Process for preparing 5N erbium by extracting and separating

A technology of extraction and process, applied in the field of rare earth separation in solvent extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

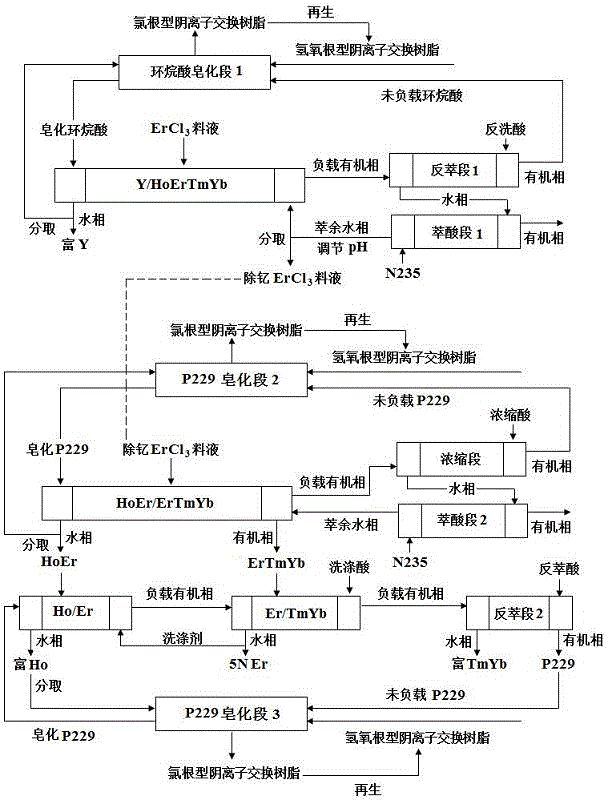

Image

Examples

Embodiment 1

[0045] 1) Y / HoErTmYb separation section

[0046] The first step is the naphthenic acid Y / HoErTmYb full-load fractionation extraction separation section to realize the separation of Y / HoErTmYb. The rare earth saponified naphthenic acid organic phase from the fourth step enters from the first stage of the Y / HoErTmYb full-load fractionation extraction system, the rare earth concentration is 1.0mol / L, the ratio of the molar concentration of erbium to the molar concentration of rare earth is 0.995, and the pH value is 4 The erbium chloride material liquid enters from the 17th stage of the Y / HoErTmYb full-load fractionation extraction system, and the raffinate aqueous phase holmium chloride, erbium, thulium, and ytterbium solution from the third step of acid extraction section I enters the Y / HoErTmYb from the 67th stage as a detergent Full-load fractionation extraction system; Y / HoErTmYb full-load fractionation extraction system obtains a yttrium-rich solution from the first-stage r...

Embodiment 2

[0076] 1) Y / HoErTmYb separation section

[0077] The first step is the naphthenic acid Y / HoErTmYb full-load fractionation extraction separation section to realize the separation of Y / HoErTmYb. The rare earth saponified naphthenic acid organic phase from the fourth step enters from the first stage of the Y / HoErTmYb full-load fractionation extraction system, the rare earth concentration is 0.8mol / L, the ratio of the molar concentration of erbium to the molar concentration of rare earth is 0.999, and the pH value is 5 The erbium chloride feed liquid enters from the 19th stage of the Y / HoErTmYb full-load fractionation extraction system, and the raffinate aqueous phase holmium chloride, erbium, thulium, and ytterbium solution from the third step acid extraction section I enters the Y / HoErTmYb from the 62nd stage as a detergent Full-load fractionation extraction system; Yttrium-rich solution is obtained from the first-stage raffinate aqueous phase of Y / HoErTmYb full-load fractionati...

Embodiment 3

[0107] 1) Y / HoErTmYb separation section

[0108]The first step is the naphthenic acid Y / HoErTmYb full-load fractionation extraction separation section to realize the separation of Y / HoErTmYb. The rare earth saponified naphthenic acid organic phase from the fourth step enters from the first stage of the Y / HoErTmYb full-load fractionation extraction system, the rare earth concentration is 1.2mol / L, the ratio of the molar concentration of erbium to the molar concentration of rare earth is 0.99, and the pH value is 3 The erbium chloride material liquid enters from the 15th stage of the Y / HoErTmYb full-load fractionation extraction system, and the raffinate aqueous phase holmium chloride, erbium, thulium, and ytterbium solution from the third step acid extraction section I enters the Y / HoErTmYb from the 70th stage as a detergent Full-load fractional distillation extraction system; obtain yttrium-rich solution from the first-stage raffinate aqueous phase of Y / HoErTmYb full-load frac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com