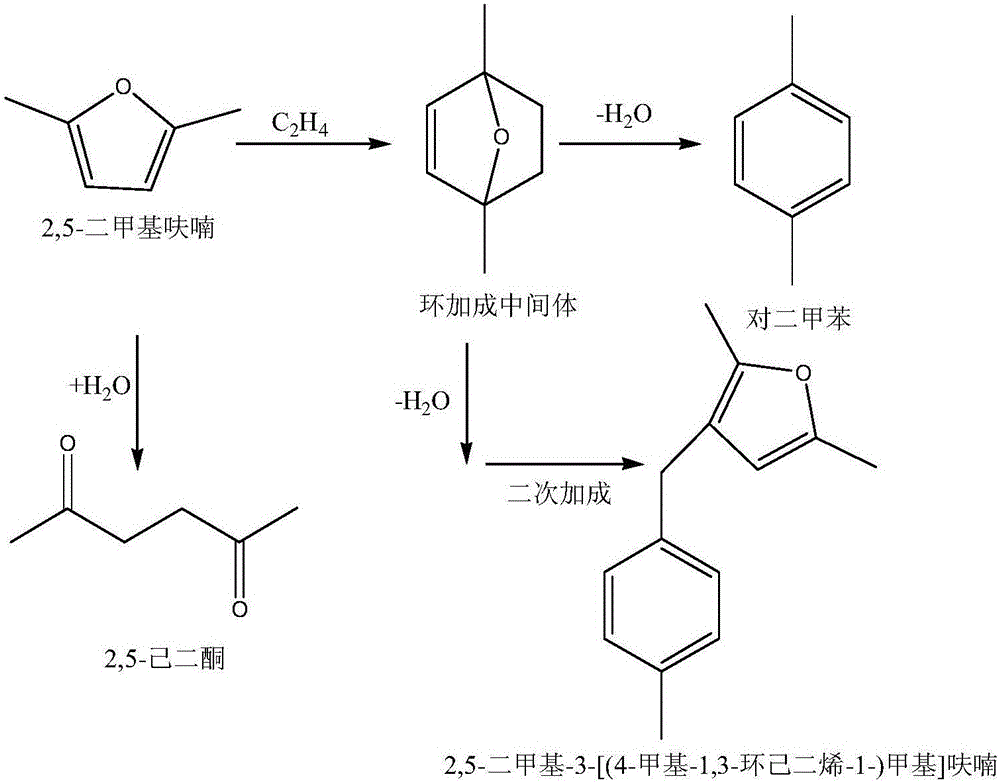

Solid acid catalyst for preparing bio-based para-xylene as well as preparation and application thereof

A solid acid catalyst and p-xylene technology, which is applied in the direction of carbon compound catalysts, physical/chemical process catalysts, catalysts, etc., can solve the problems of many by-products, serious hydrolysis, and poor selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

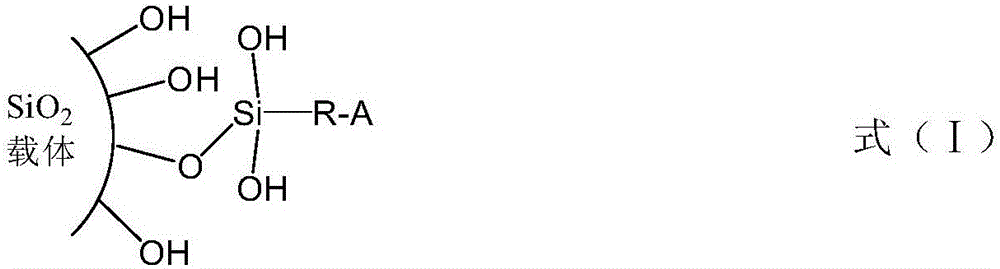

[0040] The preparation method of the above-mentioned solid acid catalyst involved in the second aspect of the present invention includes:

[0041] Step L: Disperse the silica material in an acid solution to make a silica acid suspension

[0042] Step M, adding hydrogen peroxide and 3-mercaptopropyltrimethoxysilane (MPTMS) to the acidic silica suspension, mixing and reacting to obtain a catalyst precursor solution;

[0043] In step N, the catalyst precursor solution is heat-treated, and then the solid powder is filtered out, washed with water and ethanol one or more times, and dried to obtain a powdery solid acid catalyst.

[0044] In the above preparation method of the present invention, the weight content of silica in the acidic silica suspension is 0.1% to 5%.

[0045] In the present invention, the acidic solution is an aqueous acid solution, wherein the acid includes hydrochloric acid, sulfuric acid, and phosphoric acid. In some embodiments of the present invention, the concentratio...

Embodiment 1

[0076] (1) Disperse 0.1g of silica material into 100g of acidic solution to prepare a silica acid suspension with a concentration of 0.1%;

[0077] (2) Add 0.4g 30% hydrogen peroxide and 0.163g MPTMS to the acidic silica suspension, mix and react for 2h to obtain a catalyst precursor solution;

[0078] (3) Transfer the catalyst precursor solution into a hydrothermal reactor, heat treatment at 100°C for 0.5 h, filter out the solid powder, wash it with water and ethanol several times, and dry to obtain a powdered solid catalyst.

[0079] (4) Add 0.1g of the above solid catalyst, 1.0g 2,5-dimethylfuran, 30mL n-heptane, 0.43g internal standard n-decane into a 50mL reactor, fill with 1.5MPa ethylene, and react at 250℃ 6h, PX was prepared. According to formulas (III) and (IV), the measurement and calculation show that the conversion rate of 2,5-dimethylfuran is 60%, and the PX selectivity is 63%.

Embodiment 2

[0081] (1) Disperse 0.4g of silica material into 100g of acidic solution to prepare a silica acid suspension with a concentration of 0.4%;

[0082] (2) Add 0.4g 30% hydrogen peroxide and 0.2g MPTMS to the acidic silica suspension, mix and react for 4 hours to prepare a catalyst precursor solution;

[0083] (3) Transfer the catalyst precursor solution to a hydrothermal reactor, heat treatment at 100°C for 5 hours, filter out the solid powder, wash it with water and ethanol several times, and dry to obtain a powdered solid catalyst.

[0084] (4) Add 0.2g of the above solid catalyst, 1.0g of 2,5-dimethylfuran, 30mL of n-heptane, 0.43g of n-decane into a 50mL reactor, fill with 1.5MPa ethylene, and react at 250°C for 6 hours to prepare Get PX. According to formula (III) and (IV), the measurement and calculation show that the conversion rate of 2,5-dimethylfuran is 70%, and the PX selectivity is 81%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com