A kind of cattail viscose fiber and preparation method thereof

A viscose fiber and Puhuang technology, applied in the field of Puhuang viscose fiber and its preparation, can solve the problems of difficult mixing of viscose spinning solution, large surface area of Puhuang, etc., so as to increase the contact angle and improve the fiber whiteness. The effect of preventing easy yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

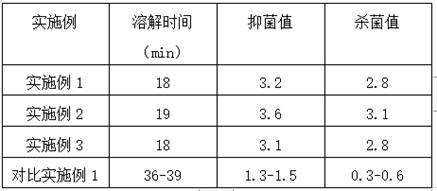

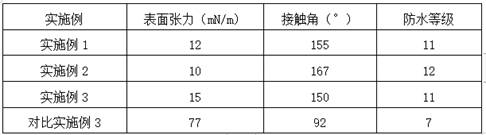

Embodiment 1

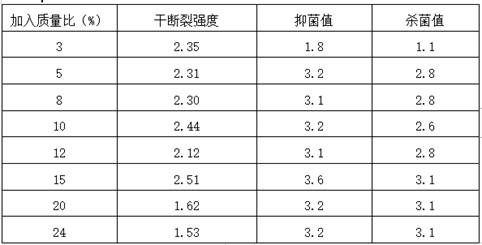

[0046] (1) Preparation of Puhuang powder mixture: Add Puhuang powder and Puhuang powder denaturant in a weight ratio of 8:1 into an electric heating mixer, mix and heat for denaturation, the heating temperature is 50°C, and the mixing time is 25 minutes to make Puhuang powder and Puhuang powder. The yellow powder denaturant is mixed evenly to make a Puhuang powder mixture; the technical indicators of the Puhuang powder are: loss on drying ≤5%, heavy metal content <10PPM, crude protein ≥9%, ash content <1.5%.

[0047] Puhuang powder denaturant includes cetyltrimethylammonium bromide, anilinoacetonitrile, barium laurate soap, sodium diacetate, dehydrated alcohol; in the Puhuang powder denaturant, cetyltrimethylammonium bromide The content is 10%, the content of anilinoacetonitrile is 3%, the content of barium laurate soap is 20%, the content of sodium diacetate is 30%, and the rest is absolute ethanol.

[0048] In the process of adding the denaturant, it is necessary to first he...

Embodiment 2

[0062] (1) Preparation of Puhuang powder mixture: Add Puhuang powder and Puhuang powder denaturant in a weight ratio of 10:1 into an electric heating mixer, mix and heat for denaturation, heating temperature is 75°C, and mixing time is 30min to make Puhuang powder and Puhuang powder. The yellow powder denaturant is evenly mixed to prepare a Puhuang powder mixture; the technical indicators of the Puhuang powder are: loss on drying ≤5%, heavy metal content <10PPM, crude protein ≥9%, ash content <1.5%.

[0063] Puhuang powder denaturant includes cetyltrimethylammonium bromide, anilinoacetonitrile, barium laurate soap, sodium diacetate, anhydrous ethanol; the content of cetyltrimethylammonium bromide in Puhuang powder denaturant is 12 %, the content of anilinoacetonitrile is 5%, the content of barium laurate soap is 23%, the content of sodium diacetate is 33%, and the rest is absolute ethanol.

[0064] In the process of adding the denaturant, firstly, heat and mix cetyltrimethylam...

Embodiment 3

[0081] (1) Preparation of Puhuang powder mixture: Add Puhuang powder and Puhuang powder denaturant in a weight ratio of 10:1 into an electric heating mixer, mix and heat for denaturation, the heating temperature is 100°C, and the mixing time is 35min, so that the Puhuang powder and the Puhuang powder are mixed. The yellow powder denaturant is mixed evenly to make a Puhuang powder mixture; the technical indicators of the Puhuang powder are: loss on drying≤5%, heavy metal content <10PPM, crude protein≥9%, ash <1.5%.

[0082]Puhuang powder denaturant includes cetyltrimethylammonium bromide, anilinoacetonitrile, barium laurate soap, sodium diacetate, anhydrous ethanol; the content of cetyltrimethylammonium bromide in the Puhuang powder denaturant is 15 %, the content of anilinoacetonitrile is 5%, the content of barium laurate soap is 25%, the content of sodium diacetate is 35%, and the rest is absolute ethanol.

[0083] In the process of adding the denaturant, it is necessary to f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com