Method for producing polycarbonate, and polycarbonate pellets

A technology of polycarbonate and manufacturing method, applied in the field of polycarbonate, can solve the problems of resin coloring, low thermal stability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

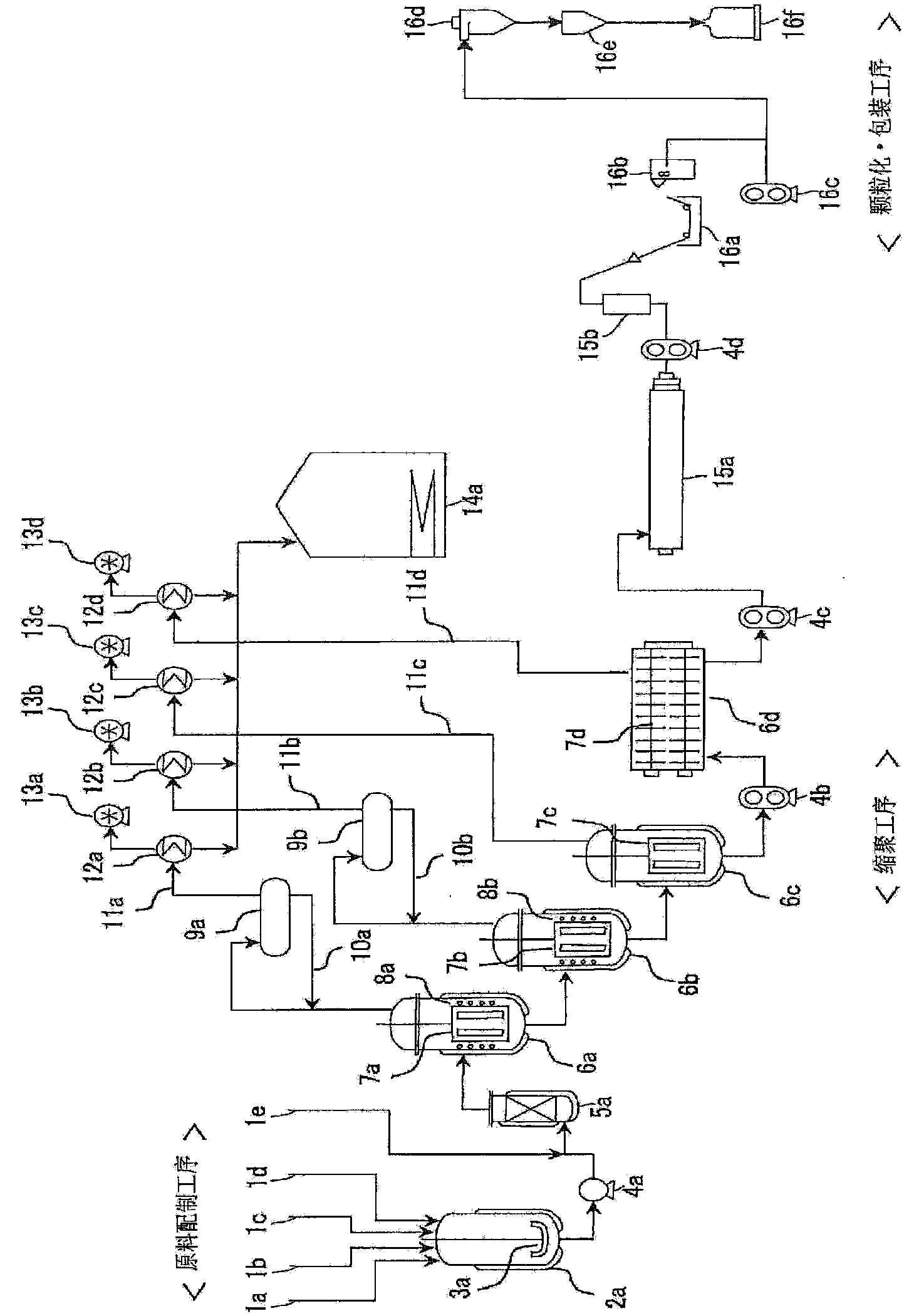

[0412] As above figure 1 As shown, polycarbonate was produced under the following conditions by a continuous production apparatus having three vertical stirred reactors and one horizontal stirred reactor. First, the reaction conditions of each reactor were previously set to the internal temperature and pressure shown in Table-1. Next, in a nitrogen atmosphere in another raw material preparation process, ISB, CHDM and DPC were mixed at a certain molar ratio (ISB / CHDM / DPC=0.500 / 0.500 / 1.010), and heated to 120° C. to obtain a raw material mixed melt.

[0413] [Table 1]

[0414]

temperature(℃)

Pressure (kPa)

Average residence time (minutes)

The first vertical stirred reactor

195

26.7

80

The second vertical stirred reactor

195

20.0

45

The third vertical stirred reactor

215

7.5

30

The fourth vertical stirred reactor

230

0.1

90

[0415] Then, the raw material mixed solution is ...

Embodiment 2

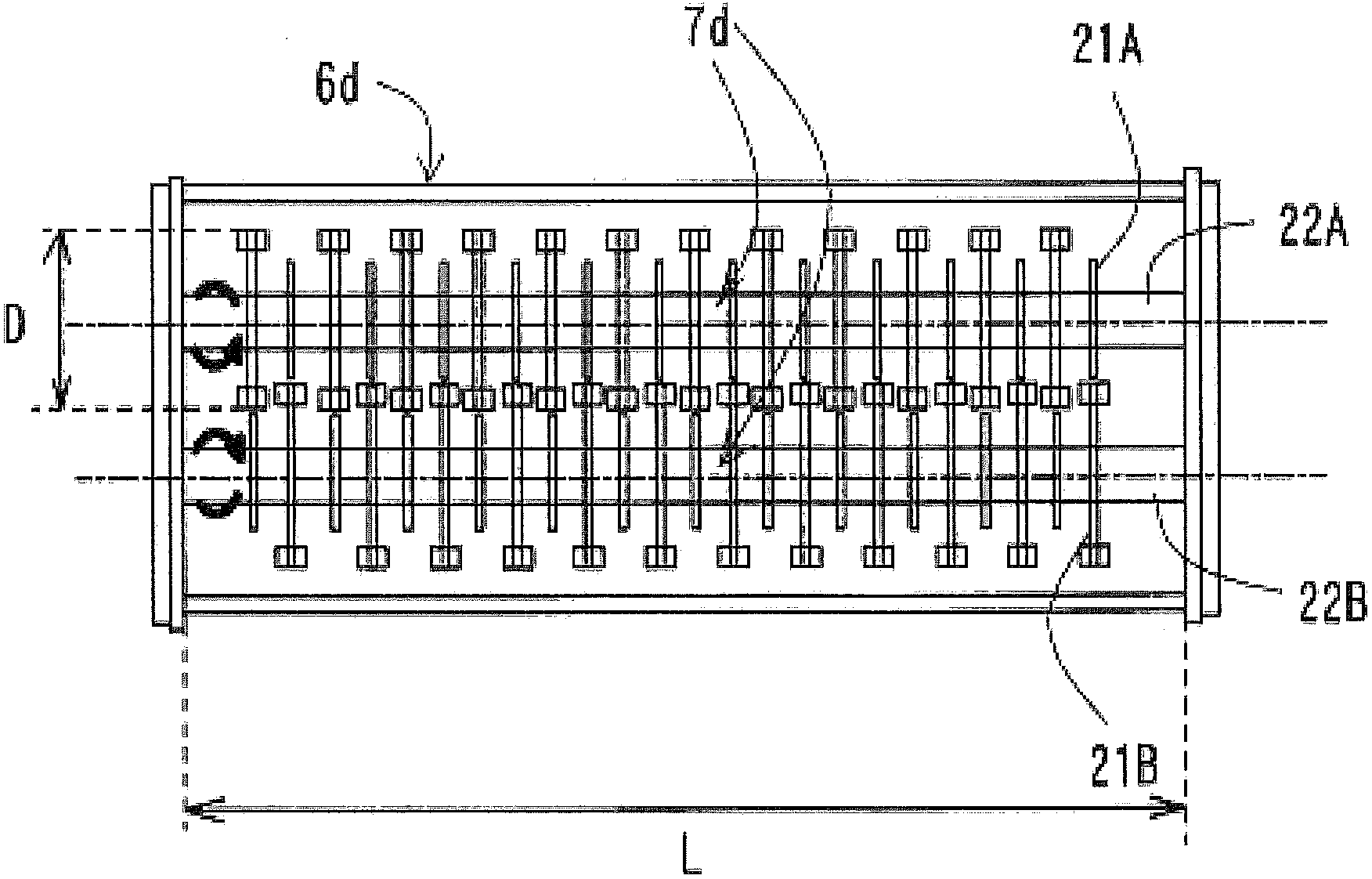

[0424] The inner temperature of the third vertical stirred reactor 6c was 210°C, and the average residence time was 15 minutes. Compared with Example 1, the molecular weight and melt viscosity at the outlet of the third vertical stirred reactor 6c were reduced. Same as in Example 1, the conditions of the 4th horizontal stirred reactor 6d were adjusted so that the reduced viscosity at the outlet was in the range of 0.68 to 0.70, and the conditions were that the pressure was 0.2kPa and the average residence time was 120 minutes. Items not mentioned were all carried out under the same conditions as in Example 1.

[0425] The color tone of the obtained polycarbonate was slightly inferior to that of Example 1 because the reaction time of the fourth horizontal stirred reactor, which had the highest temperature among the reactors, was longer. However, the content of the monohydroxy compound was small and the amount of foreign matter was very small.

Embodiment 3

[0427] The feed molar ratio of raw materials is ISB / CHDM / DPC=0.500 / 0.500 / 0.995. The conditions of the fourth horizontal stirred reactor 6d were adjusted in the same manner as in Example 1, the pressure was 1.0 kPa, and the average residence time was 90 minutes. Items not mentioned were all carried out under the same conditions as in Examples.

[0428] After the amount of hydroxyl end and phenyl carbonate end is balanced, the increase rate of molecular weight in the fourth horizontal reactor becomes faster and the pressure increases, so the content of monohydroxy compound in polycarbonate increases, the particle YI decreases, and the color tone is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com