Silicone rubber composition and preparation method of silicone rubber

A technology of silicone rubber composition and silicone rubber, which is applied in the field of preparation of silicone rubber composition and silicone rubber, and can solve problems such as poor heat resistance and thermal conductivity, difficulty in preparing materials with stable performance, and easy aging and yellowing of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

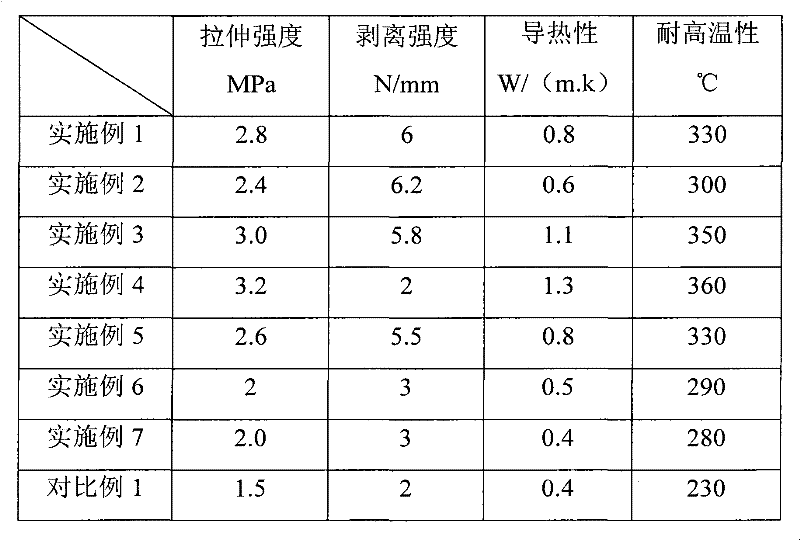

Examples

preparation example Construction

[0023] The present invention improves the preparation method of silicone rubber at the same time, and the steps include: S1: adding zinc salt into the solution containing titanium oxide to obtain a mixed solution, and then adding an alkaline solution to react until the pH value of the mixed solution is 9-10, and the bag is obtained. Titanium oxide composite material coated with zinc hydroxide;

[0024] Then add silane coupling agent 70-135 to react to prepare thermally conductive composite material;

[0025] S2: Mix the polyorganosiloxane and the thermally conductive composite material obtained in step S1 at a vacuum degree of -0.095 to -0.1Mpa and a temperature of 110-155°C;

[0026] Add silane cross-linking agent and polyether and mix under vacuum degree -0.095~-0.1Mpa, temperature 80-120°C to prepare silicone rubber. The preparation method is simple and easy to implement, easy to process and practical.

[0027]Various control methods known to those skilled in the art can b...

Embodiment 1

[0035] Add 150Kg of zinc sulfate to 300Kg of nano-titanium dioxide (average particle size about 50nm) ethanol slurry, stir evenly, and add sodium hydroxide to adjust the pH value = 9.5, so that the zinc will be in the form of Zn(OH) 2 The form is precipitated on the surface of titanium dioxide particles, and the average particle size is about 250nm, which is coated with Zn(OH) 2 Titanium dioxide, then add 20Kg coupling agent KH-550 (r-aminopropyltriethoxysilane), stir and react at 70°C for 3h, then filter and dry to obtain a modified thermally conductive composite material.

[0036] Put 100Kg of 107 glue (hydroxyl-terminated polydimethylsiloxane, 50000), 29.8Kg of fumed silica (50nm), and 12.5Kg of the modified thermally conductive composite material prepared above into the planetary mixer, and vacuumize to -0.098MPa, Stir at 150°C for 2 hours; add 5.2Kg polyphenylene ether (5000), 5.2Kg vinyl tributylketoxime silane, vacuum to -0.098MPa, stir at 120°C for 1 hour; add 0.1Kg di...

Embodiment 2

[0038] Silicone rubber was prepared by the same method as in Example 1, except that the amount of thermally conductive composite material added when preparing the silicone rubber was 5.2Kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com