Alfalfa quality improving drying method

A drying method and technology of alfalfa, applied in application, animal feed, animal feed, etc., can solve the problems of poor quality, difficult to meet the nutritional needs of cattle and sheep feeding, leaves and flower buds falling off, etc., to achieve good palatability, cellulose and The effect of high protein content and high carotene content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

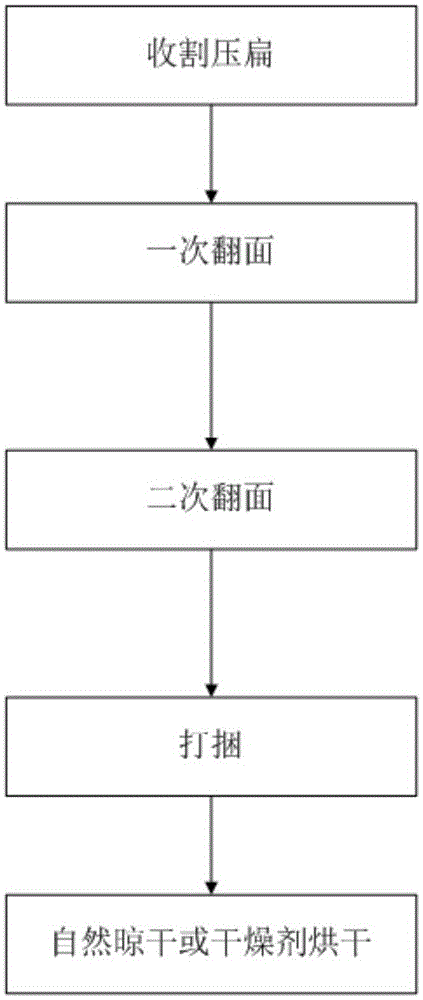

[0026] Such as figure 1 Shown, a kind of drying method that improves alfalfa quality, comprises the following steps:

[0027] 1) Harvesting and flattening;

[0028] When less than 1 / 10 of the alfalfa blooms and the moisture content of the alfalfa is 78-80%, the alfalfa plants that are more than 5cm above the ground are flattened by a harvester or manually, and the field is directly laid;

[0029] 2) Turn over once;

[0030] After drying in the sun for 9 hours on a sunny day, turn over the alfalfa in the flat field once;

[0031] 3) Second flip;

[0032] After drying in the sun for 32 hours on a sunny day, turn over the alfalfa in the flat field for the second time;

[0033] 4) bundling;

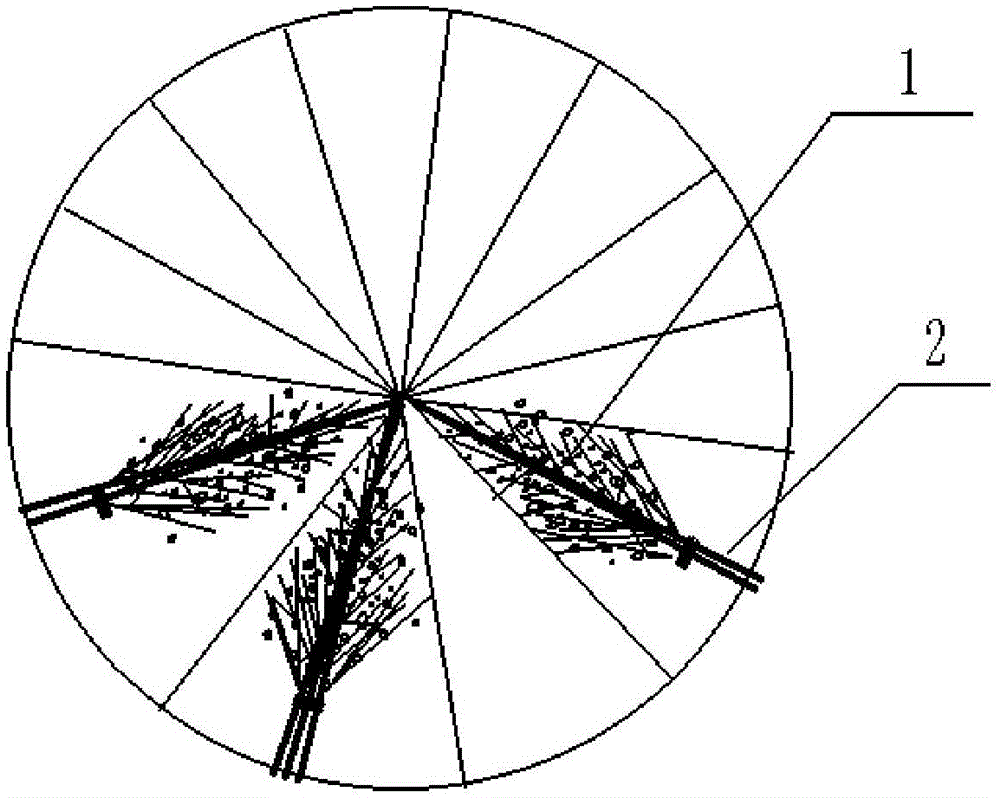

[0034] When the moisture content of the alfalfa in the flat field is 65-70% after drying for 48 hours, the bales are bundled at 7:00-11:00 on cloudy days, and the diameter of the bales is not more than 30 cm;

[0035] 5) Natural drying or desiccant drying;

[0036] For warm areas with ...

specific Embodiment 2

[0037] Roughly the same as the specific embodiment, the only difference is:

[0038] 1. After drying in the sun for 11 hours on a sunny day, turn over the alfalfa in the flat field once;

[0039] 2. After drying in the sun for 34 hours on a sunny day, turn over the alfalfa in the field for a second time.

specific Embodiment 3

[0040] A drying method for improving the quality of alfalfa, comprising the following steps:

[0041] 1) Harvesting and flattening;

[0042] When less than 1 / 10 of the alfalfa blooms and the moisture content of the alfalfa is 78-80%, the alfalfa plants that are more than 5cm above the ground are flattened by a harvester or manually, and the field is directly laid;

[0043] 2) Turn over once;

[0044] After drying for 12 hours on a cloudy day, the alfalfa in the flat field is turned over once;

[0045] 3) Second flip;

[0046] After drying in the sun for 35 hours on a cloudy day, the alfalfa in the flat field is turned over for the second time;

[0047] 4) bundling;

[0048] When the moisture content of the alfalfa in the flat field is 65-70% after drying for 48 hours, baling is carried out at 7:00-10:30 in the morning in areas above 36° north latitude on sunny days, and the diameter of the bales shall not exceed 30 cm. ;

[0049] 5) Natural drying or desiccant drying;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com