Flame-proof reinforced Valox compound and preparation thereof

The technology of polybutylene terephthalate and compound is applied in the field of environment-friendly flame retardant reinforced polybutylene terephthalate compound and preparation thereof, and achieves good thermal-oxidative aging stability and is not easy to change color. , The effect of not easy to yellow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

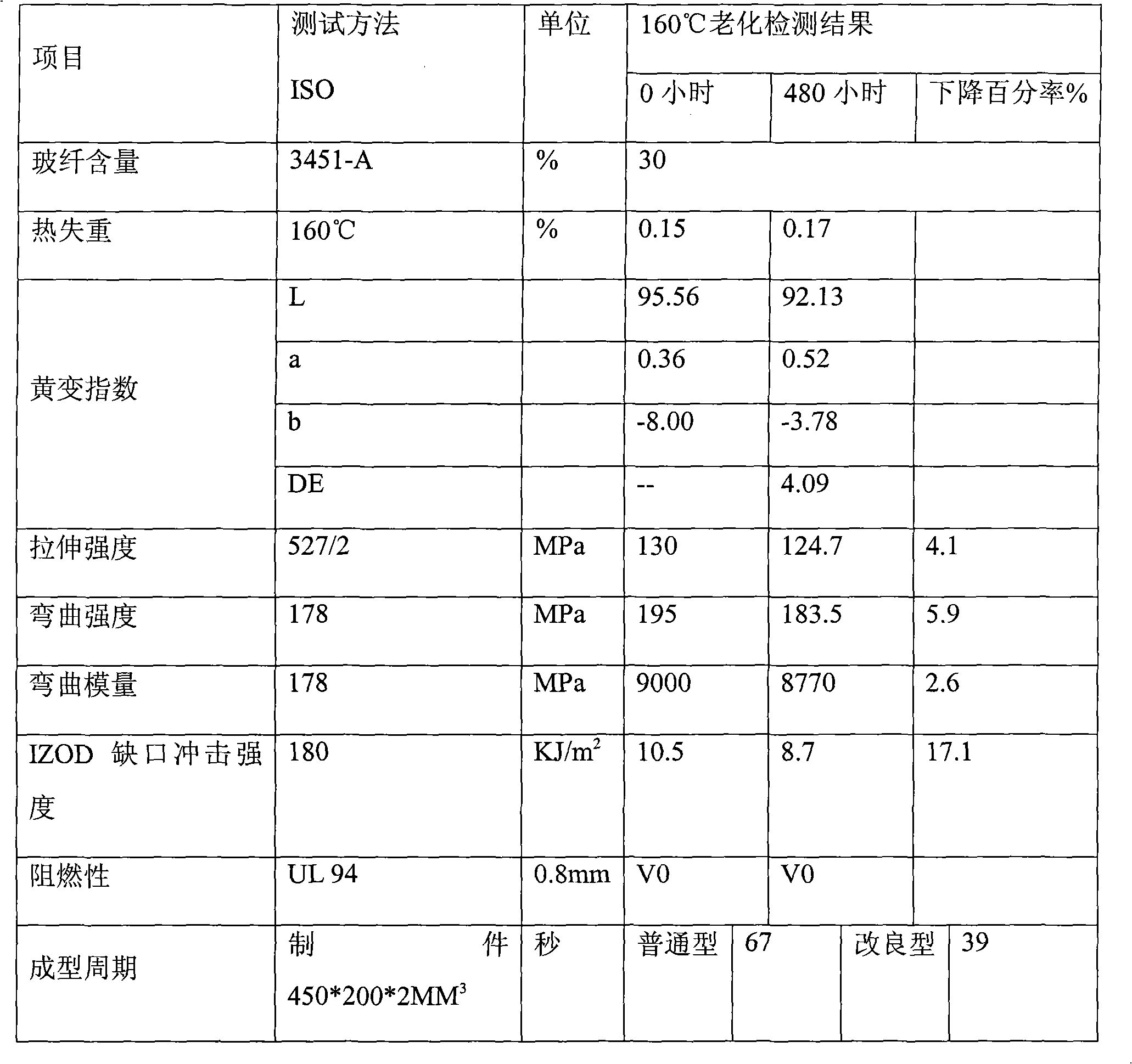

Embodiment 1

[0032] (1) Preparation of composite masterbatch:

[0033] First, 100.2 kg of auxiliary mineral powder flame retardants, namely wollastonite, zinc oxide, and silicon carbide whiskers, are mixed with 0.6 kg of surface treatment agents in a high mixer at 105°C in a ratio of (parts by weight) 200:300:1. Mix and activate for 20 minutes, the surface treatment agent is 0.3 kg of silane coupling agent, 0.1 kg of high molecular weight silicone oil and 0.2 kg of epoxy resin mixture;

[0034]Mix 100 kg of low-viscosity PBT resin with a viscosity of 0.72, 25 kg of ionic elastomer and 2 kg of compound additives, and then send them into the twin-screw extruder together with 7 kg of surface-treated auxiliary mineral powder flame retardant. Compounding and mixing to obtain composite masterbatch;

[0035] Ionic elastomers are ethylene / methacrylic acid copolymers in which acrylic acid groups are partially neutralized by Zinc ions. The copolymer contains a third acrylate comonomer. What is the ...

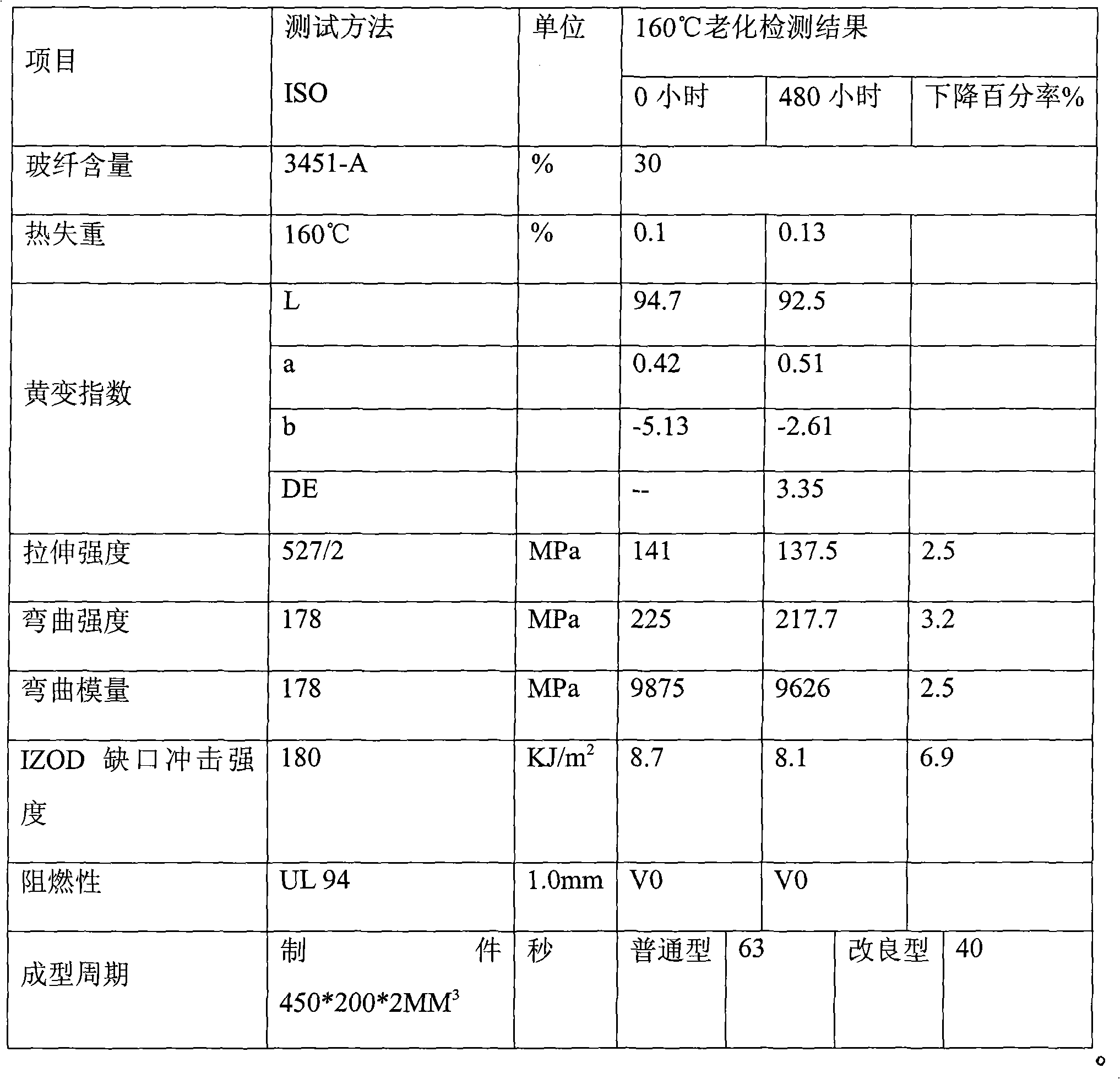

Embodiment 2

[0044] (1) Preparation of composite masterbatch:

[0045] First, 100.2 kg of auxiliary mineral powder flame retardant, namely zeolite, zinc borate, and magnesium oxide whiskers, are mixed and activated with 1.5 kg of surface treatment agent in a high mixer at 105°C in a ratio of (parts by weight) 200:300:1 Treat for 20 minutes, the surface treatment agent is 0.6 kg of silane coupling agent, 0.3 kg of high molecular weight silicone oil and 0.6 kg of epoxy resin mixture;

[0046] Mix 100 kg of low-viscosity PBT resin with a viscosity of 0.72, 15 kg of ionic elastomer and 6 kg of compound additives, and then send them into the twin-screw extruder together with 15 kg of surface-treated auxiliary mineral powder flame retardant. Compounding and mixing to obtain composite masterbatch;

[0047] Ionic elastomers are ethylene / methacrylic acid copolymers in which acrylic acid groups are partially neutralized by Zinc ions. The copolymer contains a third acrylate comonomer. What is the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com