Patents

Literature

45results about How to "Not easy to stick to the wall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Auxiliary material combination for improving atomizing and drying process of traditional Chinese medicine granules and application thereof

ActiveCN101862458AReduce dosageHigh softening pointGranular deliveryMacromolecular non-active ingredientsFlavorMedicine

The invention relates to an auxiliary material combination for improving atomizing and drying process of traditional Chinese medicine granules and an application thereof. The auxiliary material combination comprises 10 to 90 percent of betadex and 10 to 90 percent of maltodextrin or dextrine. The application of the auxiliary material combination is: after being dissolved in hot water, the auxiliary material combination is added into extract obtained by extracting Chinese medicine or is directly added into extract to be uniformly mixed and to be atomized and dried; when adding the auxiliary material combination, the temperature of the extract is 50 to 100 DEG C, relative density of the extract is 1.02 to 1.20 (60 DEG C), air inlet temperature for atomizing drying is 140 to 190 DEG C, and the air outlet temperature is 75 to 100 DEG C. by adopting the auxiliary material combination, under the same atomizing and drying condition, the consumed quantity of the auxiliary material is less, the consumption quantity of the auxiliary material can be reduced by more than 30 percent, the auxiliary material with the same quantity is added for atomizing and drying, the softening point of the extract can be improved during the atomizing and drying process, the wall is difficult to be adhered during the atomizing process, the fluidity of the atomizing and drying powder is good, the atomizing and drying powder is difficult to be moistened, the dispersion of the flavor can be effectively prevented during the atomizing and drying process, and the original flavor of the extract is maintained.

Owner:陇西一方制药有限公司

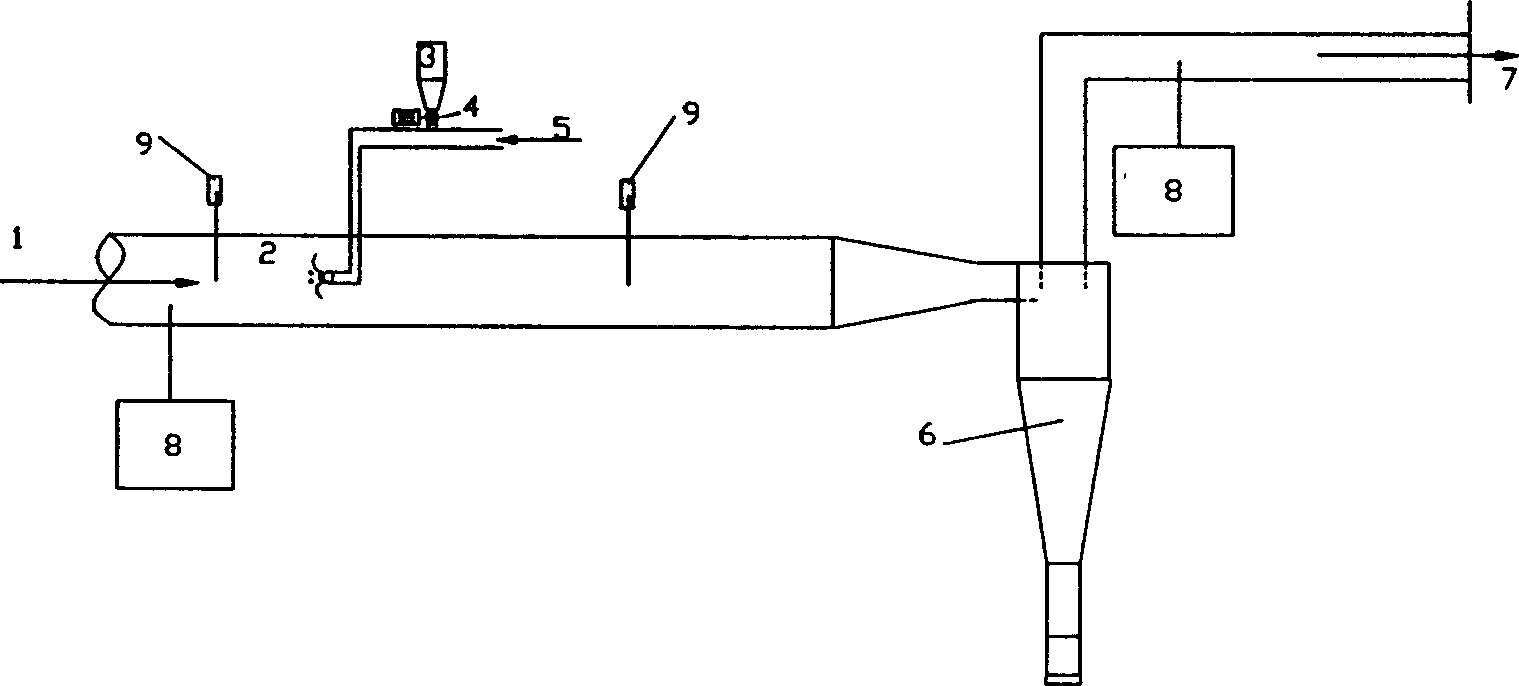

Method for purifying high-temp. smoke from garbage incinerator

InactiveCN1422689AHigh activityIncrease temperatureDispersed particle separationSolid reactionFlue gas

The method for cleaning high-temp. smoke produced by garbage incinerator is characterized by that in the flue gas with 600-800 deg.c discharged by garbage incinerator the sodium-alkali modified lime is added to make acid gas being in the flue gas react with sodium-alkali modified lime and be absorbed, then the solid reaction product and flyash carried by flue gas are collected by high-temp. dust-collector together, so that the solid reaction product can be separated from flue gas, and the cleaned flue gas can be fed into heated surface, and cooled, and the harmful substance de novo can not be synthesized in the flue gas, and the toxicity of the cleaned flue gas product and the flyash can be greatly reduced. Said invention is simple in process and good in effect.

Owner:TONGJI UNIV

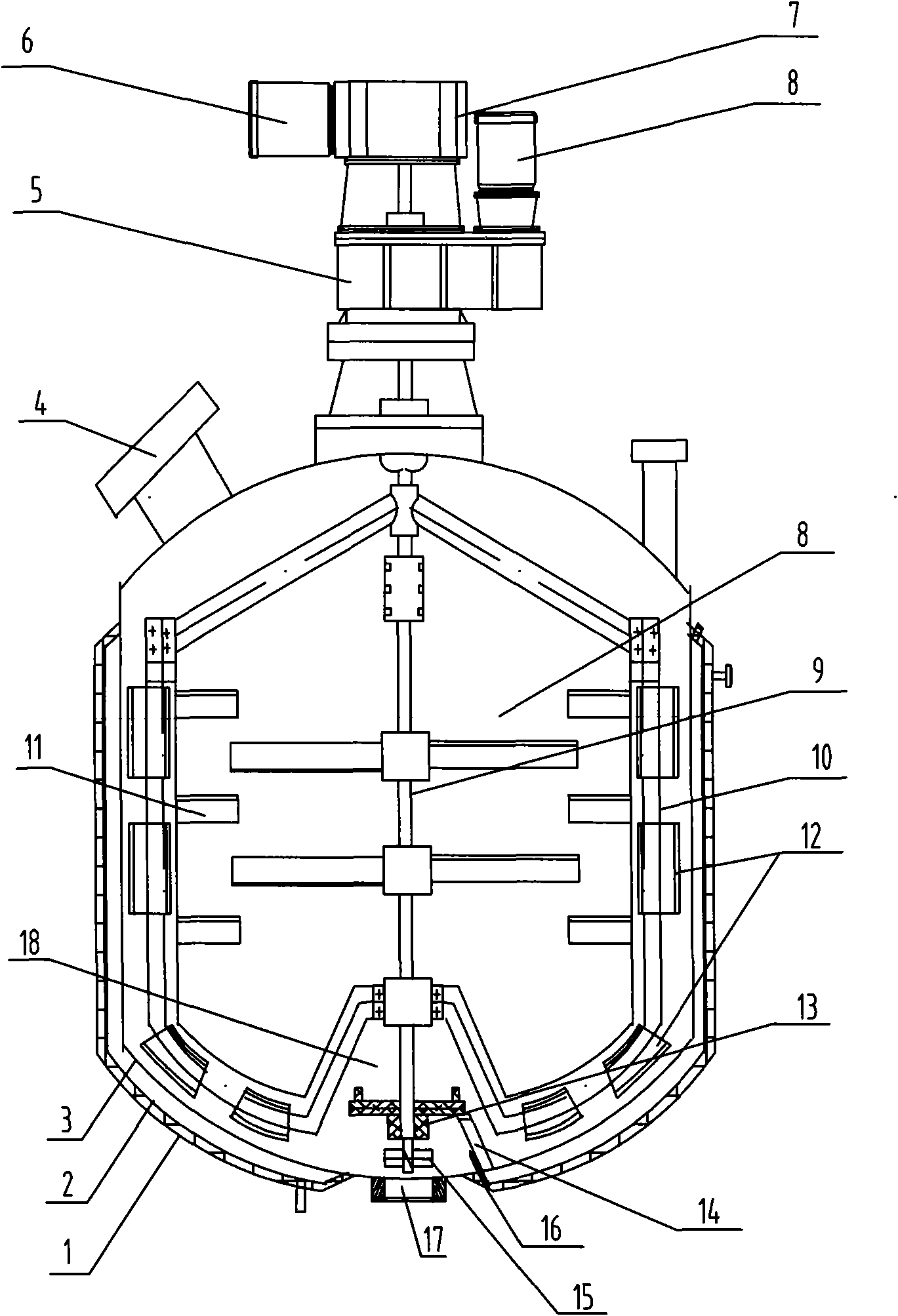

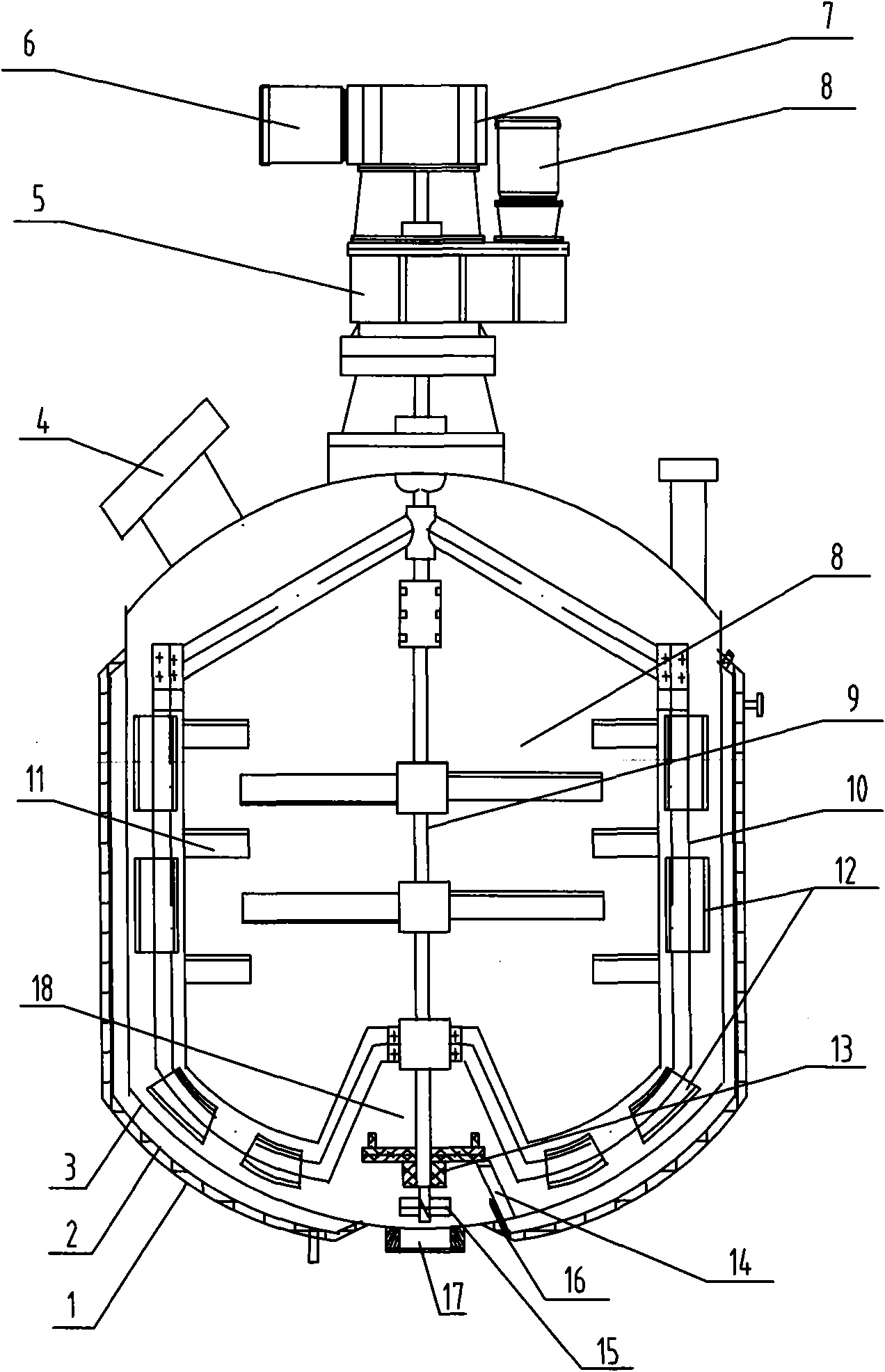

Combined stirred tank reactor

InactiveCN101972624AStir wellSmooth rotationMixersChemical/physical/physico-chemical stationary reactorsEngineeringCavity wall

The invention relates to a reactor, in particular to a combined stirred tank reactor used for producing a composite stabilizer and a modifier, which comprises a barrel, a stirring device and a material outlet, wherein the stirring device consists of a blade stirrer and a frame stirrer; the blade stirrer consists of a central rotating shaft and at least one blade stirring paddle arranged on the central rotating shaft; the frame stirrer consists of a frame body arranged along the cavity wall of the barrel, outer scraping plates arranged on the outer circumferential wall of the frame body and inner stirring paddles arranged on the inner circumferential wall of the frame body; an upwards-sunken groove is reserved above the material outlet at the bottom of the frame body; a bottom bearing is arranged on the central rotating shaft in the groove; a triangular support frame is arranged below the bottom bearing; the upper end of the triangular support frame is fixed with the bottom of the bottom bearing, while a lower end is fixed with the inner bottom of the barrel; and a small paddle is arranged below the bottom bearing on the central rotating shaft, and is in contact with the periphery of the material outlet at the bottom in the barrel. The combined stirred tank reactor can solve the problems that mixed raw materials are easy to deposit, easily adhered to the wall and unsmooth to discharge, and that reaction is incomplete, and is more environmentally-friendly and energy-saving.

Owner:NANJING CONCORD FERTILIZER CHEM

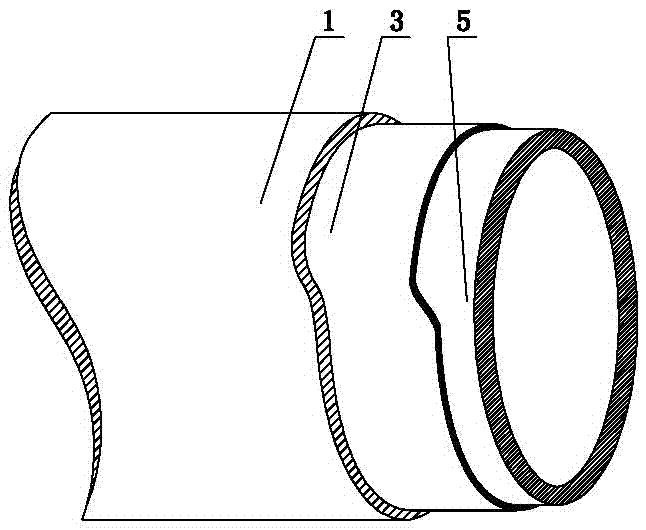

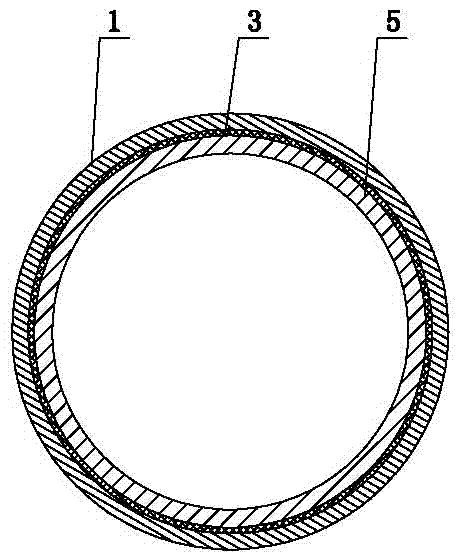

Novel high-strength HDPE (High-Density Polyethylene) composite tube and production method thereof

ActiveCN102996913AExtended service lifeInhibition of oxidative degradationRigid pipesCorrosion resistantOxidative degradation

The invention discloses a novel high-strength HDPE (High-Density Polyethylene) composite tube, which is obtained by composting an HDPE core tube, and a modified PE (Poly Ethylene) layer, wherein the innermost layer is the HDPE core tube which is enwrapped by a PE bonding layer, and the modified PE layer enwraps the PE bonding layer. The composite tube disclosed by the invention has the characteristics of good shock resistance, high compression strength, high wear resistance and the like. The HDPE core tube is corrosion resistant so that the composite tube is long in service life and capable of resisting the invasion by various corrosive media, such as an acid, an alkali and a salt, the modified PE layer is adopted so that plastic oxidative degradation is inhibited, tube ultra-violet resistance performance is improved, and tube service life is prolonged, and the PE bonding layer adopts a thermoplastic elastic body so that material performance is greatly improved, bonding capacity between the core tube and the modified PE layer is improved, and service life can reach 60 years.

Owner:HUBEI HUIFENG PLASTIC PIPE

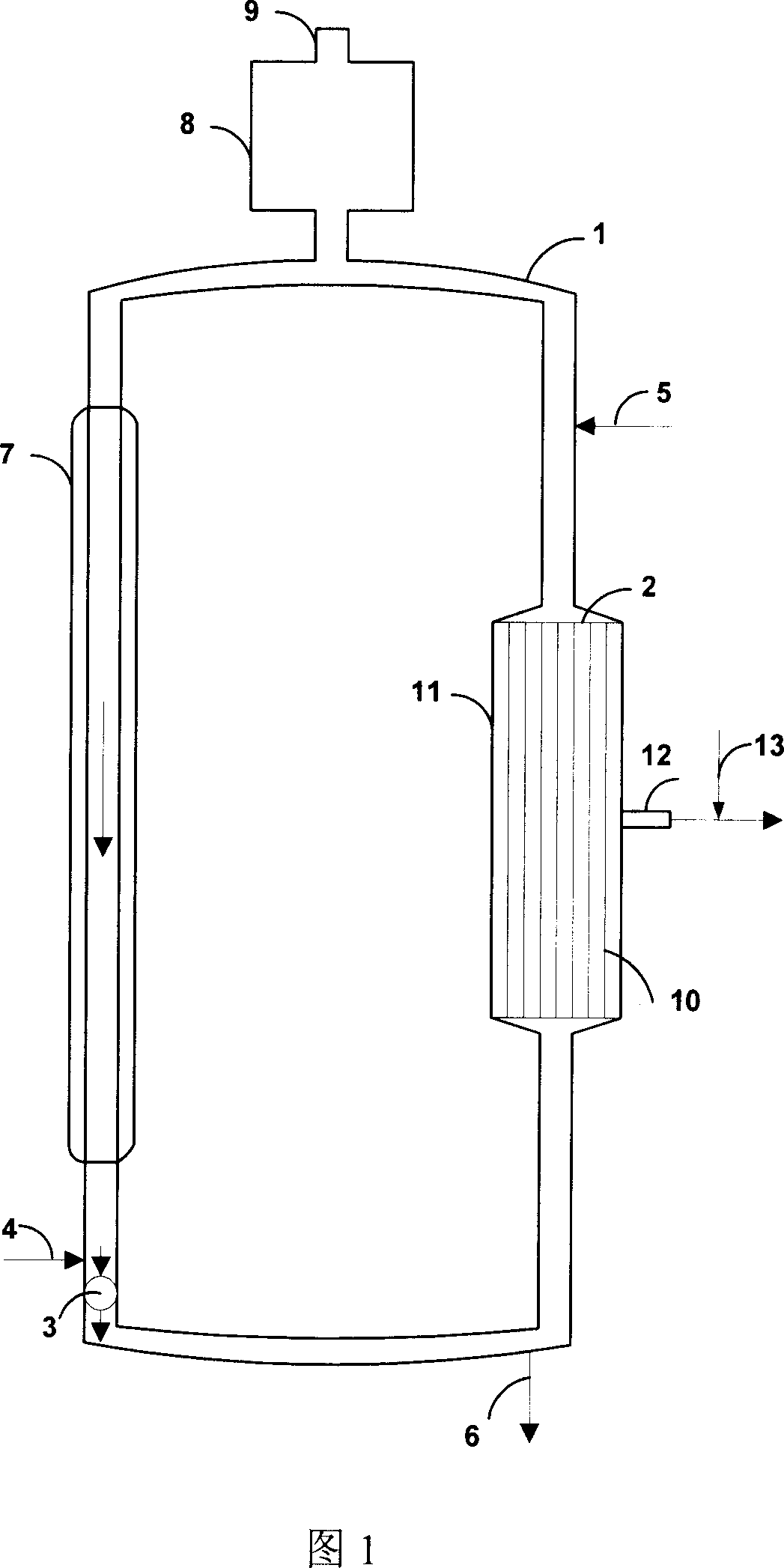

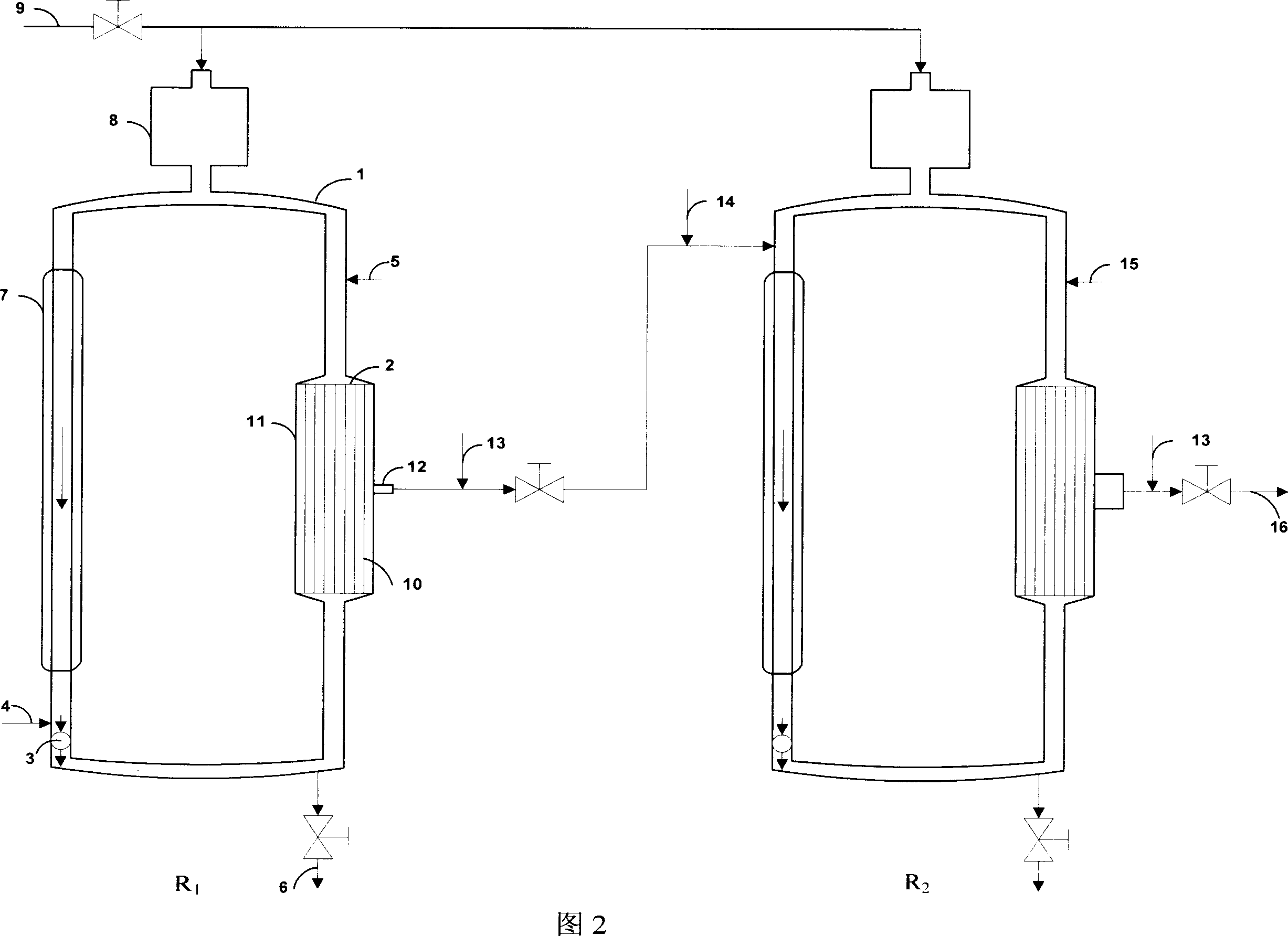

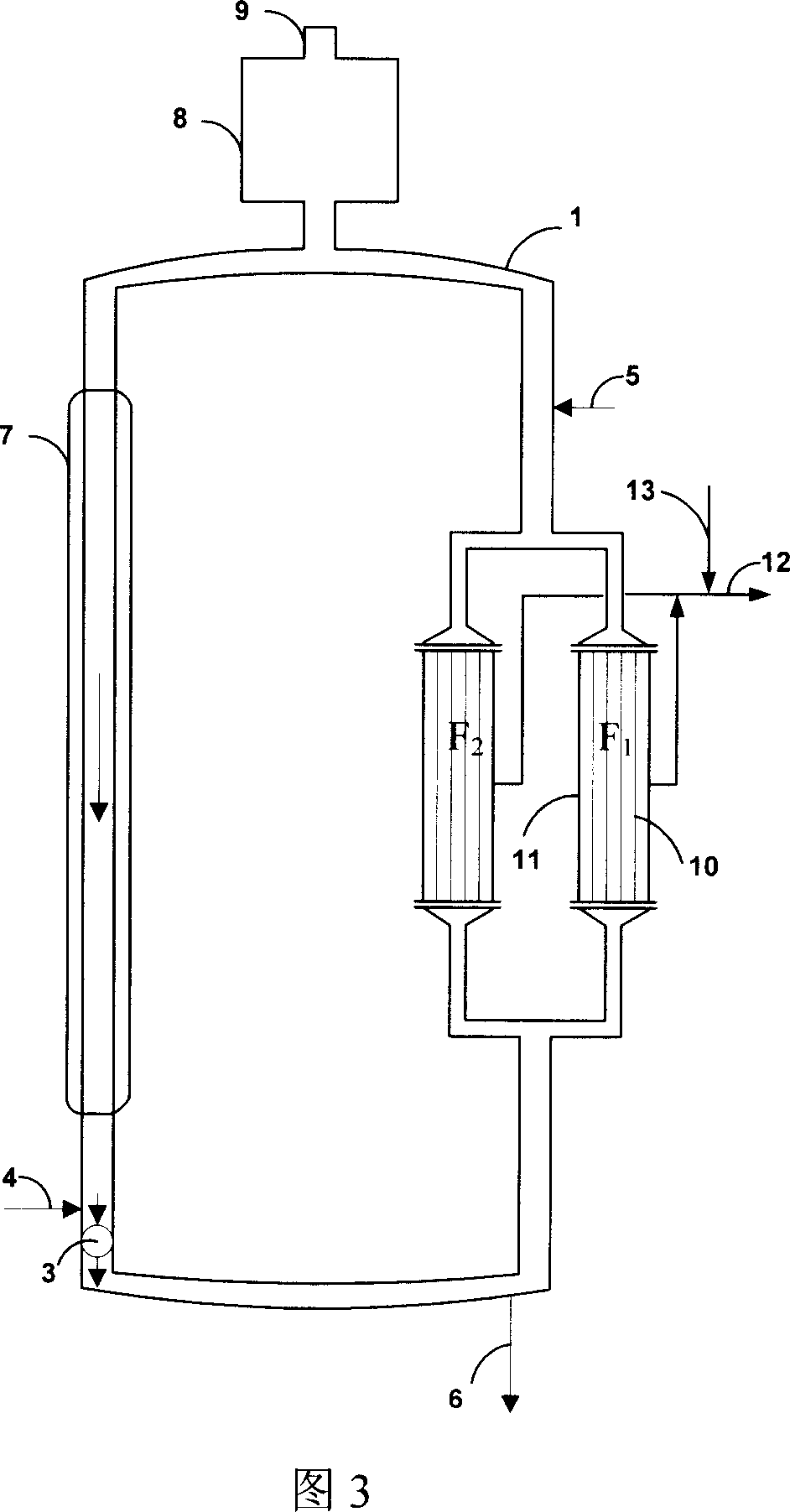

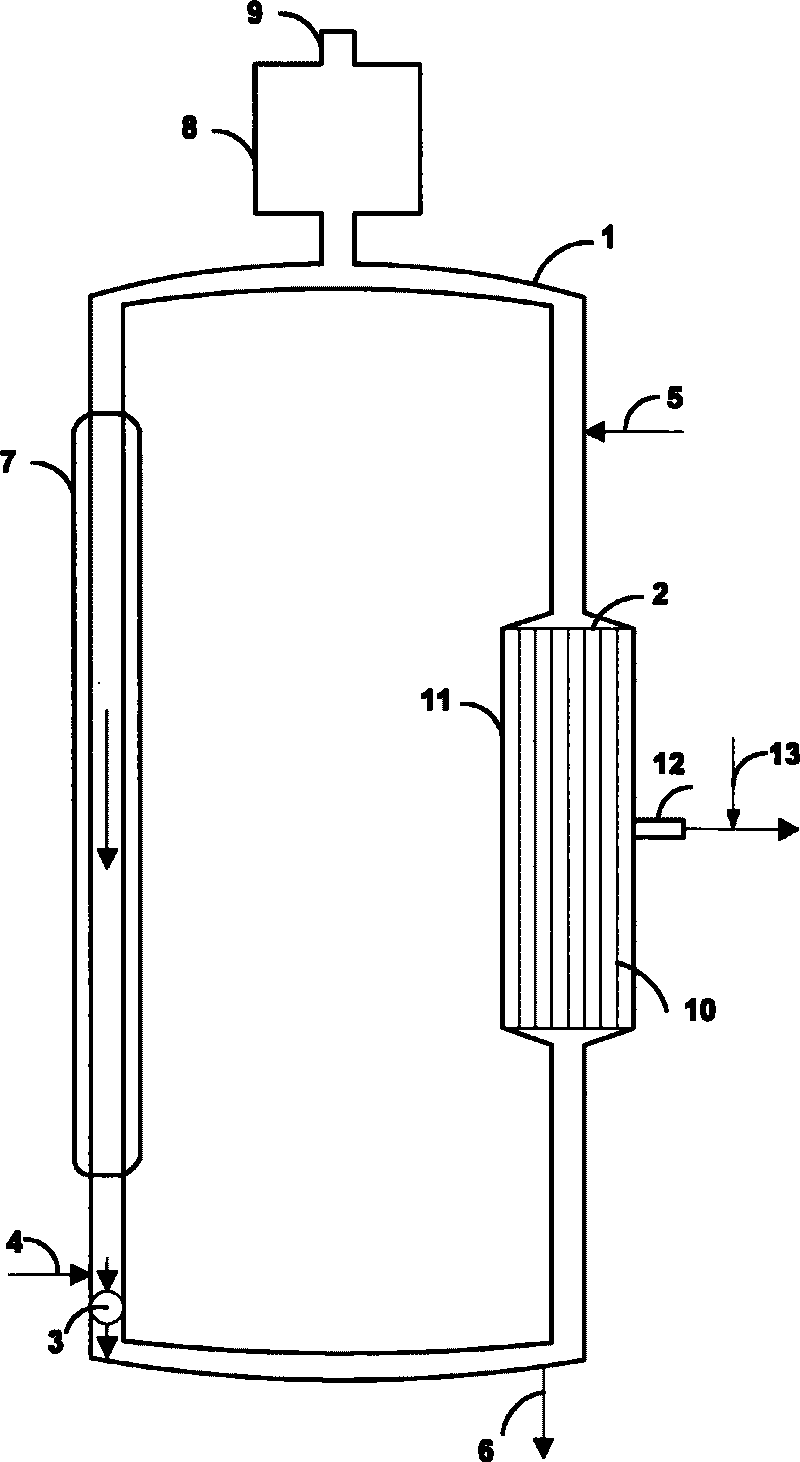

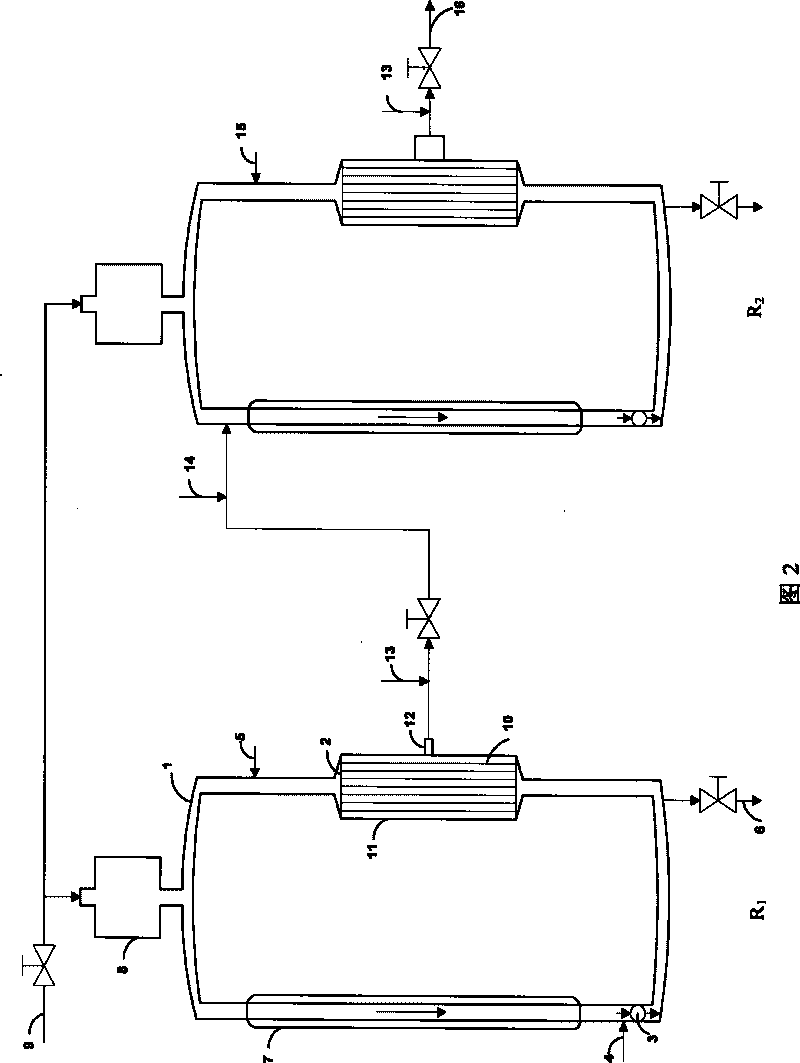

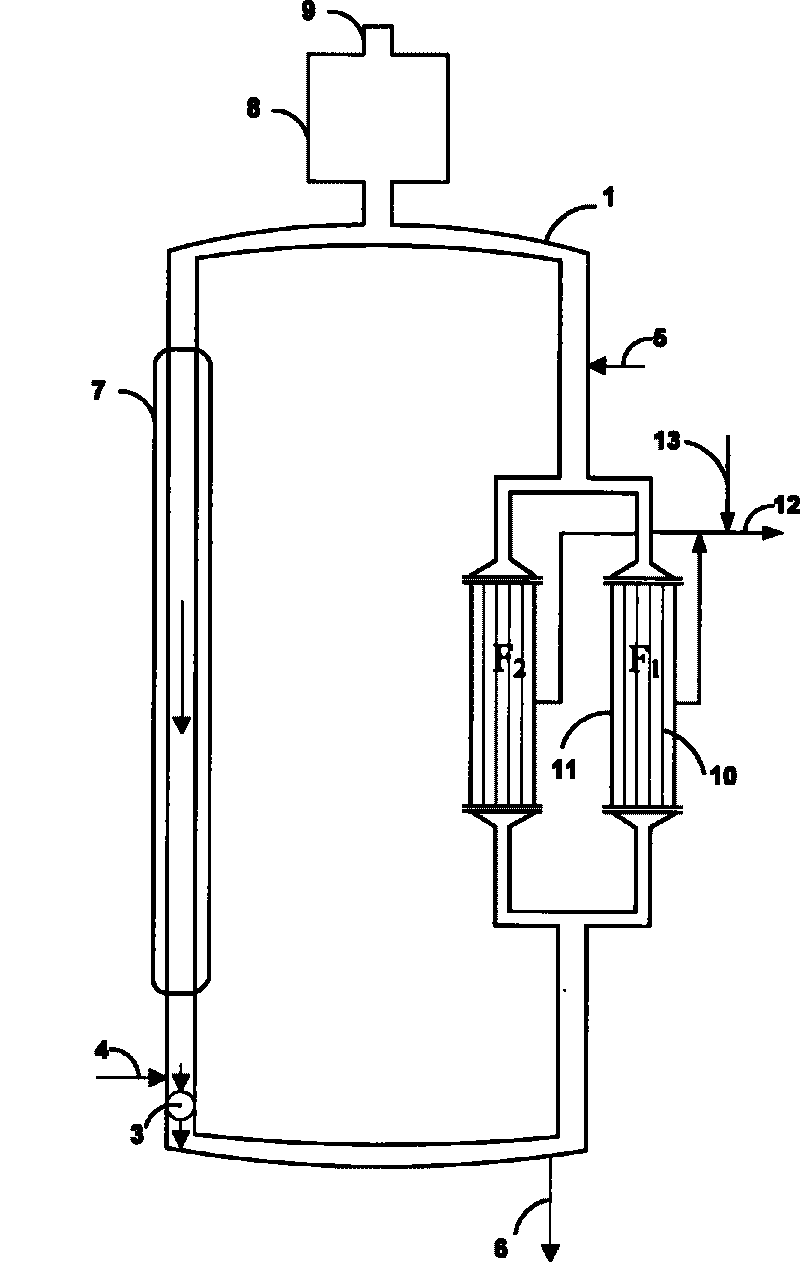

Integrated reacting and separating device

ActiveCN101116804AWell mixedImprove heat transfer effectPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesUltrafiltrationEngineeringReaction system

The present invention provides an integral reaction-separation equipment, mainly comprising a ring pipe and a separation component, wherein a circular reaction circuit is formed by the ring pipe and the separation component. The equipment is compact in structure, integrates catalytic reaction with catalyst separation and material heat transfer, especially can guarantee the high efficiency separation and the recycling use of fine particles such as nanometer or micron catalyst with reacting materials, and has good material mixing and heat transferring effects, which is suitable for strong heat absorbing or releasing solid-liquid, solid-liquid-liquid and partial gas-liquid-solid multiphase reaction system.

Owner:CHINA PETROLEUM & CHEM CORP +1

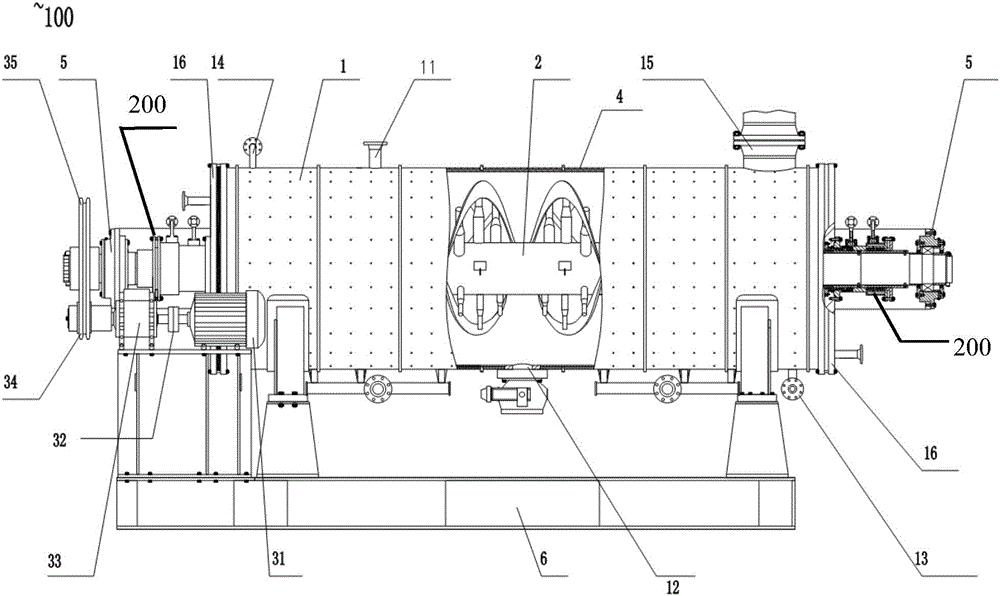

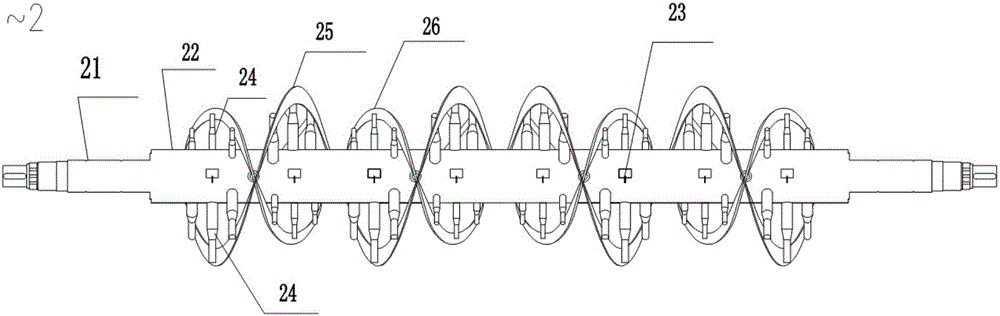

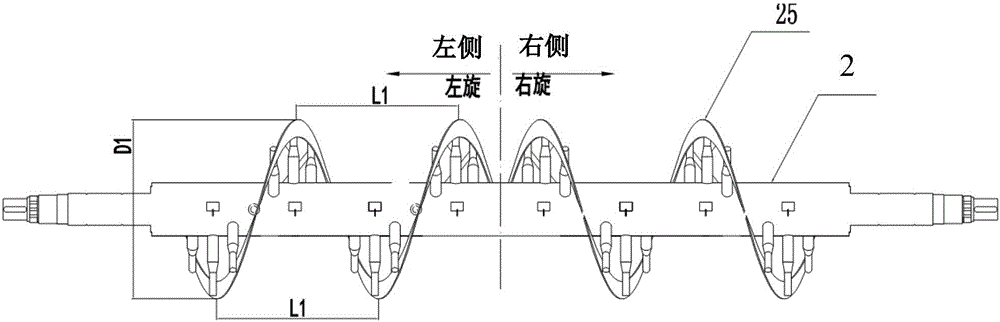

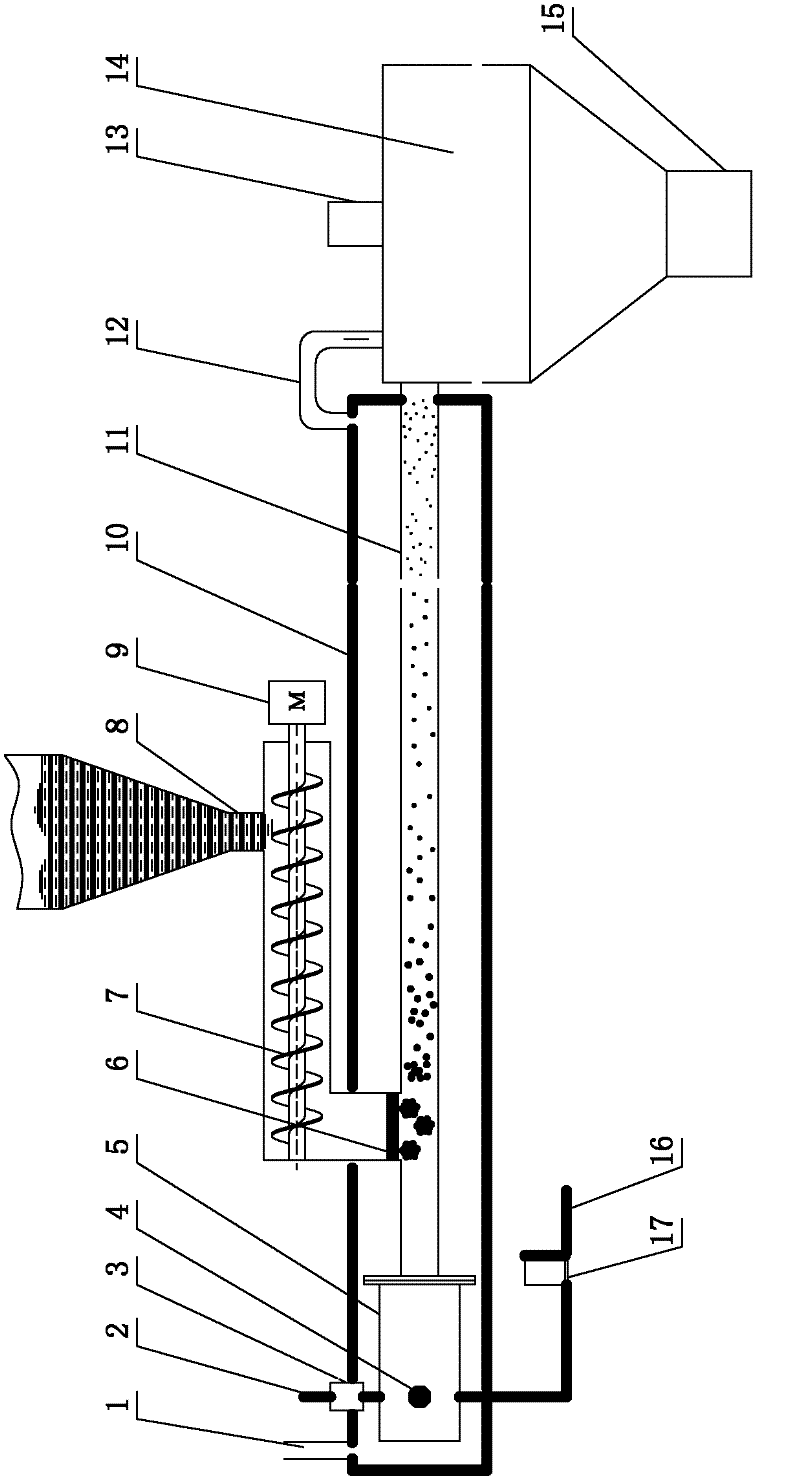

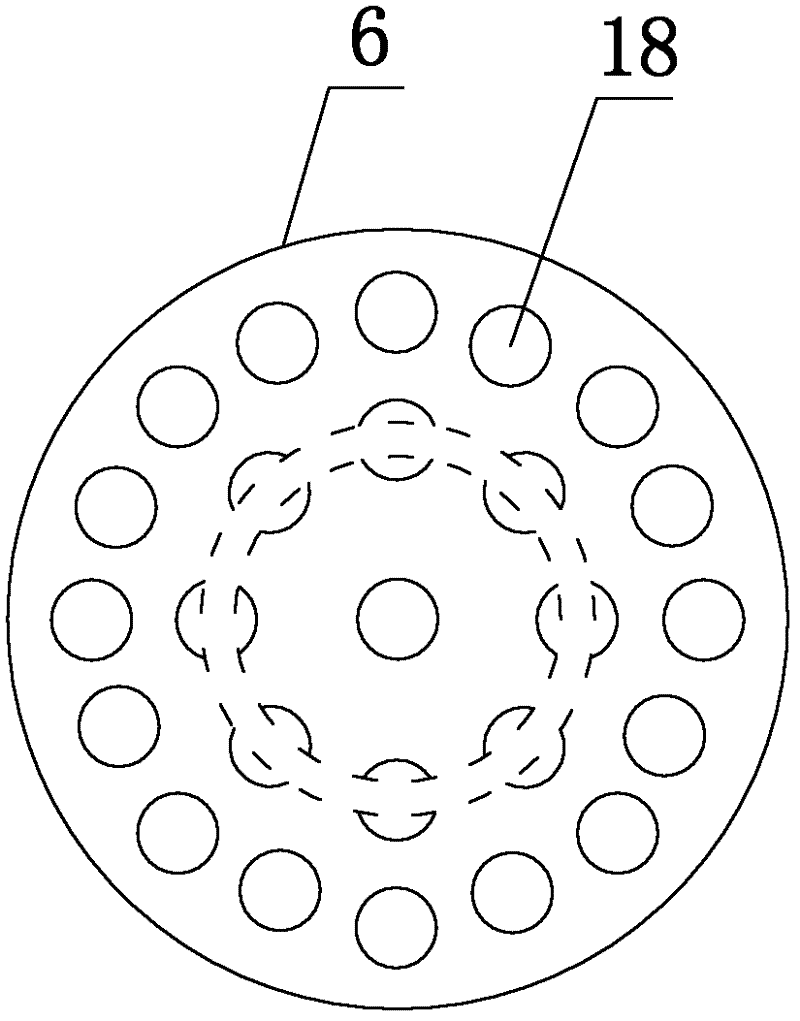

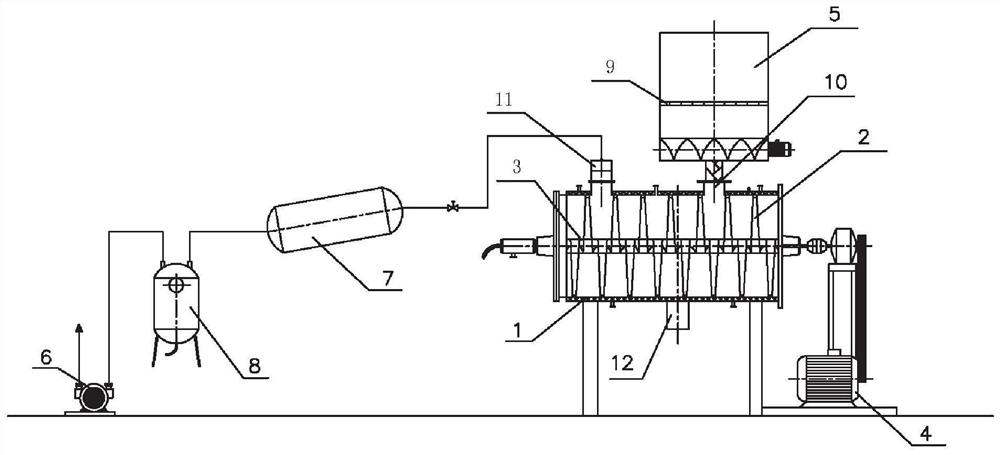

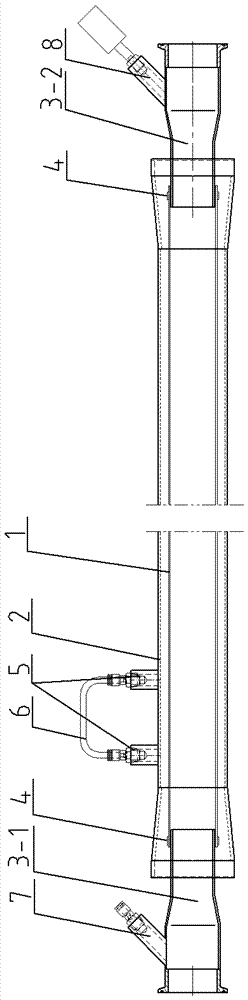

Drying stirrer and treatment system and method for silicon tetrachloride slag slurry in cold hydrogenation technology

InactiveCN106288705ANot easy to stick to the wallNot easy to agglomerateDrying gas arrangementsDrying solid materialsSlagEngineering

The invention provides a drying stirrer for silicon tetrachloride slag slurry in a cold hydrogenation technology. The drying stirrer comprises a shell, a stirring shaft and a transmission device. A drying cavity is defined by the shell. The shell is provided with a feeding port and a discharging port. The stirring shaft is horizontally arranged in the drying cavity and comprises a shaft head and a hollow shaft tube, wherein the shaft head and the hollow shaft tube are welded together. The hollow shaft tube is provided with stirring blades. A first helical band and a second helical band are fixed to the hollow shaft tube through supporting rods and are wound around the periphery of the hollow shaft tube. The respective spiral directions, on the left side and the right side of the hollow shaft tube, of the first helical band and the second helical band are opposite, and the spiral directions of the first helical band and the second helical band are opposite. Under rotation of the stirring shaft, the first helical band enables the slurry to move from the two sides to the middle, and the second helical band enables the slurry to move from the middle to the two sides. The drying stirrer enables the slurry to flow circularly, and the slurry is stirred more evenly. The invention further provides a treatment system and method for the silicon tetrachloride slag slurry.

Owner:江西赛维LDK光伏硅科技有限公司

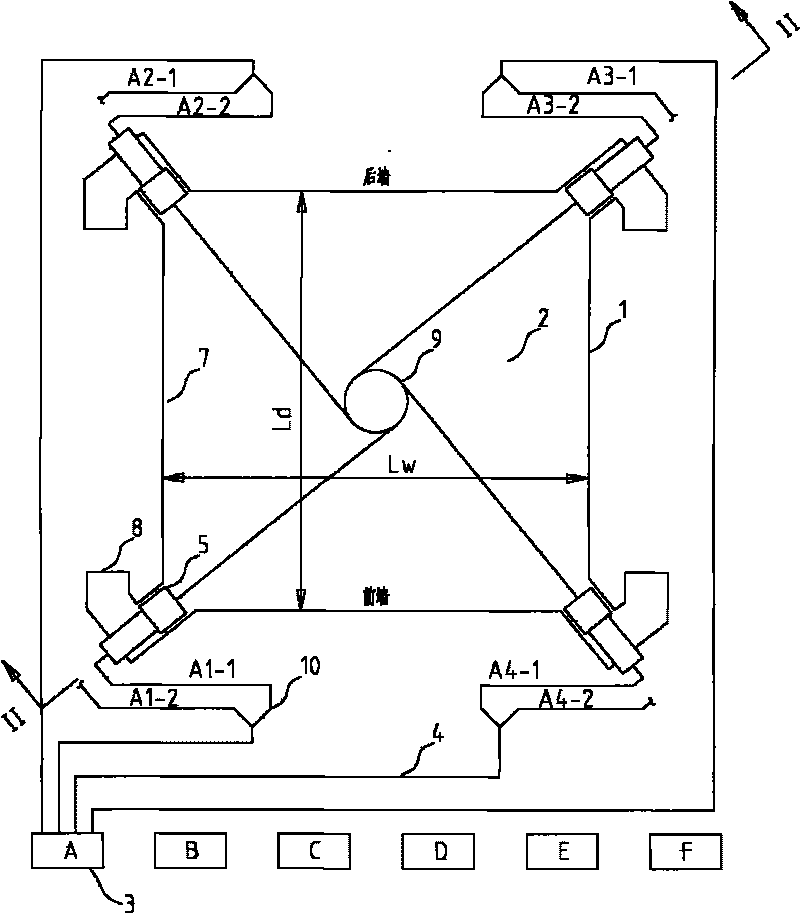

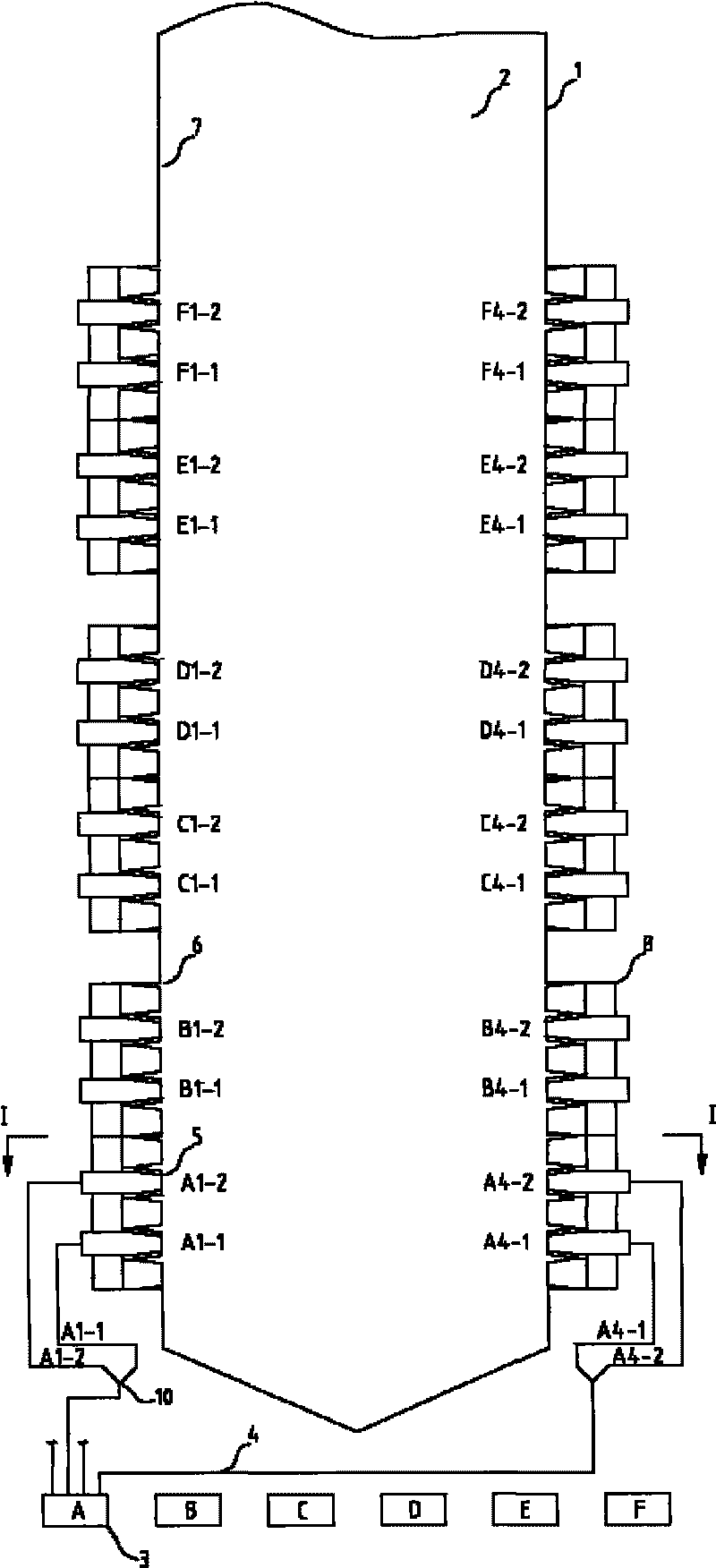

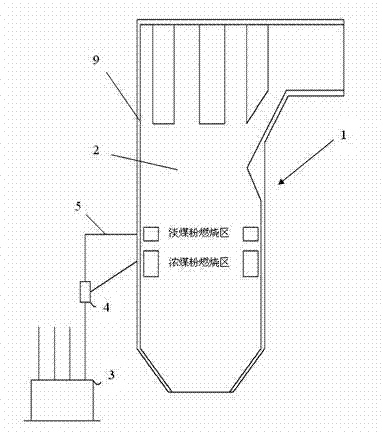

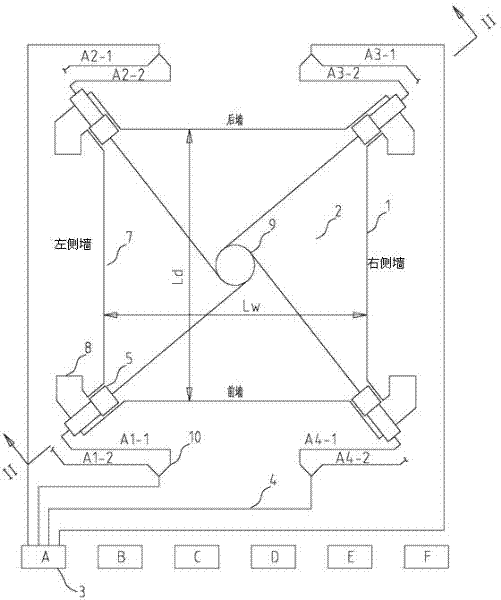

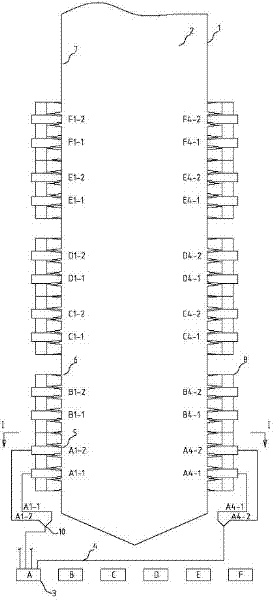

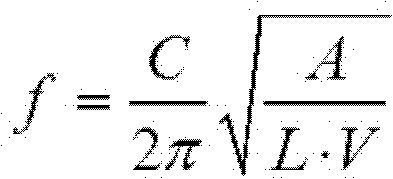

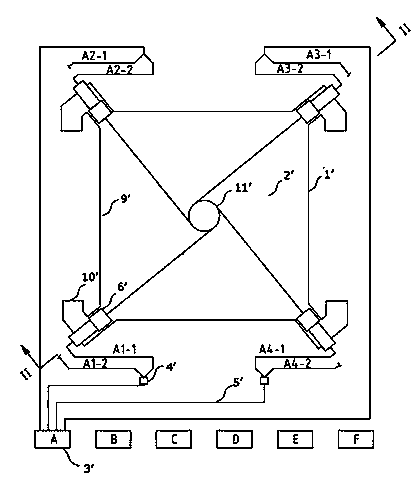

Hexagonal or octagonal tangential arrangement of anthracite burning single-fireball direct-flow combustors

ActiveCN101709871AGuaranteed to catch fire in timeReduce overall heightCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelLow loadAirflow

The invention provides hexagonal or octagonal tangential arrangement of anthracite burning single-fireball direct-flow combustors, which is characterized in that: two groups of combustors are arranged on each water-cooling wall or two groups of combustors are arranged on two opposite water-cooling walls of a hearth respectively and a group of combustors are arranged on the other two opposite water-cooling walls respectively, each group of combustors are at least divided into a small group; and each small group of combustors are vertically provided with at least two primary air pulverized nozzles and three secondary air pulverized nozzles at intervals. Each coal mill is connected with eight or six primary air pulverized nozzles which have the same level with that of the coal mill. The start and stop of each coal mill affect the running of the eight or six primary air pulverized nozzles which are on the same layer. The hexagonal or octagonal tangential arrangement of the anthracite burning single-fireball direct-flow combustors can decrease the number of the air pulverized nozzles in a single group of combustors on the premise of meeting the requirements of the thermal power of a single air pulverized nozzle and the number of the total air pulverized nozzles, allows the thermal load qHr of a wall in a combustor area to be relatively high, and guarantees the timely ignition of an pulverized anthracite flow and low-load combustion of a boiler without oil.

Owner:SHANGHAI BOILER WORKS

Red-core dragon fruit all-fruit powder and preparation method thereof

InactiveCN103549315AIncrease powder yieldSimple preparation processMulti-step food processesFood shapingBiotechnologyDietary fiber

The invention relates to the technical field of food processing, and mainly relates to red-core dragon fruit all-fruit powder and a preparation method thereof. The red-core dragon fruit all-fruit powder is prepared by adopting the step of carrying out freeze-drying or spray-drying after red-core dragon fruit pulp and beta-cyclodextrin are mixed, wherein the red-core dragon fruit pulp is prepared by peeling and pulping fresh or freezing red-core dragon fruits, the adding amount of the beta-cyclodextrin is 0.2-1.0 percent of the dry weight of the red-core dragon fruit pulp, and the red-core dragon fruit all-fruit powder has the characteristics that the content of betanin is not less than 3.4mg / g, the water content is not more than 4.5 percent, the rehydration ratio is 8.0-10, the content of dietary fibers is not less than 11.0 percent, and the fatty acid content is not less than 7 percent. The red-core dragon fruit all-fruit powder provided by the invention is pure-natural all-nutrition fruit powder, ensures the instant effect and the mouth feel and the special flavor of the red-core dragon fruit, brings convenience for storage, transportation and carrying, and is wider in market prospect.

Owner:ZHEJIANG NORMAL UNIVERSITY

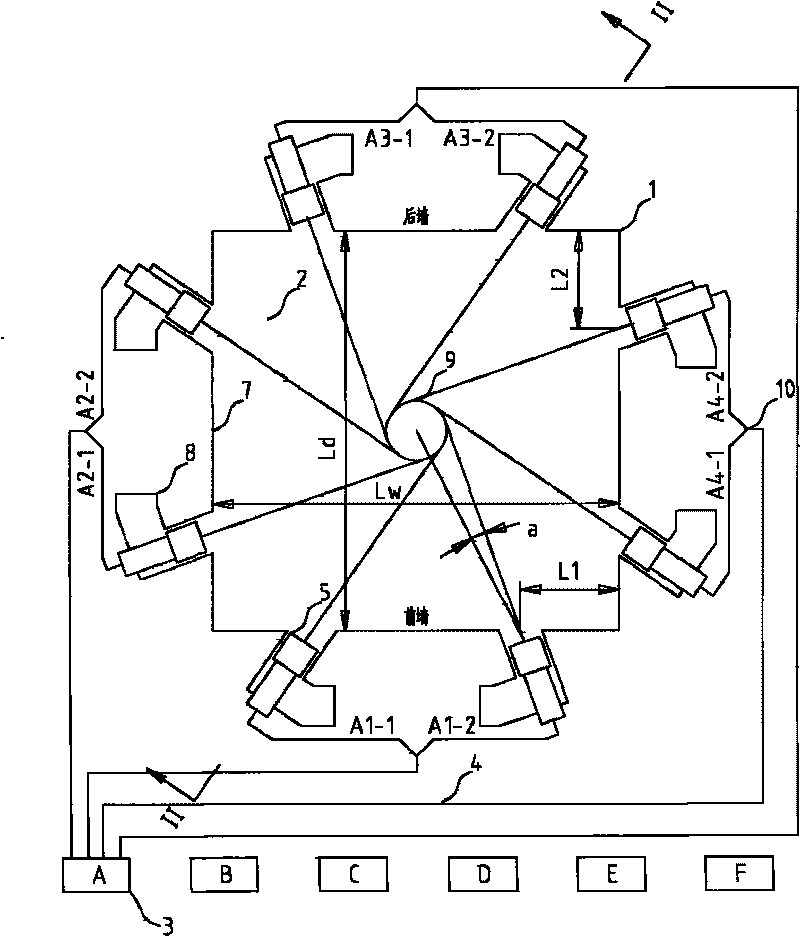

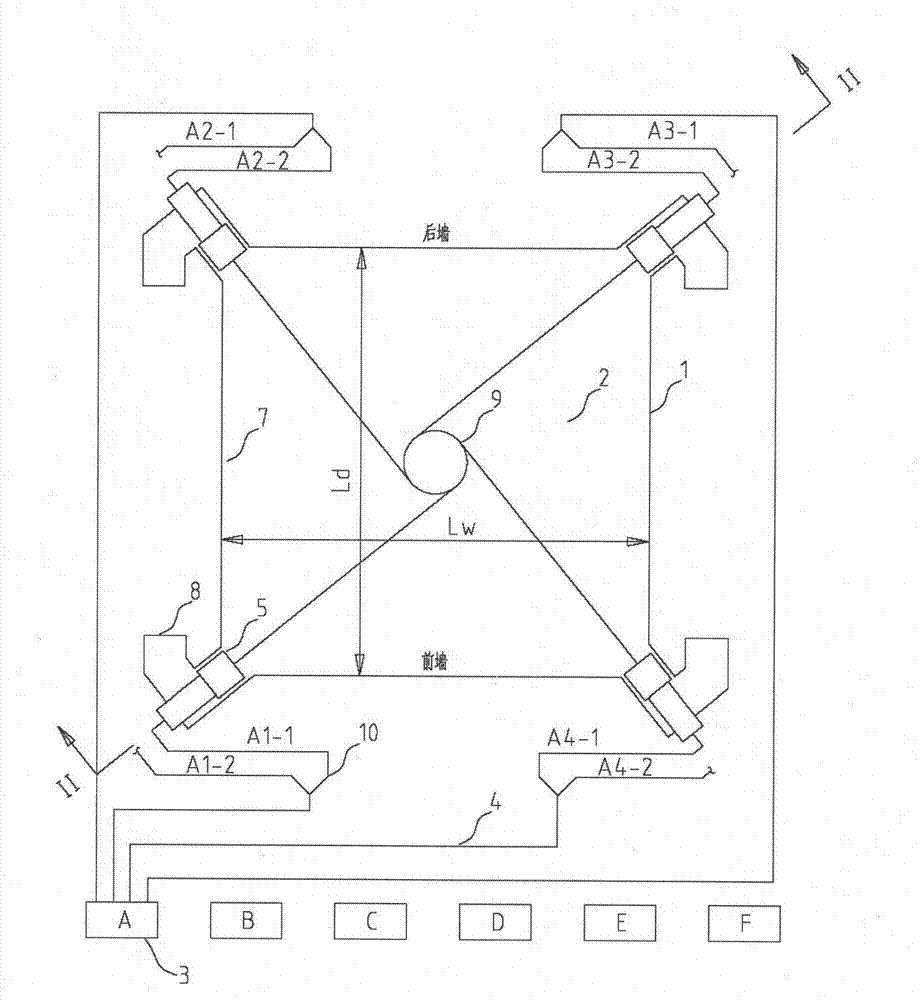

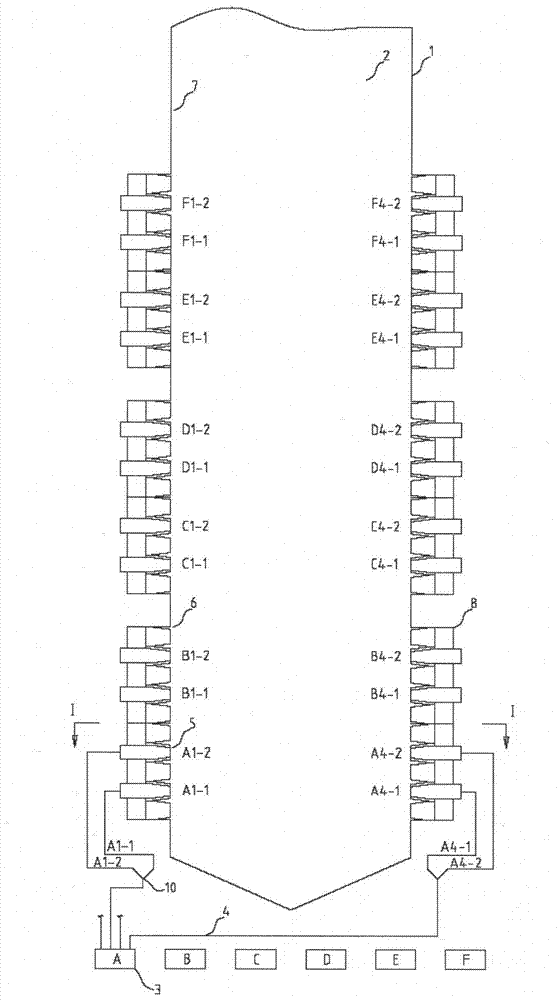

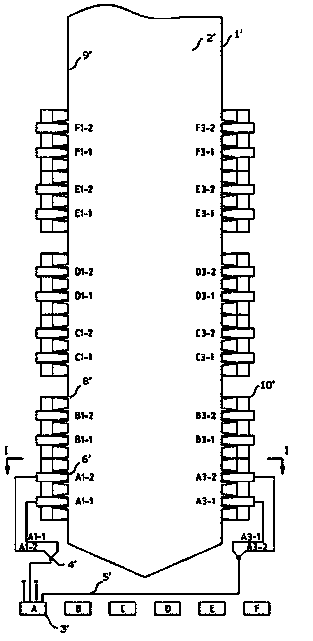

Coal dust thickness-thinness separating and distributing structure of single-fireball eight-corner direct-flow burner

ActiveCN102563634AIncrease concentrationIncrease heat loadPulverulent fuel combustion burnersWater-tube boilersDistributed structureBurns temperature

The invention discloses a coal dust thickness-thinness separating and distributing structure of a single-fireball eight-corner direct-flow burner. Eight groups of burners are arranged on a boiler body, two groups of the burners are arranged on each water cooled wall, each group of the burners comprises a plurality of the burners with nozzles facing to the same direction, and a center line of each nozzle of the eight groups of the burners forms an imaginary inscribed circle along the same tangential direction in a boiler chamber. In the coal dust thickness-thinness separating and distributing structure, the eight groups of the burners are distributed on four water cooled wall of a boiler, therefore, the coal dust concentration of a thick coal dust area is increased, the heat load qHr of the wall face of the area of the lower burners is higher, and the burning temperature in the area can achieve the requirement of stable-combustion of firing of anthracite. The distance of jet flow from outlets of the nozzles to a downstream adjacent-angle airflow is short, a lower primary air coal dust airflow speed can be adopted, the intensity of a heat flow of the outlets of the nozzles is high, and passing convection and radiation heat transfer amount are improved to ensure timely firing of the airflow of anthracite coal dust and steady burning of the boiler in low load without oil.

Owner:SHANGHAI BOILER WORKS

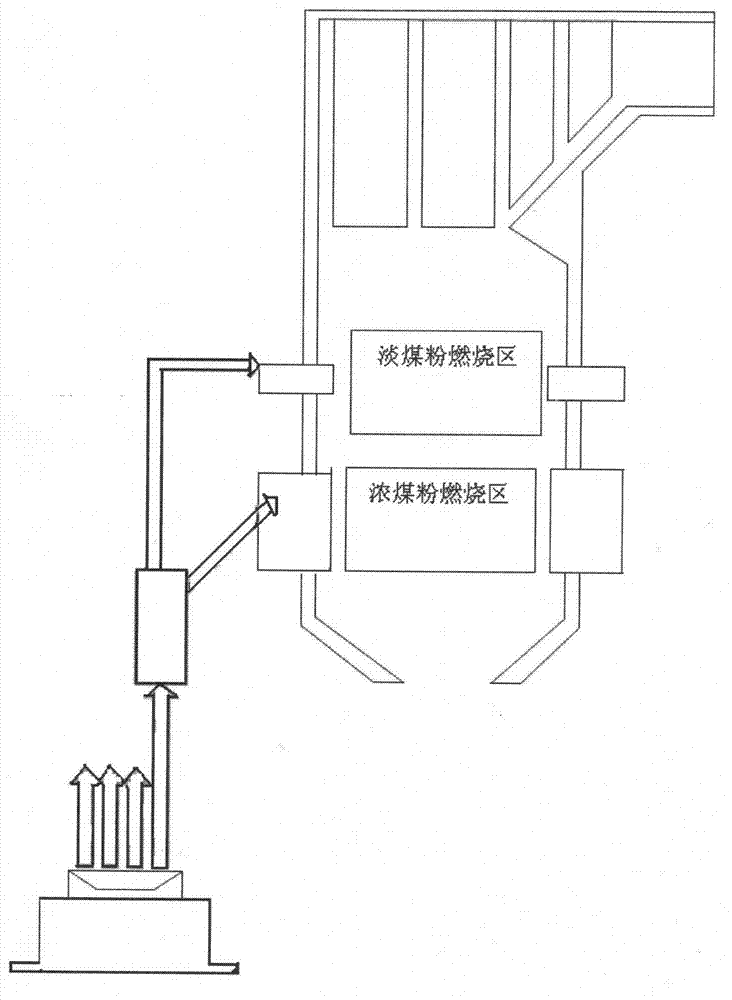

Pulverized coal shade separate arrangement mode of direct-current burner with double fireballs

ActiveCN103090368AIncrease concentrationGuaranteed not to oilCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorLow load

The invention provides a pulverized coal shade separate arrangement mode of a direct-current burner with double fireballs for burning anthracite coal. The pulverized coal shade separate arrangement mode is characterized in that each boiler is provided with eight groups of burners; the eight groups of burners are at the same level; four groups of burners form an imaginary circle inside a hearth; the other four groups of burners form another imaginary circle inside the hearth; each group of burners are divided into two small groups in the vertical direction; the first small group of burners are named as 'primary air / thick pulverized coal' burners; and the second small group of burners are named as 'primary air / thin pulverized coal' burners. The thermal load qHr of the wall surface of a burner zone is high under the premise of ensuring the power of the entire boiler; and timely inflaming of anthracite pulverized coal air flow and low-load stable combustion of the boiler without oil can be ensured.

Owner:SHANGHAI BOILER WORKS

Swirl spouting device for drying sludge

InactiveCN1654377AReduces the possibility of deflagrationImprove airtightnessSludge treatment by de-watering/drying/thickeningDrive shaftSludge

The sludge drying cyclonic spouting apparatus includes main tower body, air chamber, driving shaft and drying and stirring paddle. The air chamber is set in the lower part of the main tower body, drying and stirring paddle is set onto the driving shaft, the air chamber has tangent air inlet port and bottom with W-shaped axial section, and the main tower body over the W-shaped bottom of the air chamber with its lower part extending into the air chamber, and has material feeding port and air outlet port in the upper part as well as tangent air exhaust port and air inlet port rotating in the same direction. The present invention has the high tightness, high drying efficiency, low power consumption, sterilization effect, no jamming and simple apparatus.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD +1

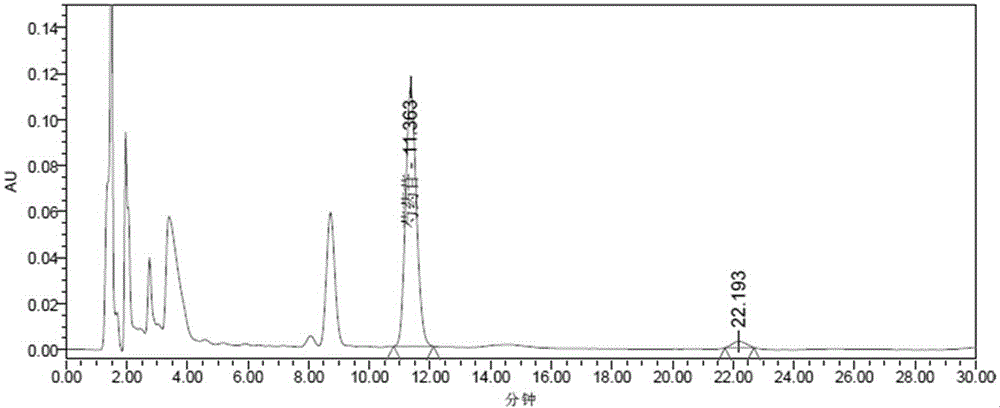

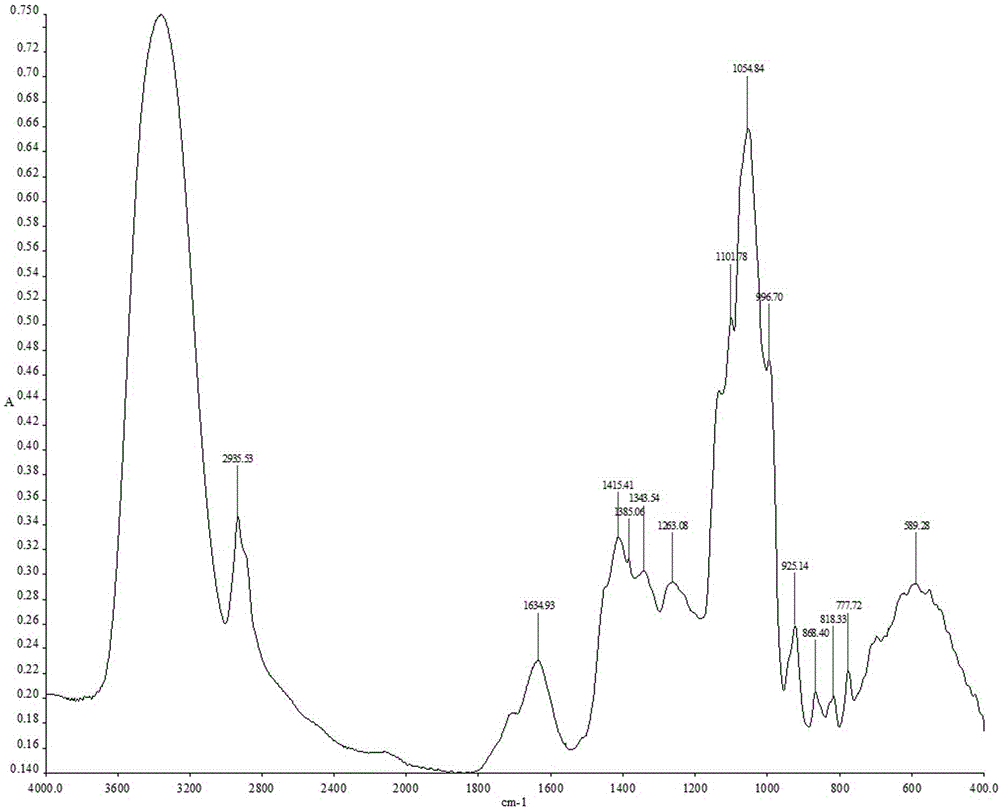

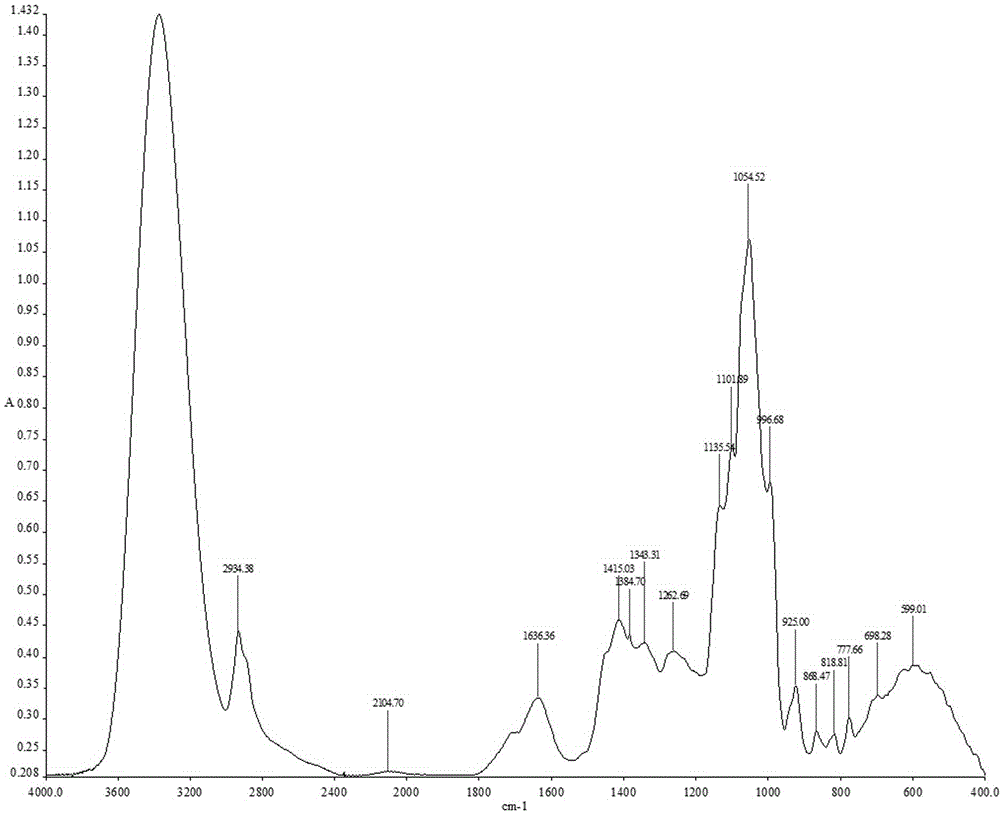

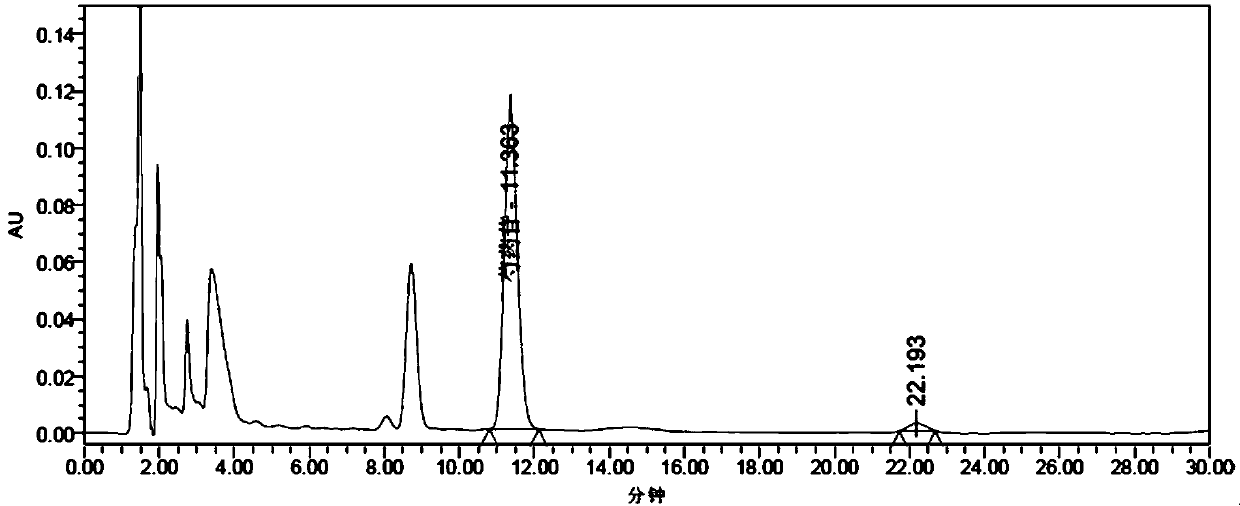

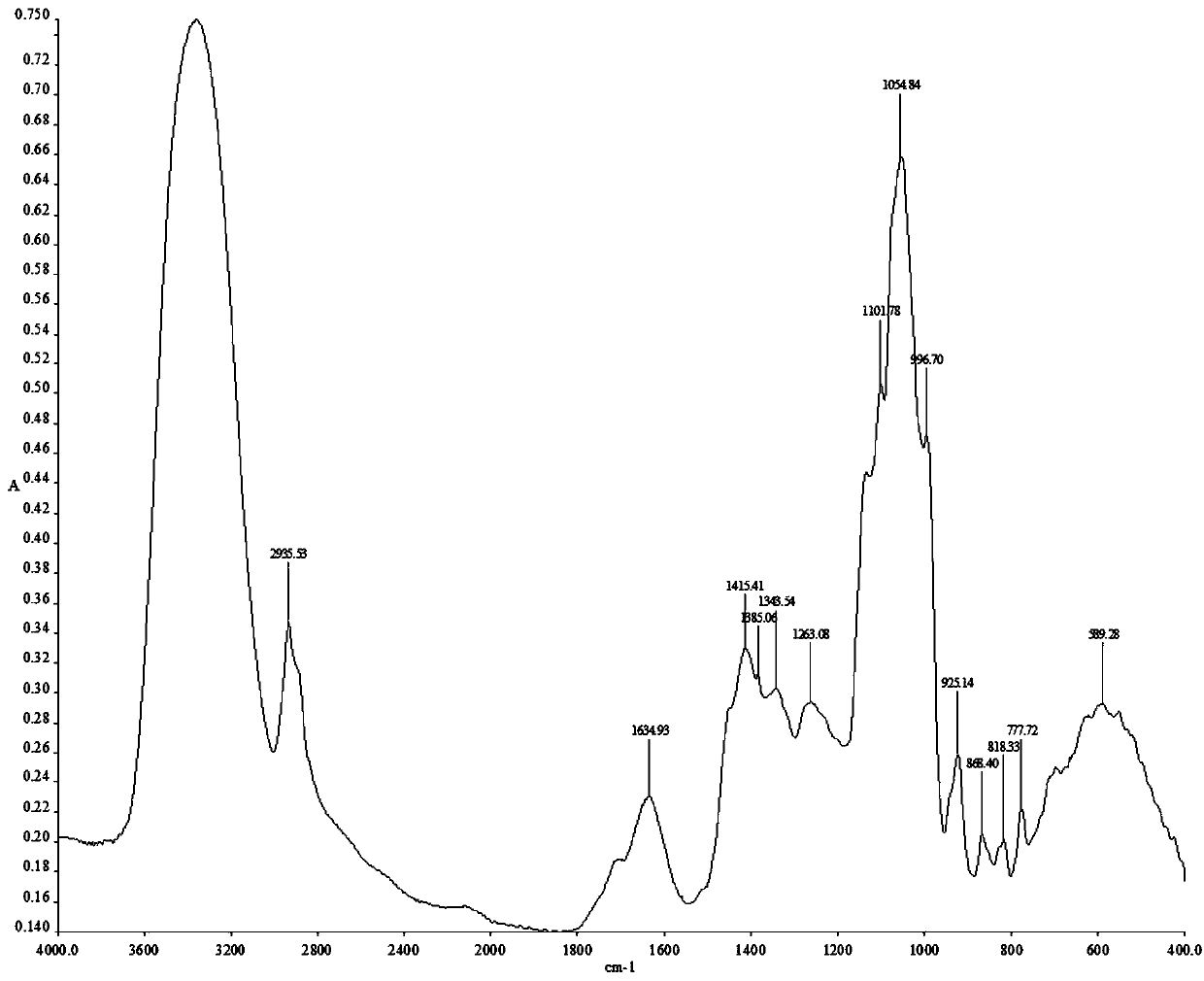

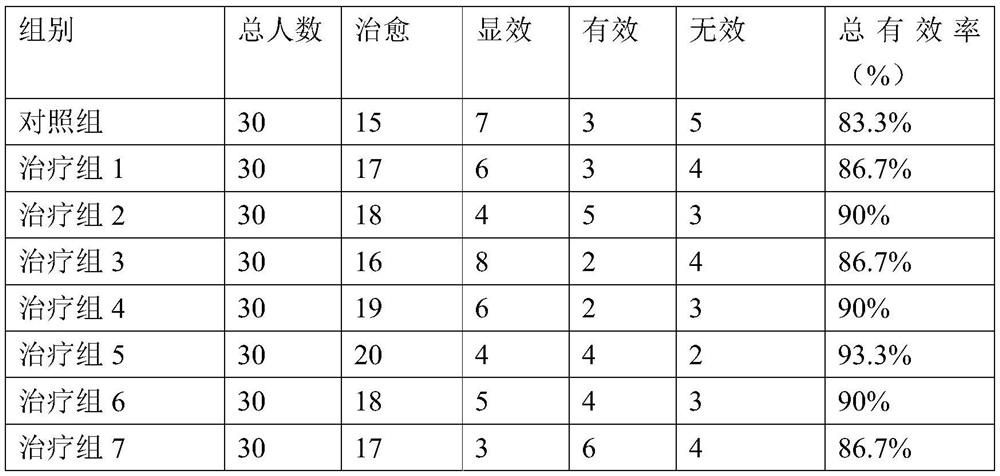

Method for preparing siwu decoction formula granules and quality control method thereof

ActiveCN105287875AEmbody conceptTo achieve the purpose of reducing toxicity and increasing efficiencyComponent separationMaterial analysis by optical meansBiotechnologyFormulary

The invention discloses a method for preparing siwu decoction formula granules and a quality control method thereof. The method for preparing the siwu decoction formula granules comprises steps: prepared rehmannia roots, angelica sinensis, radix paeoniae alba and ligusticum wallichii medicinal slices are added with water which is 5-15 times of the weight of total inventory, are extracted for two times, aromatic water is collected and is combined with two frying filter liquids, are decompressed and concentrated in vacuum, a concentrated solution is added with beta (Beta)-cyclodextrin and silicon dioxide to uniformly stir and obtains a clear paste, and the aromatic water and the aromatic water are sprayed and dried after being uniformly mixed, and are pelletized through a dry method to prepare the siwu decoction formula granules. The quality control method of the siwu decoction formula granules comprises qualitative identification of an infrared fingerprint spectrum and a thin layer and content determination of a high performance liquid chromatography (HPLC). The method for preparing siwu decoction formula granules and the quality control method thereof decoct in a combined mode according to a traditional method, can perfectly take full advantages of drug matching compared with an existing method that various medicinal odours are added when single formula particles are taken, reflects the overall concept of Chinese medicine, guarantees to achieve the purpose of reducing toxicity and enhancing efficacy, supplies novel selection for clinical medication, builds a perfect quality standard, controls quality by combining a power-spectral method and a chromatography, and can effectively control quality of complex granules from the overall to the more specific.

Owner:GUANGDONG YIFANG PHARMA

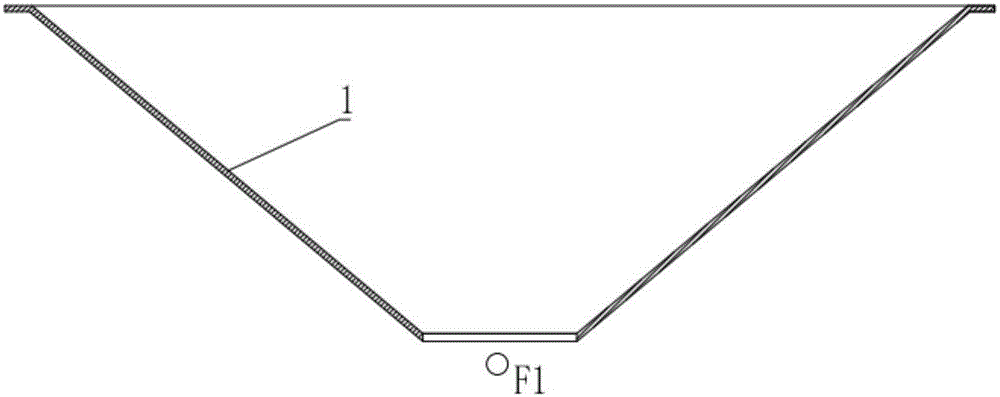

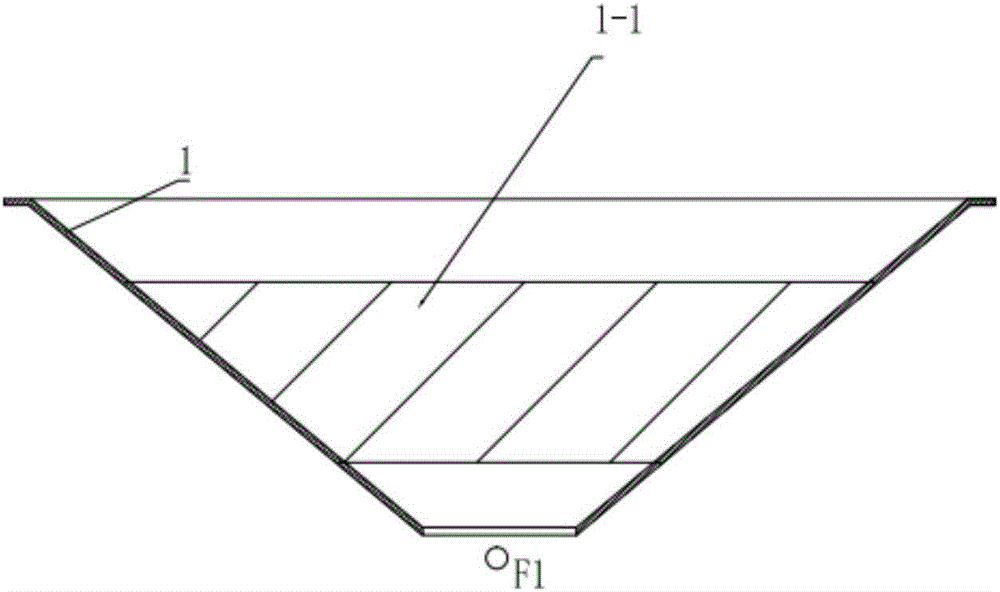

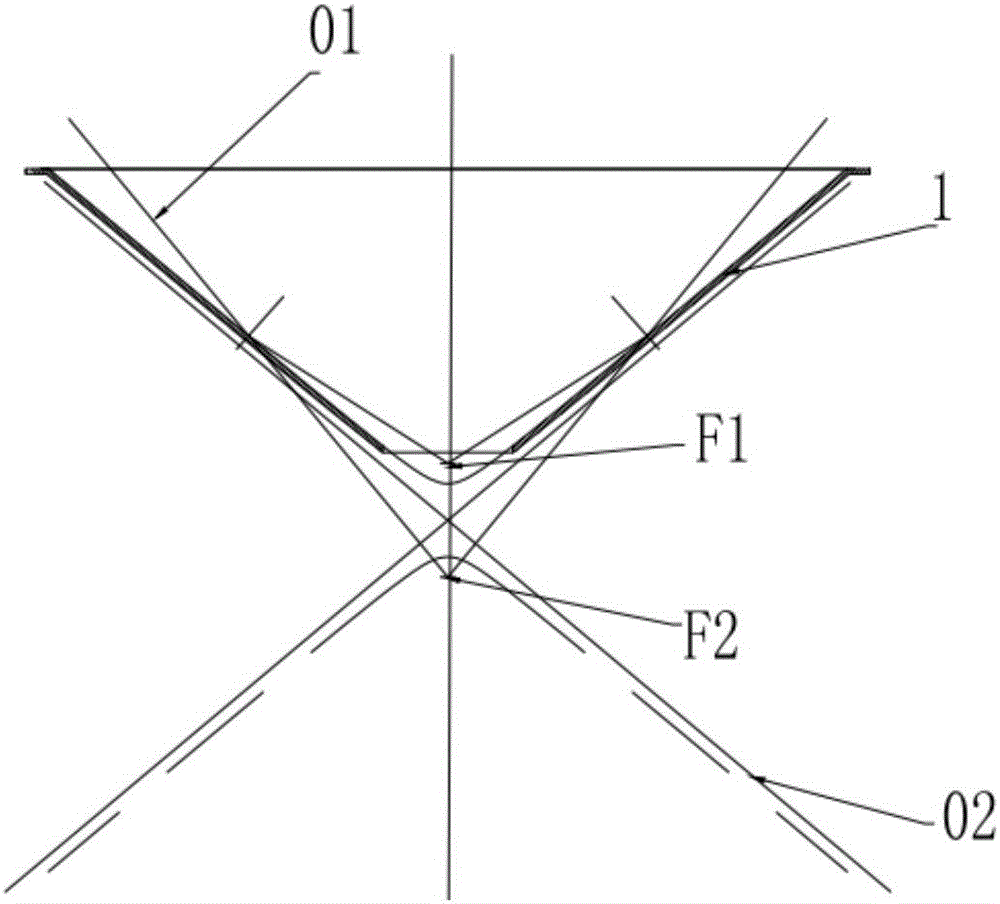

Mixing cabin and mixing apparatus

ActiveCN106422840AWon't breakAchieve mixing effectRotating receptacle mixersFlow mixersParticulatesMechanical engineering

The invention relates to the technical field of mixing of various particulate materials, in particular to a mixing chamber, comprising a mixing chamber body that is of inverted cone structure provided with an upper opening and a discharge port in the lower portion; the mixing chamber body comprises a circular inner wall, the middle of the inner wall is provided with a discharge annular face, and at least the discharge annular face is a hyperbolic annular face or a parabolic annular face. The invention also discloses a mixing apparatus, comprising the mixing chamber mentioned above, and also comprising a support and a plurality of quantitative feeding devices arranged above the mixing chamber, each quantitative feeding device comprises a feeding outlet provided with a dropping guide plate, a guide extension line of each dropping guide plate points to another focal point of the hyperbolic annular face, and a guide direction of each dropping guide plate is parallel to the axis of the parabolic annular face. The mixing chamber and the mixing apparatus have the advantages that various materials can be mixed well, and damage of particles due to stirring is avoided.

Owner:烟台中正新技术有限公司

Mixed fiber wallpaper and making method thereof

InactiveCN104790265AImprove embossing effectImprove mildew resistanceNon-fibrous pulp additionCovering/liningsMildewMoisture resistance

The invention relates to the field of building materials, in particular to a mixed fiber wallpaper and a making method thereof. The mixed fiber wallpaper comprises the following raw materials by mass part: 30-50 of cotton fiber, 15-25 of wood pulp fiber, 15-20 of polypropylene fiber, 3-5 of sodium carboxymethylcellulose, and 4-8 of a silane coupling agent. The synergistic effect of the silane coupling agent and sodium carboxymethylcellulose adopted by the mixed fiber wallpaper makes the cotton fiber, wood pulp fiber and polypropylene fiber combine compactly. The mixed fiber wallpaper provided by the invention not only has very strong tear strength up to over 30mNm<2> / g, but also has beautiful and smooth appearance and good embossing effect, has good mildew resistance, moisture resistance and permeability without other treatment, and is not easy to stick walls.

Owner:昆山文创建筑装饰工程有限公司

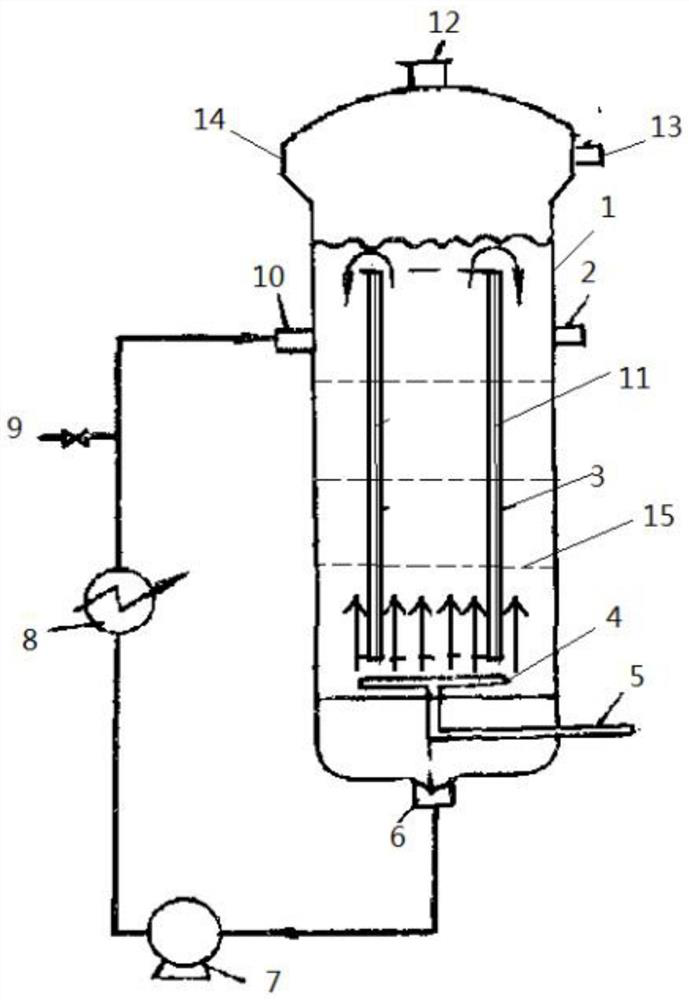

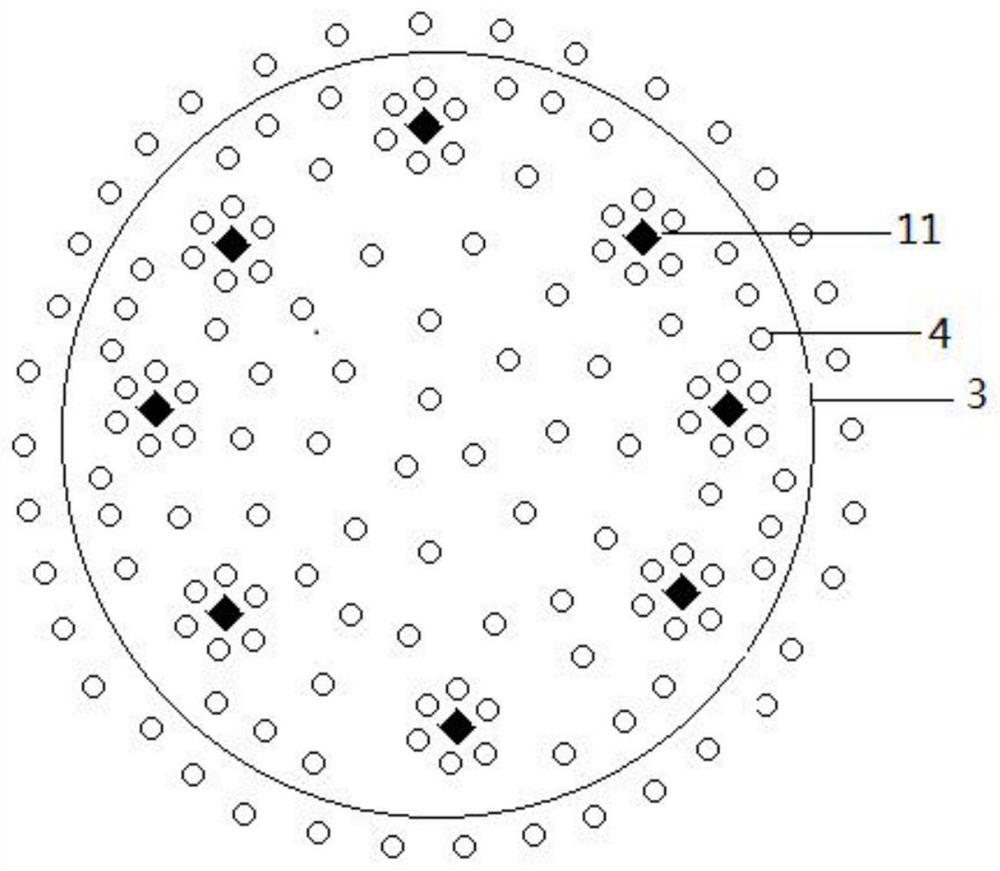

Airlift photobioreactor for microalgae culture

ActiveCN111676126ASuitable for high density cultureSimple structureBioreactor/fermenter combinationsBiological substance pretreatmentsCulture fluidPhotobioreactor

The invention discloses an airlift photobioreactor for microalgae culture, and belongs to the technical field of biological culture of microalgae. The photobioreactor includes a cylinder body, a culture liquid inlet, a culture liquid outlet, a guide cylinder, an air distributor, a light source, a sieve plate and an overflow mouth, wherein the top of the cylinder body is a gas-liquid separation zone, the guide cylinder is a hollow type, and is installed inside the cylinder body, and air outlets are evenly distributed inside the guide cylinder; nozzles are arranged at the air outlets, multiple gas outlets are evenly formed in the exterior of the guide cylinder along the circumference of the guide cylinder, and the light source is installed inside the wall of the guide cylinder; the air distributor is arranged at the bottom of the guide cylinder, the sieve plate is arranged inside the cylinder body, and the sieve plate is arranged along the height of the cylinder body; and the overflow mouth is formed in the gas-liquid separation zone. Through the photobioreactor, not only can the utilization rate of light and CO2 in the system be improved effectively, but also microalgae can be prevented from sticking to the wall effectively, the photobioreactor is suitable for culture of multiple floating microalgae of different scales, and is suitable for market promotion and application.

Owner:YANTAI UNIV

Preparation technology for piperonal crystal

InactiveCN104829585AUniform particle size distributionNot easy to agglomerateOrganic chemistryTemperature controlHigh concentration

The invention belongs to the technical field of chemical crystallization, and particularly relates to a preparation technology for piperonal crystal. The preparation technology comprises the following specific processes: mixing a piperonal crude product with absolute ethyl alcohol in a ratio, and putting the mixture into a crystallizer; adding an appropriate crystal modifier, and heating for completely dissolving solid substances; carrying out temperature-control cooling crystallizing; adding piperonal seed crystal before inoculating the crystal, and cooling to a final temperature; and growing the grain, filtering, washing and drying to obtain a piperonal crystal product. According to the preparation technology provided by the invention, the wall sticking problem in a high-concentration crystallization process can be effectively avoided; the granularity of the prepared piperonal crystal product is greater than 1mm; the granularity distribution is uniform; the product is high in purity and high in yield; and the problem of agglomeration in the storage and transportation processes is effectively avoided.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

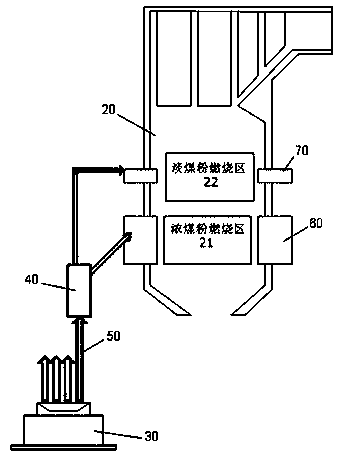

Sludge fast heat drying treating device and sludge fast heat drying treating method

InactiveCN102531323ASave on beaters and pumpsReduce mechanical energy consumptionSludge treatment by de-watering/drying/thickeningCombustorCombustion chamber

The invention relates to a sludge fast heat drying treating device, which is composed of a controllable explosion combustor, a sludge conveying mechanism and a rear dryer. The controllable explosion combustor is composed of a combustion chamber, an igniter, an air inlet pipeline, a gas inlet pipeline, a tail pipe and a jacket, the combustion chamber is fixedly installed in the jacket, the air inlet pipeline, the gas inlet pipeline and the igniter are fixedly installed on the combustion chamber, the tail pipe is installed in the jacket fixedly, one end of the tail pipe is communicated with the combustion chamber, the other end of the tail pipe extends out of the jacket to be communicated with the rear dryer, the sludge conveying mechanism is fixedly installed above the outside of the jacket, and the tail end of the sludge conveying mechanism extends into the jacket to be communicated with the jacket. The sludge fast heat drying treating device has the advantages of being simple in structure, fast in drying, low in energy consumption of drying and even in sludge particle size and capable of leading the particles to be not apt to stick onto the wall and the like. Further, the heat drying treating method has the advantages of being simple in process, easy to achieve and good in effect. The sludge fast heat drying treating device is high in innovation.

Owner:TIANJIN UNIV OF SCI & TECH

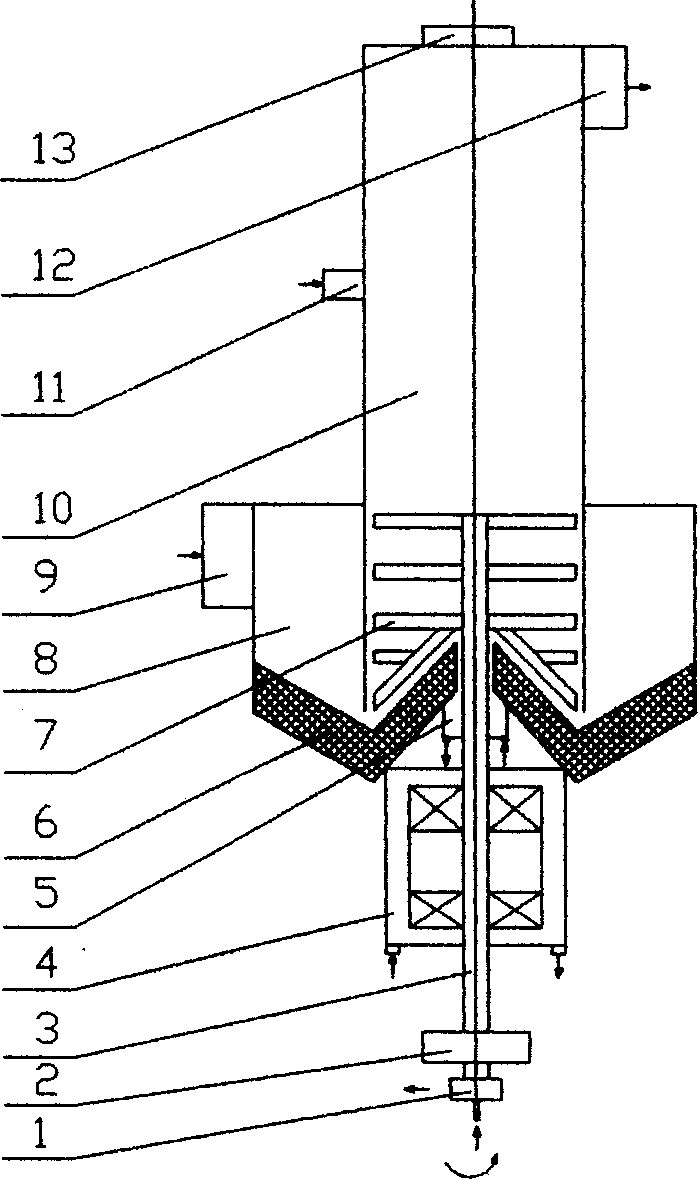

Anthracite-combusted single fire ball four-corner direct current burner

ActiveCN102494333BFire stableIncrease concentrationFuel feeding arrangementsSolid fuel pretreatmentCombustorLow load

Owner:SHANGHAI BOILER WORKS

Emulsion crystallization method of preparing crude anthracene from anthracene oil

ActiveCN103848716BReduce viscosityNot easy to stick to the wallCrystallisation purification/separationAnthraceneEmulsion

The invention provides an emulsion crystallization method of preparing crude anthracene from anthracene oil, comprises the following steps: heating anthracene oil with anthracene content of 8-10%(wt) to 85-95 DEG C to completely melt, adding a surfactant and water, stirring and uniformly mixing to form emulsion, cooling to 35-40 DEG C, transferring crystal slurry into a centrifuge to centrifuge to obtain the crude anthracene product. The method only needs one crystallization operation, the process flow is simple, the anthracene content of the prepared crude anthracene product is 44-47%(wt), the average grading is 450-600 microns, the process mass yield is 8-11%. By adding less cheap surfactant and water, the anthracene oil with great viscosity can form the emulsion, the crystal substance system viscosity is reduced, the mixing effect is improved, the material is hard to adhere on the wall in the crystallization process, the mass transfer and heat transfer are enhanced, the operation time is shortened, and the purity and the yield of the crude anthracene product are beneficial to improvement.

Owner:TIANJIN UNIV +1

A preparation method and quality control method of Siwutang formula granules

ActiveCN105287875BEmbody conceptTo achieve the purpose of reducing toxicity and increasing efficiencyComponent separationMaterial analysis by optical meansBiotechnologyFormulary

Owner:GUANGDONG YIFANG PHARMA

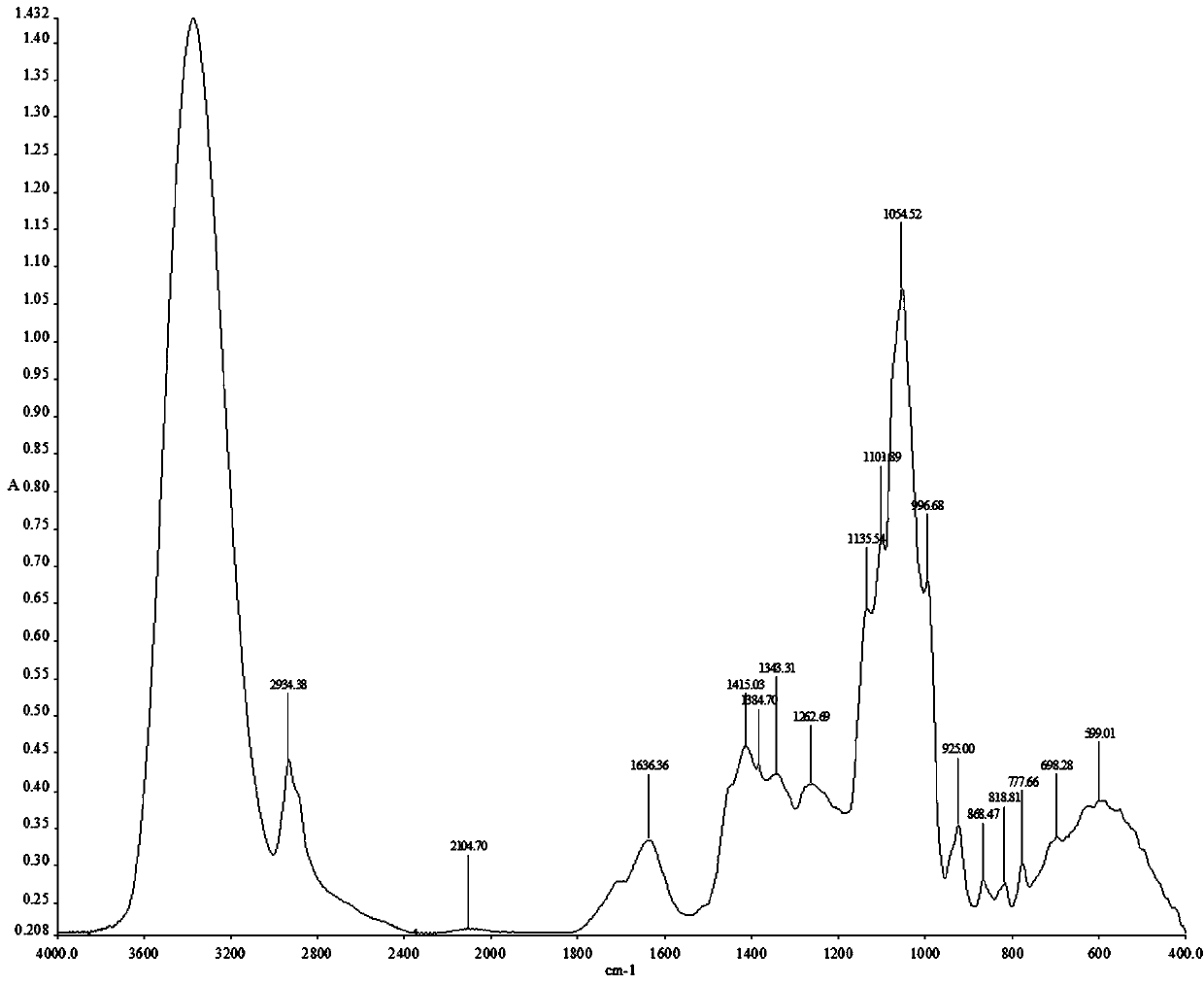

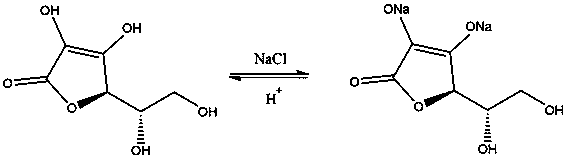

Preparation method of vitamin C granules in Rosa roxburghii

PendingCN110623951AGood groupingOptimize dosage formOrganic active ingredientsOrganic chemistryOxalateVitamin C

The invention discloses a preparation method of vitamin C granules in Rosa roxburghii, which comprises the following steps: (1) by using a sodium chloride solution containing oxalic acid as an extractant, extracting dried Rosa roxburghii fruits by using a flash extractor under ultrasonic conditions, filtering the material, and carrying out rotary evaporation concentration on a filtrate; (2) addingethanol into the filtrate, filtering the amterial, and carrying out rotary evaporation on the obtained filtrate to remove ethanol; (3) adding a diluent and an adhesive into the concentrated solutionobtained in the step (2), and obtaining the granules through spray drying. The vitamin C extraction rate is high, the vitamin C extraction speed is high, the extracted vitamin C is not prone to inactivation, the preparation process of the granules is simple, the dosage form of the vitamin C is optimized, and the granules are economical, practical and good in clustering performance.

Owner:HUBEI UNIV OF SCI & TECH

Food retention removing preparation as well as preparation method and application thereof

InactiveCN112022984ARaw materials are easy to getAvoid damagePowder deliveryDispersion deliveryBiotechnologyCannabis

The invention discloses a food retention removing preparation as well as a preparation method and application thereof. The food retention removing preparation is prepared from the following raw materials in parts by weight: 1-10 parts of malt, 1-30 parts of hawthorn fruits, 1-15 parts of radish seeds, 1-10 parts of pericarpium citri reticulatae, 1-15 parts of fructus cannabis, 1-15 parts of lotusleaves and 1-15 parts of semen cassiae. The raw materials of the food retention removing preparation are medicinal and edible materials, so that the food retention removing preparation is safe and free of toxic and side effects, causes small gastrointestinal injury, can tonify the spleen, invigorate the stomach and help digestion, has a function of relaxing bowels, can fundamentally solve the problem of food retention and has a better food retention removing effect. The preparation method of the food retention removing preparation is simple and convenient to operate and easy for industrial mass production, and an adopted microwave vacuum low-temperature drying technology has higher drying speed and higher working efficiency.

Owner:河南融易健康科技有限公司

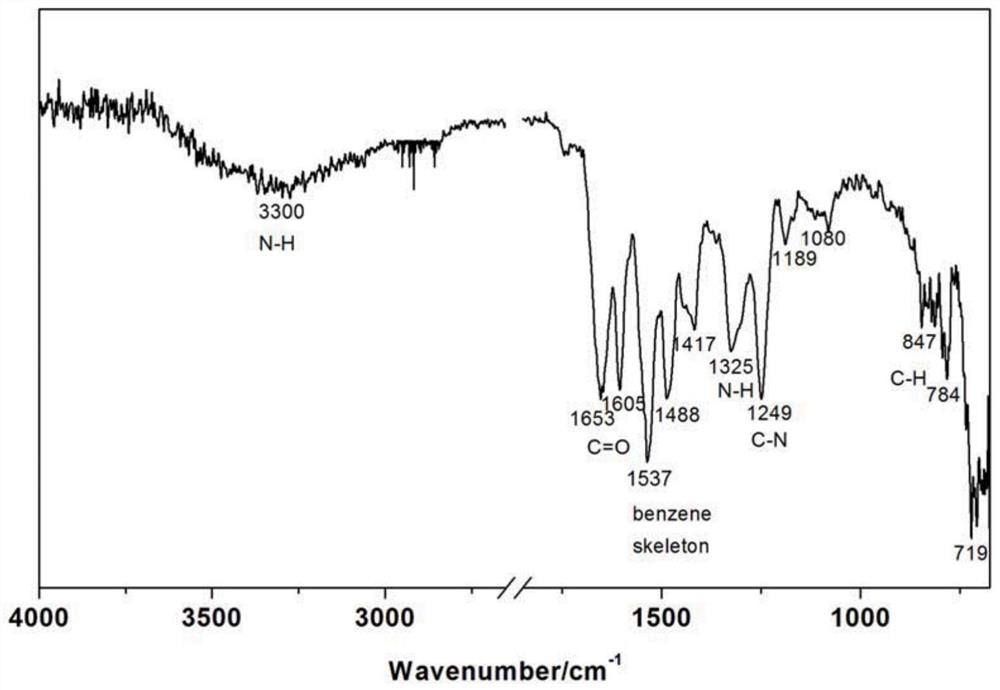

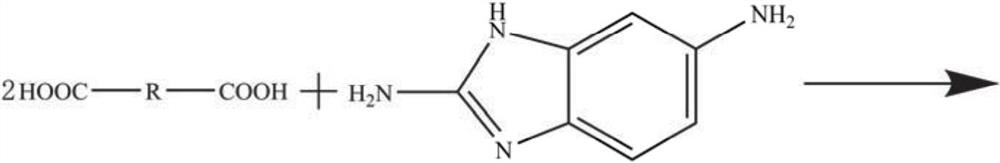

Preparation method of high temperature resistant nylon resin

The invention discloses a preparation method of high-temperature-resistant nylon resin, which comprises: making 1-hydrogen-benzimidazole-2,5-diamine, aliphatic dibasic acid or aromatic dibasic acid in the presence of a catalyst Acid and solvent are mixed and reacted under a protective atmosphere to prepare benzimidazole dicarboxylic acid; and, in the presence of a catalyst, make benzimidazole dicarboxylic acid, other binary The mixture of acid, aliphatic diamine, water and ethanol is mixed and reacted in a horizontal high-temperature and high-pressure reactor with built-in rotating stirring blades under a protective atmosphere to prepare high-temperature-resistant nylon resin. The invention truly realizes the "one-step" polymerization of high-temperature-resistant nylon resin, with simple process, mild conditions, high efficiency, environmental protection, low equipment requirements, and no agglomeration and bonding of materials during the polymerization process, which is suitable for industrialization. The high temperature resistance performance, tensile strength, bending strength and other mechanical properties of high temperature resistant nylon resin products are also significantly improved.

Owner:ZHEJIANG XINLI NEW MATERIAL CO LTD

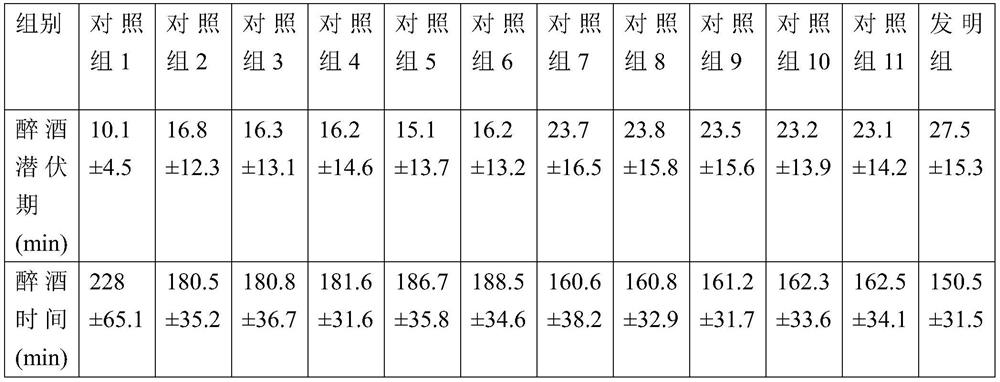

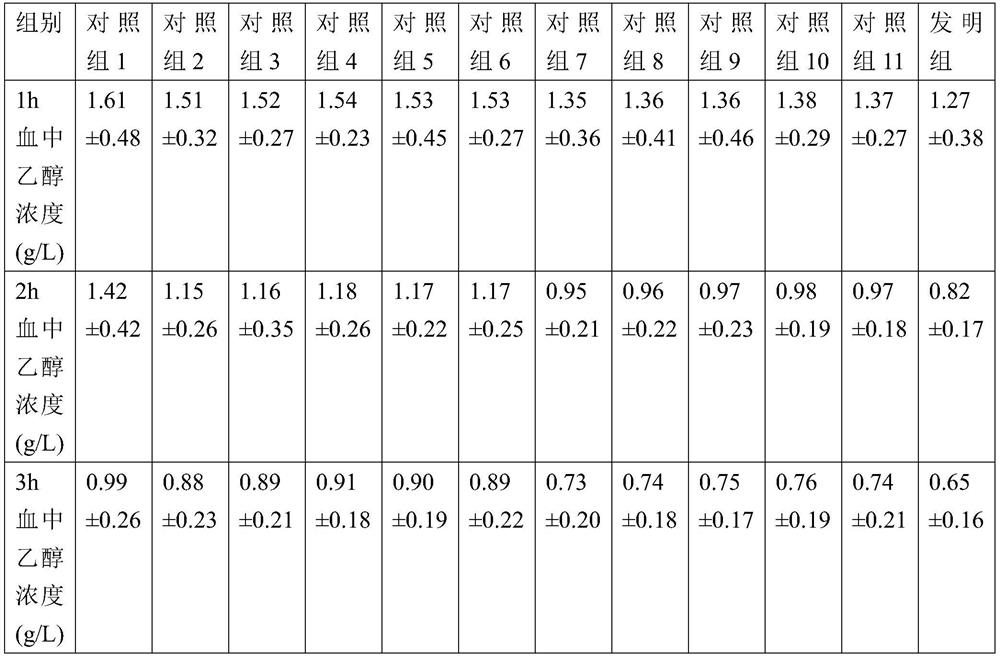

Hangover alleviating preparation and preparation method and application thereof

InactiveCN111870627AHas a hangover effectGood hangover effectPharmaceutical delivery mechanismAntinoxious agentsHovenia dulcisProcess engineering

The invention discloses a hangover alleviating preparation as well as a preparation method and application thereof. The hangover alleviating preparation is prepared from the following raw materials inparts by weight of 10-30 parts of radix puerariae, 10-30 parts of hovenia dulcis thumbs, 10-30 parts of mung beans, 10-20 parts of dried orange peel, and 10-20 parts of dandelion. The raw materials of the hangover alleviating preparation disclosed by the invention are medicinal and edible materials, so that the hangover alleviating preparation is safe, free of toxic and side effects, relatively good in hangover alleviating effects and relatively low in cost. The preparation method of the hangover alleviating preparation is simple and convenient to operate and easy for industrial mass production, and an adopted microwave vacuum low-temperature drying technology has the advantages of higher drying speed and higher working efficiency.

Owner:河南融易健康科技有限公司

A kind of piperonal crystal preparation process

InactiveCN104829585BUniform particle size distributionNot easy to agglomerateOrganic chemistryHigh concentrationTemperature control

The invention belongs to the technical field of chemical crystallization, and particularly relates to a preparation technology for piperonal crystal. The preparation technology comprises the following specific processes: mixing a piperonal crude product with absolute ethyl alcohol in a ratio, and putting the mixture into a crystallizer; adding an appropriate crystal modifier, and heating for completely dissolving solid substances; carrying out temperature-control cooling crystallizing; adding piperonal seed crystal before inoculating the crystal, and cooling to a final temperature; and growing the grain, filtering, washing and drying to obtain a piperonal crystal product. According to the preparation technology provided by the invention, the wall sticking problem in a high-concentration crystallization process can be effectively avoided; the granularity of the prepared piperonal crystal product is greater than 1mm; the granularity distribution is uniform; the product is high in purity and high in yield; and the problem of agglomeration in the storage and transportation processes is effectively avoided.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

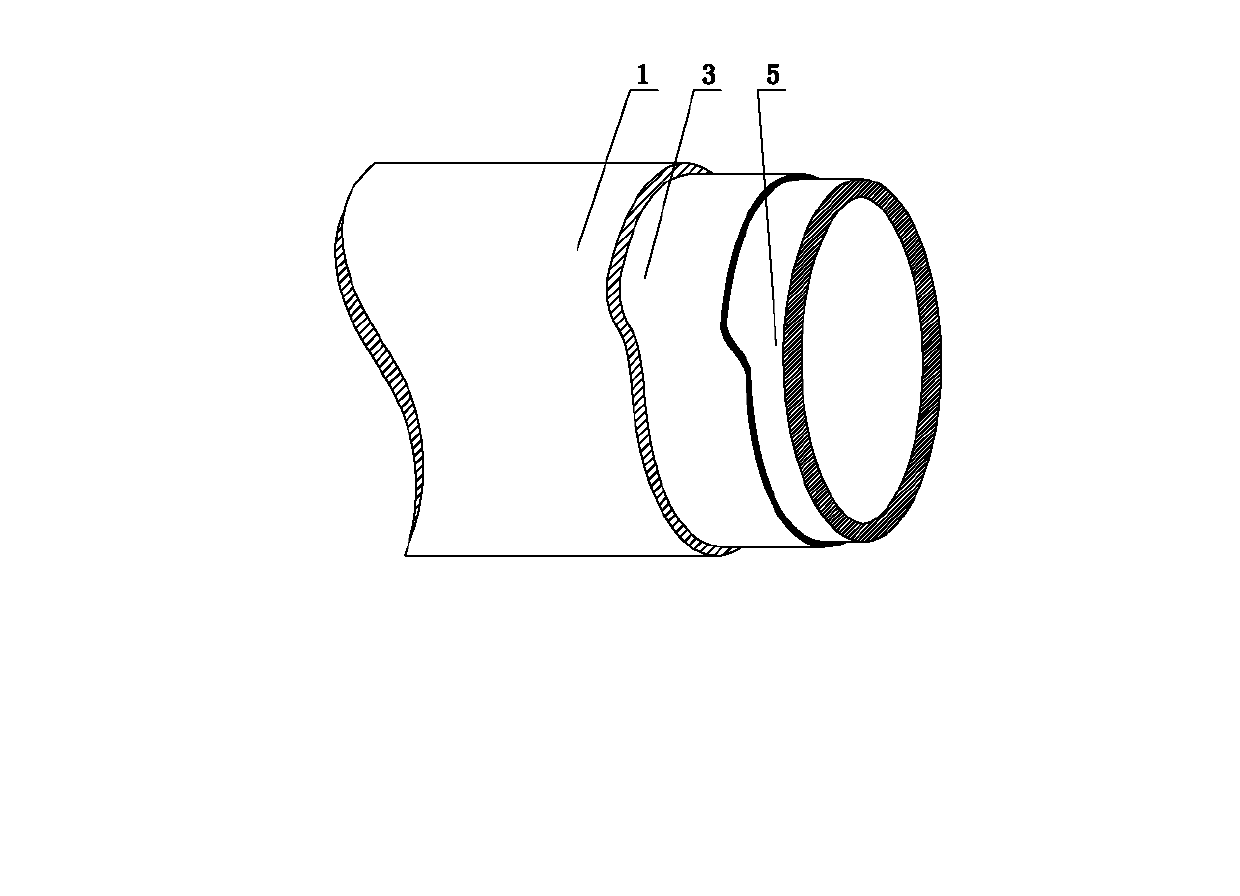

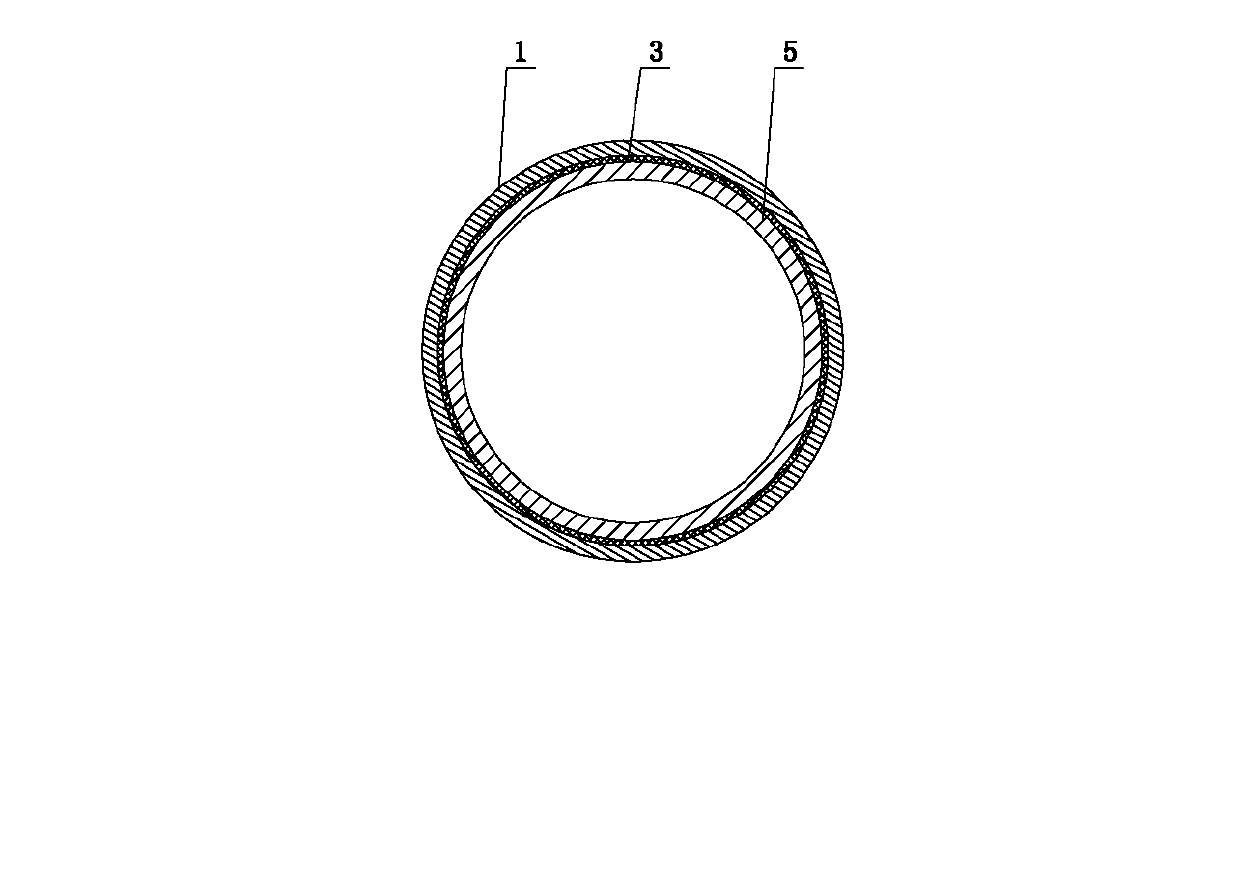

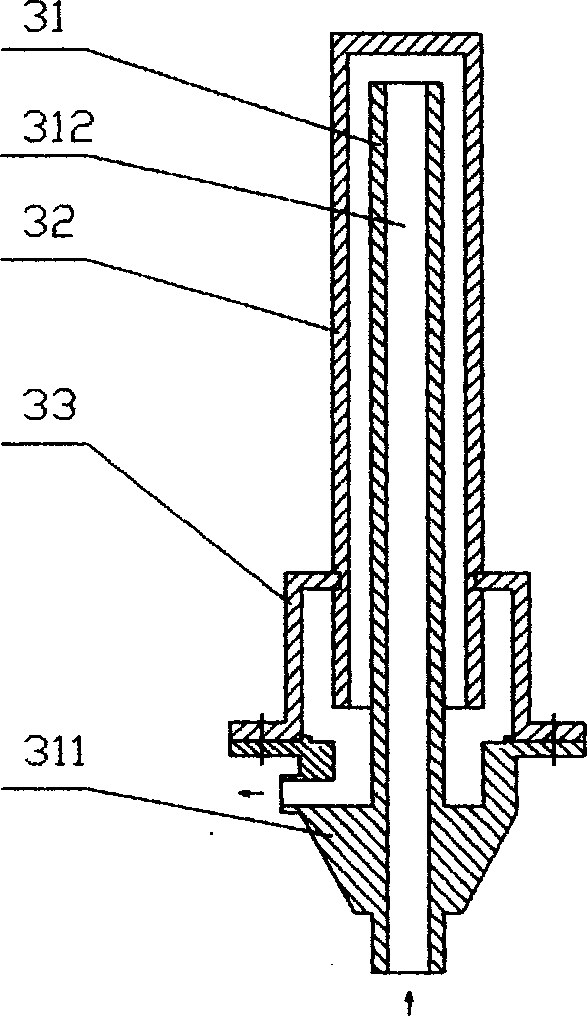

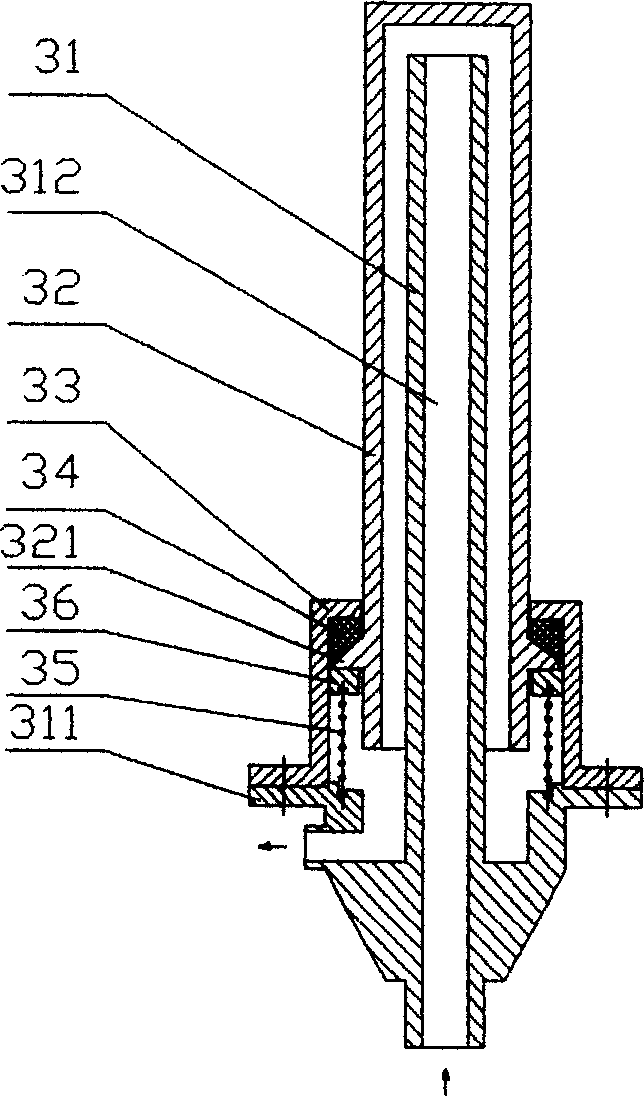

Main material double-layer pipe conveying system

PendingCN107381062ANot easy to stick to the wallPrevent leakageBulk conveyorsDouble-walled pipeClassical mechanics

The invention relates to the technical field of powder conveying systems, in particular to a main material double-layer pipe conveying system. When powder is conveyed by the main material double-layer pipe conveying system, no powder remains on the pipe wall, and normal feeding is ensured. The main material double-layer pipe conveying system comprises a conveying pipeline and is characterized in that the conveying pipeline comprises an elastic inner pipe and a rigid outer pipe; a gap is reserved between the elastic inner pipe and the rigid outer pipe; the two ends of the rigid outer pipe are fixedly connected with the outer circumferential faces of joints and sealed with the outer circumferential faces of the joints; and the two ends of the elastic inner pipe are fixedly connected with the joints in a sleeving mode correspondingly.

Owner:WUXI RICH INTELLIGENT EQUIP CO LTD

Integrated reacting and separating device

ActiveCN101116804BWell mixedImprove heat transfer effectPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesUltrafiltrationEngineeringReaction system

The present invention provides an integral reaction-separation equipment, mainly comprising a ring pipe and a separation component, wherein a circular reaction circuit is formed by the ring pipe and the separation component. The equipment is compact in structure, integrates catalytic reaction with catalyst separation and material heat transfer, especially can guarantee the high efficiency separation and the recycling use of fine particles such as nanometer or micron catalyst with reacting materials, and has good material mixing and heat transferring effects, which is suitable for strong heat absorbing or releasing solid-liquid, solid-liquid-liquid and partial gas-liquid-solid multiphase reaction system.

Owner:CHINA PETROLEUM & CHEM CORP +1

Auxiliary material combination for improving atomizing and drying process of traditional Chinese medicine granules and application thereof

ActiveCN101862458BReduce dosageHigh softening pointGranular deliveryMacromolecular non-active ingredientsFlavorMedicine

The invention relates to an auxiliary material combination for improving atomizing and drying process of traditional Chinese medicine granules and an application thereof. The auxiliary material combination comprises 10 to 90 percent of betadex and 10 to 90 percent of maltodextrin or dextrine. The application of the auxiliary material combination is: after being dissolved in hot water, the auxiliary material combination is added into extract obtained by extracting Chinese medicine or is directly added into extract to be uniformly mixed and to be atomized and dried; when adding the auxiliary material combination, the temperature of the extract is 50 to 100 DEG C, relative density of the extract is 1.02 to 1.20 (60 DEG C), air inlet temperature for atomizing drying is 140 to 190 DEG C, and the air outlet temperature is 75 to 100 DEG C. by adopting the auxiliary material combination, under the same atomizing and drying condition, the consumed quantity of the auxiliary material is less, the consumption quantity of the auxiliary material can be reduced by more than 30 percent, the auxiliary material with the same quantity is added for atomizing and drying, the softening point of the extract can be improved during the atomizing and drying process, the wall is difficult to be adhered during the atomizing process, the fluidity of the atomizing and drying powder is good, the atomizing and drying powder is difficult to be moistened, the dispersion of the flavor can be effectively prevented during the atomizing and drying process, and the original flavor of the extract is maintained.

Owner:陇西一方制药有限公司

A new type of high-strength HDPE composite pipe and its production method

A new type of high-strength HDPE composite pipe, which is composed of HDPE core pipe and modified PE layer, the innermost layer is HDPE core pipe, the HDPE core pipe is wrapped with PE bonding layer, and the PE bonding layer is wrapped with modified PE layer. The invention has the characteristics of good impact resistance, high compressive strength, high wear resistance and the like. Among them, the HDPE core tube is corrosion-resistant and has a long service life. It can resist the erosion of various corrosive media such as acid, alkali, and salt. The modified PE layer can inhibit the oxidative degradation of plastics, improve the anti-ultraviolet performance of the tube body, and prolong the service life of the tube body. . The PE bonding layer is made of thermoplastic elastomer, which greatly improves the material performance, improves the bonding ability of the core tube and the modified PE layer, and its service life can reach 60 years.

Owner:HUBEI HUIFENG PLASTIC PIPE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com