Water-based finishing agent for leather as well as preparation method and roller coating process

A water-based coating and leather technology, applied in leather surface treatment, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., can solve the problem of insufficient flexibility and coating film hardness Good, high cost, insufficient heat resistance, etc., to achieve oil resistance and other chemical corrosion resistance, low cost, and improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

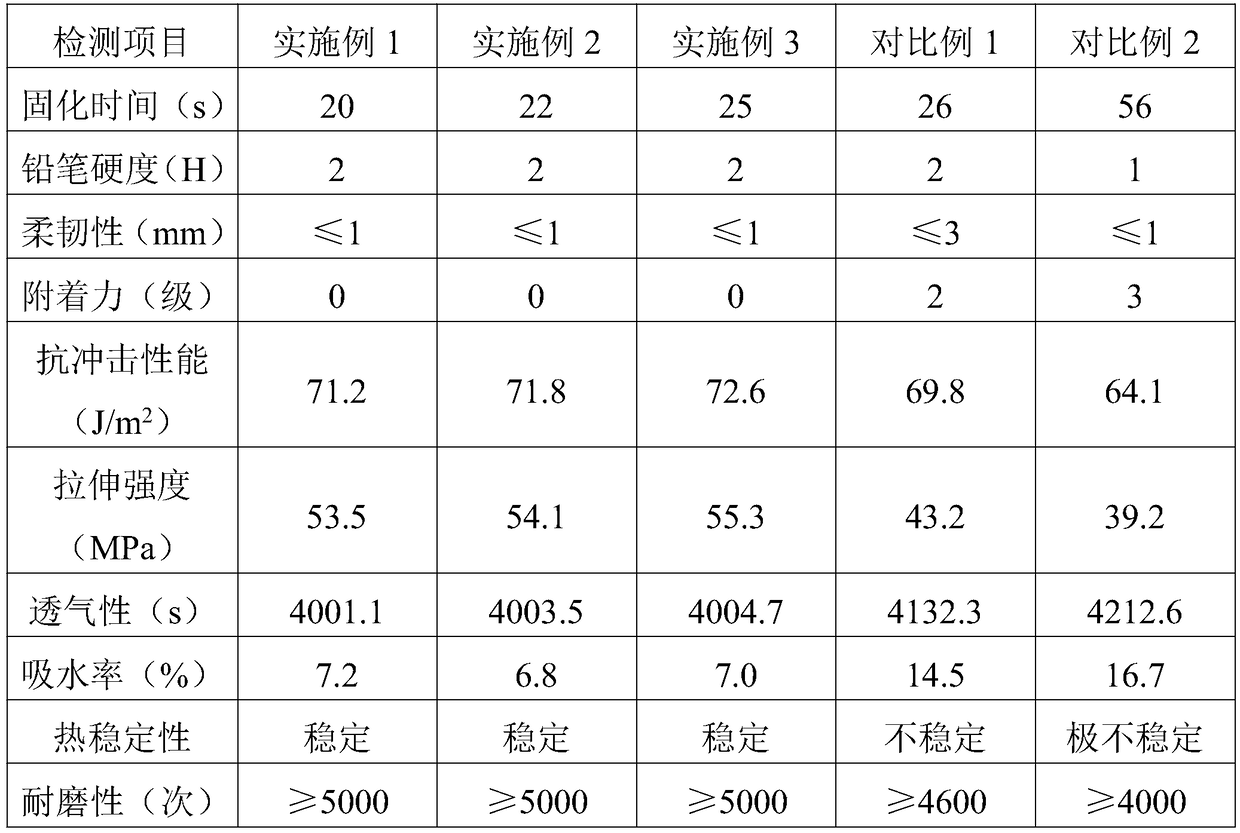

Examples

Embodiment 1

[0050] A kind of leather water-based finishing agent, comprises A component and B component used in conjunction,

[0051] Component A is prepared from the following raw materials in parts by weight: 30 parts of cationic water-based polyurethane, 1 part of associative alkali-swellable thickener, 0.5 part of leveling agent BYK-333, and 70 parts of distilled water;

[0052] Component B is prepared from the following raw materials in parts by weight: 10 parts of polyethylene adipate diethylene glycol, 15 parts of polyoxypropylene glycol, 100 parts of isophorone diisocyanate, 0.01 part of dibutyltin dilaurate, 2 parts of 2,2-dimethylolpropionic acid, 0.1 part of cumene peroxide, 10 parts of acetone, 1 part of triethylamine, 1 part of ethylenediamine, 95 parts of distilled water, 15 parts of isobornyl acrylate, potassium sulfate 0.05 parts, 4 parts of associative alkali swelling thickener, 2 parts of leveling agent BYK-333, 4 parts of casein, 10 parts of pigment paste.

[0053] The...

Embodiment 2

[0068] A kind of leather water-based finishing agent, comprises A component and B component used in conjunction,

[0069] Component A is prepared from the following raw materials in parts by weight: 40 parts of cationic water-based polyurethane, 1.5 parts of cellulose ether, 1.2 parts of leveling agent BYK-348, and 80 parts of distilled water;

[0070] Component B is prepared from the following raw materials in parts by weight: 15 parts of neopentyl glycol polyadipate, 20 parts of polytetrahydrofuran diol, 15 parts of aliphatic hexamethylene diisocyanate, 0.3 parts of stannous octoate, 1,2-di 3 parts of sodium hydroxy-3-propanesulfonate, 0.3 parts of zinc oxide, 13 parts of butanone, 3 parts of triethylamine, 3 parts of hexamethylenediamine, 120 parts of distilled water, 20 parts of isoborneol methacrylate, 0.1 parts of sodium persulfate 6 parts, 6 parts of cellulose ether, 3 parts of leveling agent BYK-348, 6 parts of casein, 20 parts of pigment paste.

[0071] The preparati...

Embodiment 3

[0086] A kind of leather water-based finishing agent, comprises A component and B component used in conjunction,

[0087] Component A is prepared from the following raw materials in parts by weight: 50 parts of cationic water-based polyurethane, 1.5 parts of nonionic polyurethane thickener, 1.2 parts of leveling agent BYK-349, and 90 parts of distilled water;

[0088] Component B is prepared from the following raw materials in parts by weight: 20 parts of polyethylene adipate diethylene glycol, 25 parts of tetrahydrofuran-propylene oxide copolymerized glycol, 20 parts of aliphatic hexamethylene diisocyanate, 0.05 parts of stannous octoate, 5 parts of 2,2-dimethylolpropionic acid, 0.4 parts of zinc oxide, 15 parts of acetone, 5 parts of triethylamine, 5 parts of 1,4-butanediol, 200 parts of distilled water, polyethylene glycol (200) acrylic acid 30 parts of ester, 0.15 parts of ammonium persulfate, 8 parts of non-ionic polyurethane thickener, 4 parts of leveling agent BYK-349, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com