Fiber fully drawn yarn (FDY) spinning oil and preparation method thereof

A technology of spinning oil and fiber, applied in the chemical field, can solve the problems of unevenness, difficulty in rinsing, unsatisfactory fiber smoothness and bunching, etc., to meet the penetration effect, improve the anti-corrosion effect, and improve the anti-oxidation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

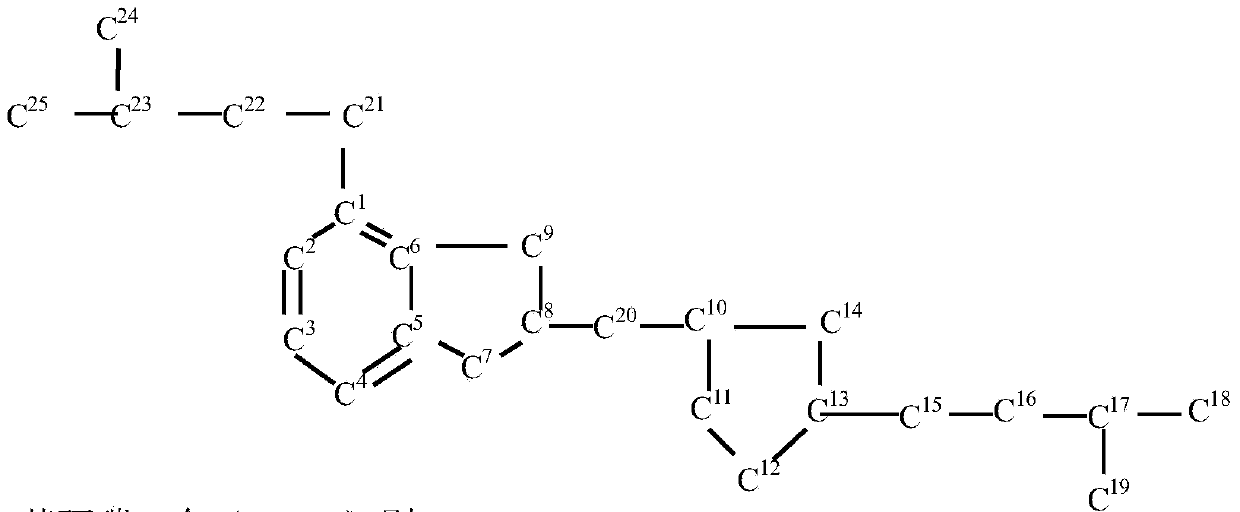

Method used

Image

Examples

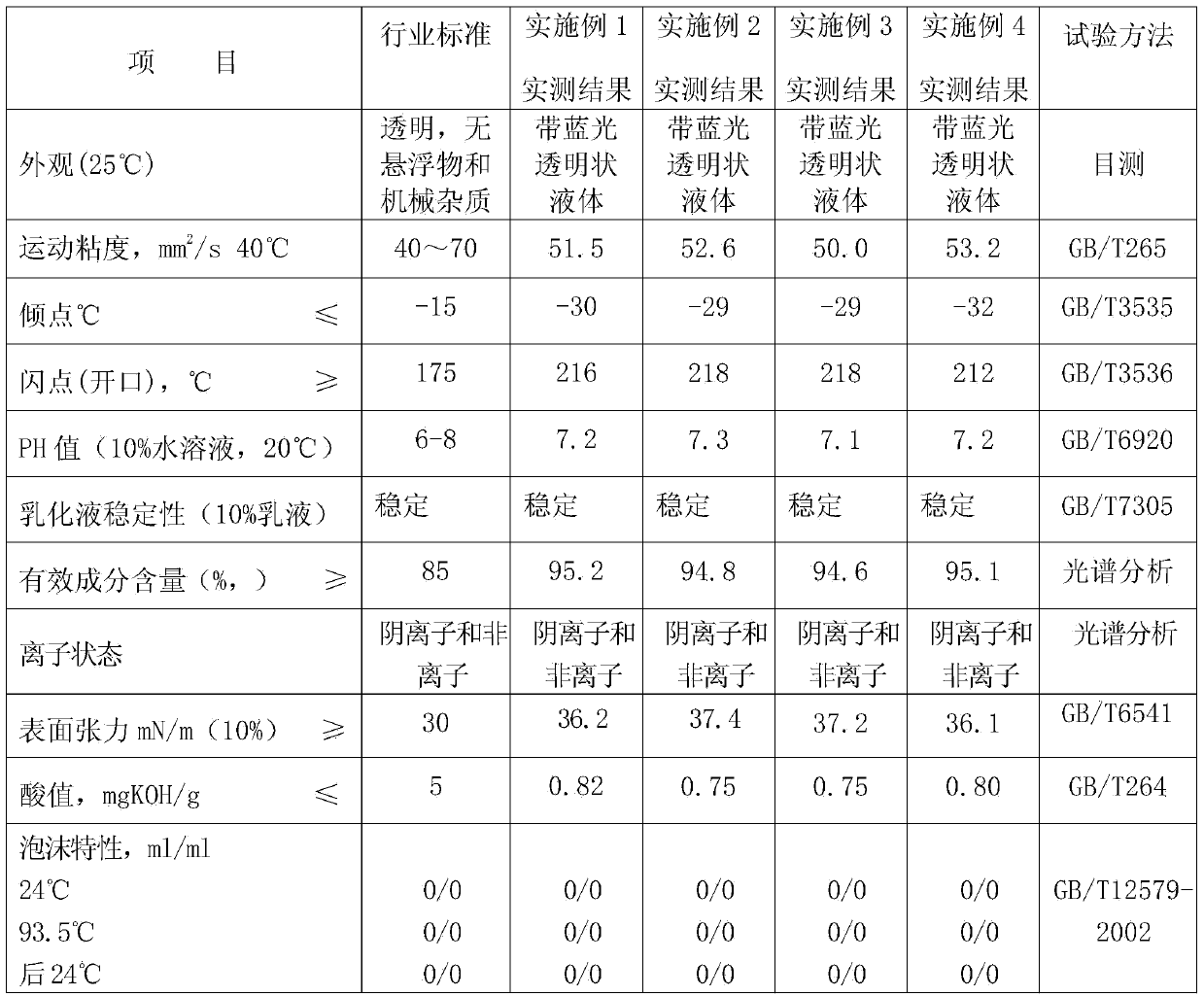

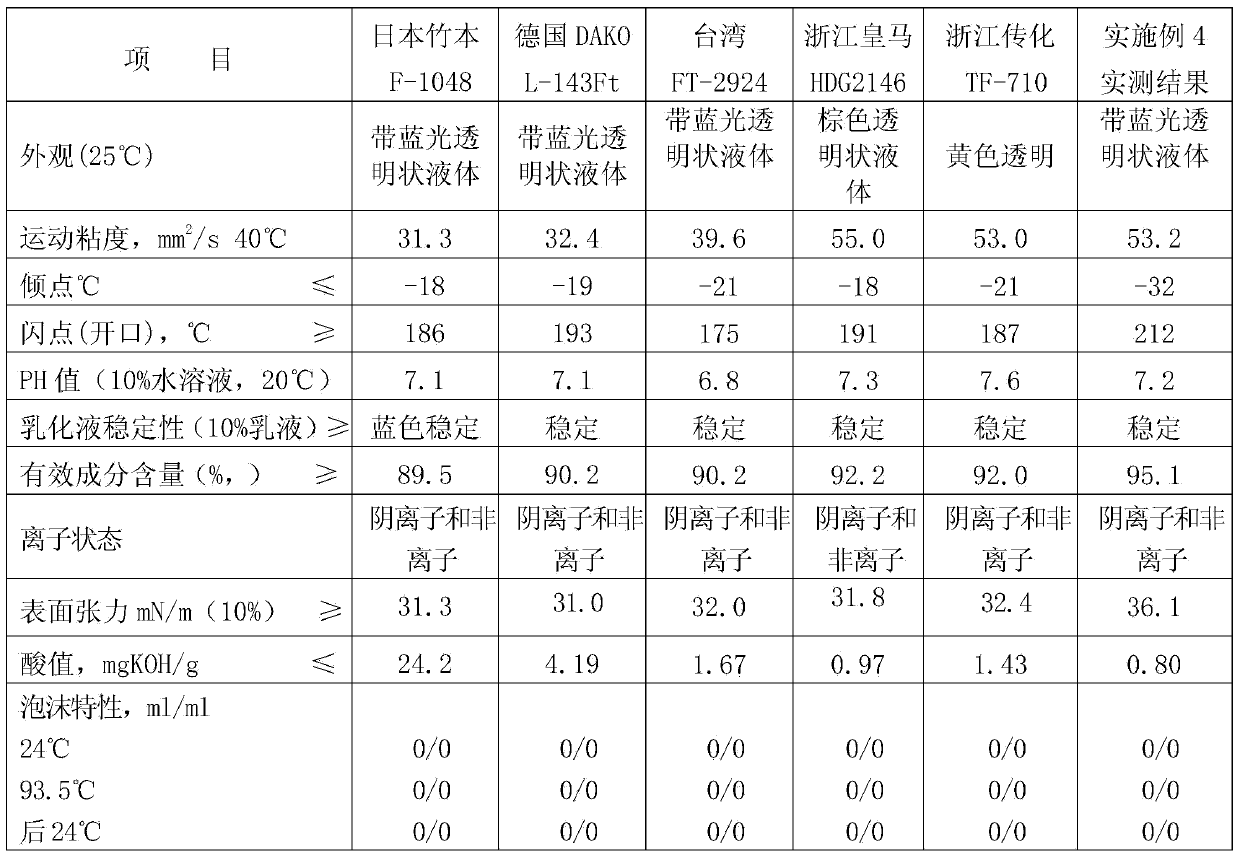

Embodiment 1

[0054] A kind of fiber FDY spinning oil agent of the present invention is made of high-temperature smoothing agent (hydrogenated paraffin base oil, hydrogenated naphthenic oil), composite antistatic agent, sizing agent, phenol-based antioxidant, anilino antioxidant , Acrylic acid antioxidant, high temperature dispersant, softener, environmentally friendly emulsifier, defoamer, preservative, and environmentally friendly penetrating agent. In the described fiber FDY spinning oil, the high-temperature smoothing agent (the weight percentage of hydrogenated paraffinic base oil is 48%, the weight percentage of hydrogenated naphthenic oil is 20%), and the weight percentage of composite antistatic agent is 6%, sizing agent weight percentage is 4%, phenolic antioxidant weight percentage is 0.2%, anilino antioxidant weight percentage is 0.1%, alkene acid antioxidant weight percentage is 1%, high temperature dispersant weight percentage is 0.8%, softener 1.6% by weight, environment-frien...

Embodiment 2

[0073] A kind of fiber FDY spinning oil agent of the present invention is made of high-temperature smoothing agent (hydrogenated paraffin base oil, hydrogenated naphthenic oil), composite antistatic agent, sizing agent, phenol-based antioxidant, anilino antioxidant , Acrylic acid antioxidant, high temperature dispersant, softener, environmentally friendly emulsifier, defoamer, preservative, and environmentally friendly penetrating agent. In the described fiber FDY spinning oil, the high-temperature smoothing agent (the weight percent of hydrogenated paraffin base oil is 50%, the weight percent of hydrogenated naphthenic oil is 18%), and the weight percent of composite antistatic agent is 5%, sizing agent weight percentage is 6%, phenolic antioxidant weight percentage is 0.3%, anilino antioxidant weight percentage is 0.4%, alkene acid antioxidant weight percentage is 0.8%, high temperature dispersant weight percentage is 1%, the weight percentage of softener is 1.8%, the weight...

Embodiment 3

[0092] A kind of fiber FDY spinning oil agent of the present invention is made of high-temperature smoothing agent (hydrogenated paraffin base oil, hydrogenated naphthenic oil), composite antistatic agent, sizing agent, phenol-based antioxidant, anilino antioxidant , Acrylic acid antioxidant, high temperature dispersant, softener, environmentally friendly emulsifier, defoamer, preservative, and environmentally friendly penetrating agent. In the described fiber FDY spinning oil, the high-temperature smoothing agent (the weight percent of hydrogenated paraffin base oil is 52%, the weight percent of hydrogenated naphthenic oil is 16%), and the weight percent of composite antistatic agent is 4%, the weight percentage of sizing agent is 8%, the weight percentage of phenolic antioxidant is 0.4%, the weight percentage of anilino antioxidant is 0.5%, the weight percentage of alkene acid antioxidant is 0.6%, the weight percentage of high temperature dispersant is 1.5% %, the weight per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com