Technique for using methylbenzene to prepare benzaldehyde and benzene methanol by multistage oxidation and equipment

A technology for oxidizing toluene and benzaldehyde, which is applied in the preparation of oxidation reaction, the preparation of oxygenated compounds by oxidation of hydrocarbons, and the preparation of carbon-based compounds. It can solve complex operations, poor product purity, and unsatisfactory conversion rates of toluene and substituted toluene. problem, to achieve the effect of increasing conversion rate and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The reaction equipment consists of 6 reactors with stirring and air distributors and 2 fractionation towers connected in series.

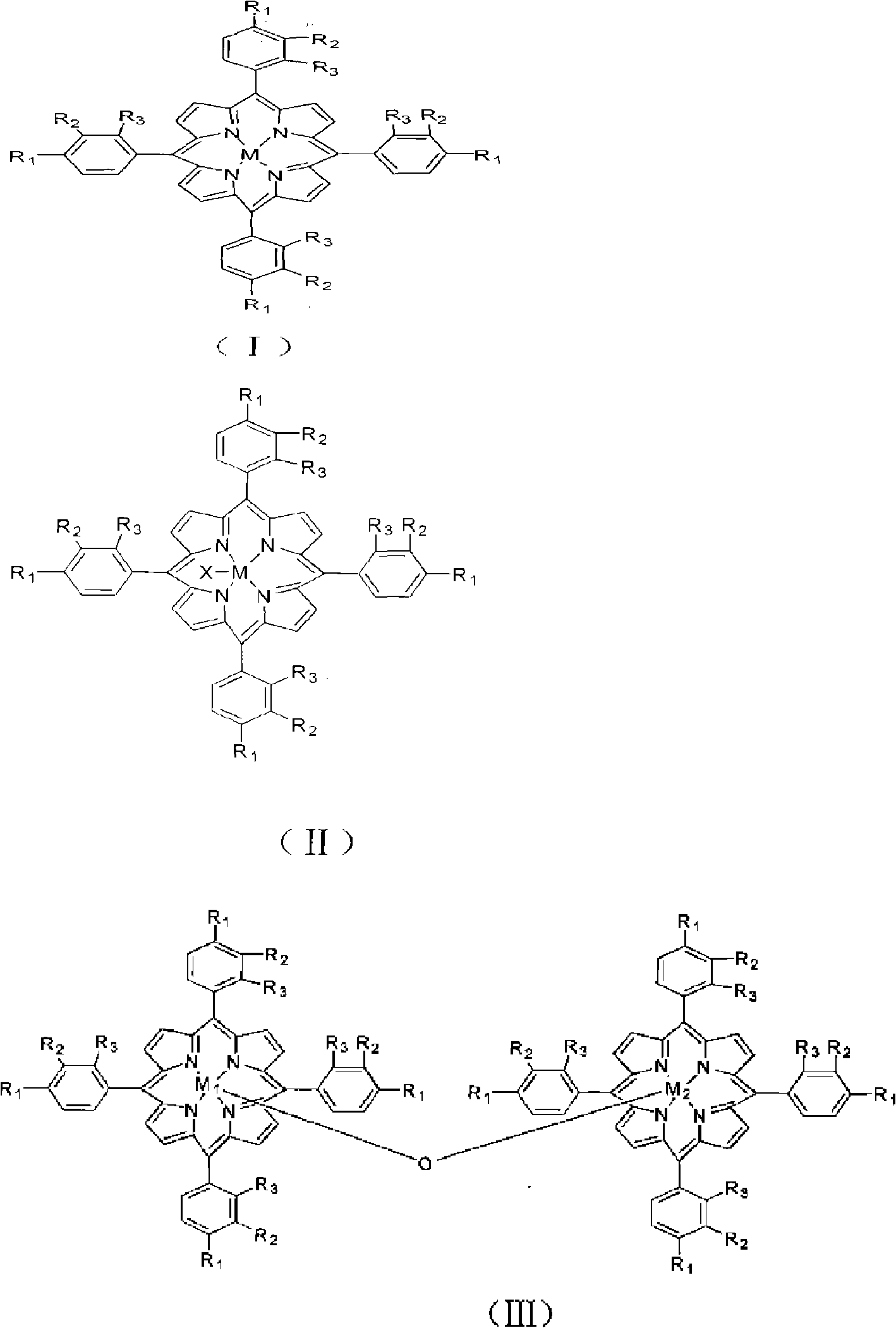

[0020] The production process is as follows: at 190°C, the metalloporphyrin dissolved with 5ppm structural formula (III) is introduced, R 1 = Cl, R 2 = R 3 =H, M=Fe's toluene, 10atm air is passed into the bottom of the first stirred reactor through the gas distributor, and the reaction liquid overflowed from the upper part of the first stirred reactor is mixed with air and then passed into the second The bottom of the stirred reactor, the reaction solution overflowed from the upper part of the second stirred reactor is mixed with air and passed through the third stirred reactor, and so on. Control the toluene flow rate so that the average residence time is 73 minutes, and control the air flow rate so that the tail oxygen content does not exceed 5%. The reaction mixture overflowed from the sixth stirred reactor enters the fractionation col...

Embodiment 2

[0022] The reaction equipment consists of 3 reactors with stirring and air distributors and 3 fractionation towers connected in series.

[0023] The production process is: pass into the metalloporphyrin that dissolves 20ppm structural formula (II), R 1 =CH 3 , R 2 = R 3 =H, the toluene of M=Cr, 11atm air is passed into the bottom of the first stirred reactor through the gas distributor, and the reaction liquid overflowed from the upper part of the first stirred reactor is mixed with air and then passed into the second The bottom of the stirring reactor is stirred, and the reaction liquid overflowed from the upper part of the second stirred reactor is mixed with air and passed through the third stirred reactor. Control the temperature of the three reactors to be 190°C, 185°C, and 180°C respectively, control the toluene flow rate so that the average residence time is 73 minutes, and control the air flow rate so that the tail oxygen content does not exceed 5%. The reaction mi...

Embodiment 3

[0025] The reaction equipment consists of a reactor with stirring and air distributor and two fractionation towers.

[0026] The production process is: pass into the metalloporphyrin that dissolves 10ppm structural formula (III), R 1 =OCH 3 , R 2 = R 3 =H, the toluene of the N-hydroxyphthalimide of M=Ni and 120ppm, 5atm oxygen-containing 23% gas is passed into the bottom of the stirred reactor through a gas distributor, and the temperature of the controlled reactor is 90°C, and the toluene The flow rate makes the average residence time 180 minutes, and the air flow rate is controlled so that the tail oxygen content does not exceed 5%. The reaction mixture overflowed from the stirred reactor enters the fractionation column system. Pure products of toluene, benzaldehyde, benzyl alcohol and benzoic acid were obtained after separation. The recovered toluene is mixed with the toluene containing the metal porphyrin catalyst and passed into the stirred reactor for secondary oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com