Rigid polyurethane foam composition, rigid polyurethane foam material, and preparation method of rigid polyurethane foam material

A polyurethane rigid foam and composition technology, applied in the field of environmentally friendly polyurethane rigid foam insulation materials, can solve the problems of polyurethane rigid foam heat insulation performance, poor strength, and difficulty in meeting energy-saving and environmental protection standards, and achieve good dimensional stability and satisfy aesthetics Requirements, the effect of reducing the degree of yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

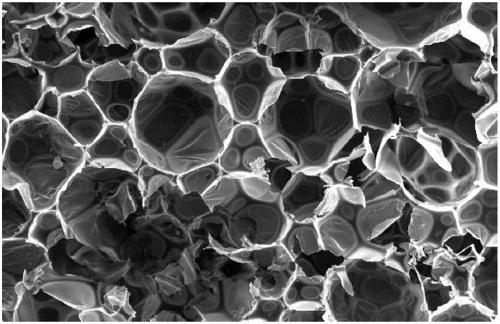

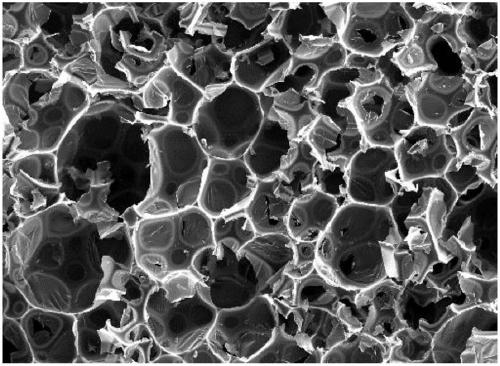

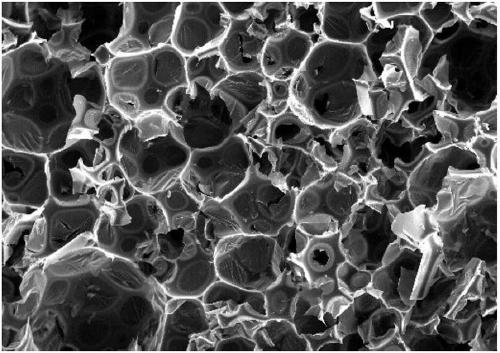

Image

Examples

Embodiment 1

[0036] A kind of polyurethane rigid foam composition in the present embodiment, by weight, comprises the component of following weight ratio:

[0037]

[0038]

[0039] In some other embodiments, the nanometer metal oxide includes one or more combinations of iron oxide, zinc oxide, ferric oxide, aluminum oxide, copper oxide, indium oxide, bismuth oxide, and manganese dioxide; catalyst 1 It is an amine catalyst, including N,N-dimethylcyclohexylamine, pentamethyldiethylenetriamine, N,N-dimethylbenzylamine, 1,3,5-tris(dimethylaminopropyl) One or more combinations of hexahydrotriazine, bis(2-dimethylaminoethyl) ether and triethylenediamine; catalyst 2 is a metal catalyst, including one of organic tin, organic bismuth or organic zinc compounds one or more combinations.

[0040] This embodiment also provides a polyurethane rigid foam material prepared according to the above polyurethane rigid foam composition, and the specific preparation method is as follows:

[0041] Step ...

Embodiment 2

[0052] A kind of polyurethane rigid foam composition in the present embodiment, by weight, comprises the component of following weight ratio:

[0053]

[0054]In some other embodiments, the nanometer metal oxide includes one or more combinations of iron oxide, zinc oxide, ferric oxide, aluminum oxide, copper oxide, indium oxide, bismuth oxide, and manganese dioxide; catalyst 1 It is an amine catalyst, including N,N-dimethylcyclohexylamine, pentamethyldiethylenetriamine, N,N-dimethylbenzylamine, 1,3,5-tris(dimethylaminopropyl) One or more combinations of hexahydrotriazine, bis(2-dimethylaminoethyl) ether and triethylenediamine; catalyst 2 is a metal catalyst, including one of organic tin, organic bismuth or organic zinc compounds one or more combinations.

[0055] This embodiment also provides a rigid polyurethane foam material prepared according to the rigid polyurethane foam composition as described above. The specific preparation method is similar to that of Embodiment 1...

Embodiment 3

[0057] A kind of polyurethane rigid foam composition in the present embodiment, by weight, comprises the component of following weight ratio:

[0058]

[0059]

[0060] In some other embodiments, the nanometer metal oxide includes one or more combinations of iron oxide, zinc oxide, ferric oxide, aluminum oxide, copper oxide, indium oxide, bismuth oxide, and manganese dioxide; catalyst 1 It is an amine catalyst, including N,N-dimethylcyclohexylamine, pentamethyldiethylenetriamine, N,N-dimethylbenzylamine, 1,3,5-tris(dimethylaminopropyl) One or more combinations of hexahydrotriazine, bis(2-dimethylaminoethyl) ether and triethylenediamine; catalyst 2 is a metal catalyst, including one of organic tin, organic bismuth or organic zinc compounds one or more combinations.

[0061] This embodiment also provides a rigid polyurethane foam material prepared according to the rigid polyurethane foam composition as described above. The specific preparation method is similar to that of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com