Preparation method of high temperature resistant nylon resin

A nylon resin, high temperature resistant technology, applied in the field of high temperature resistant nylon resin preparation, can solve the problems of large difference in reactivity, sticking to walls, large difference between product batches, etc., shortening polymerization time, low equipment requirements, improving The effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

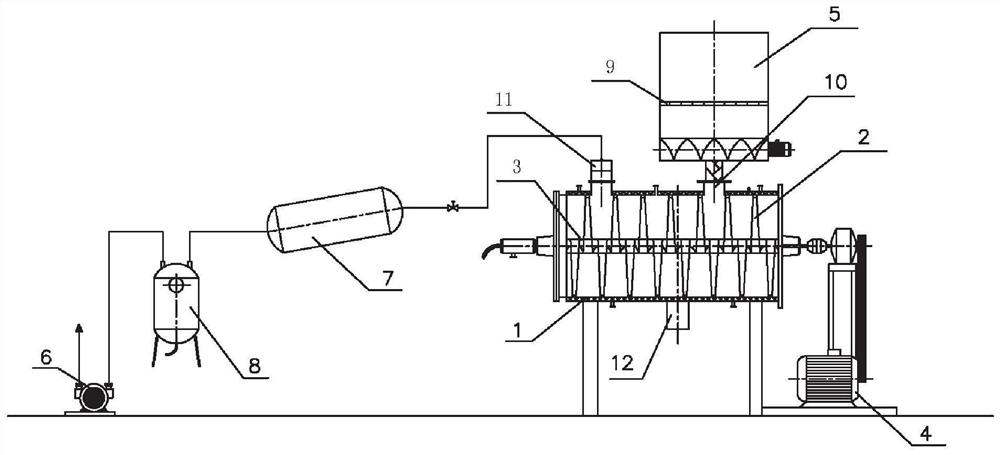

preparation example Construction

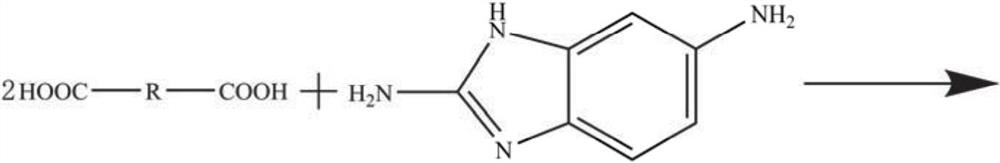

[0022] Some embodiments of the present invention provide a kind of preparation method of high temperature resistant nylon resin, it comprises:

[0023] (1) In the presence of the first catalyst, 1-hydrogen-benzimidazole-2,5-diamine (hereinafter referred to as BZDD), aliphatic dibasic acid or aromatic diacid and the first solvent are protected Mixed reaction under neutral atmosphere, make benzimidazole dicarboxylic acid;

[0024] (2) In the presence of the second catalyst, mix benzimidazole dicarboxylic acid, other dibasic acids except benzimidazole dicarboxylic acid, aliphatic diamine and the second solvent under protective atmosphere reaction to produce high temperature resistant nylon resin.

[0025] In some embodiments, the step (1) includes: adding 1-hydro-benzimidazole-2,5-diamine, aliphatic dibasic acid or aromatic diacid, first auxiliary agent and first solvent to In a reaction kettle, heat up to 50-60°C in a protective atmosphere and stir for 1-4h, then heat up to 12...

Embodiment 1

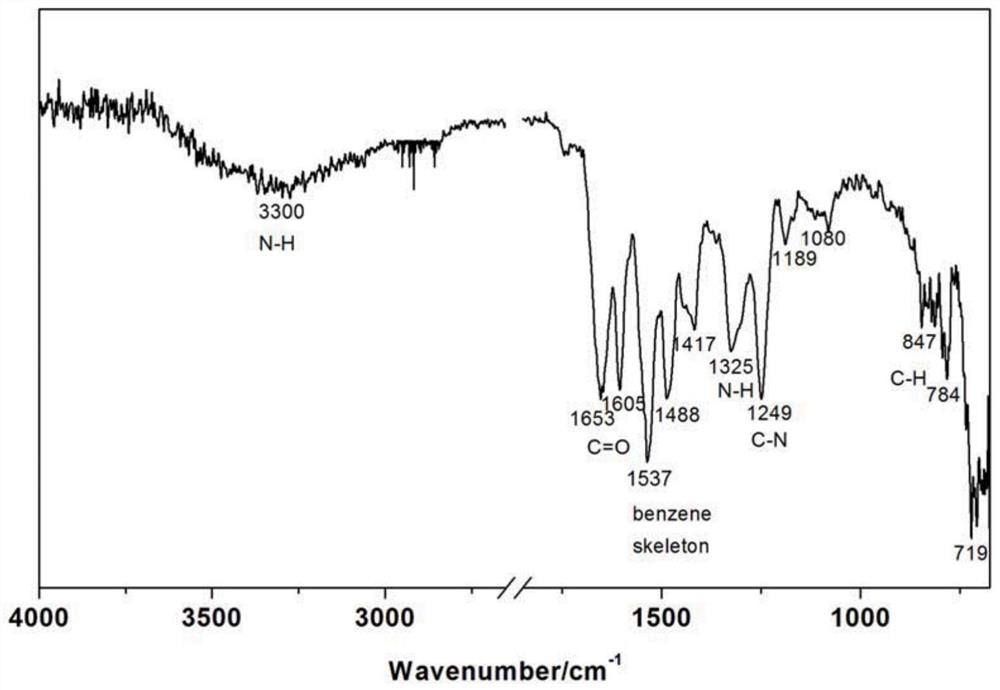

[0091] (1) Preparation of benzimidazole dicarboxylic acid: a total of 100 parts of equimolar 1-hydrogen-benzimidazole-2,5-diamine (hereinafter referred to as BZDD) and terephthalic acid (if not specified below, all parts by weight), zinc chloride (accounting for 0.3% of the total weight of the reaction raw materials) and 400 parts of polyphosphoric acid were added to the reactor, and nitrogen was replaced three times in the kettle, and under the protection of nitrogen, the stirring was started and the temperature was raised to 60°C. Stir for 2 hours; the temperature in the kettle rises to 140°C, react for 5 hours, and cool down to obtain benzimidazole dicarboxylic acid.

[0092] (2) Preparation of polymer: 100 parts of reaction monomers (if not specified below, all are parts by weight, which contain 31.8 parts of terephthalic acid, 17.16 parts of adipic acid, 15.17 parts of benzimidazole dicarboxylic acid and 39.04 parts of hexamethylenediamine, that is, the molar ratio of ter...

Embodiment 2

[0093] Embodiment 2: the synthetic technique of high temperature resistant nylon resin is the same as embodiment 1 in the present embodiment, difference is:

[0094] In step (2), hexamethylenediamine in the reaction monomer is replaced by pentamethylenediamine, and the molar ratio of terephthalic acid, adipic acid and benzimidazole dicarboxylic acid is 0.57:0.35:0.08.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com