Patents

Literature

180results about How to "Not easy to turn yellow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

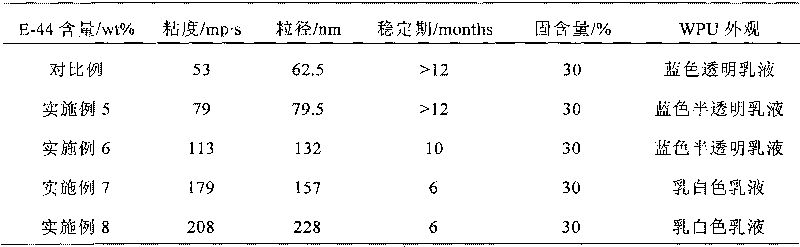

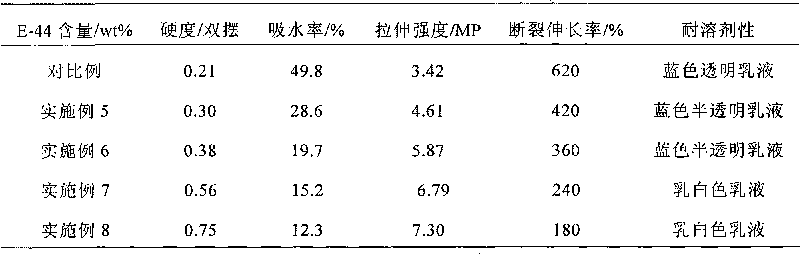

Epoxy resin modified water-based polyurethane emulsion and preparation method thereof

InactiveCN101717488AHigh molecular weightImprove cohesive energyPolyurea/polyurethane coatingsPolyesterWater based

The invention relates to an epoxy resin modified water-based polyurethane emulsion and a preparation method thereof. The emulsion comprises the following components in percentage by weight: 20 to 40 percent of isophorone diisocyanate, 20 to 40 percent of polyester, 5 to 10 percent of hydrophilic chain extender, 2 to 10 percent of chain extender, 1 to 3 percent of crosslinker, 3 to 10 percent of neutralizing agent, 2 to 10 percent of epoxy resin and 10 to 20 percent of acetone. The preparation method comprises the steps of feed preparation, polyester dehydration, the synthesis and neutralization of prepolymer, and chain extension and emulsification. Compared with the prior art, the epoxy resin modified water-based polyurethane emulsion has the advantages of high hardness of film, good water resistance and solvent resistance and the like, and is widely applied in the field of packaging coatings.

Owner:SHANGHAI WEIKAI CHEM

Low-temperature dyeing and finishing technology of cottonette

InactiveCN105002730AProcess temperature changeLow processing temperatureBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsDiastase

The invention discloses a low-temperature dyeing and finishing technology of cottonette. The technology comprises the following steps: pretreatment; preshaping; modification treatment; dyeing; mordant removing; soaping; color fixing; post-treatment; drying; shaping; calendaring; rolling. According to the technology, pretreatment is carried out through the adoption of helicase and alpha-amylase, and modification treatment is carried out before dyeing, so that the property of the cottonette is fundamentally modified, and the dye-uptake of the fabric is increased; during the dyeing procedure, large quantities of alkaline substances and inorganic salt are not used, and a levelling agent, a low-temperature dyeing accelerant, a migration inhibitor and a dispersing agent are added, so that the dye uniformity is improved; during the whole dyeing process, the temperature is lower than 80 DEG C, and the dyeing process belongs to low-temperature dyeing, so that energy consumption is reduced; self-cleaning treatment is added in post-treatment, so that the self-cleaning capacity, wrinkle resistance and water washable firmness of the fabric are improved; post-treatment is carried out through the adoption of silk fibroin and sericin, so that the pilling resistance and antistatic property of the cottonette are improved; the whole technology is environment-friendly and free of pollution.

Owner:TAICANG TIANLONG CHEM FIBER

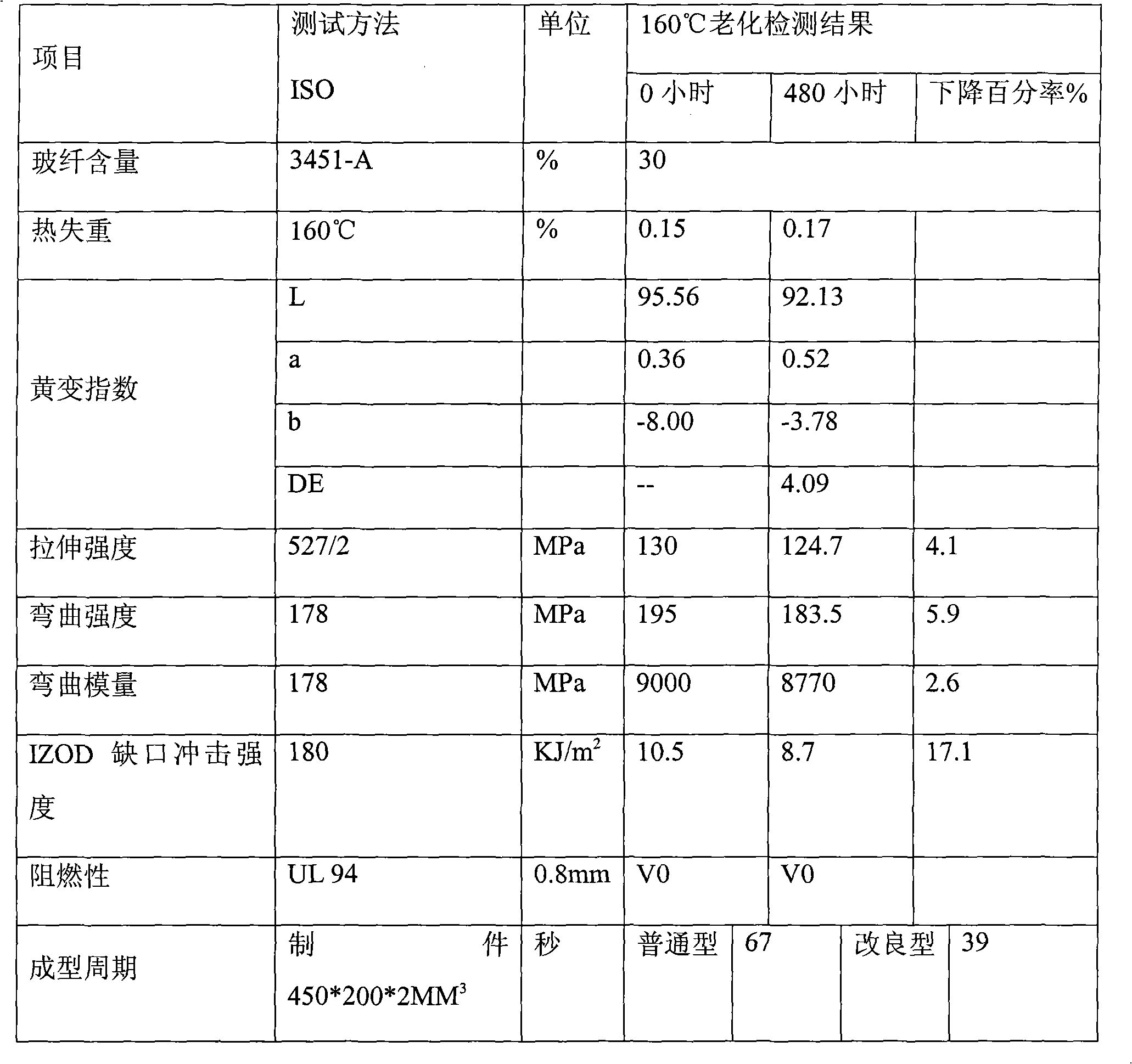

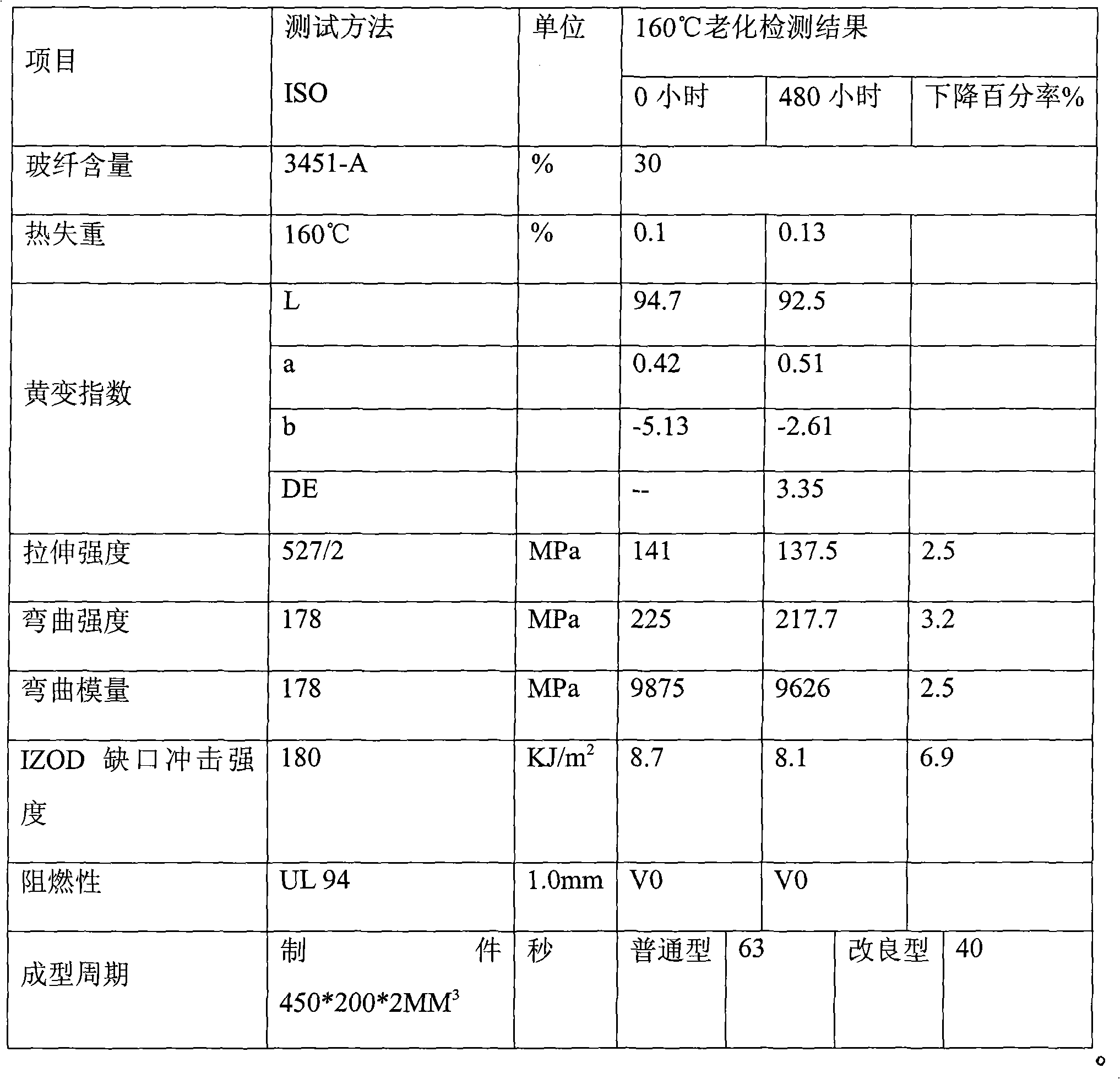

Flame-proof reinforced Valox compound and preparation thereof

InactiveCN101275010ANot easy to change colorGood thermal and oxygen aging stabilityPolytetramethylene terephthalateGlass fiber

The invention discloses a flame retardant intensified polybutylene terephthalate composite and a preparation method thereof; weight portions of the compositions for preparing the flame retardant intensified polybutylene terephthalate composite are: 100 portions of medium viscosity PBT resin, 15 to 30 portions of brominated flame retardants, 10 to 30 portions of composite mother particles, and 15 to 150 portions of fiber glass. The product of the invention has good stability of heat resistance and oxygen aging in the treatment process and good stability of heat resistance and oxygen aging in long-term use at high temperature, so light color and bright color products are difficult to change color during the processing period, and difficult to turn yellow or black under long-term use at high temperature, which can satisfy the application in long-term use at high temperature for electronic and electrical components and appearance parts and large power energy-saving light.

Owner:SHANGHAI KINGFA SCI & TECH +1

Natural dyestuff dyeing and finishing process of polyester fabric

The invention discloses a natural dyestuff dyeing and finishing process of polyester fabric. The natural dyestuff dyeing and finishing process of the polyester fabric comprises pretreatment, preshaping, modification treatment, dyeing, mordant removing, soaping, fixation, finishing, drying, shaping, calendering and winding. According to the natural dyestuff dyeing and finishing process of the polyester fabric, helicase and alhpa-amylase are adopted to conduct pretreatment, modification treatment is radically conducted on the performance of the polyester fabric through a acetic acid aqueous solution of chitosan, hydrogen peroxide and epoxy chloropropane, and the dyeing rate of the fabric is increased; in the dyeing process, a large amount of alkaline matter and inorganic salt are not used, a levelling agent and diffusant are added, the level-dyeing property is improved, natural dyestuff is used, therefore, environmental pollution is avoided, and requirements of green environmental protection are met; modification treatment and fire-retardant treatment are conducted on the fabric through montmorillonite, and the fire resistance of the fabric is high; anti-yellowing reagents are used in the preshaping and the shaping, and the final fabric is not prone to yellowing.

Owner:TAICANG CHENGLE CHEM FIBER

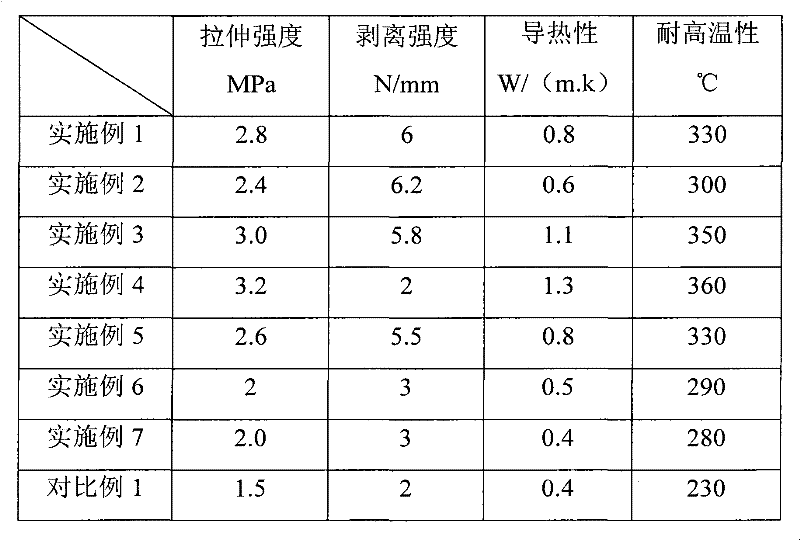

Silicone rubber composition and preparation method of silicone rubber

The invention provides a silicone rubber composition comprising, a heat conductive composite material, a silane cross-linking agent, and polyether. The heat conductive composite material comprises a silane coupling agent, and titanium oxide coated with zinc hydroxide. The invention also relates to a preparation method of silicone rubber. The silicone rubber composition provided by the invention is easy to prepare and to store. Prepared silicone rubber has advantages of high-temperature resistance, high heat conductivity, stable performance, and good anti-yellowing performance. With the technical schemes provided by the invention, application environment of the silicone rubber composition is extended. Materials manufactured with the silicone rubber composition have good mechanical properties and improved mechanical strengths. With good adhesion of the silicone rubber, sealing performances of manufactured materials are improved. Comprehensive property of the silicone rubber is excellent. With the silicone rubber composition and the preparation method provided by the invention, a basis is established for further development of silicone rubber.

Owner:宁海县集美特电器有限公司

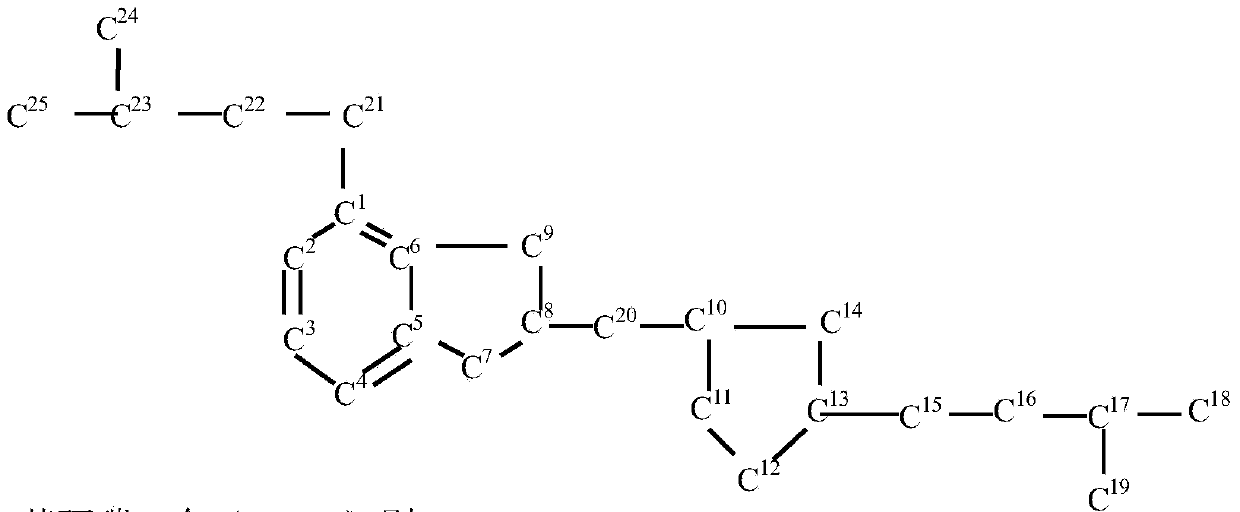

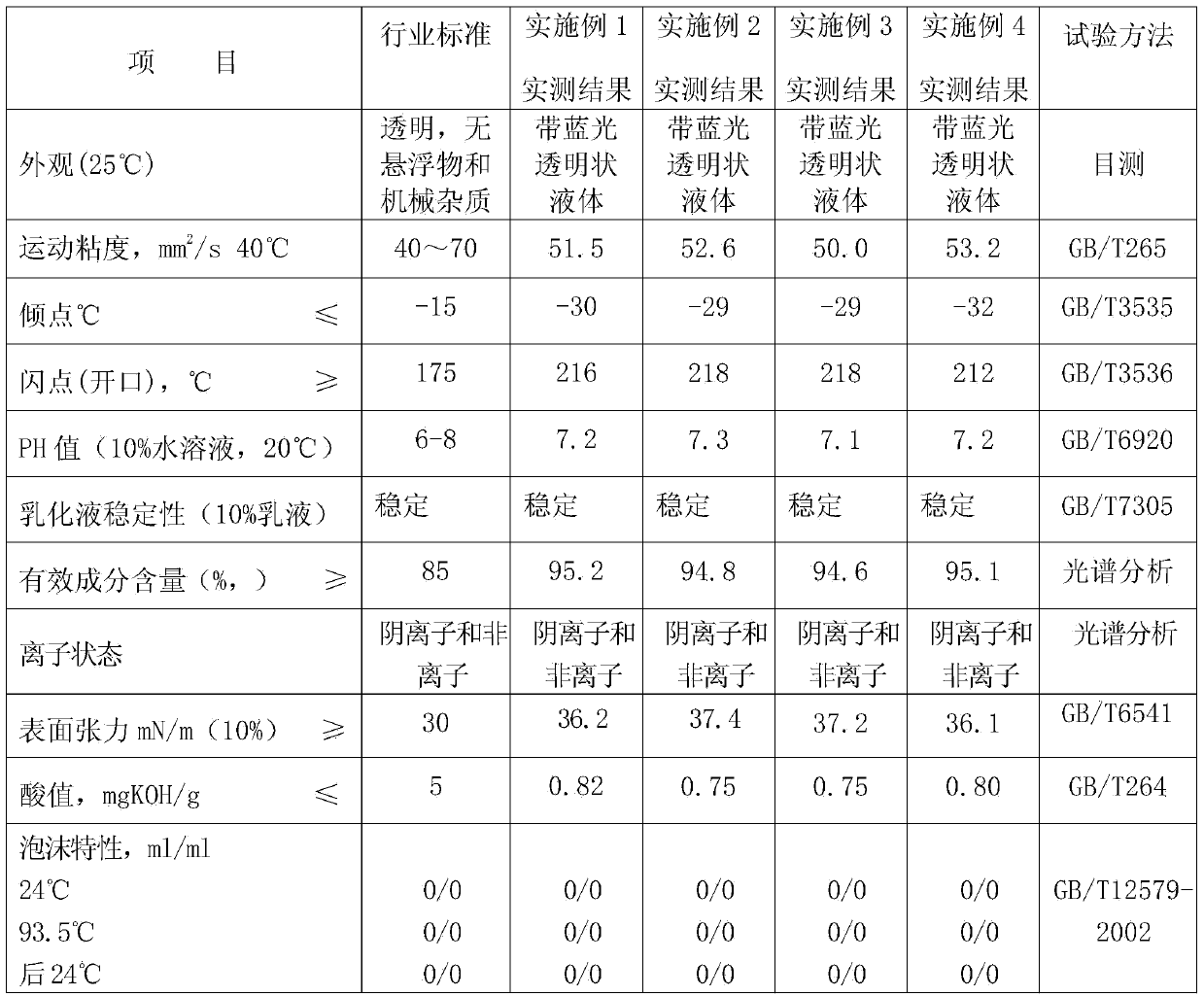

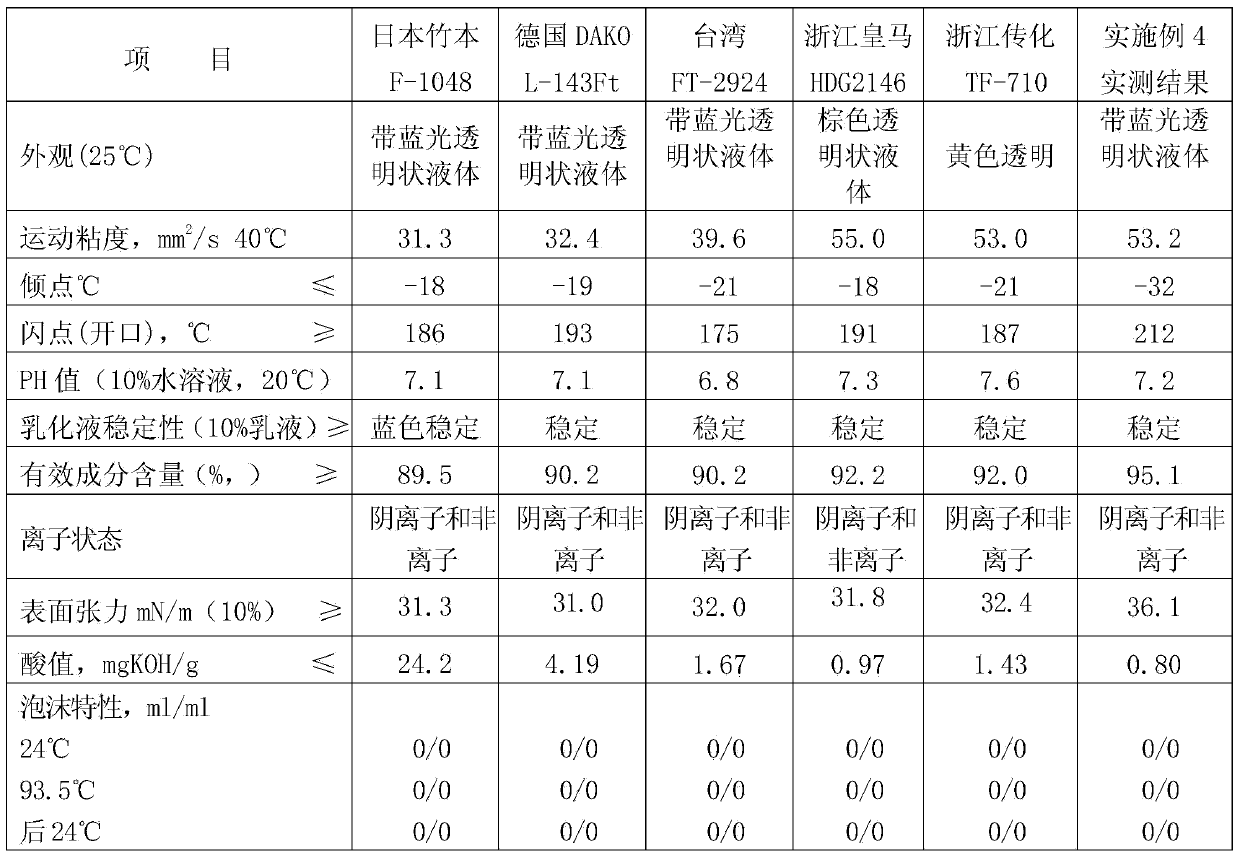

Fiber fully drawn yarn (FDY) spinning oil and preparation method thereof

The invention relates to a fiber fully drawn yarn (FDY) spinning oil which comprises a high-temperature smoothing agent, a composite antistatic agent, a bundling agent, a phenolic group antioxidant, a phenylamino group antioxidant, an olefine acid antioxidant, a high-temperature dispersant, a softening agent, an environment-friendly emulsifying agent, a defoaming agent, a preservative and an environment-friendly penetrating agent, wherein the high-temperature smoothing agent comprises hydrogenation paraffin-based oil and hydrogenation naphthenic oil. The invention also provides a preparation method of the fiber FDY spinning oil. The fiber FDY spinning oil is stable in emulsion and free from stratification and odor, and is not easily rotted; the fiber is easily not yellowed by dyeing, and the fiber FDY spinning oil is easy to rinse; the production process is stable, and the fiber FDY spinning oil has few broken ends, is good in heat resistance, does not have smoke formation, is not coked on a hot roller, has the excellent anti-static performance under the different humidity conditions, and thus the fiber FDY spinning oil can meet the requirements of high-speed spinning technologies of various specifications of fiber including thick fibers and thin fibers; after the fiber FDY spinning oil is used, the fiber can smoothly pass through the after the spinning of various equipment, so that the yield and the good rate of fiber spinning can be effectively increased.

Owner:上海中孚油品集团有限公司

Dyeing and finishing process for linen and cotton blended fiber fabric

InactiveCN105063998AProcess temperature changeLow processing temperaturePhysical treatmentBiochemical fibre treatmentInorganic saltsManufacturing engineering

The invention discloses a dyeing and finishing process for linen and cotton blended fiber fabric. The dyeing and finishing process comprises preprocessing, pre-sizing, modified processing, dyeing, mordant removing, soaping, color fixing, after finishing, drying, sizing, calendaring and rolling. Helicase, scouring enzyme and alpha-amylase are used for pretreatment, modification treatment is adopted before dyeing, the performance of linen and cotton blended fabric is modified fundamentally, and the dye-uptake rate is increased; the dyeing procedure does not require a large quantity of alkaline substances and inorganic salt, a leveling agent, substitutive alkali, a migration inhibitor and a dispersing agent are added, the dye uniformity is improved, environment pollution is avoided due to use of natural dye, and requirements for environmental protection are met; self-cleaning processing is added in the after finishing procedure, and the self-cleaning capacity, the crease-resistant performance, the washing resistance and the color fastness of the fabric are improved; crease-resistance finishing is added, and the crease-resistant performance of the fabric is improved; the whole process is environment-friendly and pollution-free.

Owner:TAICANG TIANLONG CHEM FIBER

Production process of bamboo-dissolving pulp

ActiveCN102127877AIncreased alkali consumptionExtended cook cycleCellulose material pulpingAcid treatmentManufacturing engineering

The invention provides a production process of bamboo-dissolving pulp, relating to a treatment method in the field of textile chemical fiber. The process comprises the following procedures of: preparing materials; steaming and pre-hydrolyzing; exchanging steaming and boiling; hermetically screening; bleaching in oxygen-alkali; carrying out acid treatment; manufacturing paper with pulp; and the like. The bamboo-dissolving pulp produced by the invention has the advantages of good product quality, uniform viscosity, high alphacellulose content, high whiteness, yellowing resistance, low pentaose content and good reaction performance and is favorable to production of post-procedures, chlorine-free bleaching and environment-friendly production.

Owner:YIBIN GRACE GROUP CO LTD

Environment-friendly dyeing and finishing technology of cotton cellulose fabric

InactiveCN105002720AHigh whitenessAvoid damagePhysical treatmentBiochemical fibre treatmentEpoxyCellulose

The invention discloses an environment-friendly dyeing and finishing technology of a cotton cellulose fabric. The technology comprises the following steps: pretreatment; preshaping; modification treatment; dyeing; mordant removing; soaping; color fixing; post-treatment; drying; shaping; calendaring; rolling. According to the technology, pretreatment is carried out through the adoption of helicase and alpha-amylase, and acetic acid aqueous solution of chitosan, hydrogen peroxide and epoxy chloropropane is adopted, so that the property of the cotton cellulose fabric is fundamentally modified, and the dye-uptake of the fabric is increased; during the dyeing procedure, large quantities of alkaline substances and inorganic salt are not used, and a levelling agent and a dispersing agent are added, so that the dye uniformity is improved; natural dye is used, so that environmental pollution is avoided, and the demand of environmental protection is met; modification treatment and fire retardant treatment are carried out on the fabric through the adoption of montmorillonite, so that the fire resistance of the fabric is high; self-cleaning treatment is added in post-treatment, so that the self-cleaning capacity, wrinkle resistance and water washable firmness of the fabric are improved; the whole technology is environment-friendly and free of pollution.

Owner:TAICANG CHENGLE CHEM FIBER

Dyeing and finishing process for polyamide fabric

InactiveCN105177987AProcess temperature changeLow processing temperatureBiochemical fibre treatmentUltrasonic/sonic fibre treatmentPolyamideAmmonium chloride mixture

The invention discloses a dyeing and finishing process for polyamide fabric. The provided process comprises pretreatment, pre-setting, modified processing, dyeing, soaping, dye fixation, post-finishing, drying, setting, calendering and rolling. Supersonic waves are employed for pretreatment, fabric is subjected to low temperature plasma processing before the dyeing step, then 2,3-epoxy propyl trimethyl ammonium chloride is employed for modification processing of the fabric, the dyeing degree of the fabric is raised, and difficulty of the subsequent dyeing step is lowered. During the dyeing step, a lot of alkaline substances and inorganic salt are not used, natural dyes are employed, colophony powder is added as a dye-fixing agent, the dye-fixing effect is enhanced, environment pollution is avoided, and green environmental protection requirements are met. Montmorillonite is employed for modification processing and flame retardation processing of the fabric, and thus the flame retardation of the fabric is high. Anti-yellowing reagents are used both in the pre-setting and setting steps, and thus the final fabric is not easy to turn yellow.

Owner:TAICANG TIANLONG CHEM FIBER

Flax fabric dyeing and finishing process

InactiveCN104988768AReduce pollutionAvoid damageUltrasonic/sonic fibre treatmentDyeing processInorganic saltsMontmorillonite

The invention discloses a flax fabric dyeing and finishing process including pretreatment, pre-sizing, modification treatment, dyeing, soaping, color fixation, post-finishing, drying, sizing, calendering, and coiling. Ultrasonic waves are used for pretreatment, and at the same time, the modification treatment step is added; in the dyeing process, a large amount of alkaline substances and inorganic salts are not used, natural dyes are used, and at the same time, a colophony powder is added as a color fixing agent, so that the color fixing effect is enhanced, besides, the environmental pollution is avoided, and the requirements of environmental protection are met; montmorillonite is used for modification treatment and flame retardant treatment on the fabric, so that the flame retardancy of the fabric is high; and an anti-yellowing reagent is used in the processes of pre-sizing, sizing and post-finishing, so that a final fabric does not easily turn yellow.

Owner:太仓市宝明化纤有限公司

Solvent-free double-constituent polyurethane compound adhesive and preparation method for same

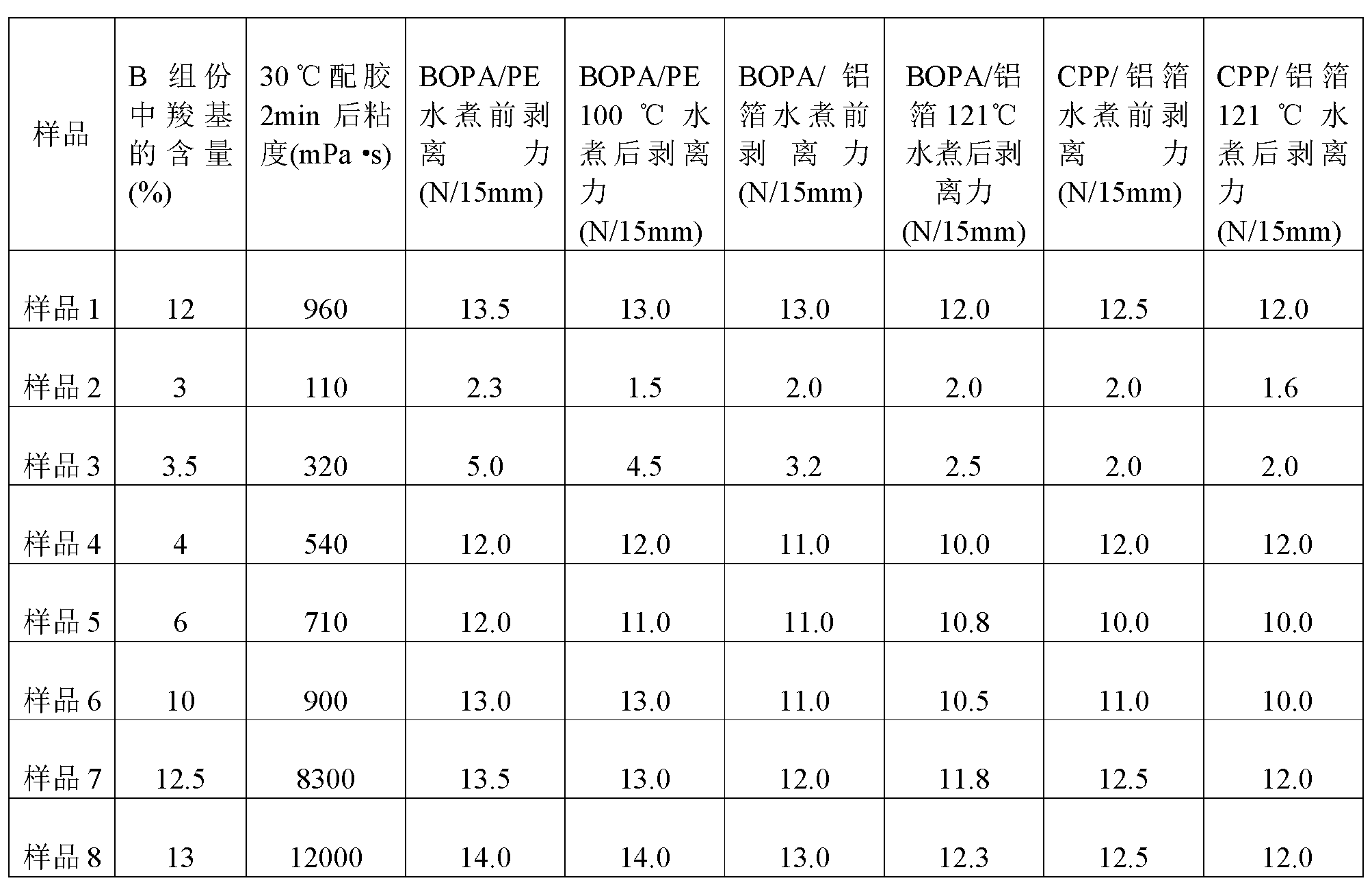

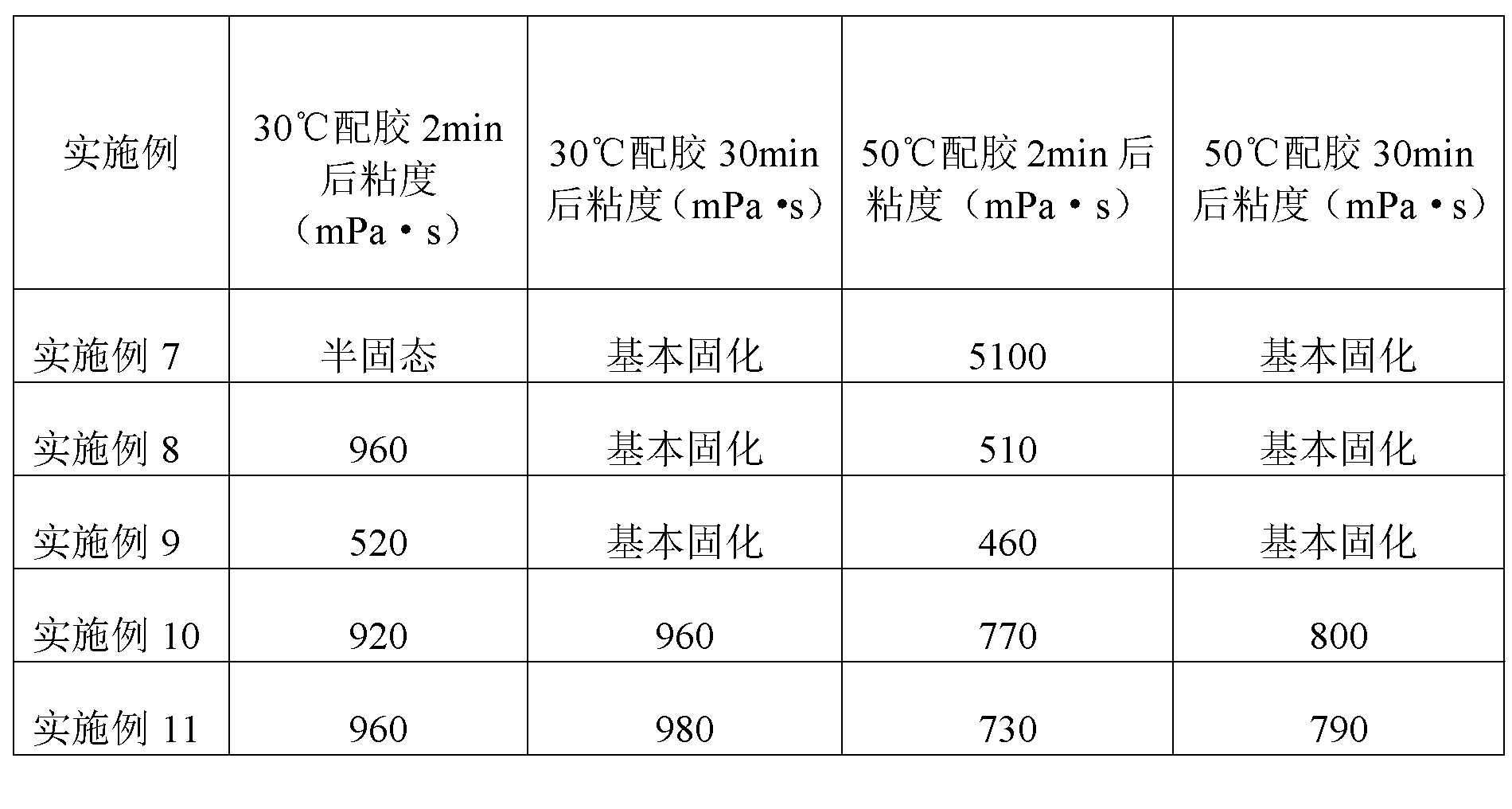

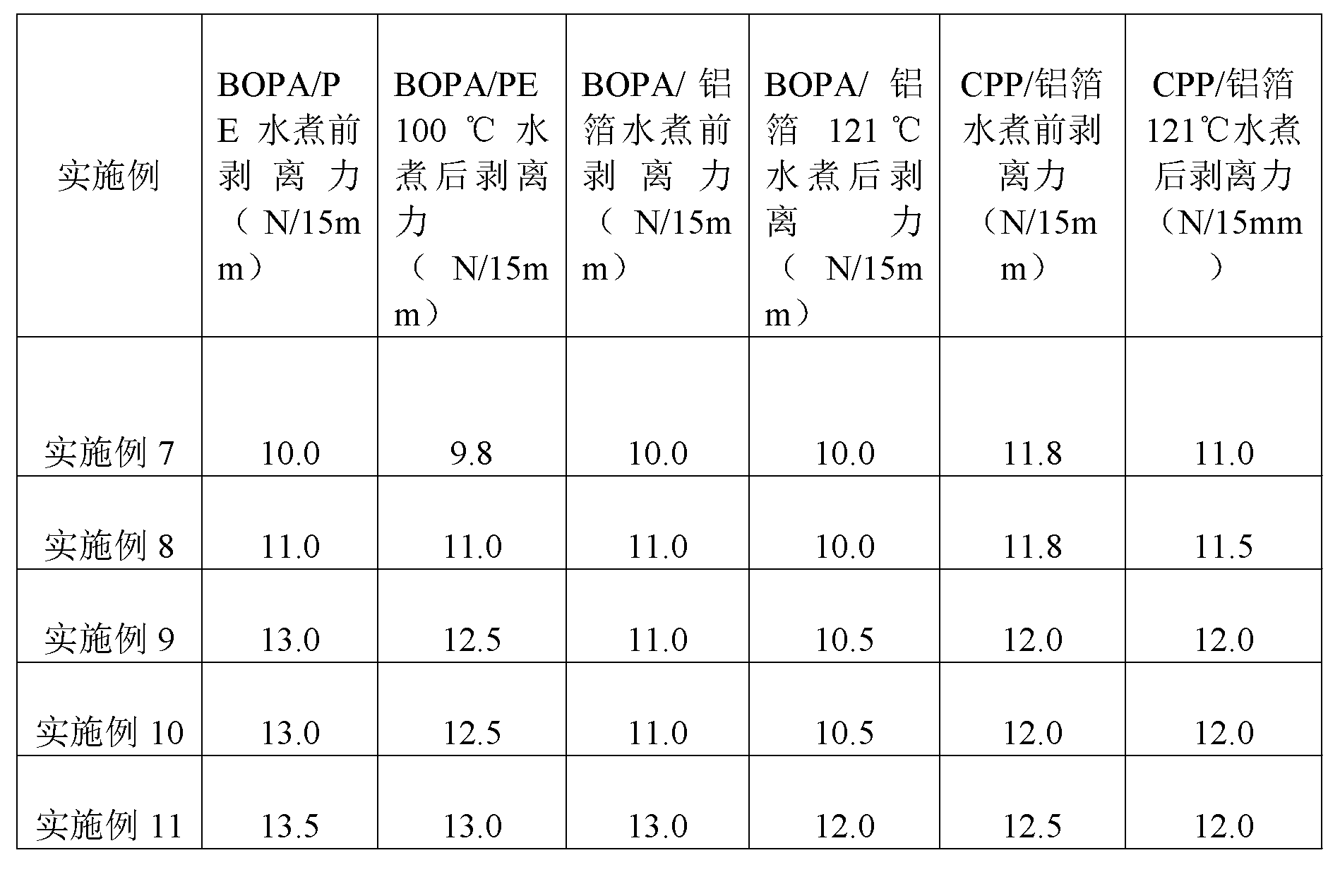

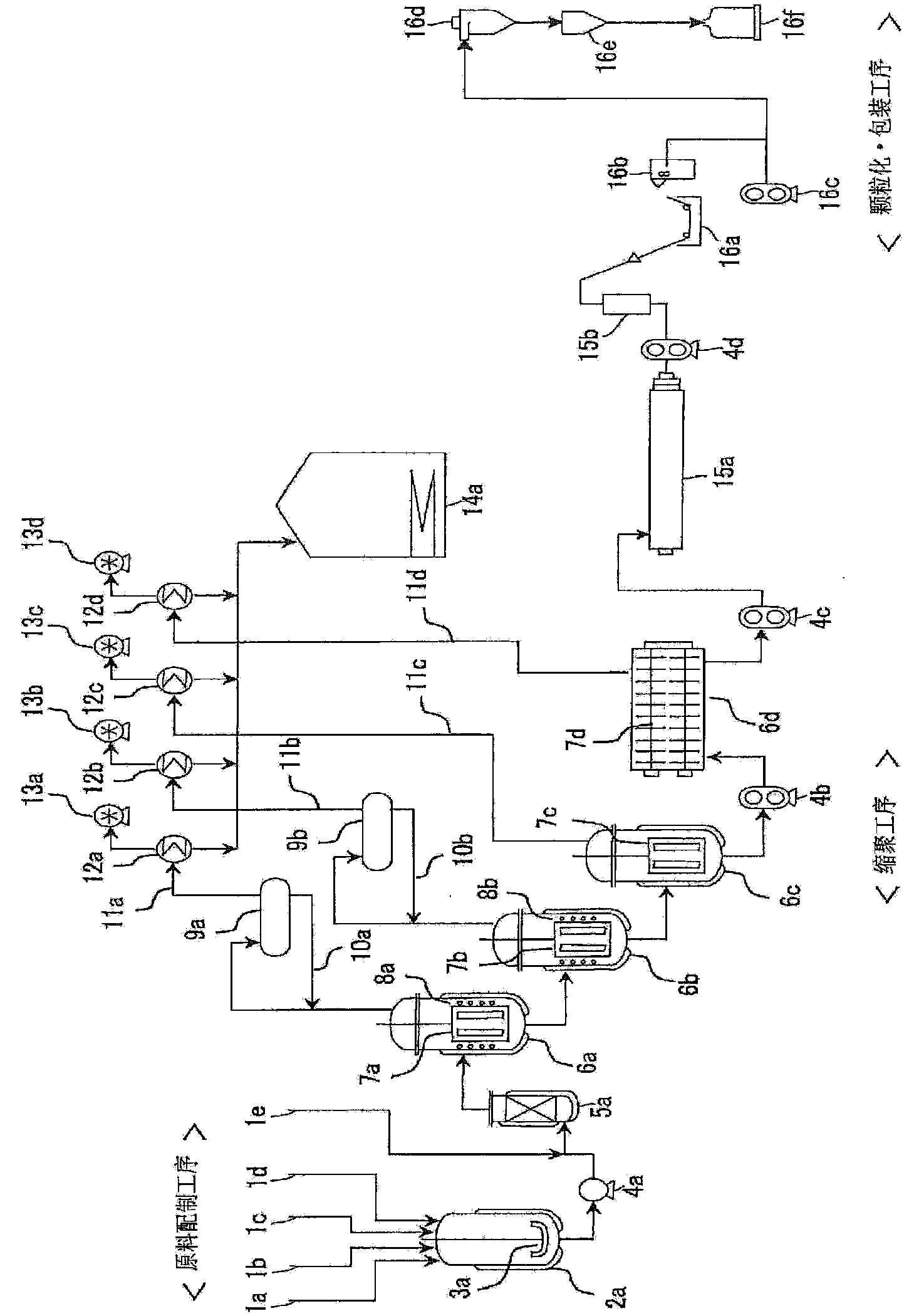

ActiveCN103013417AGood adhesionEliminates undesirable effects of uneven or even non-uniform coatingPolyureas/polyurethane adhesivesPolyolPolyurethane adhesive

The invention provides a solvent-free double-constituent polyurethane adhesive which is composed of a constituent A and a constituent B, wherein the constituent A is end isocyanate-group polyurethane prepolymer, and the constituent B is carboxyl-containing polyether polyol. The solvent-free polyurethane adhesive is strong in compounding fastness, long in service usage period and wide in suitable base material range; and moreover, the compound film prepared from the adhesive can still keep an excellent appearance and excellent adhesion property after high-temperature sterilization treatment.

Owner:苏州博莱特新材料有限公司

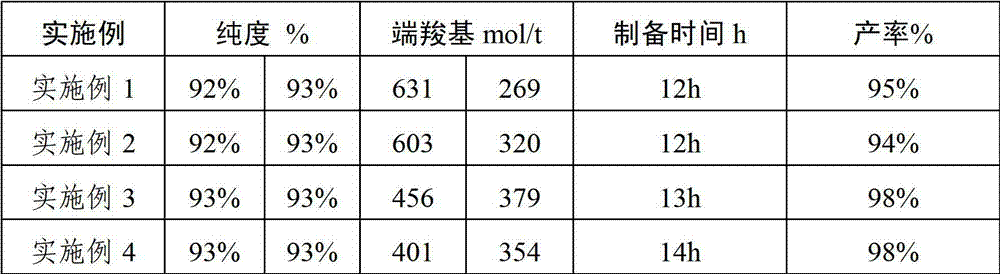

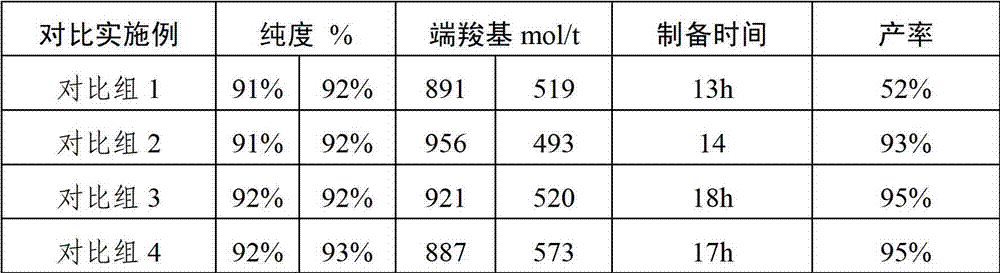

Method for producing polycarbonate, and polycarbonate pellets

When producing a polycarbonate using a specific dihydroxy compound having a -CH2-O- structure, the thermal stability is low compared to bisphenols. The present invention pertains to a method for producing a polycarbonate which solves a plurality of problems such as the abovementioned, wherein a polycarbonate with excellent characteristics, such as hue and mechanical properties, is produced with stable quality and high yields.

Owner:MITSUBISHI RAYON CO LTD

Method for preparing medical lactide

The invention relates to the method for preparing medical lactide. The method includes: adding catalyst and high boiling-point solvent in lactic acid for condensation polymerization to enable the lactic acid to generate lactic-acid oligomer, and adding catalyst in the generated lactic-acid oligomer for depolymerization to obtain the medical lactide. The high boiling-point solvent is added during the condensation polymerization, so that a reaction system during depolymerization cannot become viscous, and is less prone to steam out, carbonize and turn yellow caused by distillation and reduction of lactide, stability of production process, product quality and variability of physical indexes are guaranteed; and the method for preparing medical lactide is high in yield, simple in reaction operation, free of danger, short in production time and beneficial to industrial production, and has quite high economic value.

Owner:上海绿色盛世生态材料有限公司

Aramid fabric high-efficiency dyeing and finishing process

InactiveCN104988711AImprove hydrophilicityImprove dye uptakePhysical treatmentFibre typesInorganic saltsProcess engineering

The invention discloses an aramid fabric high-efficiency dyeing and finishing process including modification treatment, scouring and dyeing in one bath, soaping, color fixation, post-finishing, drying, sizing, calendering, and coiling. According to the dyeing and finishing process, before the dyeing process, a fabric is subjected to low temperature plasma treatment, then the fiber fabric is subjected to modification treatment with 2,3-epoxypropyltrimethylammonium chloride and chitosan, and thus the fabric dyeing degree is increased, and the difficulty of the subsequent dyeing steps is reduced; at the same time, ultrasonic treatment is adopted during modification treatment, so that the time is saved and the treatment efficiency is improved; with adopting of scouring and dyeing in one bath, the efficiency is increased, and the cost is reduced; in the dyeing process, a large amount of alkaline substances and inorganic salts are not used, natural dyes are used, and at the same time, a colophony powder is added as a color fixing agent, so that the color fixing effect is enhanced, besides, the environmental pollution is avoided, and the requirements of environmental protection are met; and with increase of anti-yellowing finishing, a final fabric does not easily turn yellow.

Owner:TAICANG SHUANGYU CHEM FIBER CO LTD

Water-based gravure polishing oil and preparing method thereof

ActiveCN102392387AQuality improvementNo pollution in the processPaper coatingCoatingsAlcoholSolvent free

The invention provides water-based gravure polishing oil and is characterized in that the water-based gravure polishing oil is prepared with the following raw materials in percentage by weight: water: 10-25; alcohols solvent: 5-20; emulsion: 20-45; solid resin: 5-25; amine assistant: 5-15; foam killer: 0.1-0.5; anti-wear additive: 0.5-5; flatting agent: 0.1-3; and film forming assistant: 1-5. Theinvention further discloses a polishing oil preparing method. Compared with the traditional gravure polishing oil, through the adoption of more reasonable raw materials, the water-based gravure polishing oil has the advantages of stable quality, innocuity, zero environment pollution, no solvent volatilization, high glossiness, strong abrasion resistance, low probability of yellowing and good adhesive attraction, can improve production environment, and is favorable for the health of operating staff; and the attenuant can be water and also can be the mixture of alcohols solvent and water with the ratio of 1 to 1 according to specific circumstances, so that the use cost of attenuant is greatly reduced.

Owner:江苏泰格油墨有限公司

Dyeing and finishing process of polyester and cotton blended fiber fabric

InactiveCN105063997AHigh whitenessAvoid damageSucessive textile treatmentsBiochemical fibre treatmentPolyesterFiber

The invention discloses a dyeing and finishing process of polyester and cotton blended fiber fabric. The process comprises pretreatment, presetting, modification treatment, dyeing, mordant removal, soaping, color fixing, after finishing, drying, sizing, calendaring and rolling. Snailase and alpha-amylase are adopted for pretreatment, modification treatment is adopted before dyeing, the polyester and cotton blended fabric is modified fundamentally, and the dye-uptake of the fabric is increased; in the dyeing procedure, fewer alkaline substances and inorganic salt are used, a dye leveler, substitution alkali, a migration inhibitor and a diffusant are added, the dye leveling performance is improved, natural dye is used, environmental pollution is avoided, and the environment-friendly requirement is met; self-cleaning treatment is added during aftertreatment, and the self-cleaning capacity, the crease-resistant performance, the wash durability and color fastness are improved; silk fibroin and sericin are adopted for afterfinish, and the anti-pilling performance and the antistatic performance of the fabric are provided; the whole process is environment-friendly and pollution-free.

Owner:TAICANG TIANLONG CHEM FIBER

Low-temperature dyeing and finishing technology for bamboo fiber fabric

InactiveCN105019250AAvoid damageLower processing temperaturePhysical treatmentBiochemical fibre treatmentAmylaseFiber

The invention discloses a low-temperature dyeing and finishing technology for bamboo fiber fabric. The low-temperature dyeing and finishing technology includes the steps of pretreatment, preshaping, modification treatment, dyeing, mordant removal, soaping, color fixation, after finishing, drying, shaping, calendering and rolling. Helicase, scouring enzyme and alpha-amylase are adopted for pretreatment, modification treatment is adopted before dyeing, the performance of the bamboo fiber fabric is modified fundamentally, and the dye-uptake rate of the fabric is increased; as in the dyeing working procedure, alkaline substance and inorganic salts are not used in quantity, and a levelling agent is added, the dyeing levelness is improved; environment pollution is avoided by using natural dyestuff, which meets the requirement for environmental protection; as self-cleaning treatment is added in after treatment, the self-cleaning capacity, crease-resistant performance and wash-resisting firmness of the fabric are improved; crease-resistant finishing is added, and therefore the crease-resistant performance of the fabric is improved; the whole technology is environmentally friendly and free from pollution.

Owner:TAICANG TIANLONG CHEM FIBER

Dyeing and finishing process for modal fabric

InactiveCN104975499AReduce pollutionAvoid damageBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsProcess engineering

The invention discloses a dyeing and finishing process for modal fabric. The process comprises the procedures of pretreatment, pre-setting, modification treatment, dyeing, soaping, fixation, after-finishing, drying, sizing, calendering and rolling. According to the invention, pretreatment is carried out by adopting ultrasonic wave, and a step of modification treatment is added; in the dyeing procedure, a base substituent SA is used, use of a large quantity of alkaline substances and inorganic salt is avoided, nature dye is adopted, and colophony powder is added as a fixing agent, so that the color fixing effect is enhanced, environmental pollution is avoided, and the requirement of green environmental protection is met; furthermore, montmorillonoid is adopted to carry out modification treatment and flame retardant treatment on the fabric, so that the flame retardancy of the fabric is high. According to the invention, a yellowing-resisting reagent is used in the procedures of pre-setting, sizing and after-finishing, so that the final fabric cannot become yellow easily.

Owner:TAICANG CHENGLE CHEM FIBER

Polyamide fabric modifying, dyeing and finishing process

InactiveCN105019266AProcess temperature changeLow processing temperatureBiochemical fibre treatmentFibre typesPolyamideDyeing

The invention discloses a polyamide fabric modifying, dyeing and finishing process. The process comprises the steps of pretreatment, pre-setting, modification treatment, dyeing, soaping, color fixing, after treatment, drying, setting, calendering and rolling. Helicase and alpha-amylase are adopted for carrying out pretreatment, mixed liquor of nanometer titanium dioxide, gamma-(2, 3-epoxypropoxy) trimethoxypropylsilane and caprolactam is adopted for modifying performance of polyamide fabric fundamentally, and the dye-uptake rate of the fabric is increased; in the dyeing working procedure, a large number of alkaline substances and inorganic salts are not used, a leveling agent and a dispersing agent are added, and dyeing levelness is improved; meanwhile, as rosin powder is added to serve as a color fixing agent, the color fixing effect is enhanced, environmental pollution is avoided, and the requirement for environmental protection is met; moreover, montmorillonite is adopted for carrying out modifying and flame retarding on the fabric, and therefore the fire retarding property of the fabric is high; anti-yellowing reagents are used in the presetting and setting steps, and therefore the final fabric is not prone to yellowing.

Owner:TAICANG CHENGLE CHEM FIBER

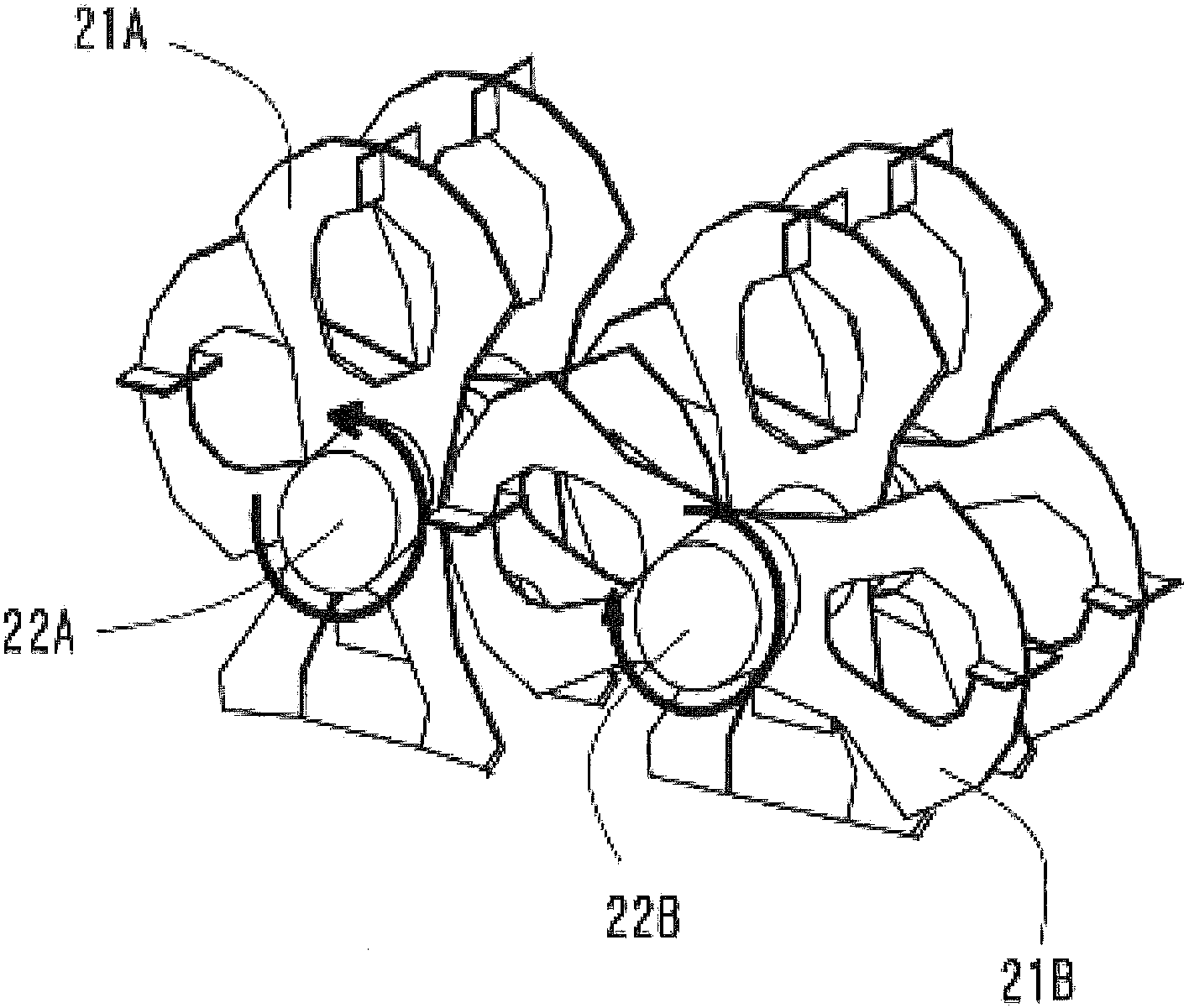

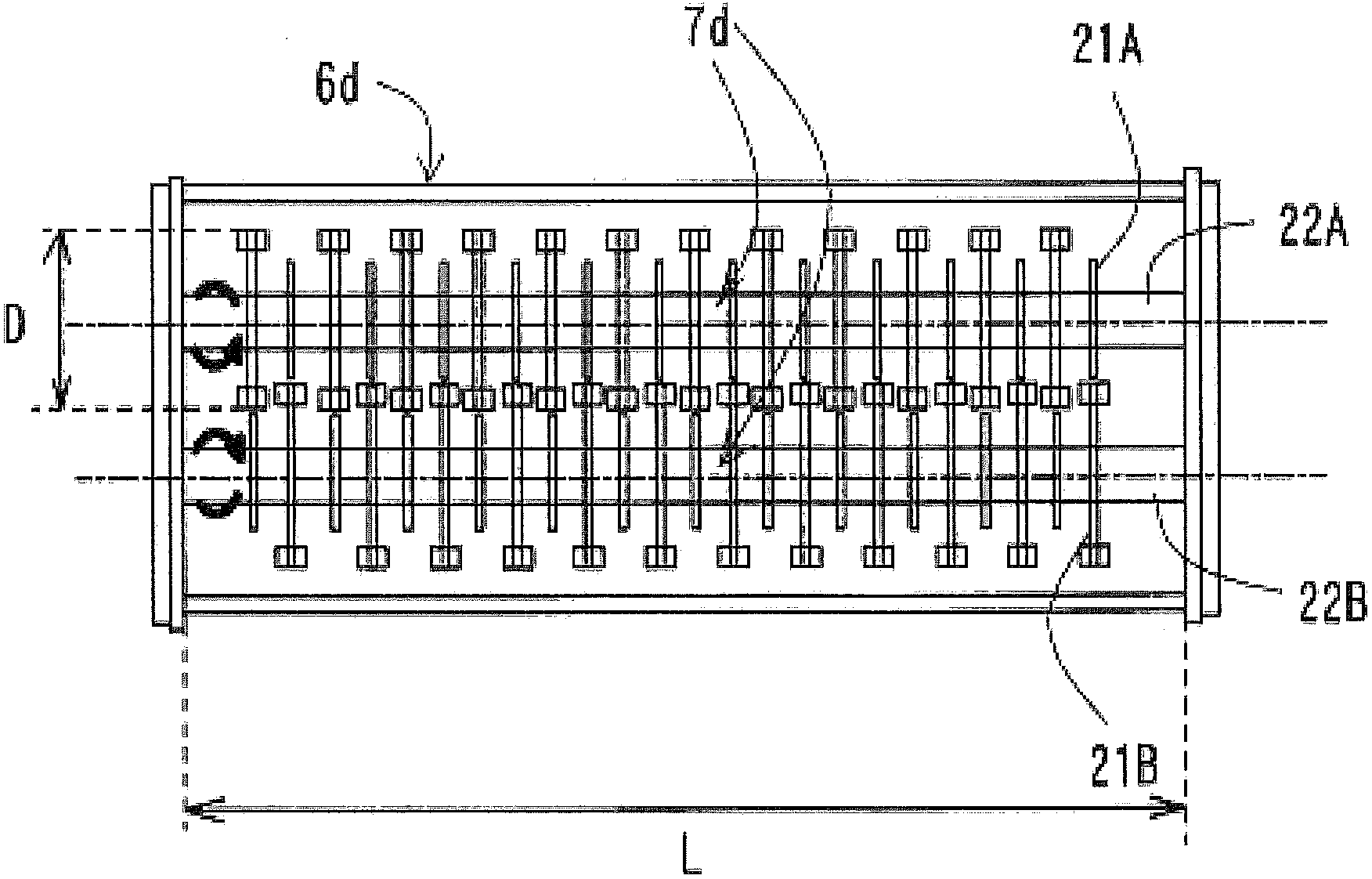

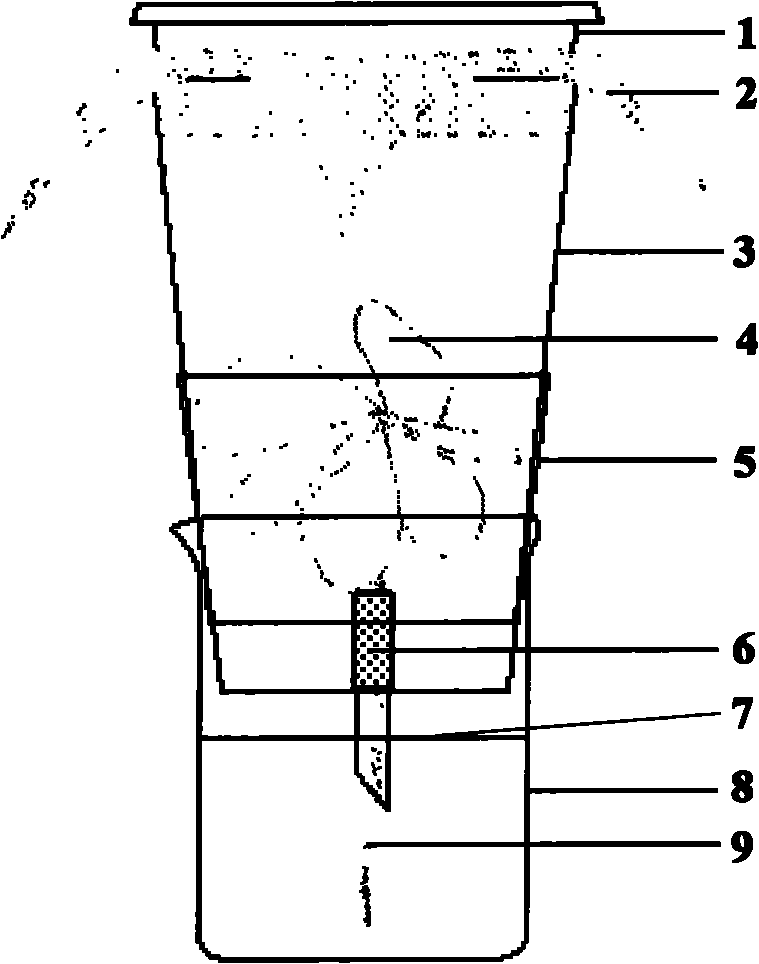

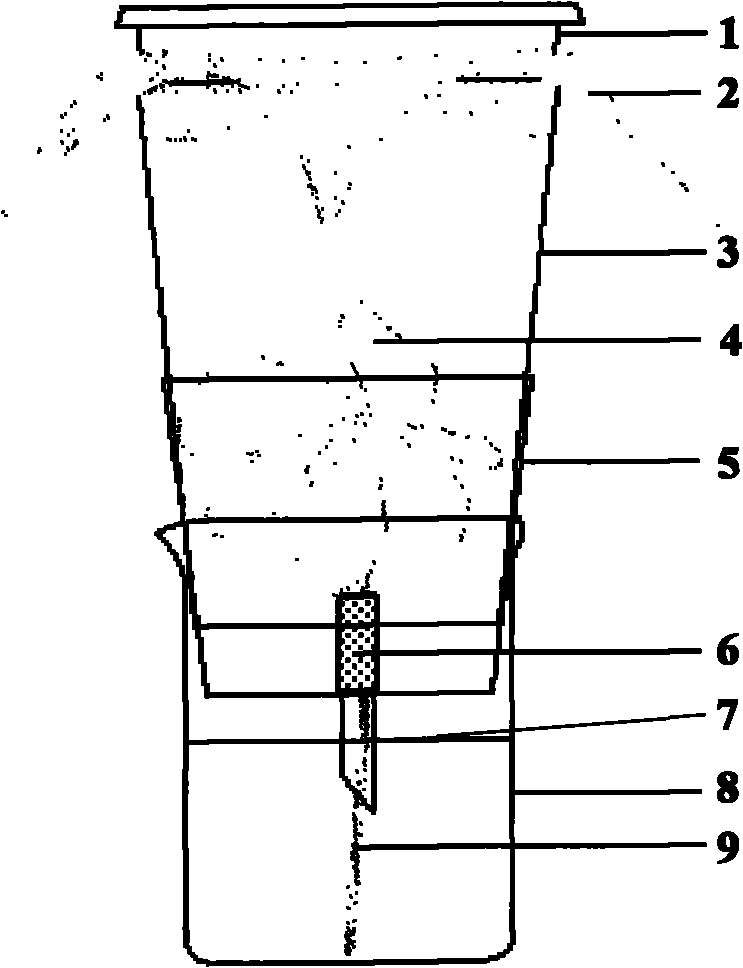

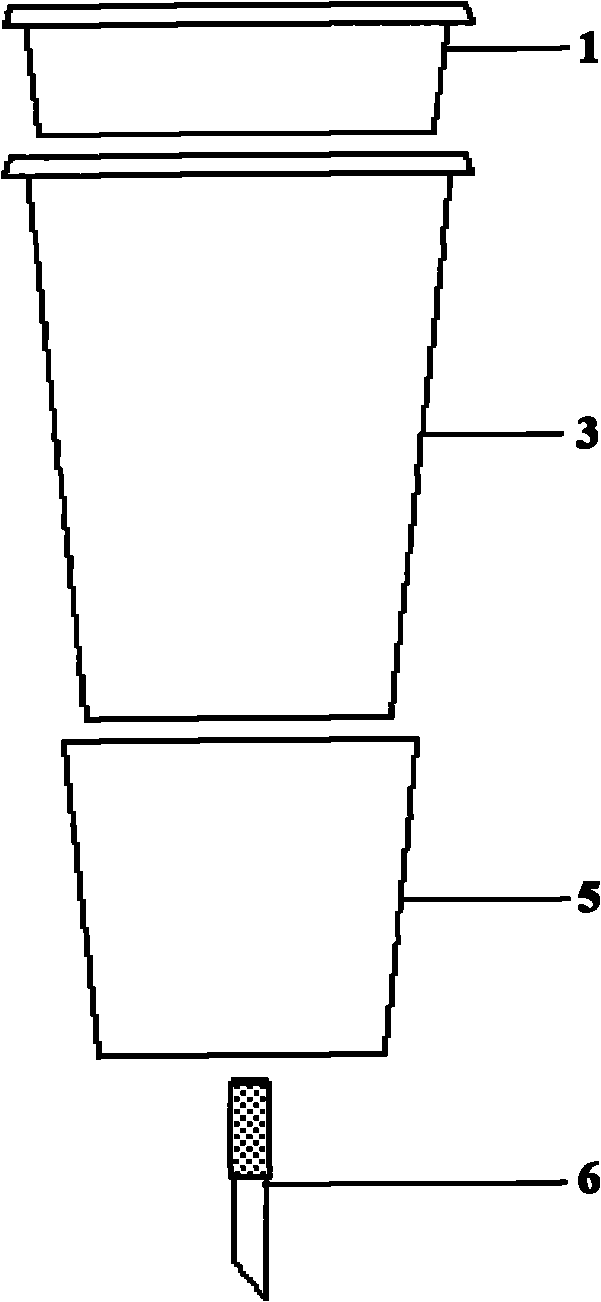

Tetranychina harti feeder

InactiveCN101810155AAvoid deathPrevent escape from disappearanceAnimal husbandryMicroscopic observationEngineering

The invention relates to a Tetranychina harti feeder, which belongs to the technical field of entomology experiment. The feeder consists of an upper feeding chamber and a lower water pool. Safflower oxalis leaf isolated leaf with petiole is vertically planted into the feeder. The blade in which the mite is cultivated is hung in the feeding chamber. The petiole enters under the water level of the water pool through a petiole inserting pipe at the bottom of the feeding chamber. When the Tetranychina harti is fed by the feeder, the blade part of the safflower oxalis leaf is free from the preserving liquid, therefore the blade is difficult to yellow and mildew, the blade surface is dry, and the mite can freely move on the blade, and has natural living state. The feeding chamber is manufactured by a disposable plastic cup, a gauge and the like, and has the advantages of sealing property, permeability and light transmission; and the microenvironment in which the mite is cultivated is consistent with the set feeding condition. Each component of the feeder is easy to disassemble and assemble, therefore the microscopic observation and replacement of the blade are convenient.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

Pulp

InactiveCN103485233ANo reduction in mechanical strengthNot easy to turn yellowNon-fibrous pulp additionPaper/cardboardEpoxyFiber

The invention discloses a pulp. The pulp comprises the following raw material components at weight ratio: 50-60 straw pulp, 10-20 raphioid hardwood fiber, 1-10 silkworm cocoon, 2-8 debregeasia edulis, 3-8 agar, 1-2 adhesive, 1-2 flexibilizer, 1-2 waterproof agent and 1-2 adjuvant. The pulp enables the paper whitenness to meet the requirement of paper without lowering the mechanical strength of paper, and ensures low yellowing probability and stable quality of paper. A Sirain high-side-chain-density paper-making retention and filtration aid, which has higher flocculation capability than linear molecules and particularly extremely strong retention capability to fiber fines, is adopted. The high-strength positive charge density also helps to retain more fillers. The common raw materials, such as straw pulp, silkworm cocoon, raphioid hardwood fiber, debregeasia edulis and the like, are adopted, epoxy resin and other flexibilizers are added to increase the tenacity, and agar is added to increase the smoothness of paper, so that an embroidery picture book prepared from the pulp has a certain glossiness and nice color.

Owner:句容市植保植检站

Efficient dyeing and finishing process for chemical fiber fabric

InactiveCN104975498AImprove hydrophilicityImprove dye uptakeHeating/cooling textile fabricsDry-cleaning apparatus for textilesInorganic saltsFiber

The invention discloses an efficient dyeing and finishing process for a chemical fiber fabric, which comprises the procedures of modification treatment, one-bath scouring dyeing, soaping, fixation, after finishing, drying, sizing, calendering and rolling. According to the invention, pretreatment is carried out by adopting ultrasonic wave; before the procedure of dyeing, the fabric is subjected to low-temperature plasma treatment, and then 2, 3-glycidyl trimethyl ammonium chloride is adopted for carrying out modification treatment on the fiber fabric, so that the degree of dyeing of the fabric is increased, and the difficulty of subsequent dyeing step is lowered; since one-bath scouring dyeing is adopted, the efficiency is increased, and the cost is lowered; in the dyeing procedure, use of a large quantity of alkaline substances and inorganic salt is avoided, nature dye is adopted, and colophony powder is added as a fixing agent, so that the color fixing effect is enhanced, environmental pollution is avoided, and the requirement of green environmental protection is met; furthermore, montmorillonoid is adopted to carry out flame retardant treatment on the fabric, so that the flame retardancy of the fabric is high. According to the invention, a yellowing-resisting reagent is used in the procedure of sizing, so that the final fabric cannot become yellow easily.

Owner:TAICANG TIANLONG CHEM FIBER

Preserved pork ribs

The invention discloses preserved pork ribs, and relates to food, in particular to food made of pork ribs. The preserved pork ribs are prepared by the following steps of: preparing raw materials, pickling, and air-drying. According to the preserved pork ribs prepared by the process, nitrate for the traditional pickling is replaced by iodized table salt, and relatively low salt consumption is adopted; the preserved pork ribs prepared by the process are low in salt content, and the content of nitrite of the preserved pork ribs is far lower than the national related standard; and the pickling period of the preserved pork ribs is shortened, the pickling quality is improved, and the preserved pork ribs can be massively produced to meet daily increasing eating requirements.

Owner:芮茂能

Fatigue-resistant ultraviolet-resistant one-component dealcoholization type silicone structure sealant and preparation method thereof

ActiveCN105385408AGood mechanical propertiesGood storage stabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePtru catalyst

The present invention discloses a fatigue-resistant ultraviolet-resistant one-component dealcoholization type silicone structure sealant and a preparation method thereof, the sealant comprises the following raw materials in parts by weight: 100 parts of terminal hydroxyl polydimethylsiloxane, 60 to 120 parts of a reinforcing filler, 5 to 15 parts of a plasticizer, 3 to 8 parts of a crosslinking agent, 0.2 to 2 parts of a bi-metal aluminum-zirconium coupling agent, 0.5 to 3 parts of a catalyst and 0.5 to 2 parts of a deep layer curing agent. The bi-metal aluminum-zirconium coupling agent is one or more agents of aluminium adipate-zirconium coupling agent, aluminium itaconate-zirconium coupling agent and aluminium stearate-zirconium coupling agent. The fatigue-resistant ultraviolet-resistant one-component dealcoholization type silicone structure sealant has good mechanical properties and good storage stability, has the characteristics of being not easy to turn yellow and fast to cure, also has fatigue resistance, ultraviolet irradiation resistance and other performances, is suitable for being widely used in insulated cable and automotive industries, and has good economic and social benefits.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

Heat transfer printing adhesive for metal shell and preparation method thereof

ActiveCN103275627AFacilitate cross-linkingImprove adhesionNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveEpoxyAdhesive

The invention discloses a heat transfer printing adhesive for a metal shell. The adhesive is prepared from the following raw materials in parts by weight: 12-15 parts of acrylic resin (AR-2630), 20-25 parts of E-42 epoxy resin, 8-12 parts of polyethylene glycol, 4-6 parts of maleic anhydride, 8-10 parts of ethylene glycol, 2-3 parts of tert-butyl hydroperoxide, 8-10 parts of oleic acid polyoxyethylene ester, 5-8 parts of polyvinyl pyrrolidone, 1-2 parts of crosslinking agent TAIC, 4-6 parts of coumarone, 2-3 parts of 1-hydroxyethyl-2-oleic imidazoline, 4-6 parts of dibutyl phthalate, 2-3 parts of 1,2-diaminocyclohexane, 55-60 parts of acetone and 40-45 parts of dimethylbenzene. Compared with the prior art, the adhesive is used for transferring a pattern on the metal shell, has the advantages that the adhesive is firm in bonding and enables the product not to break, shed or yellow easily, and has the effect on improving the product quality. The crosslinking agent TAIC is added in the formula, thus greatly improving the crosslinking property of various components, improving the bonding strength and improving the weatherability through initiation and polymerization of an initiator. 1-hydroxyethyl-2-oleic imidazoline enables the corrosion resistance to be greatly improved.

Owner:ANHUI YICAI GLASSWARE

Water-based finishing agent for leather as well as preparation method and roller coating process

InactiveCN108822675AGood film formingStrong adhesionPolyurea/polyurethane coatingsLeather surface finishingWater basedPolyester

The invention discloses a water-based finishing agent for leather as well as a preparation method and a roller coating process. The water-based finishing agent comprises a component A and a componentB in matched use. The adhesive force between the water-based finishing agent and the leather body is improved; according to the component B, by utilizing complementary advantages of polyester glycol and polyether glycol, the water-based finishing agent for leather has high tensile strength and elongation at break and excellent water resistance; the acrylate monomer is added into the component B for modifying, so that the agent has excellent film-forming agent, adhesive force, water resistance, solvent resistance and heat resistance, and the cost is reduced; casein is added into the component B, so that the bending resistance of the water-based finishing agent is improved, the water resistance and water-resisting property are improved, and the market prospects are wide.

Owner:山东莱福特皮革制品有限公司

Processing technology for extracting agar from laver

The invention provides a processing technology for extracting agar from laver, aiming at the problems existing in the conventional processing technology for extracting agar. The technology comprises the following six steps of: performing alkaline treatment; performing alkali rinsing, acid rinsing and bleaching treatment; performing acid rinsing, and washing and bleaching; extracting the agar; and finely filtering. The technology is environmentally-friendly; the extraction rate and the gel strength of the agar are improved; and a produced agar product is difficult to yellow during storage.

Owner:青岛聚大洋藻业集团有限公司

Colour cement tile coating, and its preparing process

InactiveCN1891769AEmphasis on glass transition temperatureGood weather resistanceMulticolor effect coatingsTemperature controlVitrification

The invention relates to color cement roof paint and its preparation technology. Its material constituents and weight percentages are as follows: acrylic resin 20-45%, pigment or dye 0.5-15%, auxiliary 0.1-3%, and solvent 45-78%. Its preparation technology adopts resin and paint manufacturing steps. Compared with the current technique, it emphasizes glass temperature control more to make the product have better weathering and water resistances. Thus it can be used in outdoor cement product, especially for the protection and decoration of the cement roof tile surface.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

TPU thin film with light reflection and thermal insulation functions and preparation method thereof

The invention relates to a TPU thin film with light reflection and thermal insulation functions and a preparation method thereof. The TPU thin film is prepared from, by weight, 50-100 parts of polyester glycol, 15-30 parts of diisocyanate, 5-35 parts of a chain extender, 1-5 parts of molybdenum disulfide micro powder, 1-5 parts of white carbon black, 2-5 parts of metal oxide-modified diatomaceous earth powder, 2-5 parts of dibutyl phthalate, 0.5-1 parts of a titanate coupling agent, 1-5 parts of talcum powder and 1-5 parts of sepiolite. The TPU thin film has the excellent light reflection and thermal insulation functions.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com