Main material double-layer pipe conveying system

A conveying system and double-layer pipe technology, which is applied in the direction of conveyors, conveying bulk materials, transportation and packaging, etc., can solve problems such as easy sticking to the wall, and achieve the effect of preventing powder leakage and ensuring normal feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

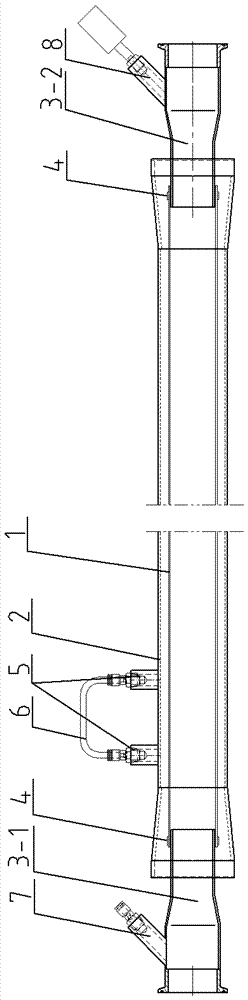

[0011] See figure 1 As shown, a main material double-layer pipe conveying system includes a conveying pipeline, and the conveying pipeline includes an elastic inner pipe 1 and a rigid outer pipe 2. There is a gap between the elastic inner pipe 1 and the rigid outer pipe 2, and the rigid outer pipe 2 The two ends are fixedly connected to the outer peripheral surfaces of the joints 3-1, 3-2 and sealed, and the two ends of the elastic inner tube 1 are respectively fixedly fitted on the joints 3-1, 3-2 and fixed by the clamp 4, which ensures reliable and stable connection. The elastic inner tube 1 is a silicone tube, which is elastic, and the flow of gas drives the silicone tube to fluctuate, so as to realize vibration and prevent the powder from sticking to the wall. The rigid outer tube 2 is a steel pipe. There are two interfaces 5 on the side wall of the rigid outer tube 2, and the two interfaces 5 are connected through a transparent air tube 6. When the elastic inner tube 1 br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com