Magnetic material catalyst separating device and system

A magnetic material and separation device technology, applied in the field of magnetic material catalyst separation device and system, can solve the problems of increasing production hardware investment cost, increasing production cost investment, reducing production efficiency of chemical products, etc., achieving reliable separation effect and shortening settlement Time and work load reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

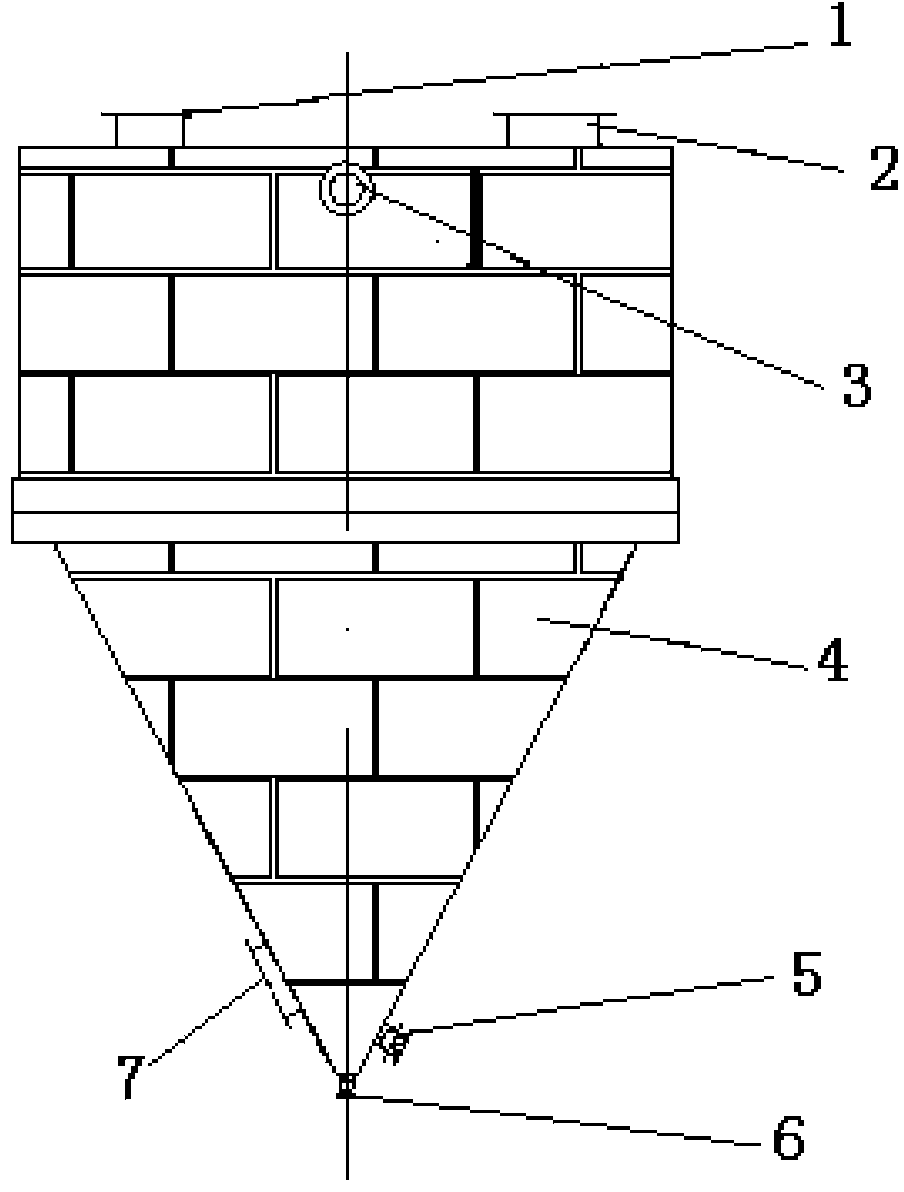

[0043] Figure 3 ~ Figure 5 As shown, a magnetic substance catalyst separation device of the present invention, the magnetic substance catalyst separation cavity 20 and the magnetic bar assembly located inside the separation device substrate can be placed horizontally or vertically and then firmly connected with the separation device substrate; the magnetic substance catalyst The separation device includes: a separation device base body and a magnetic rod assembly;

[0044] The base body of the separation device includes: a material overflow port 15, a magnetic material catalyst separation chamber 20, a material inlet 21 and a separation device cover plate 24 for opening and closing the base body of the separation device to realize taking and placing the magnetic bar assembly; The magnetic material catalyst separation chamber 20 is a multi-pipeline array formed by a plurality of identical pipe-like cavities parallel to each other; the cavity material of the magnetic material c...

Embodiment 2

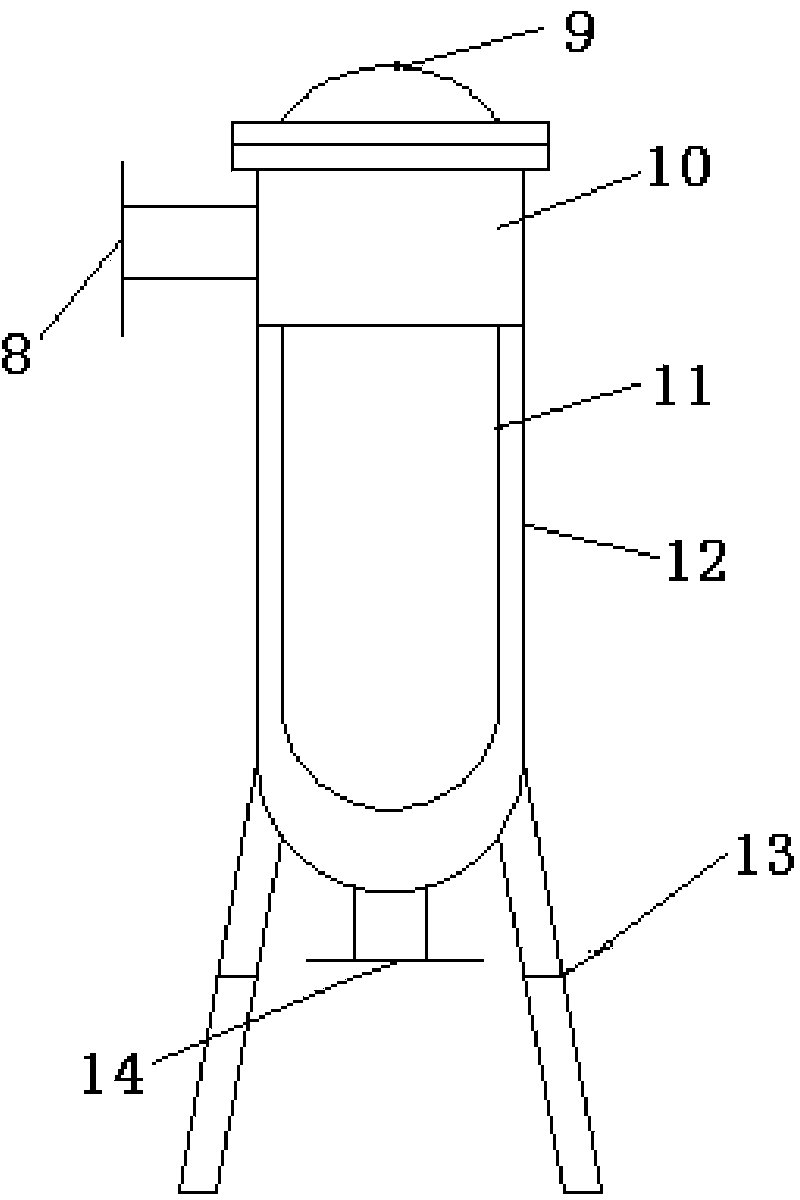

[0047] Image 6 As shown, the present invention provides a magnetic material catalyst separation device, the magnetic material catalyst separation device includes: separation device base and magnetic bar assembly;

[0048] The base body of the separation device includes: a material overflow port 15, a material buffer chamber 18, a magnetic material catalyst separation chamber 20, a material inlet 21, and a separation device for opening and closing the base body of the separation device to realize taking and placing the magnetic bar assembly Cover plate 24; the magnetic substance catalyst separation chamber 20 is a multi-pipeline array formed by a plurality of identical pipe-like cavities parallel to each other; the cavity material of the magnetic substance catalyst separation chamber 20 is a non-magnetic material; the The material buffer chamber 18 communicates with the material inlet 21; the material buffer chamber 18 communicates with the magnetic material catalyst separatio...

Embodiment 3

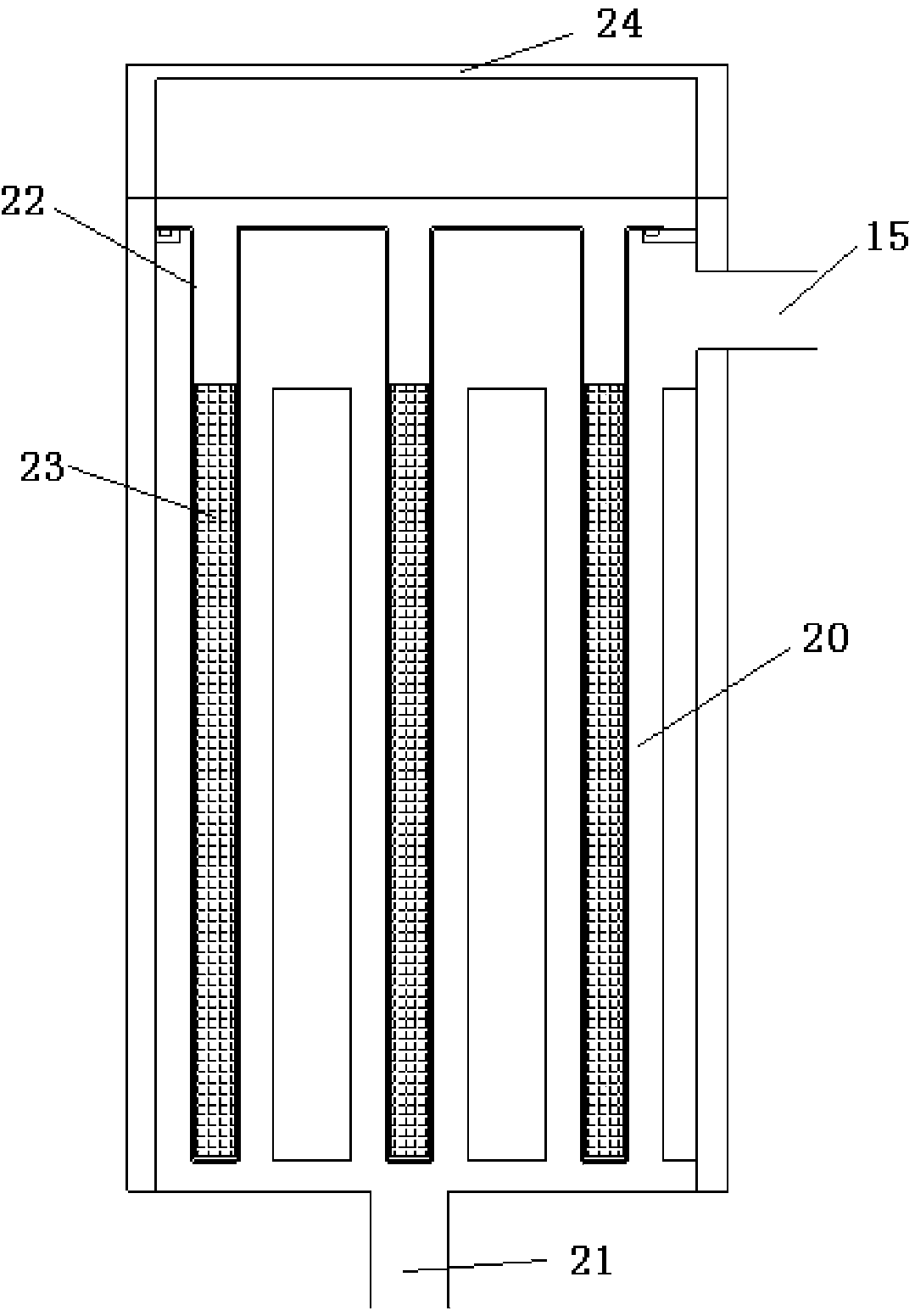

[0051] Figure 7 As shown, the present invention provides a magnetic material catalyst separation device, the magnetic material catalyst separation device includes: separation device base and magnetic bar assembly;

[0052] The base of the separation device includes: a material overflow port 15, a temperature control medium A interface 16, a temperature control medium jacket layer 17, a material buffer chamber 18, a temperature control medium B interface 19, a magnetic material catalyst separation chamber 20, and a material inlet 21 And be used for opening and closing described separation device base body and realize the separation device cover plate 24 of taking and placing described magnetic bar assembly; Described magnetic material catalyst separation chamber 20 is the multi-pipeline that a plurality of identical pipe-like cavities parallel to each other form array; the cross-sectional view of the magnetic material catalyst separation chamber is as Figure 11 As shown; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com