Integrated reacting and separating device

A separation equipment and ammoximation reaction technology, applied in the field of integrated equipment, can solve problems such as the difficulty of timely detection of membrane tube rupture, and achieve the effects of good material mixing and heat exchange effects, convenient operation and high separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

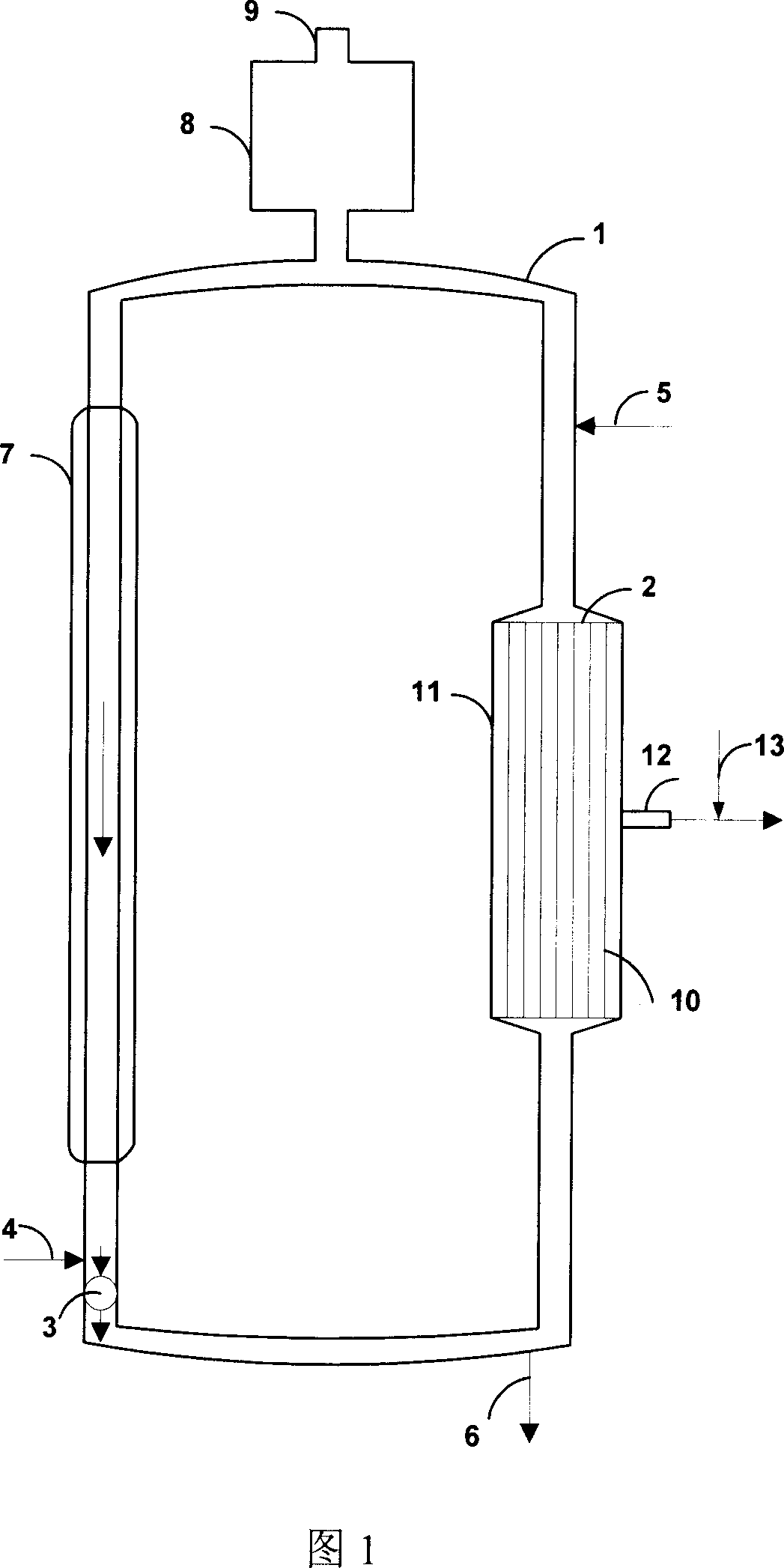

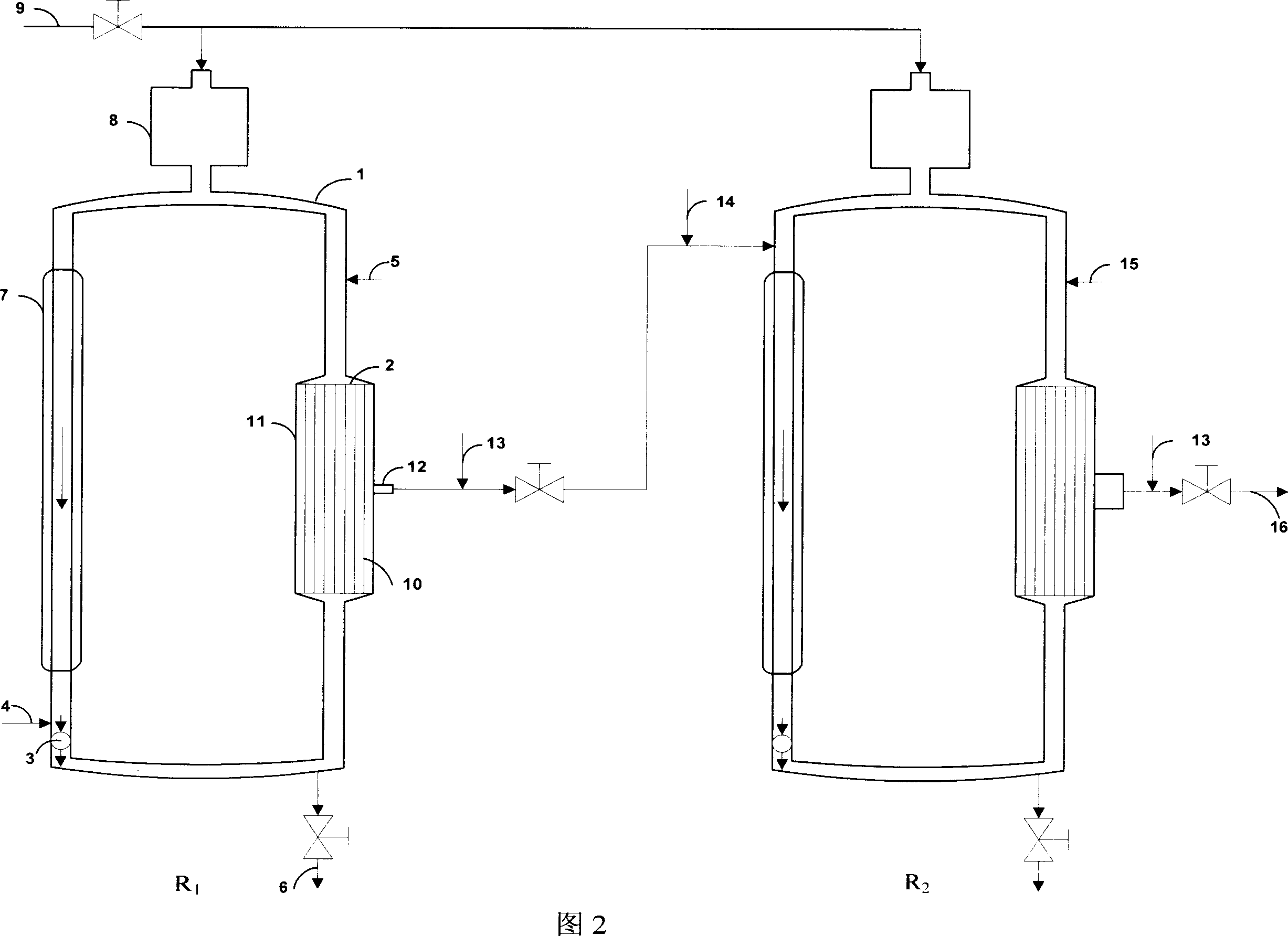

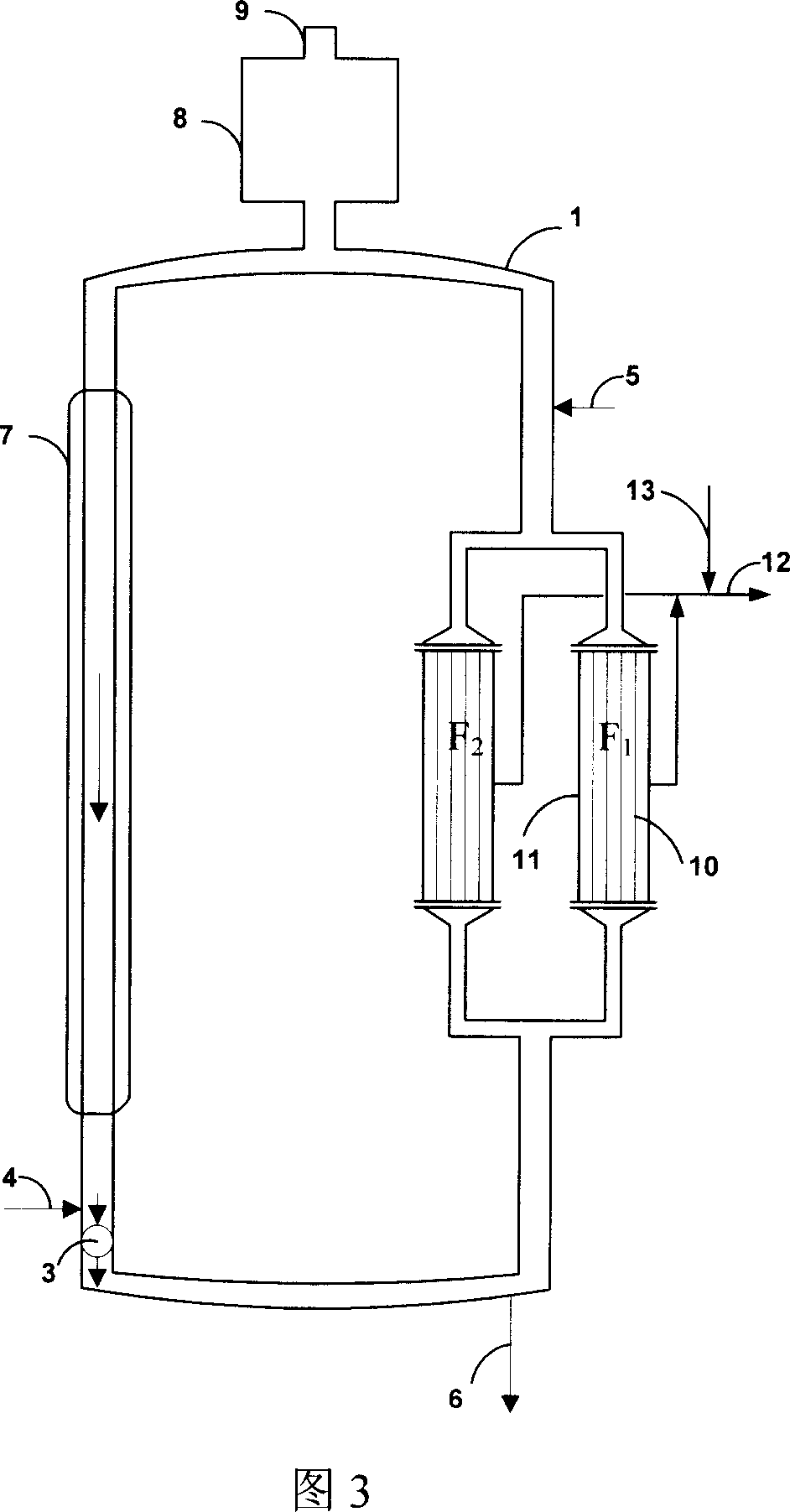

[0022] In the integrated reaction and separation equipment provided by the present invention, the main catalytic reaction process occurs in the ring pipe 1. The ring pipe 1 includes upper and lower horizontal sections and vertical sections, and the upper and lower horizontal sections limit the flow of the upper and lower horizontal reaction materials. Each section is connected to the adjacent section by means of a smooth elbow or elbow. The diameter and length of the ring pipe 1 (including the number of upper and lower horizontal sections and vertical sections, etc.) depends on the specific reaction production capacity, reaction residence time, etc. Depending on time and productivity requirements, ring pipes can be machined from steel, titanium, nickel or other alloys.

[0023] The circulation pump 3 on the loop pipe 1 provides energy to circulate the reaction material in the loop pipe 1. The circulation pump 3 can be installed at an appropriate position in the loop pipe 1. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com