Pulverized coal shade separate arrangement mode of direct-current burner with double fireballs

A technology of concentration separation and burner, applied in burners, combustion methods, burners burning powder fuel, etc., can solve the problems of inability to adapt to anthracite combustion, low heat load, etc., and achieve good air supply conditions and secondary air speed. Reduced, adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

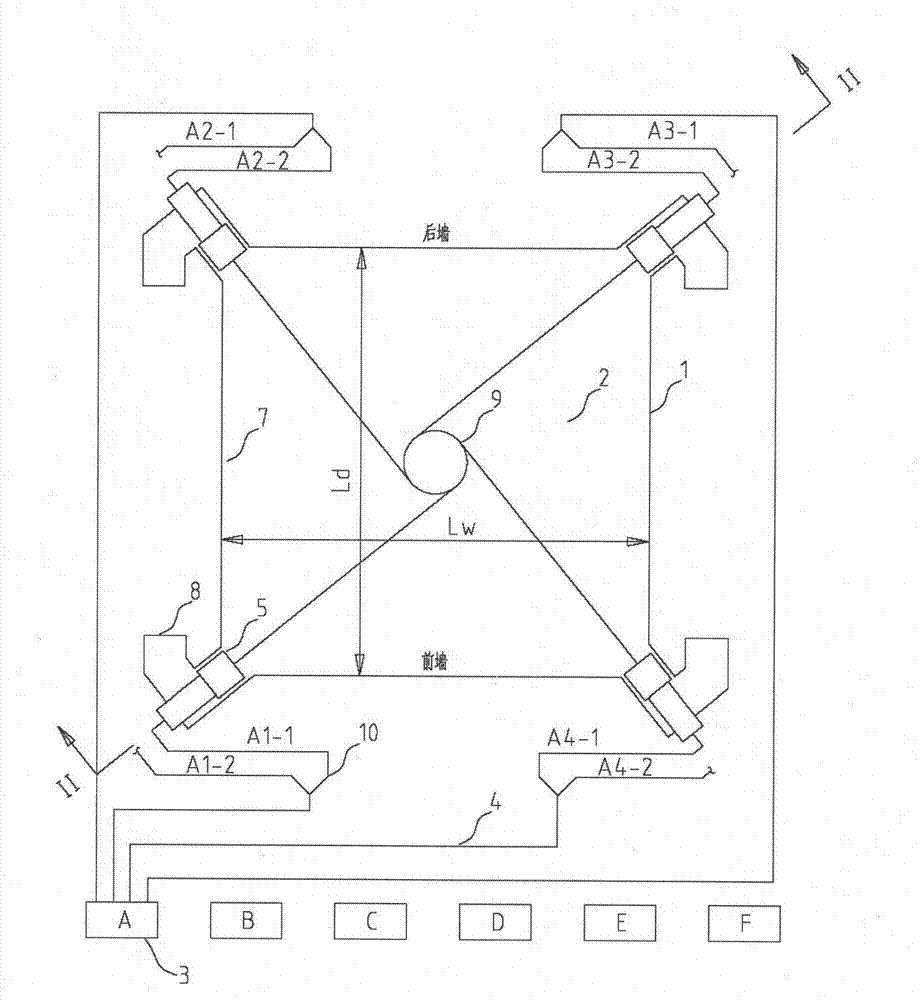

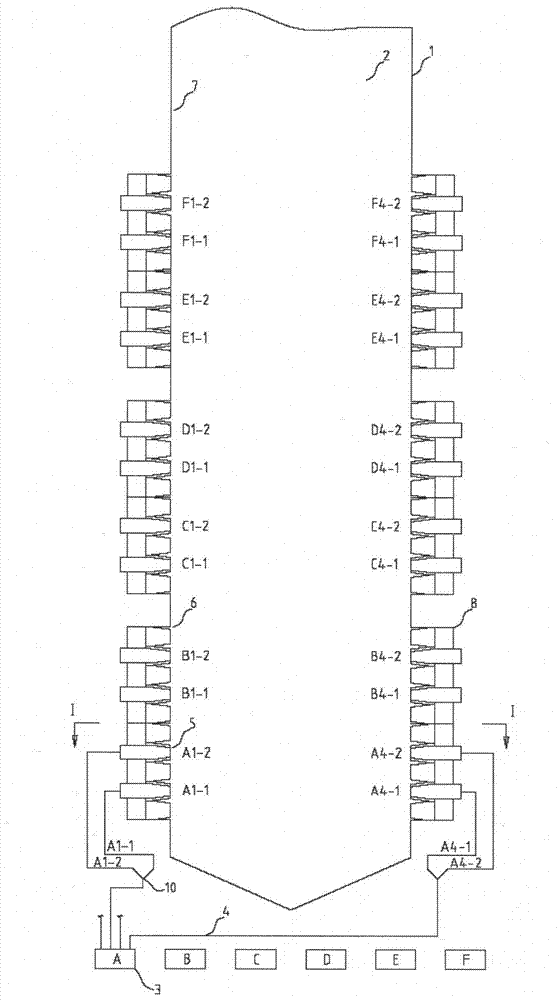

[0025] to combine Figure 4 and Figure 5 To describe this embodiment, Figure 4 for Figure 5 I-I sectional view, Figure 5 for Figure 4 Section view of II-II.

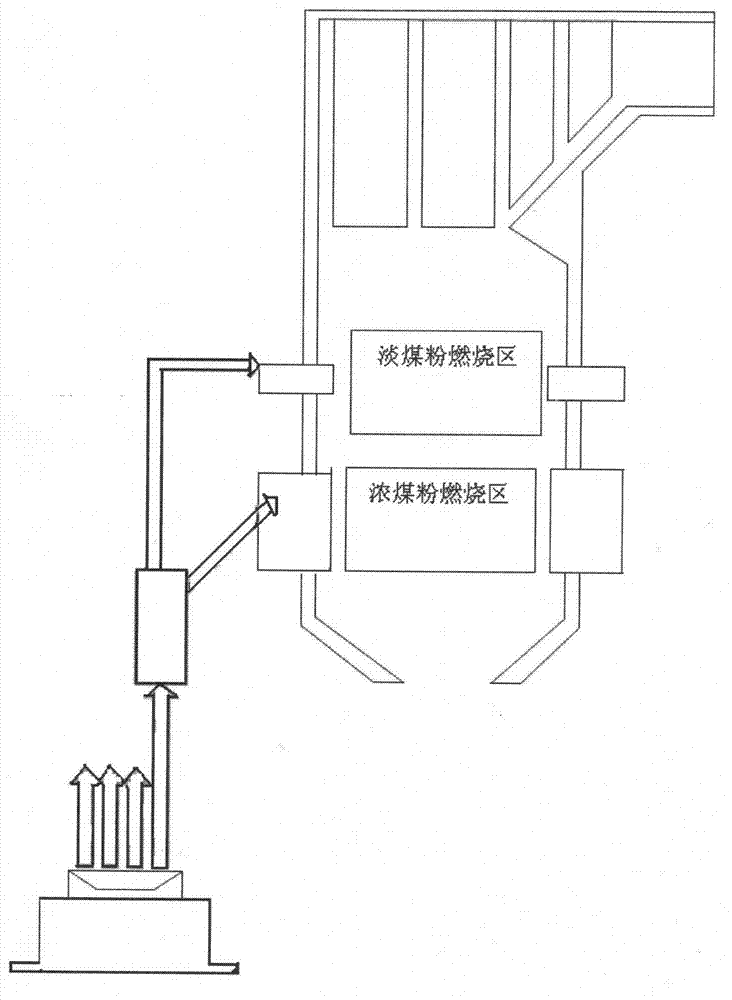

[0026] The present invention provides an anthracite double-fireball octagonal direct-flow burner with a separation arrangement of pulverized coal concentration and light, including a boiler body 1, a furnace 2, a coal mill 3, a pulverized coal separator 4, a pulverized coal pipeline 5, and a primary air / concentration furnace. Pulverized coal nozzle 6, primary air / light coal pulverized nozzle 7, secondary air nozzle 8, pulverized coal thick-lean separator 13. Each boiler body 1 is equipped with six coal mills 3, namely the first coal mill A, the second coal mill B, the third coal mill C, the fourth coal mill D, the fifth coal mill E and The sixth coal mill F. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com