Mixing cabin and mixing apparatus

A technology of mixing device and mixing bin, which is applied in mixers, fluid mixers, transportation and packaging, etc., can solve the problems of fertilizer particle crushing, fertilizer particle refinement and crushing, and achieve uniform mixing and ensure mixing. The effect of high material quality and batching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

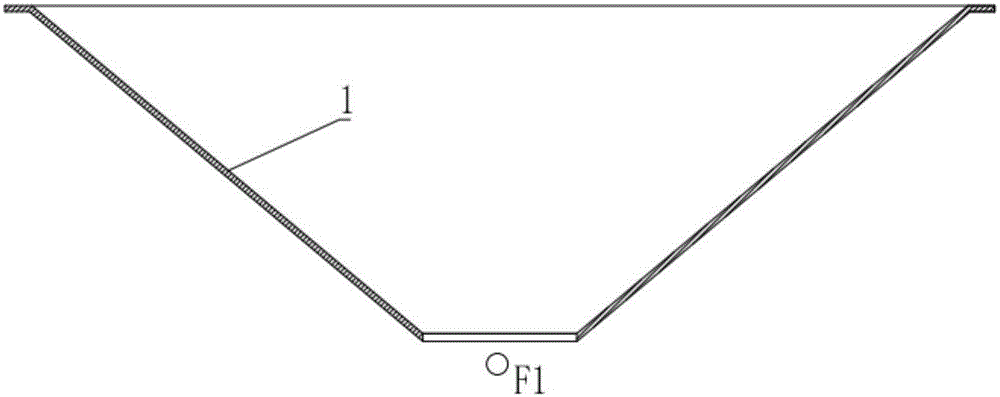

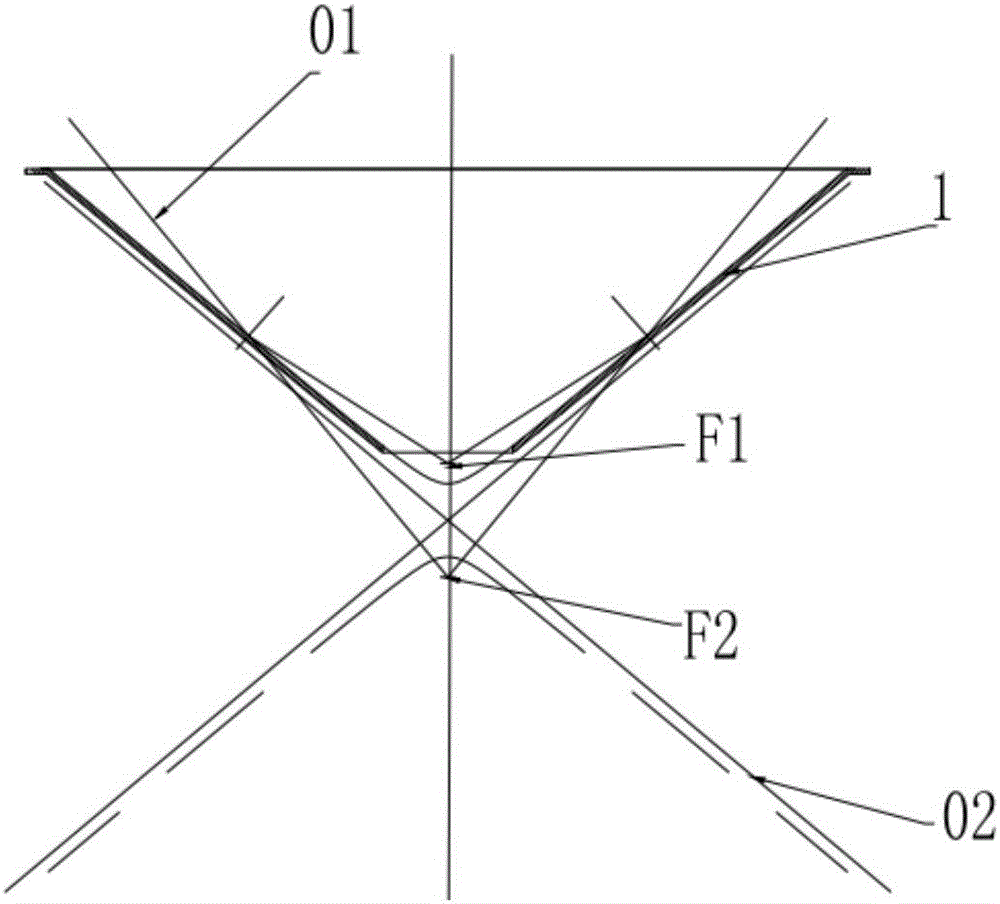

[0038] Such as figure 1 As shown, a mixing bin includes a mixing bin body 1, the mixing bin body 1 is an inverted conical structure with an upper opening, and a lower part is provided with a blanking port, and the mixing bin body 1 includes an annular inner wall, The middle part of the inner wall is a blanking torus 1-1, at least the blanking torus is a hyperbolic torus or a parabolic torus.

[0039] The high line of the blanking annulus can be close to the upper edge of the mixing bin body 1, and the low line should generally be higher than the focal point.

[0040] The inner wall as a whole is a hyperbolic torus or a parabolic torus.

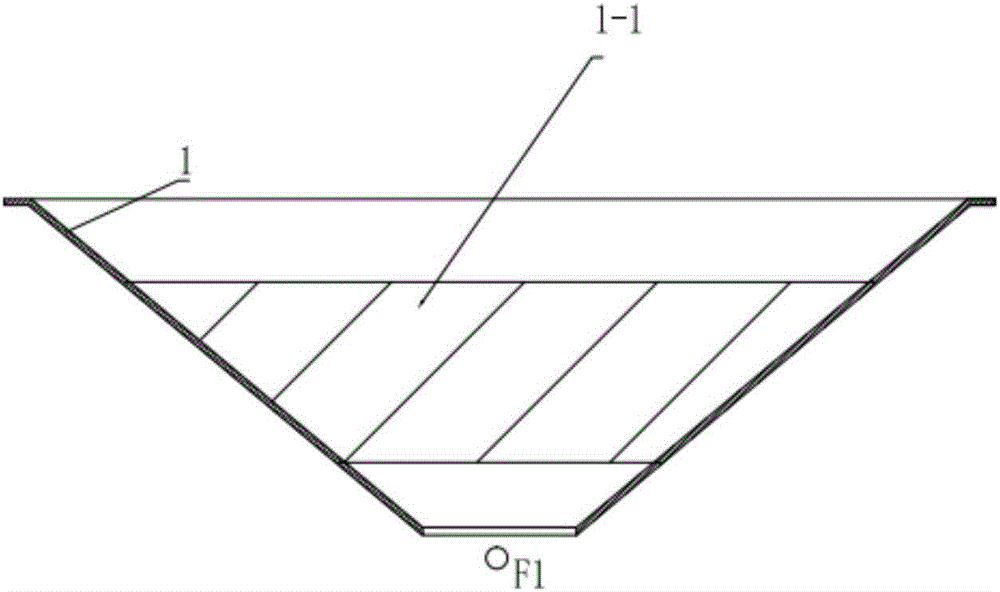

[0041] Such as figure 2 As shown, the blanking ring surface 1-1 and the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com