Copper nano composite antibacterial coating and preparation method thereof

A composite antibacterial and copper nanotechnology, applied in coatings, devices for coating liquid on the surface, special surfaces, etc., can solve the problems of poor anti-mold effect, narrow application range, easy discoloration, etc., and achieve not easy discoloration, excellent antibacterial Good performance and anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The embodiment of the present invention provides a kind of preparation method of copper nanocomposite antibacterial coating, comprises the following steps:

[0038] S1, adopt chemical reduction method to prepare copper nano colloid, obtain copper nano powder after centrifugation and drying;

[0039] Wherein, the step of preparing copper nano colloid by chemical reduction method specifically includes:

[0040] Copper nanoparticles with particle size of 50-400nm are prepared by chemical reduction method in organic solvent, and surfactant is added to control particle size and shape. The copper salt may be copper oxide, the reducing agent used is hydrazine hydrate or ascorbic acid, the surfactant is polyvinylpyrrolidone and cetyltriethylammonium bromide, and the organic solvent used is absolute ethanol. In the reaction system for preparing copper nanocolloids by the chemical reduction method, the proportions of each substance are as follows: 10-15% of copper salt, 55-65% o...

Embodiment 1

[0054] A preparation method of copper nanocomposite antibacterial coating, comprising the following steps:

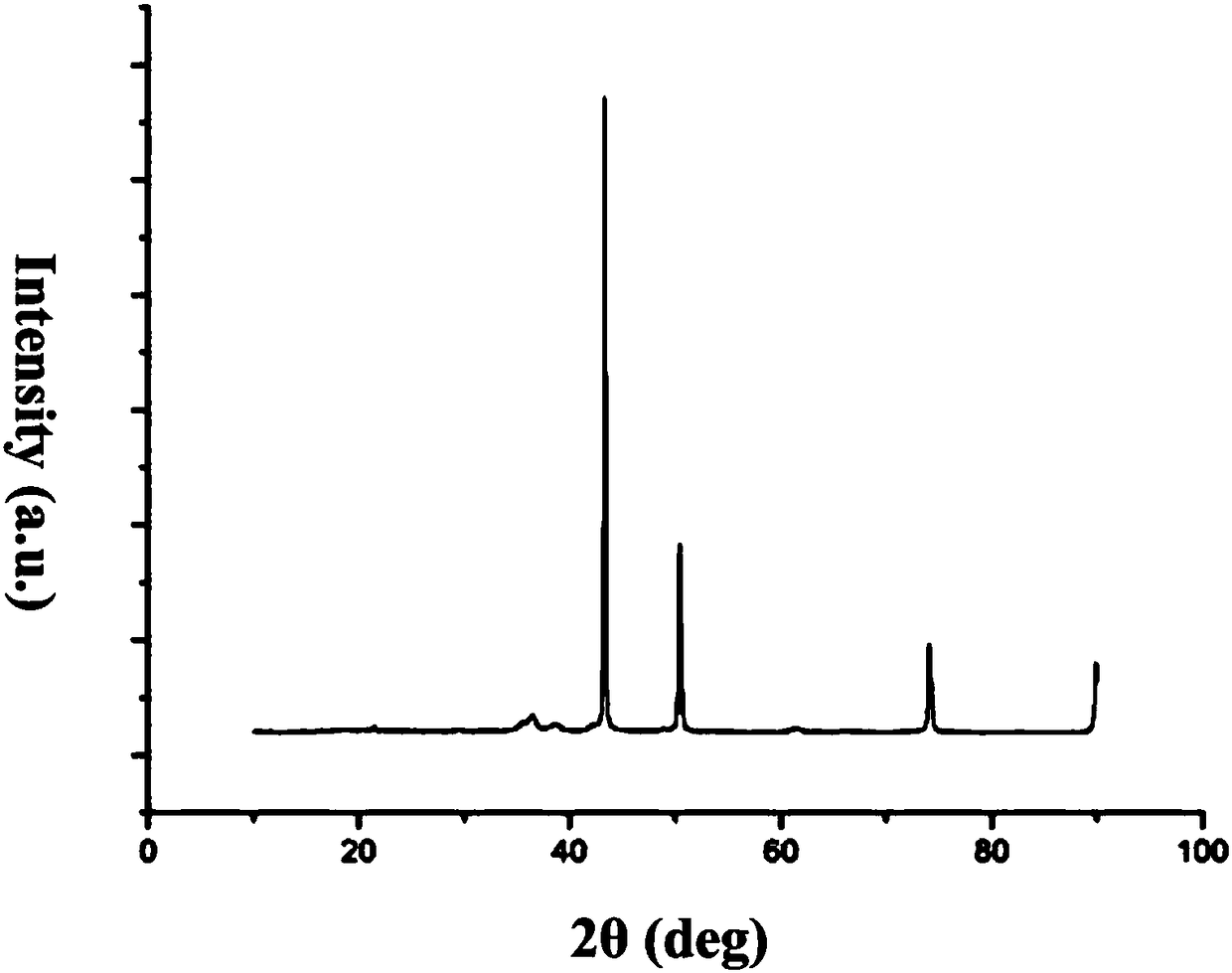

[0055] S1. Preparation of copper nanopowder: fully dissolve 6g of copper oxide powder, 3g of polyvinylpyrrolidone (PVP), and 3g of cetyltrimethylammonium bromide (CTAB) in 50ml of absolute ethanol, slowly drop into 10ml of hydrazine hydrate solution (80%) carry out chemical reduction reaction, centrifuge, dry to obtain copper nanopowder after reaction finishes; The XRD collection of illustrative plates of the copper nanopowder that makes can refer to figure 1 , each diffraction peak corresponds to the diffraction peak of pure copper.

[0056] S2. Put the copper nano-powder and electrostatic spraying powder prepared in step S1 into a mixer at a weight ratio of 0.2:99.8 for full mixing, and put the uniformly mixed raw materials in a high-temperature extruder to melt, extrude and cool to form a sheet , and then the raw material sheet is crushed and sieved into an ultrafin...

Embodiment 2

[0060] A preparation method of copper nanocomposite antibacterial coating, comprising the following steps:

[0061] S1, preparation of copper nanopowder: 6g copper oxide powder, 3g polyvinylpyrrolidone, 3g hexadecyltrimethylammonium bromide are fully dissolved in 50ml absolute ethanol, slowly drop into 10ml hydrazine hydrate solution (80%) for chemical Reduction reaction, after the reaction is completed, centrifuge and dry to obtain copper nano powder.

[0062] S2. Put the copper nano powder and electrostatic spraying powder prepared in step S1 into the mixer at a weight ratio of 1:99

[0063] Fully mixed in a high-temperature extruder, the uniformly mixed raw materials are melted in a high-temperature extruder, extruded and cooled into flakes, and then the raw flakes are crushed and sieved into ultrafine copper nanocomposite antibacterial powders.

[0064] S3. Copper nanocomposite antibacterial powder is sprayed on the metal surface by electrostatic spraying process to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com