Polyurethane foam fire retardant, and preparation method and applications thereof

A polyurethane foam and flame retardant technology, which is applied in the field of polyurethane foam flame retardants, can solve the problems of high cost of DOPO and restrictions on DOPO flame retardants, and achieve the effects of improving durability, improving compression performance, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

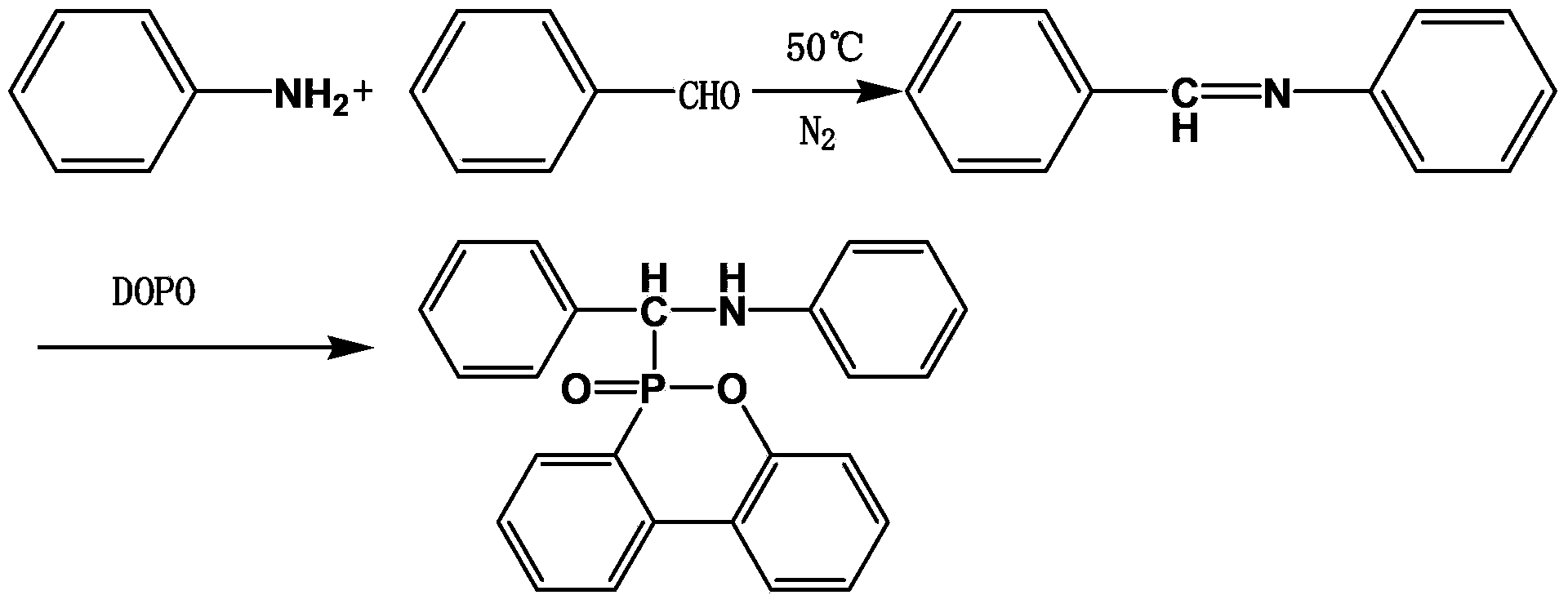

[0048] Step 1: Mix 80-100 parts by mass of aniline and 100-110 parts by mass of benzaldehyde evenly, heat up to a temperature of 50-60° C. in a nitrogen atmosphere, and react for 4-6 hours. The quality of aniline can choose 80 parts, 84 parts, 88 parts, 92 parts, 96 parts, 100 parts, the quality of benzaldehyde can choose 100 parts, 102 parts, 104 parts, 106 parts, 108 parts, 110 parts, and the temperature can be selected 50°C, 52°C, 54°C, 56°C, 58°C, 60°C, the reaction time can be selected from 4h, 4.5h, 5h, 5.5h, 6h.

[0049] Step 2: Mix 40-60 parts by mass of raw material 2-[(phenyliminomethyl)]benzene, 60-80 parts by mass of DOPO, and 450-500 parts by mass of tetrahydrofuran obtained in step 1. Under the environment of 50~70℃, react for 11~12h. The mass parts of 2-[(phenyliminomethyl)]benzene obtained in step 1 can be selected from 40 parts, 44 parts, 48 parts, 52 parts, 56 parts, and 60 parts, and DOPO can be selected from 60 parts, 64 parts, and 68 parts , 72 parts, ...

Embodiment 2

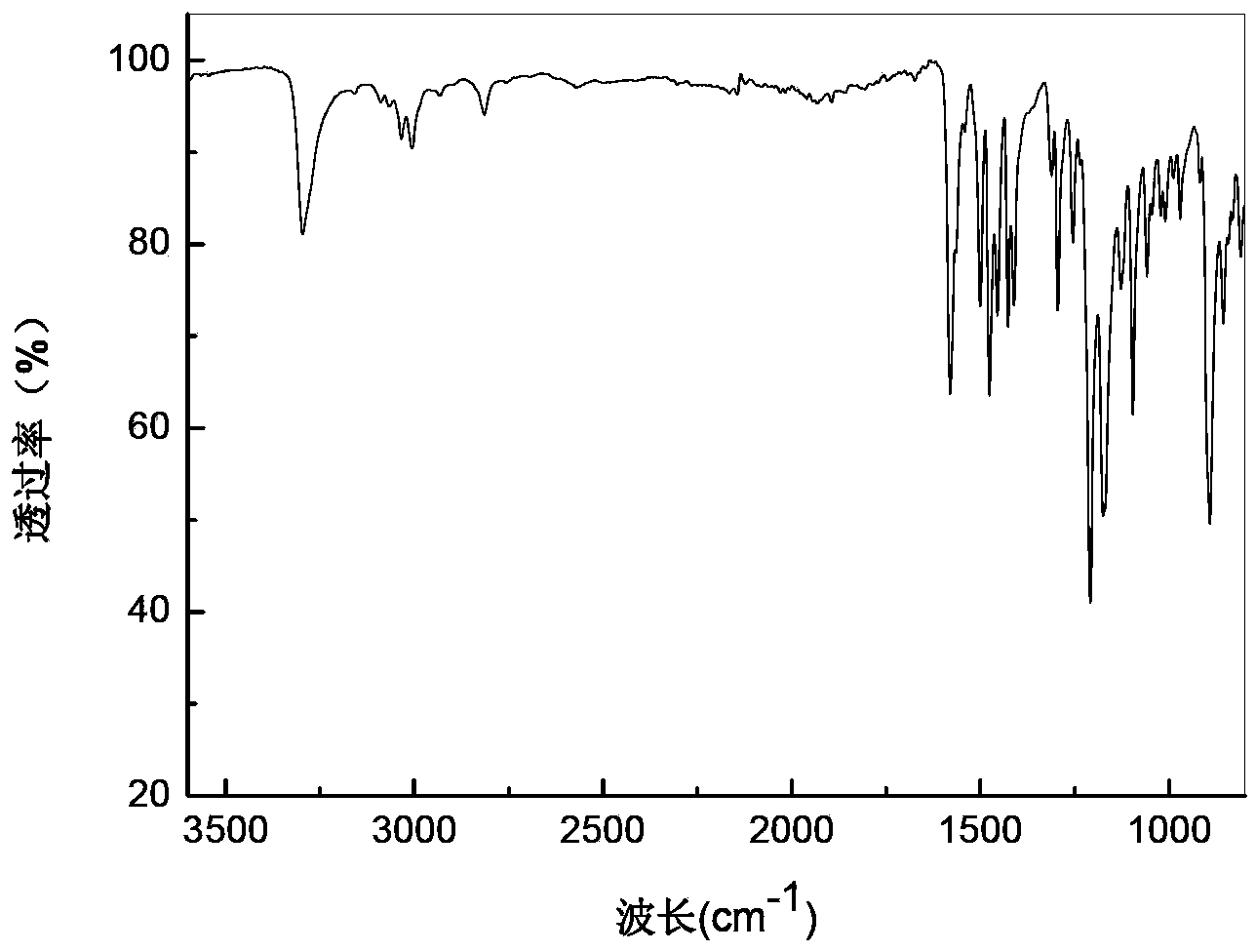

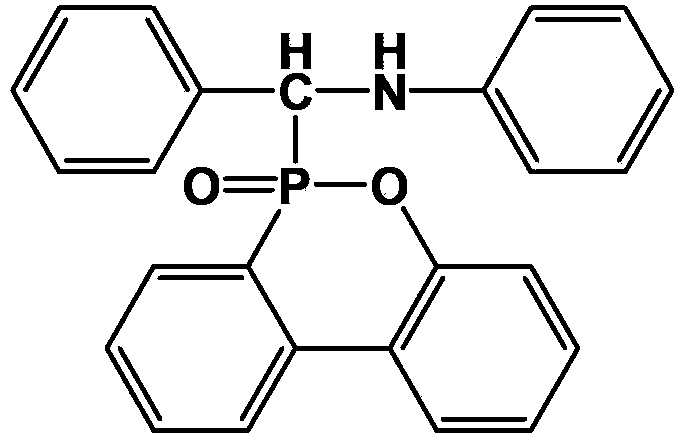

[0051] Weigh 80 parts by mass of aniline and 100 parts by mass of benzaldehyde and mix them uniformly, heat up to 50°C in an atmosphere of nitrogen gas, and react for 4h to obtain 2-[(phenyliminomethyl)]benzene. Methanol crystallized. Weigh 40 parts by mass of the intermediate product 2-[(phenyliminomethyl)]benzene, 60 parts by mass of DOPO, and 500 parts by mass of tetrahydrofuran, mix them uniformly, and react at 50° C. for 11 h in a nitrogen atmosphere. The flame retardant 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide-4-[(aniline)methyl]benzene was obtained by washing with cold tetrahydrofuran three times. Then according to the formula in Table 1, firstly mix the phthalic anhydride polyol and additives evenly under high-speed stirring, then ultrasonically mix for 30 minutes, and then stir with isocyanate under high-speed stirring for 20-30s at a speed of 2000-3000r / min, pour Put it into the mold and mature for 48 hours.

Embodiment 3

[0053] Take by weighing 80 parts by mass of aniline and 102 parts by mass of benzaldehyde and mix them uniformly, heat up to a temperature of 50° C. in an atmosphere of nitrogen, and react for 4.5 hours to obtain 2-[(phenyliminomethyl)]benzene. Crystallization from cold methanol. Weigh 40 parts by mass of the intermediate product 2-[(phenyliminomethyl)]benzene, 64 parts by mass of DOPO, and 500 parts by mass of tetrahydrofuran, mix them uniformly, and react at 54° C. for 11.2 h in a nitrogen atmosphere. The flame retardant 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide-4-[(aniline)methyl]benzene was obtained by washing with cold tetrahydrofuran three times. Then according to Table 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide-4-[(aniline) methyl] benzene flame-retardant rigid polyurethane foam Alcohol, 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide-4-[(aniline)methyl]benzene and additives were mixed evenly under high-speed stirring, and then ultrasonic Mix for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com