Gas-solid phase reaction separation system and separation method thereof

A separation system and separation method technology, applied in the gas-solid phase reaction separation system and its separation field, can solve the problems of water washing process wastewater polluting the environment, complex dust removal process, etc., and achieve high mechanical strength, achieve continuity, and prevent membrane pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Biomass Power Generation Dust Removal System

[0029] The present invention is described in detail below in conjunction with accompanying drawing:

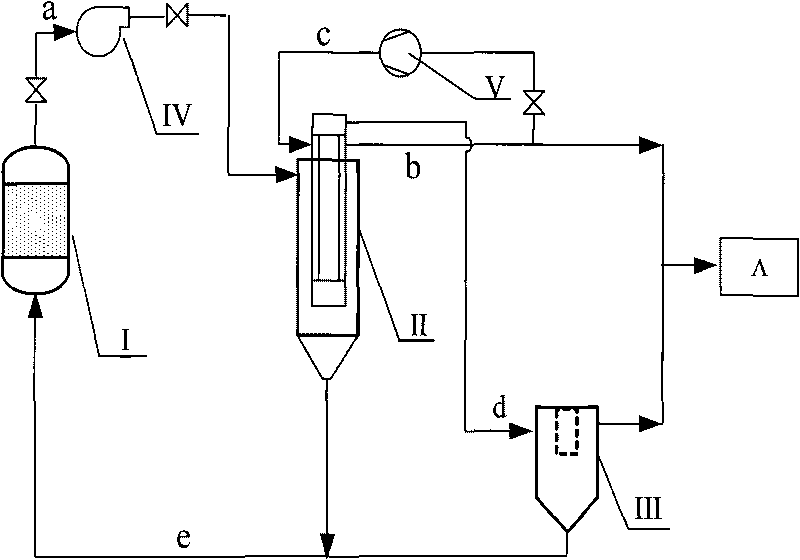

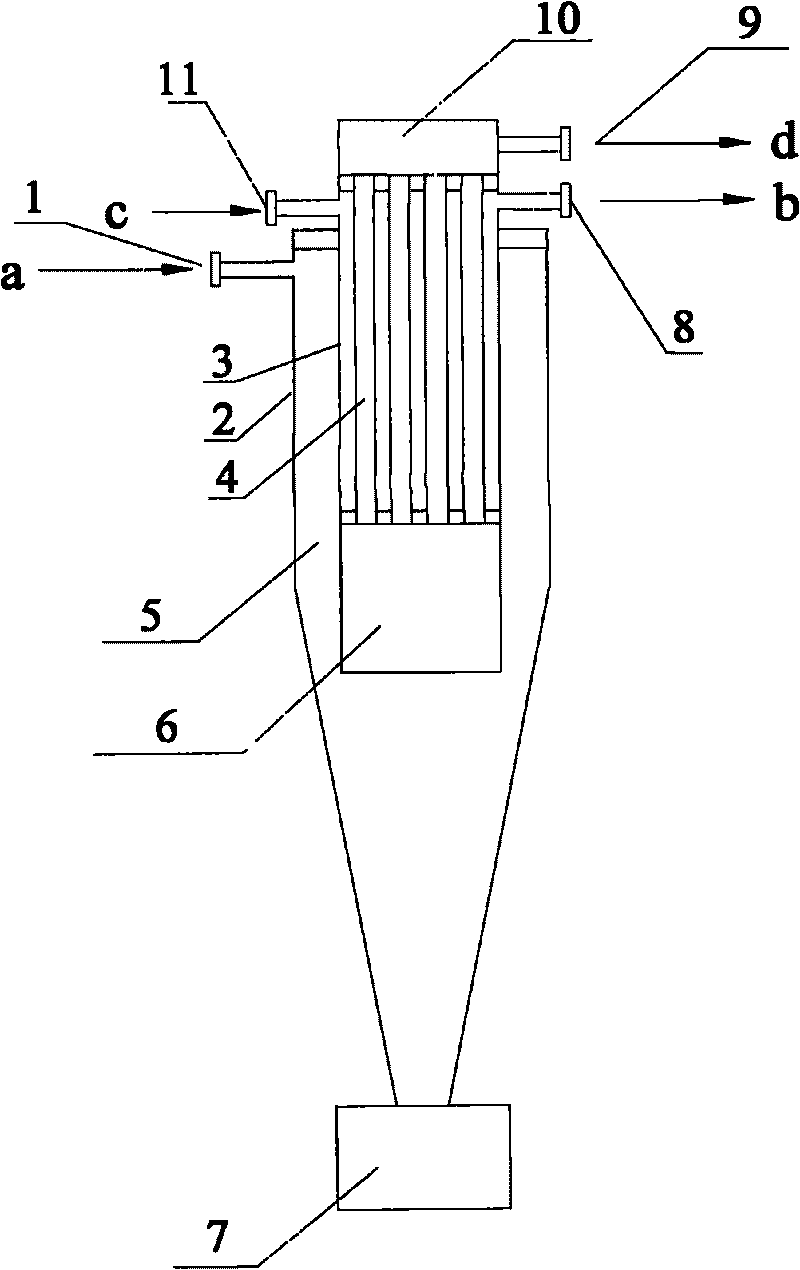

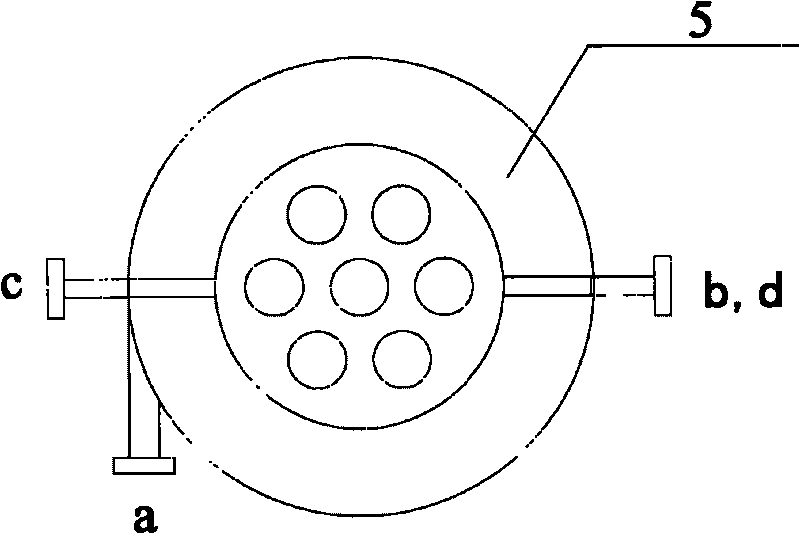

[0030] A) The entire system consists of a gasifier, an inorganic membrane cross-flow filter, a bag filter, a fan and a compressor. The gasifier and the inorganic membrane cross-flow filter are all made of stainless steel. High-temperature flue gas inlet 1, clean gas outlet 8, dense dust gas outlet 9 and blowback gas inlet 11; gasifier outlet is equipped with a fan, and is connected to high-temperature flue gas inlet 1 through stainless steel pipelines; clean gas outlet 8 is through stainless steel The pipeline is connected to the post-processing section, and a port on the pipeline is connected to the blowback gas inlet 11 through the compressor through the stainless steel pipeline; the dusty gas outlet 9 is connected to the bag filter through the stainless steel pipeline; the outlet of the bag filter is connected...

Embodiment 2

[0036] Embodiment 2: organosilicon dust removal device

[0037] The present invention is described in detail below in conjunction with accompanying drawing:

[0038] A) The high-temperature flue gas (a) enters the inorganic membrane cross-flow filter (II) under the action of the centrifugal fan (IV) for separation, using a zirconia membrane with a pore size of 0.2 μm, 19 channels, and the inner diameter of the channel is 6mm. The cross-flow velocity is 30m / s, the transmembrane pressure difference is 0.1MPa, and the gas dust concentration at the feed side is 0.9308g / m 3 , at the beginning of filtration, the flux of the membrane tube is 51.5m 3 / m 2 h, the mixed gas containing dense dust passes through the bag filter (III) under the action of the fan, and the total content of the gas mixed through the inorganic membrane cross-flow filter (II) and the bag filter (III) Dust concentration is 1.1mg / m 3 .

[0039] Such as figure 2 As shown, the high-temperature flue gas (a) at...

Embodiment 3

[0043] Embodiment 3: coal gasification dust removal

[0044] Coal powder and air are gasified in the reactor to generate gas; during normal operation, the high-temperature flue gas is passed into the inorganic membrane cross-flow filter along the tangential direction under the action of the centrifugal fan, and the airflow rotates from top to bottom. In the process, the dust moves along the filter wall along the filter wall to the bottom of the filter for dust collection under the joint action of the downward airflow and gravity. The dust-laden gas flows upward from the bottom of the filter through the ceramic filter tube, and a part of the dust in the mixed gas It is captured and removed by the inorganic membrane, and the dense dust gas trapped by the inorganic membrane flow filter enters the bag filter for terminal dust removal; four porous FeAl alloy symmetrical membranes with a pore diameter of 10 μm are used, a single tube, an inner diameter of 50mm, and a cross-flow veloc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com