Fatigue-resistant ultraviolet-resistant one-component dealcoholization type silicone structure sealant and preparation method thereof

A UV single-dealcoholization type technology, applied in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problem of anti-fatigue, anti-ultraviolet has not been reported, can not guarantee the excellent performance, and restricts the wide range of sealants Use and other issues to achieve good economic and social benefits, low cost, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

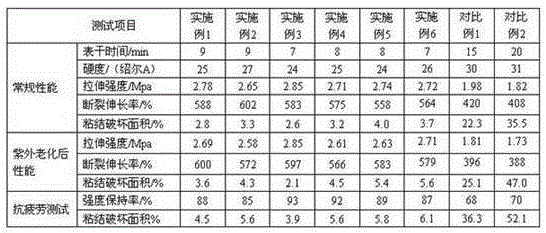

Examples

Embodiment 1

[0033] An anti-fatigue, anti-ultraviolet one-component dealcoholized silicone structural sealant, which is composed of the following raw materials in parts by weight: 1000g of hydroxyl-terminated polydimethylsiloxane with a viscosity of 20000Pa·s, 900g of active nano-calcium carbonate, 200 g of fumed silica, 70 g of simethicone oil with a viscosity of 100 Pa s, 50 g of methyltrimethoxysilane crosslinking agent, 20 g of aluminum-zirconium stearate coupling agent, 22 g of siloxane titanate, and dilauryl 1.6g of dibutyltin acid constitutes the catalyst and 6g of polyether silicone oil deep layer curing agent.

[0034] Preparation method of one-component dealcoholized silicone structural sealant:

[0035] (1) Add 1000g of hydroxyl-terminated polydimethylsiloxane, 900g of activated nano-calcium carbonate, 200g of fumed silica, and 70g of dimethyl silicone oil into a strong dispersion mixer. Stirring and dehydration for 4h at 500rpm to obtain mixed raw materials;

[0036] (2) Cool...

Embodiment 2

[0038] An anti-fatigue and anti-ultraviolet single-component dealcoholized silicone structural sealant, which is composed of the following raw materials in parts by weight: 1000g of hydroxyl-terminated polydimethylsiloxane with a viscosity of 20000Pa·s, 600g of active nano-calcium carbonate, Composed of 200g of fumed silica, 50g of simethicone oil with a viscosity of 500Pa·s, 40g of tetramethoxysilane crosslinking agent, 10g of aluminum-zirconium methacrylate coupling agent, 5g of dibutyltin dilaurate and 10g of citric acid Catalyst, polyethylene oxide deep curing agent 6g.

[0039] Preparation method of one-component dealcoholized silicone structural sealant:

[0040] (1) Add 1000g of hydroxyl-terminated polydimethylsiloxane, 600g of activated nano-calcium carbonate, 200g of fumed silica, and 50g of dimethyl silicone oil into a strong dispersion mixer. Stirring and dehydration for 5 hours at 300 rpm to obtain mixed raw materials;

[0041] (2) Cool the mixed raw materials to...

Embodiment 3

[0043] An anti-fatigue, anti-ultraviolet one-component dealcoholized silicone structural sealant, which is composed of the following raw materials in parts by weight: 1000g of hydroxyl-terminated polydimethylsiloxane with a viscosity of 50000Pa·s, 800g of active nano-calcium carbonate, 300 g of fumed silica, 120 g of simethicone oil with a viscosity of 200 Pa s, 30 g of trimethylsilane crosslinking agent, 8 g of aluminum oxalate-zirconium coupling agent, 10 g of silyl titanate catalyst, Polyethylene glycol deep curing agent 10g.

[0044] Preparation method of one-component dealcoholized silicone structural sealant:

[0045] (1) Add 1000g of hydroxyl-terminated polydimethylsiloxane, 800g of activated nano-calcium carbonate, 300g of fumed silica, and 120g of dimethyl silicone oil into a strong dispersion mixer. Stirring and dehydration for 3 hours at 800 rpm to obtain mixed raw materials;

[0046] (2) Cool the mixed raw materials to 40°C, and add 30 g of trimethylsilane orthos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com