Potassium chloride and ammonium nitrate double decomposition and circulation method for producing high quality potassium nitrate

A technology of potassium nitrate and ammonium nitrate, which is applied in the preparation of alkali metal nitrate, etc., can solve the problems that the product quality cannot meet the quality standard of industrial grade potassium nitrate, a series of disadvantages have not been fundamentally solved, and the impurity content of potassium nitrate products is high. Achieve the effect of realizing large-scale continuous production, reducing losses and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

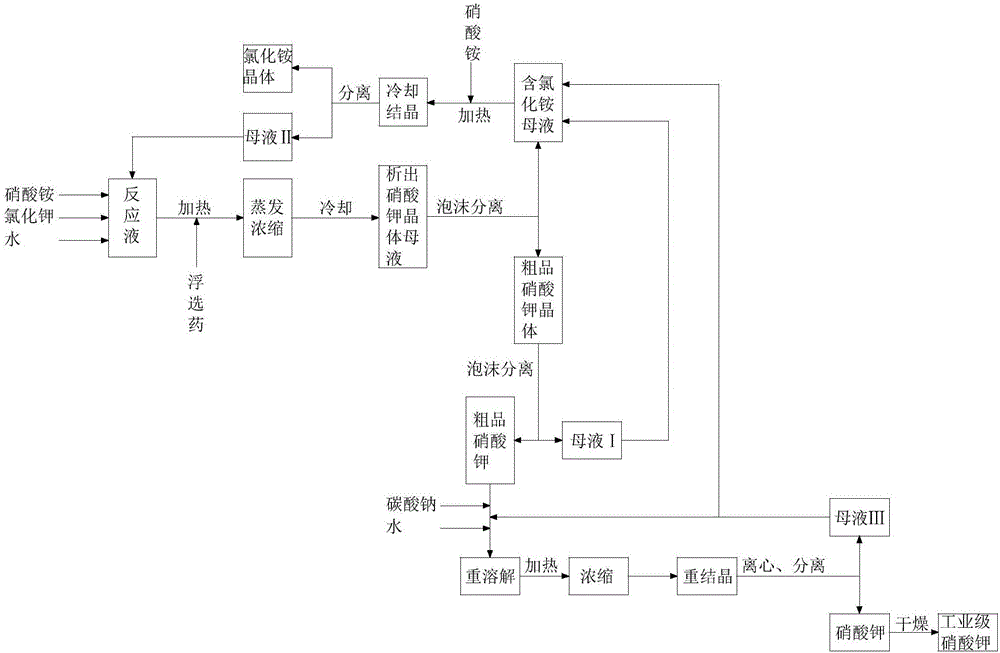

[0037] like figure 1 Shown, the method for the production of high-quality potassium nitrate by double decomposition circulation method of the present invention is raw material with Repone K, ammonium nitrate and water, adopts mother liquor circulation method to produce high-quality potassium nitrate, specifically implements by the following methods:

[0038] (1) Ingredients: When producing for the first time, potassium chloride, ammonium nitrate and water are mixed into potassium nitrate reaction liquid, and NH 4 + with Cl - The mass ratio of the substance is (1.6~1):1, and it is heated by steam under constant stirring; during circulation, potassium chloride, water and the circulating mother liquor in step (8) are mixed into the ingredients in a certain proportion according to the conservation of materials Groove, be prepared to the state that is consistent with potassium nitrate reaction solution when producing for the first time;

[0039] (2) Addition of flotation agent: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com