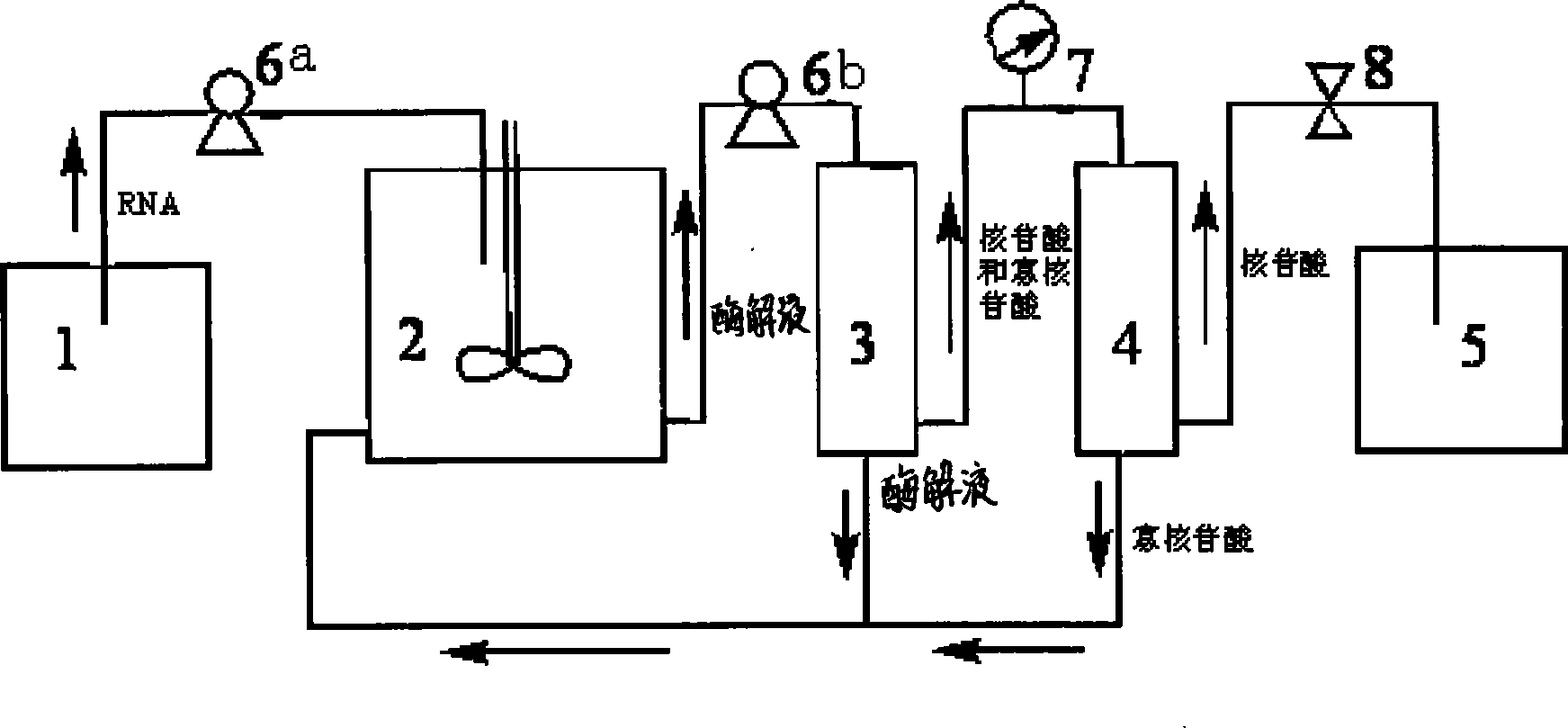

Method for preparing nucleotide by reaction separation coupling technology

The invention discloses a method for preparing nucleotide by utilizing a reaction separation coupling technique, namely the nucleotide is prepared by using nuclease P1 for enzymatic hydrolysis of ribonucleic acid and the reaction separation coupling technique combining an enzymatic hydrolysis reactor, an ultrafiltration device and a nanofiltration device. The method utilizes the ultrafiltration device to separate an enzymatic hydrolysis product from an RNA phase, overcomes the product inhibiting effect in the production of the nucleotide, improves the enzymatic hydrolysis rate of the RNA and the concentration of the nucleotide, simultaneously utilizes the nanofiltration technique to recover the oligonucleotide lost in the ultrafiltration process, and further improves the enzymatic hydrolysis rate of the RNA. The method has the advantages of realizing the continuous separation production of products, shortening the process flow, breaking through the limitation of chemical balance, greatly improving the utilization ratio and the reaction yield of the enzyme, lowering energy consumption, and reducing production cost.

Owner:NANJING UNIV OF TECH +1

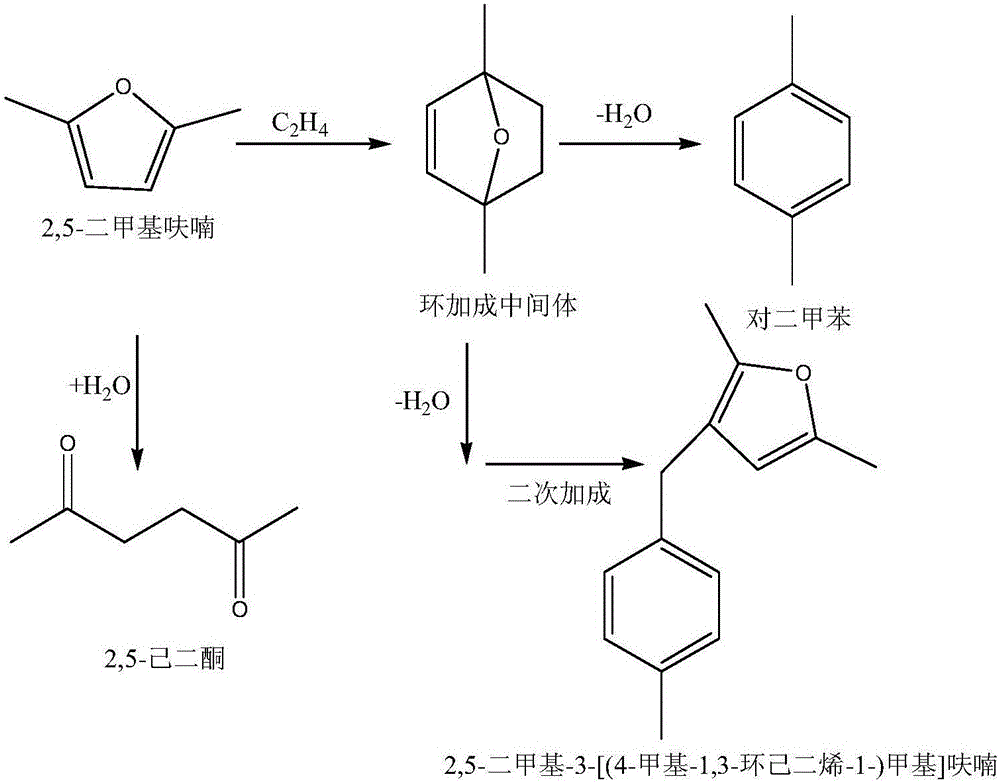

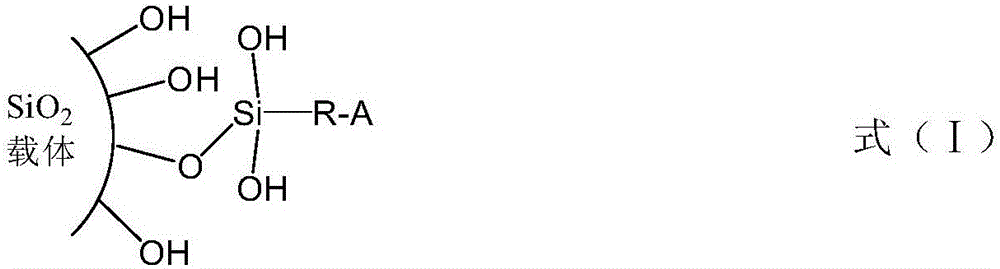

Solid acid catalyst for preparing bio-based para-xylene as well as preparation and application thereof

InactiveCN105903489AHas a non-microporous structureHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsFuranPtru catalyst

The invention relates to a solid acid catalyst for preparing bio-based para-xylene (PX) as well as preparation and application thereof. A novel solid catalyst with a mesoporous structure is prepared by carrying out acid modification on the surface of a silicon dioxide material. The catalyst has proper acidity and is used for the reaction for catalyzing addition of 2,5-dimethyl furan and ethylene and dehydrating to prepare the PX; the coupling of reaction-separation in a PX preparation process is realized and a novel method for highly selectively preparing the bio-based PX is provided; and in a reaction process, excellent catalytic activity, selectivity and stability are represented and a firm foundation is laid for industrial production of the bio-based PX.

Owner:BEIJING UNIV OF CHEM TECH

Method for cleaning nanomorphic carbon species

An exemplary method for substantially non-chemically-reactive separation of nanomorphic carbon species (140) comprises inter alia the steps of suspending a nanomorphic carbon sample (100) in an aqueous surfactant suspension (110), adding nanoparticles to the sample suspension (115), sonicating the sample (120), centrifugating the sample suspension (125) and decanting off the resulting supernatant (130). Disclosed features and specifications may be variously controlled, adapted or otherwise optionally modified to improve carbon nanospecies purification. An exemplary embodiment of the present invention representatively provides for non-oxidative cleaning of carbon nanotubes via at least partial removal of amorphous carbon contaminants.

Owner:MOTOROLA INC

Alkylation product separation method, alkylation reaction separation method and alkylation reaction separation device

ActiveCN110876855AIncrease temperatureTo achieve the purpose of saving energy and reducing consumptionHydrocarbon distillationChemical industryAlkaneFluid phase

The invention discloses an alkylation product separation method. According to the method, a liquid-phase alkylation product is pressurized by an optional booster pump; the pressurized liquid-phase alkylation product is introduced into a first heat exchanger, and is subjected to heat exchange with a gas-phase material from a high-pressure fractionating tower; the heat exchanged material is furtherheated to 100-180 DEG C in a second heat exchanger; the heated material enters the high-pressure fractionating tower, and is fractionated under a condition of 2.0-6.0 MPa; the gas-phase material at the top of the high-pressure fractionating tower is subjected to heat exchange with the liquid-phase alkylation product; the liquid-phase material at the bottom of the high-pressure fractionating towerenters a low-pressure fractionating tower and is fractionated under a condition of 0.2-1.0 MPa; low-carbon alkane is obtained at the top of the low-pressure fractionating tower, and an alkylation oilproduct is obtained at the bottom of the low-pressure fractionating tower; and the low-pressure fractionating tower is provided with an intermediate reboiler, and the gas-phase material at the top ofthe high-pressure fractionating tower after heat exchange of the first heat exchanger is used as a heat source of the intermediate reboiler. The method provided by the invention can improve the heat utilization efficiency and reduce the separation operation energy consumption in the alkylation process.

Owner:CHINA PETROLEUM & CHEM CORP +1

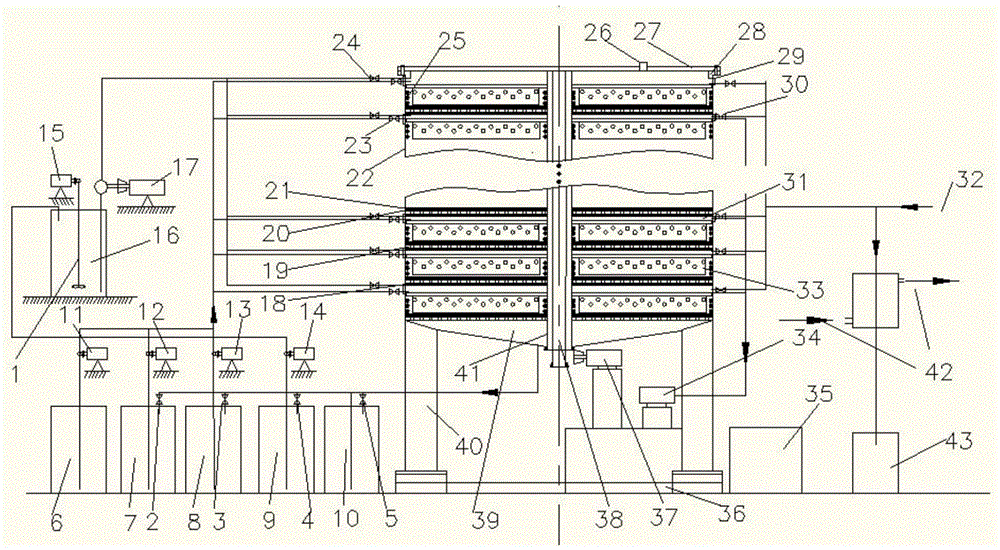

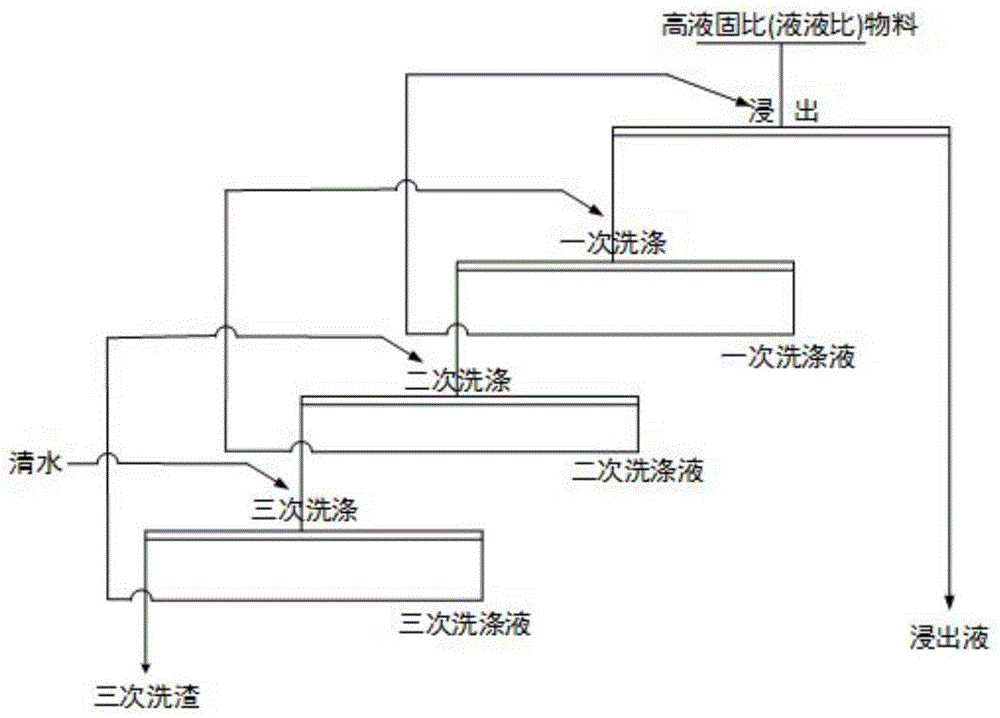

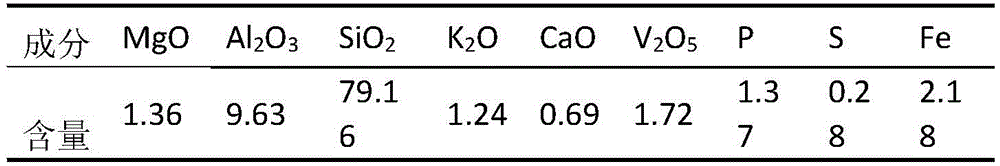

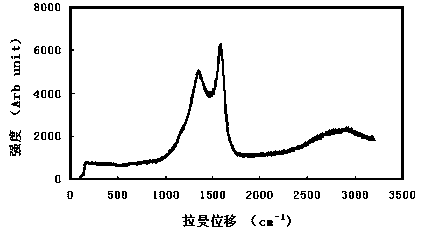

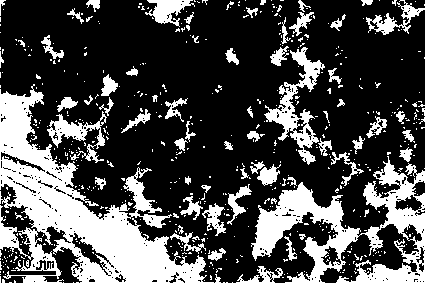

Reaction, separation, washing, evaporation and drying integrated device and method

InactiveCN105483372AAdaptableEasy to operateProcess efficiency improvementEnvironmental resistanceHigh concentration

The invention provides a reaction, separation, washing, evaporation and drying integrated device and method and belongs to the field of hydrometallurgy and the chemical industry. The device is mainly composed of unit partition chambers and accessory equipment. The partition chambers are connected through partition plates with holes, and according to different process combinations of the leaching reaction process, the separation and washing process, the crystallization and drying process and the like and different treatment objects, specific filtering films are selected and used for the partition plates with the holes, and upper sealing rings and lower sealing rings are arranged to seal the partition chambers. According to the different treatment objects, certain process procedures of the leaching reaction process, the separation and washing process and the crystallization and drying process are finished continuously in the partition chambers. By the adoption of the high-diameter high-ratio independent partition chamber space, control over the pressure, the temperature, the stirring speed and other reaction conditions is facilitated; and by the adoption of stirring scrapper devices with holes, the high-solid-liquid-ratio solid-liquid phase reaction and the high-concentration liquid phase reaction are easy to accelerate, and the mass transfer rate is increased. By the adoption of the method, adaptability to the procedures and treatment capacity is high, energy, water and chemicals can be used in a cyclic manner, cleanness and environment friendliness are achieved, and operation is convenient.

Owner:UNIV OF SCI & TECH BEIJING

Novel integrated solid acid catalyst with carbon-based structure as well as preparation of integrated solid acid catalyst and application in preparation of biodiesel

InactiveCN103316695ALess acid lossImprove thermal stabilityPhysical/chemical process catalystsFatty acid esterificationBiodieselPtru catalyst

The invention discloses a novel integrated solid acid catalyst with a carbon-based structure. The novel integrated solid acid catalyst is a sulfonating carbon nano tube (CNT-SO3H@) stainless steel material and is prepared by using the stainless steel material as a support material, growing a carbon nano tube on the surface of the support material, vulcanizing through polysulfide and oxidizing. The invention simultaneously discloses a preparation method of the novel catalyst and an application in preparation of biodiesel by means of catalytic distillation. The loss of an acid position of the solid acid catalyst with the carbon-based structure is reduced; because of high heat stability and structure stability, the catalyst is easily made into various shapes and is filled into a catalytic distillation tower to be used. An original element having functions of catalyzing and separating is used for coupling a reaction process with a separation process, and because of the process, the complicated processes of pre-esterification, purification and subsequent separation are avoided; meanwhile, a glycerinum product which is used for catalyzing waste oil and methyl alcohol ester to perform exchange reaction is converted into products of glyceraldehydes, glyceric acid, hexanal dimethyl acetal, acraldehyde dimethyl acetal and the like, so that the reaction is greatly intensified; finally, a biodiesel product with high purity can be directly obtained on the top of the tower and at the bottom of the tower.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com