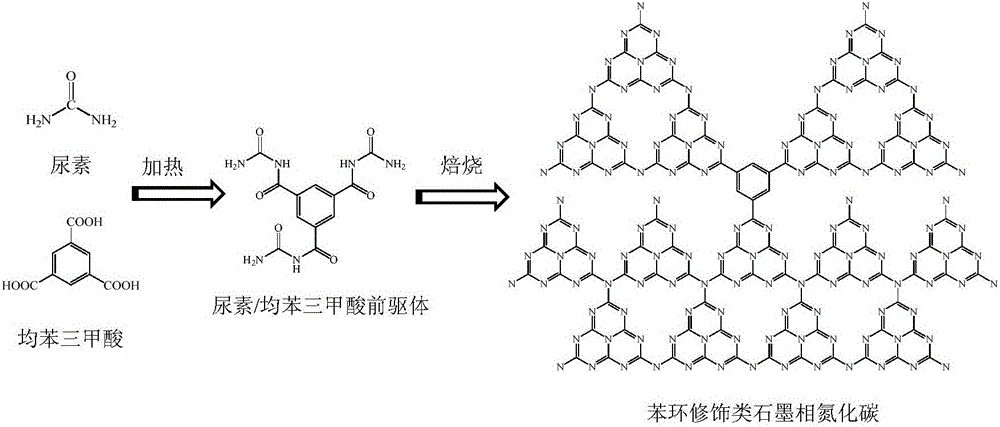

Phenyl ring modified graphite-like carbon nitride photocatalyst, and preparation method and application thereof

A phase carbon nitride photocatalyst technology, used in physical/chemical process catalysts, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of low quantum efficiency, limitation, poor absorption performance in the visible light region, etc. Effective separation and widening of the visible light response range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of a benzene ring-modified graphitic phase carbon nitride photocatalyst, comprising the following steps:

[0032] (1) Dissolving 10.0 g of urea in 50 mL of deionized water to obtain an aqueous urea solution;

[0033] (2) Add trimesic acid with a mass of 4mg into the above urea solution, stir and dissolve for 5min, and then place it in an oil bath at 100°C and evaporate to dryness;

[0034] (3) Put the evaporated powder above into a mortar and grind it evenly, then place it in a crucible, put it in a muffle furnace and bake it at 550°C for 4h, and the heating rate is 3°C / min to obtain benzene ring-modified graphite phase carbon nitride photocatalyst. The specific surface area of the photocatalyst prepared in this embodiment is 102.7m 2 g -1 ; Its hydrogen production rate is about 72.5 μmol h -1 .

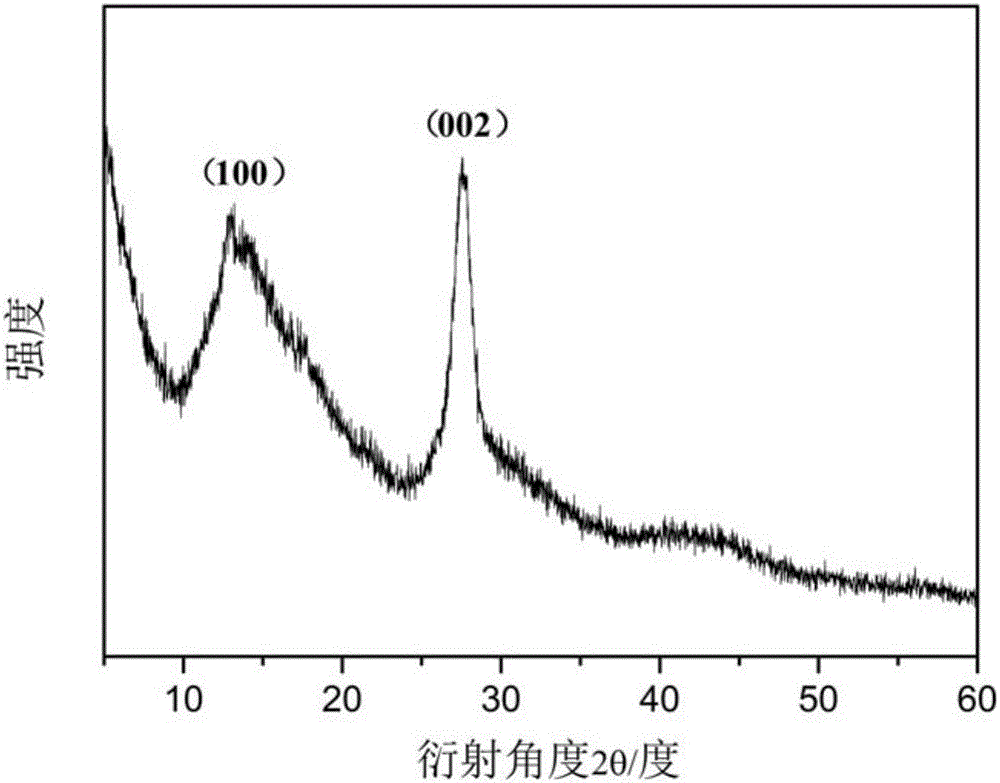

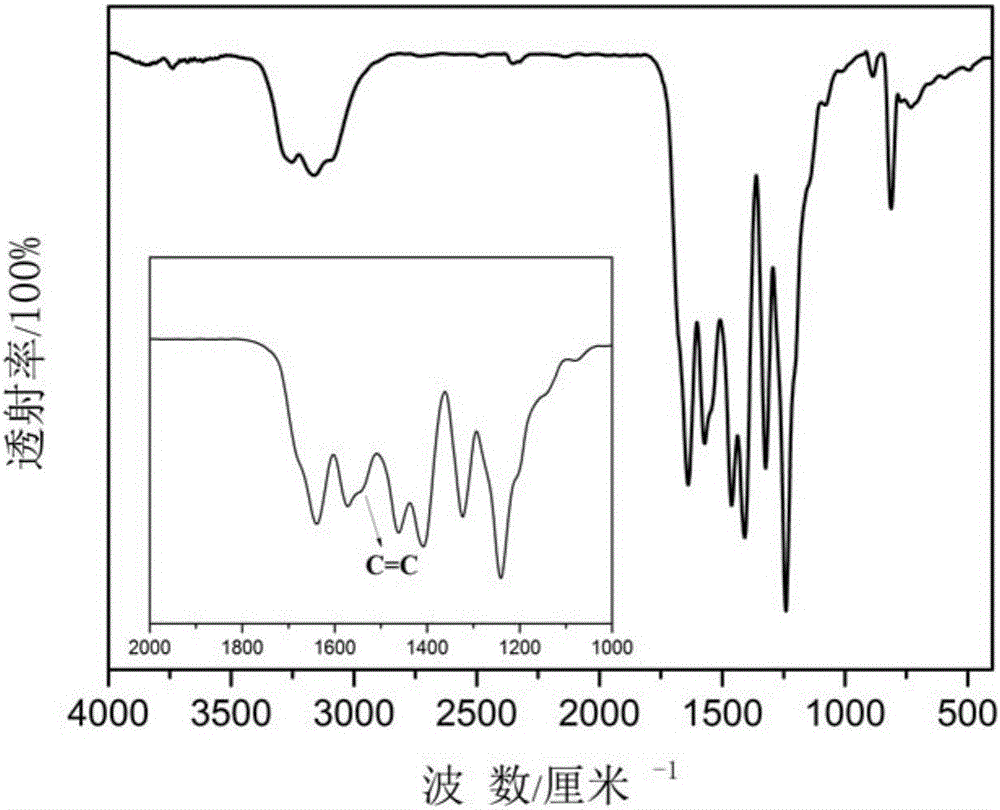

[0035] The structural characterization and performance testing of the benzene ring-modified graphite-like carbon nitride photocatalyst are as follo...

Embodiment 2

[0043] A preparation method of a benzene ring-modified graphitic phase carbon nitride photocatalyst, comprising the following steps:

[0044] (1) Dissolving 10.0 g of urea in 50 mL of deionized water to obtain an aqueous urea solution;

[0045] (2) Add trimesic acid with a mass of 2 mg to the above urea solution, stir and dissolve for 5 minutes, and then place it in an oil bath at 100°C and evaporate to dryness;

[0046] (3) Put the evaporated powder above into a mortar and grind it evenly, then place it in a crucible, put it into a muffle furnace and bake it at 550°C for 4h, and the heating rate is 10°C / min to obtain benzene ring-modified graphite phase carbon nitride photocatalyst. The specific surface area of the photocatalyst prepared in this example is 93.1m 2 g -1 ; Its hydrogen production rate is about 42.7μmol·h -1 .

Embodiment 3

[0048] A preparation method of a benzene ring-modified graphitic phase carbon nitride photocatalyst, comprising the following steps:

[0049] (1) Dissolving 10.0 g of urea in 50 mL of deionized water to obtain an aqueous urea solution;

[0050] (2) Add trimesic acid with a mass of 6 mg to the above urea solution, stir and dissolve for 5 minutes, and then place it in an oil bath at 100°C and evaporate to dryness;

[0051] (3) Put the evaporated powder above into a mortar and grind it evenly, then place it in a crucible, put it in a muffle furnace and bake it at 550°C for 4h, and the heating rate is 3°C / min to obtain benzene ring-modified graphite phase carbon nitride photocatalyst. The specific surface area of the photocatalyst prepared in this embodiment is 113.4m 2 g -1 , and its hydrogen production rate is about 46.2μmol·h -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com