Method for preparing medical lactide

A lactide and medical technology, applied in the field of polymer compound preparation, can solve the problems of incapable of large-scale production, complicated process, low yield, etc., to ensure stability and product quality, facilitate industrial production, and simple reaction operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

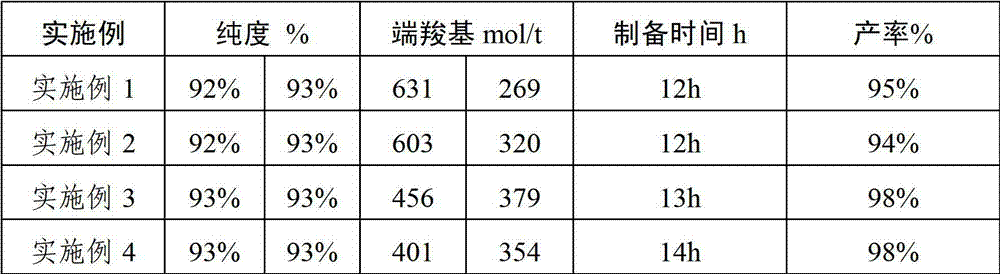

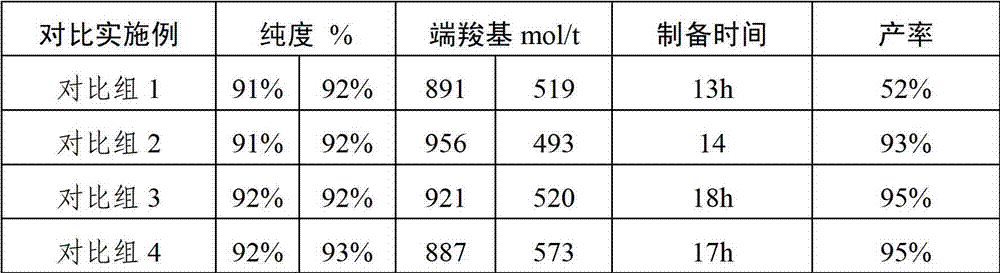

Examples

Embodiment 1

[0054] Add 50kg of L-lactic acid to the reaction kettle to replace the air in the reaction kettle (vacuumize-nitrogen, cycle 3 times); the heating medium is oil, so that the oil temperature rises to 120°C, slowly vacuumize to 200Kpa, and condense and dehydrate ( There is water until the condenser tube flows out), and the water gradually stops after 3 hours;

[0055] After passing nitrogen to normal pressure and draining water, add 50g of antimony trioxide and 25kg of diethyl phthalate; the oil temperature is raised to 170°C, and the vacuum is continuously and slowly pumped to 30Kpa, and the reaction is carried out for 4 hours; at this time, the lactic acid is initially removed ( LA) through the dehydration polycondensation of intermolecular hydroxyl and carboxyl groups, the lactic acid molecules start to polymerize;

[0056] Then pass nitrogen to normal pressure to drain water, then replace the heating medium with water, control the temperature at 175°C, continue vacuuming to ...

Embodiment 2

[0059] Other conditions were the same as in Example 1, except that 50 kg of D,L-lactic acid was added as raw material to prepare D,L-lactide in the form of white crystals.

Embodiment 3

[0061] Other conditions were the same as in Example 1, except that L-lactic acid and diethyl phthalate in a weight ratio of 1:1 were added to prepare L-lactide in the form of white crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com