Integrated spiral-flow reaction and separation system and process for sulfur containing gas desulfuration

A cyclone reaction and cyclone separator technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of large initial investment in space-occupied equipment, inconvenient maintenance and increased energy consumption, etc. Achieve the effects of saving space, simplifying structural complexity, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

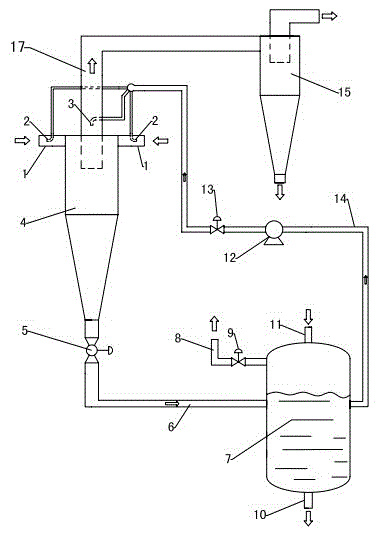

[0037] Refer to attached figure 1 : An integrated cyclone reaction and separation system for sulfur-containing gas desulfurization, comprising a cyclone reactor 4, a bottom flow ratio regulating valve 5, a rich liquid drainage pipeline 6, an amine liquid storage tank 7 and a gas-liquid cyclone separator 15, and the cyclone The lower part of the flow reactor 4 is connected to one side of the amine liquid storage tank 7 through the rich liquid discharge line 6, and the other side of the amine liquid storage tank 7 is connected to the upper liquid inlet end of the swirl reactor 4 through the absorption liquid circulation line 14, and the swirl reaction The upper part of the device 4 is connected to the gas-liquid cyclone separator 15 through an exhaust device.

[0038] The swirling flow reactor 4 comprises a main body and a tangential inlet nozzle 1, the upper part of the main body is provided with a tangential inlet nozzle 1, one or several tangential inlet nozzles 1 are provide...

Embodiment 2

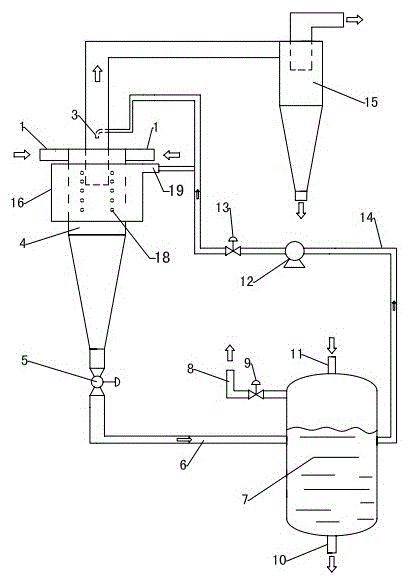

[0050] Refer to attached figure 2 : The outer cylinder body 16 for temporarily storing the absorption liquid is set on the outer side of the upper part of the swirling flow reactor 4 main body, the upper part of the main body is uniformly distributed with liquid inlet holes 18 in a ring, and the upper part of the outer cylinder body 16 is provided with a liquid inlet port 3 tangentially. The end of the absorption liquid circulation pipeline 14 is divided into two lines, and the two lines are respectively connected to the atomizing nozzle 2 inserted into the liquid inlet 3 and the exhaust core pipe 17 . The liquid inlet hole 18 can be a plurality of small circular holes uniformly distributed in a ring. Other settings and working principles are the same as in Embodiment 1.

Embodiment 3

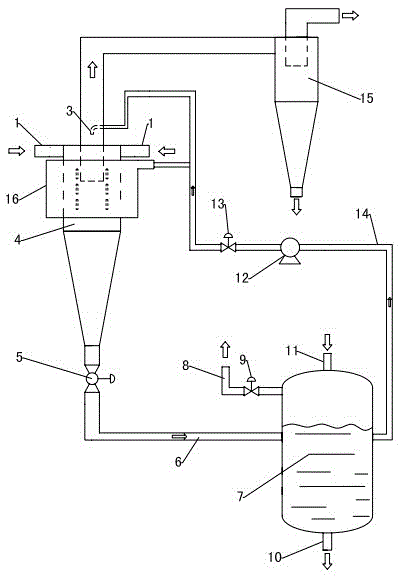

[0052] Refer to attached image 3 : The outer cylinder 16 for temporary storage of the absorption liquid is set outside the upper part of the swirling flow reactor 4 main body, the upper part of the main body is uniformly distributed with liquid inlet holes 18 in a ring, and the upper outer cylinder 17 is provided with a liquid inlet 3 tangentially. The liquid inlet hole 18 can be a plurality of circular uniformly distributed elongated holes. Other settings and working principles are the same as in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com