Method for producing tertiary carboxylic acid

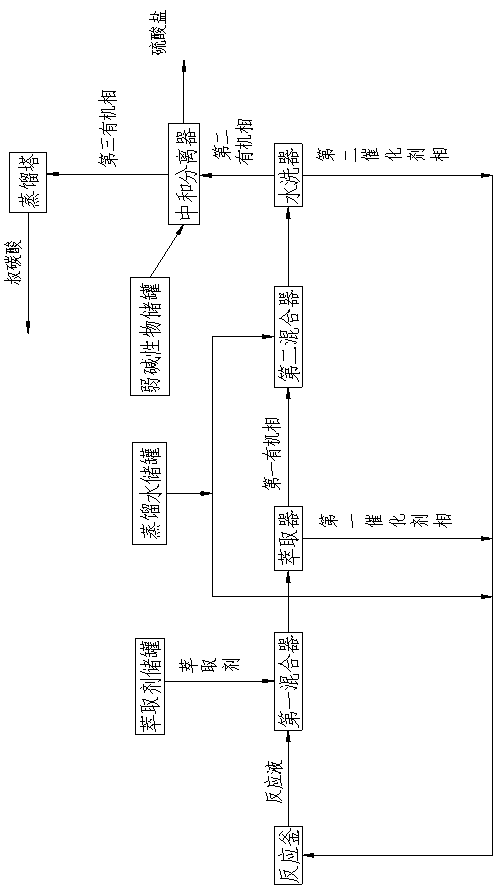

A production method and technology of tertiary carbonic acid, applied in the chemical industry, can solve the problems of large discharge of dilute sulfuric acid, environmental pollution, and difficulty in separating catalysts and products, and achieve the effects of small loss, less discharge of "three wastes" and avoiding poor separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 6 moles of concentrated sulfuric acid with a mass concentration of 85% into the catalyst preparation kettle with a mechanical pump, add 0.2 moles of cuprous oxide under stirring conditions, feed carbon monoxide into the catalyst preparation kettle, keep the pressure in the kettle at 2~3MPa, and continuously After stirring for 5 hours, a gray transparent liquid was obtained, namely concentrated sulfuric acid-copper carbonyl catalyst. Add the concentrated sulfuric acid-copper carbonyl catalyst prepared in the previous step to the 2-liter high-pressure preparation kettle, pass through carbon monoxide, pressurize to raise the pressure of the kettle to 1.0 MPa, start the stirrer at a speed of 600 rpm, and maintain the temperature in the kettle at 15°C , then open the feed pump, inject 0.5 moles of nonene per hour into the kettle, add it in two hours, then react for 20 minutes, transfer the reaction solution to the first mixer and mix with 160 milliliters of n-hexane, extr...

Embodiment 2

[0026]Put 6 concentrated sulfuric acid with a molar mass concentration of 87% into the catalyst preparation kettle with a mechanical pump, add 0.05 moles of cuprous oxide under stirring conditions, and feed carbon monoxide into the catalyst preparation kettle, keep the pressure in the kettle at 1-2 MPa, and continuously After stirring for 1 hour, a gray transparent liquid was obtained, namely concentrated sulfuric acid-copper carbonyl catalyst. Add the concentrated sulfuric acid-copper carbonyl catalyst prepared in the previous step to the 2-liter high-pressure reaction kettle, pass carbon monoxide, pressurize to raise the pressure of the kettle to 3 MPa, start the stirrer at a speed of 600 rpm, and maintain the temperature in the kettle at 20°C , then open the feed pump, inject 0.25 moles of nonene per hour in the still, add it in two hours, then after reacting for 60 minutes, the reaction solution is transferred to the first mixer and mixed with 80 milliliters of chlorobenzen...

Embodiment 3( Embodiment 2

[0027] Embodiment 3 (embodiment 2 comparative embodiment)

[0028] Put 6 concentrated sulfuric acid with a molar mass concentration of 87% into the catalyst preparation kettle with a mechanical pump, add 0.05 moles of cuprous oxide under stirring conditions, and feed carbon monoxide into the catalyst preparation kettle, keep the pressure in the kettle at 1-2 MPa, and continuously After stirring for 2 hours, a gray transparent liquid was obtained, namely concentrated sulfuric acid-copper carbonyl catalyst. Add the concentrated sulfuric acid-copper carbonyl catalyst prepared in the previous step to the 2-liter high-pressure reaction kettle, pass carbon monoxide, pressurize to raise the pressure of the kettle to 3MPa, start the stirrer at a speed of 600 rpm, and maintain the temperature in the kettle at 20°C. Then open the feed pump, inject 0.25 moles of nonene per hour in the kettle, add it in two hours, and after reacting for 60 minutes, the reaction solution is transferred to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com