Patents

Literature

508results about "Mixing solids with solids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

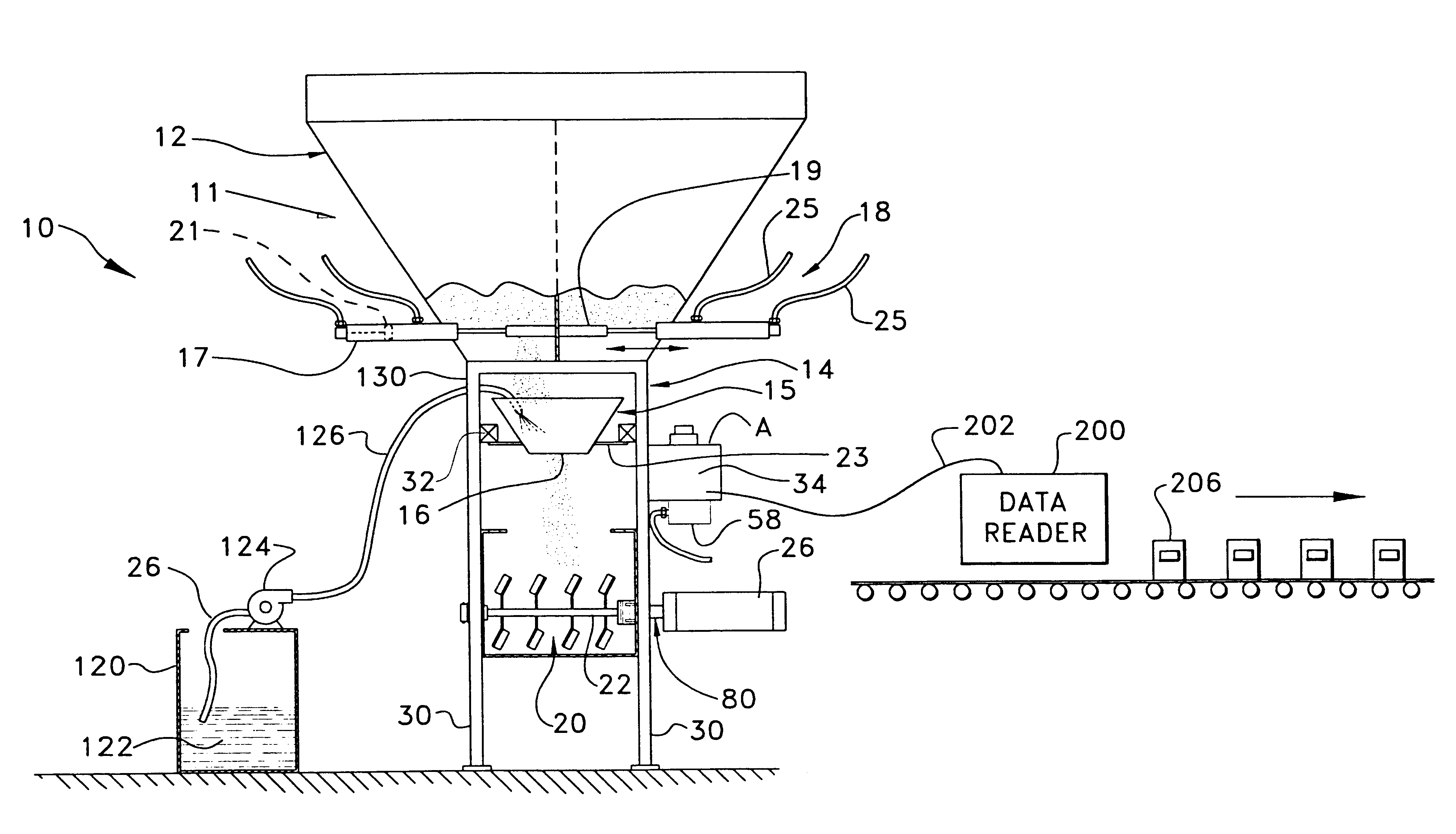

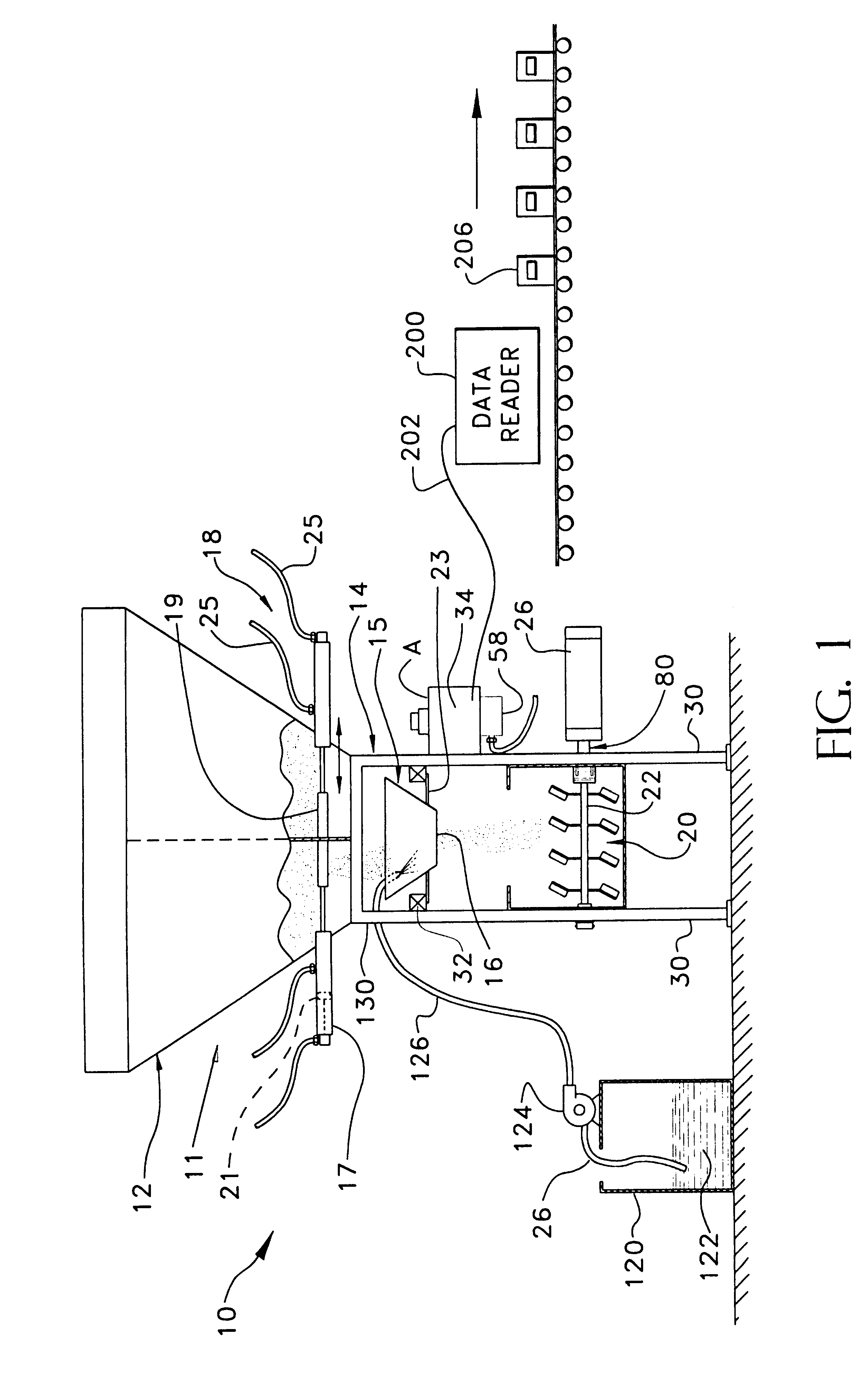

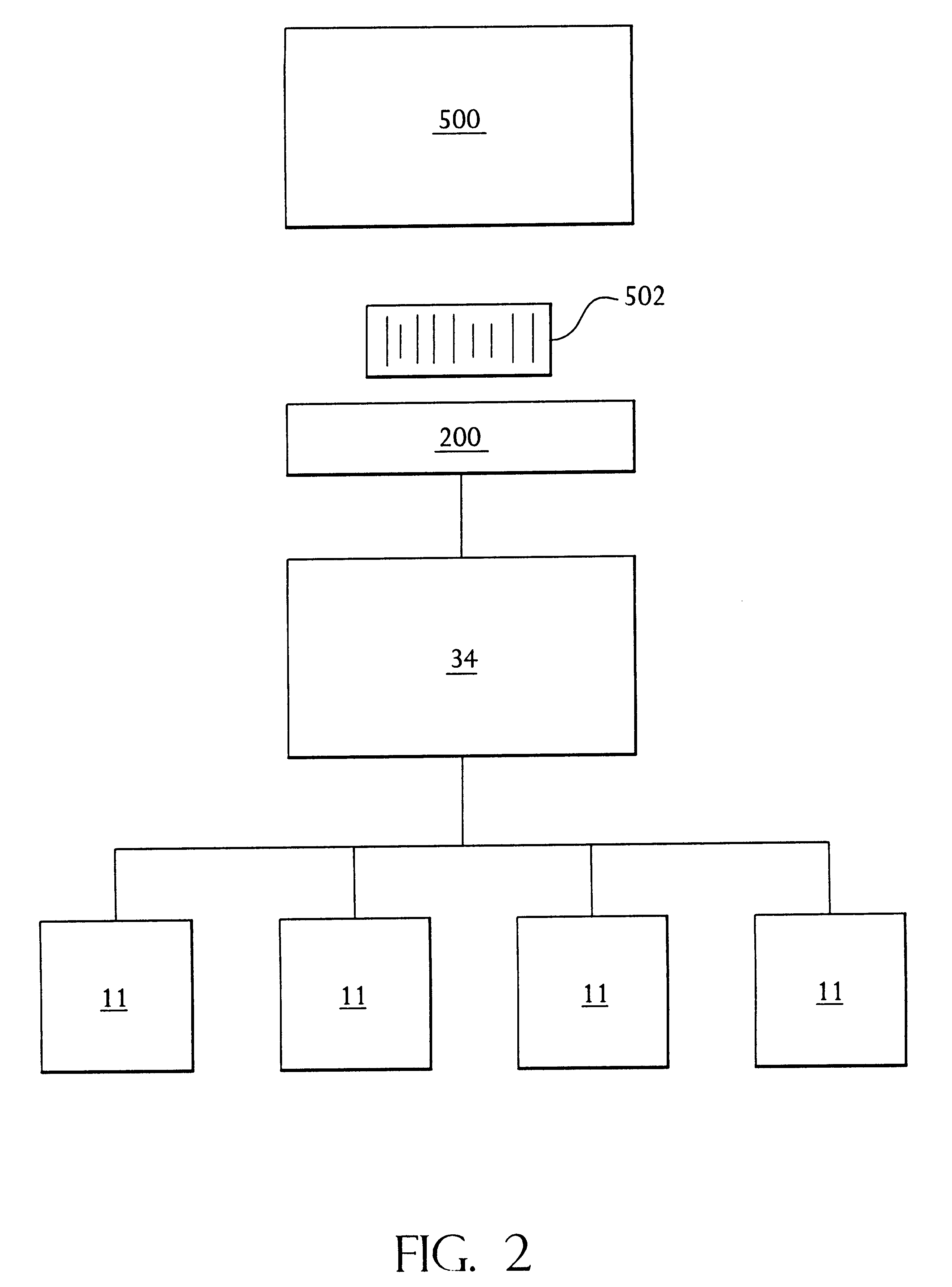

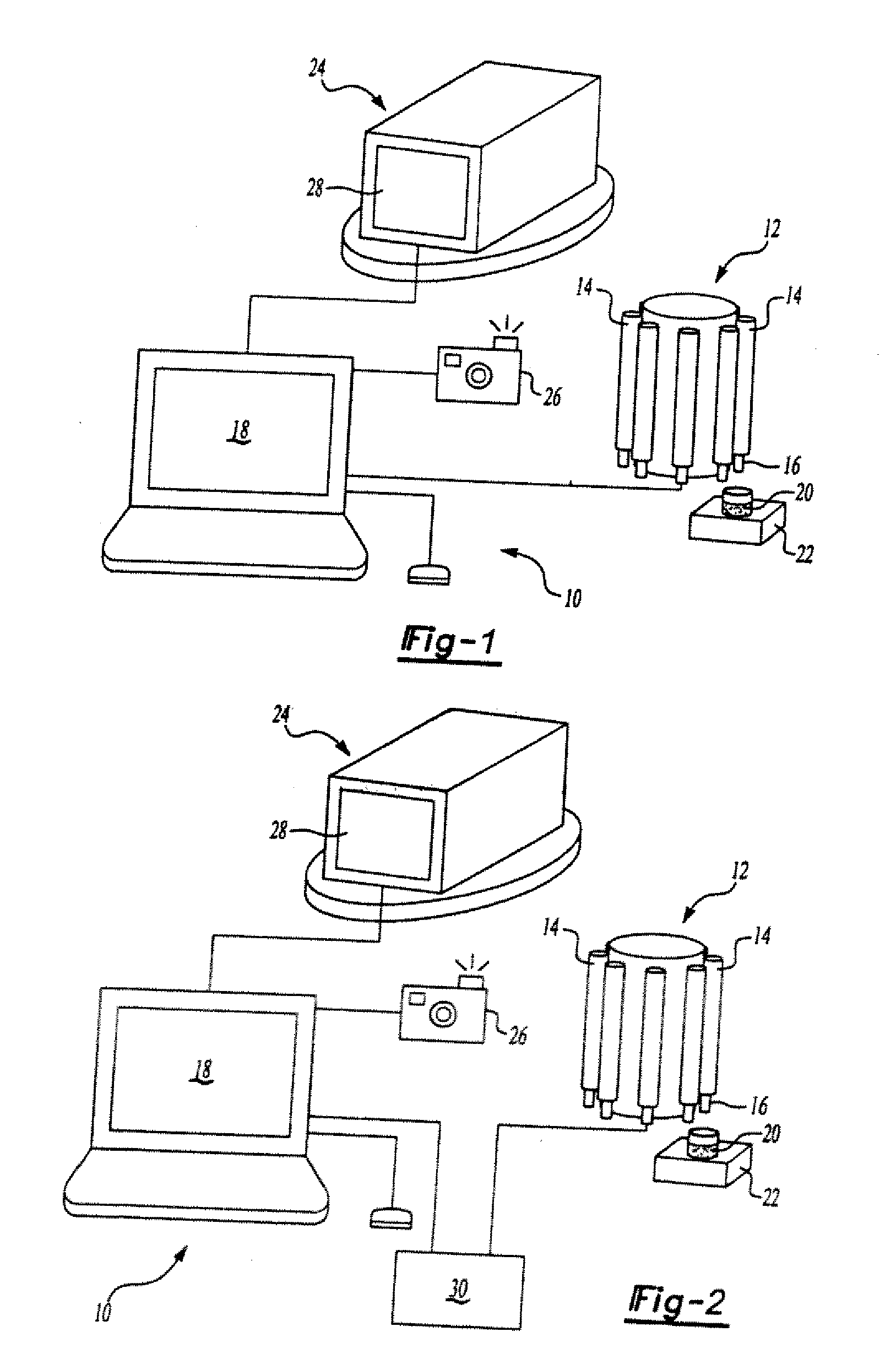

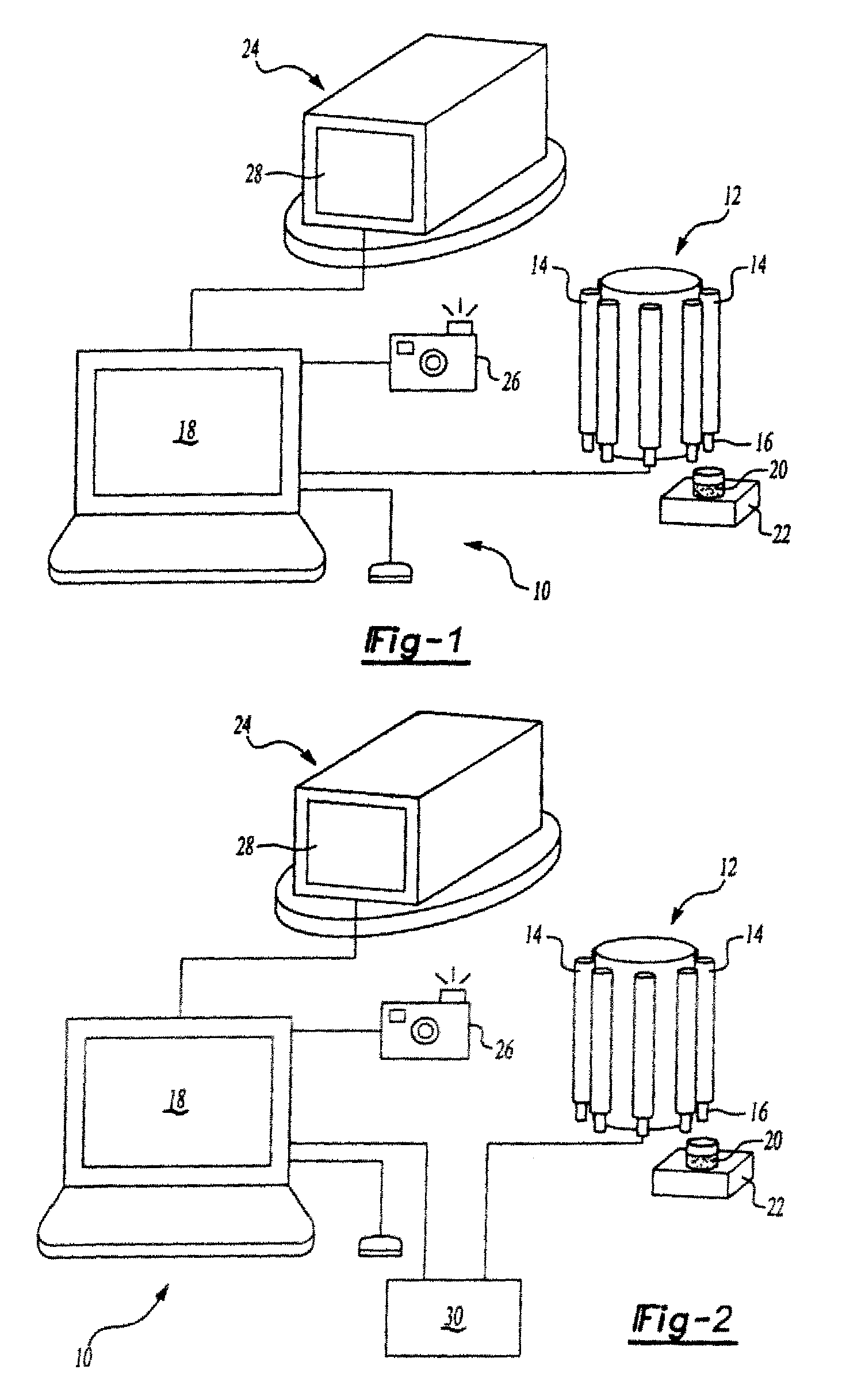

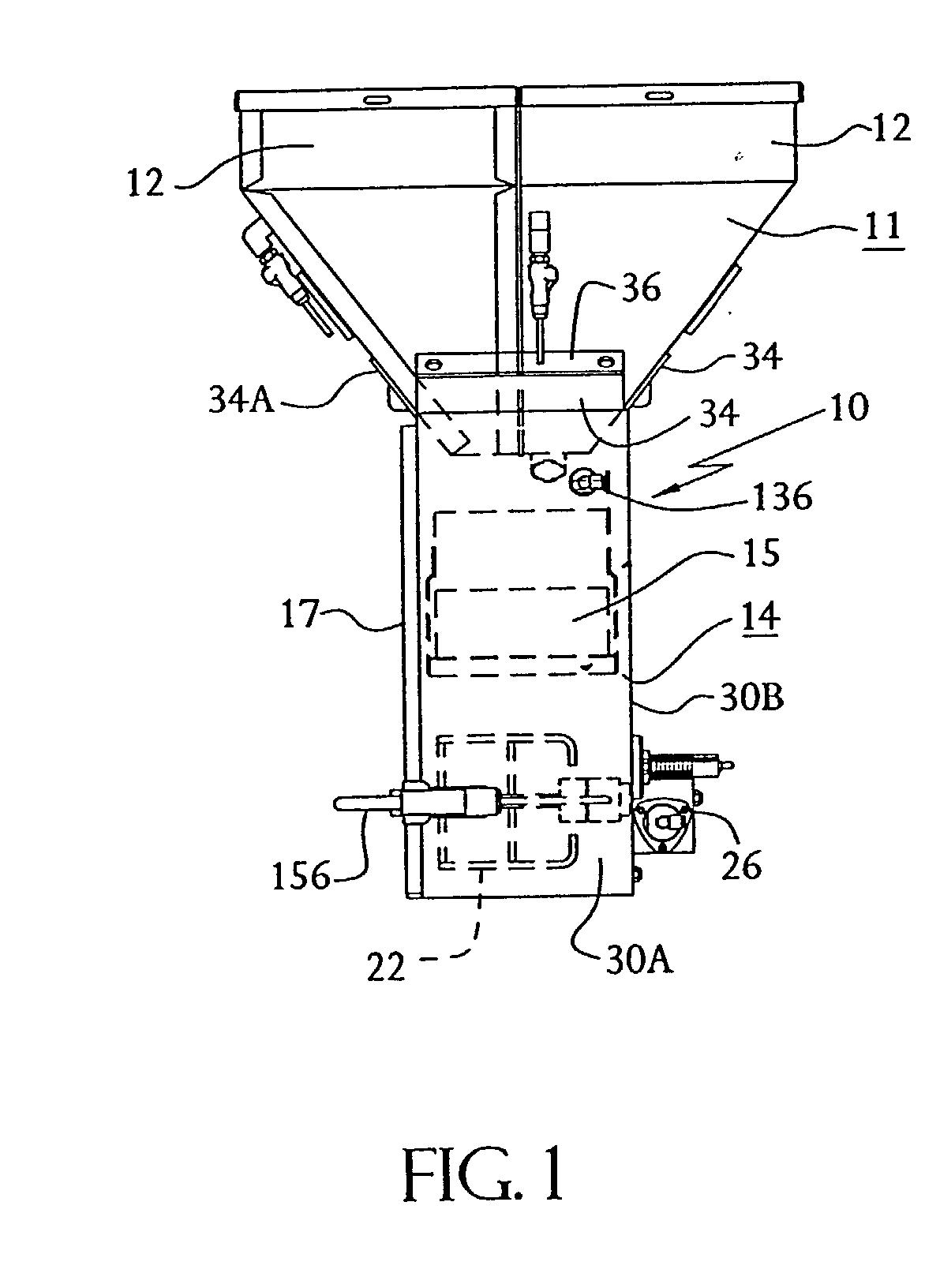

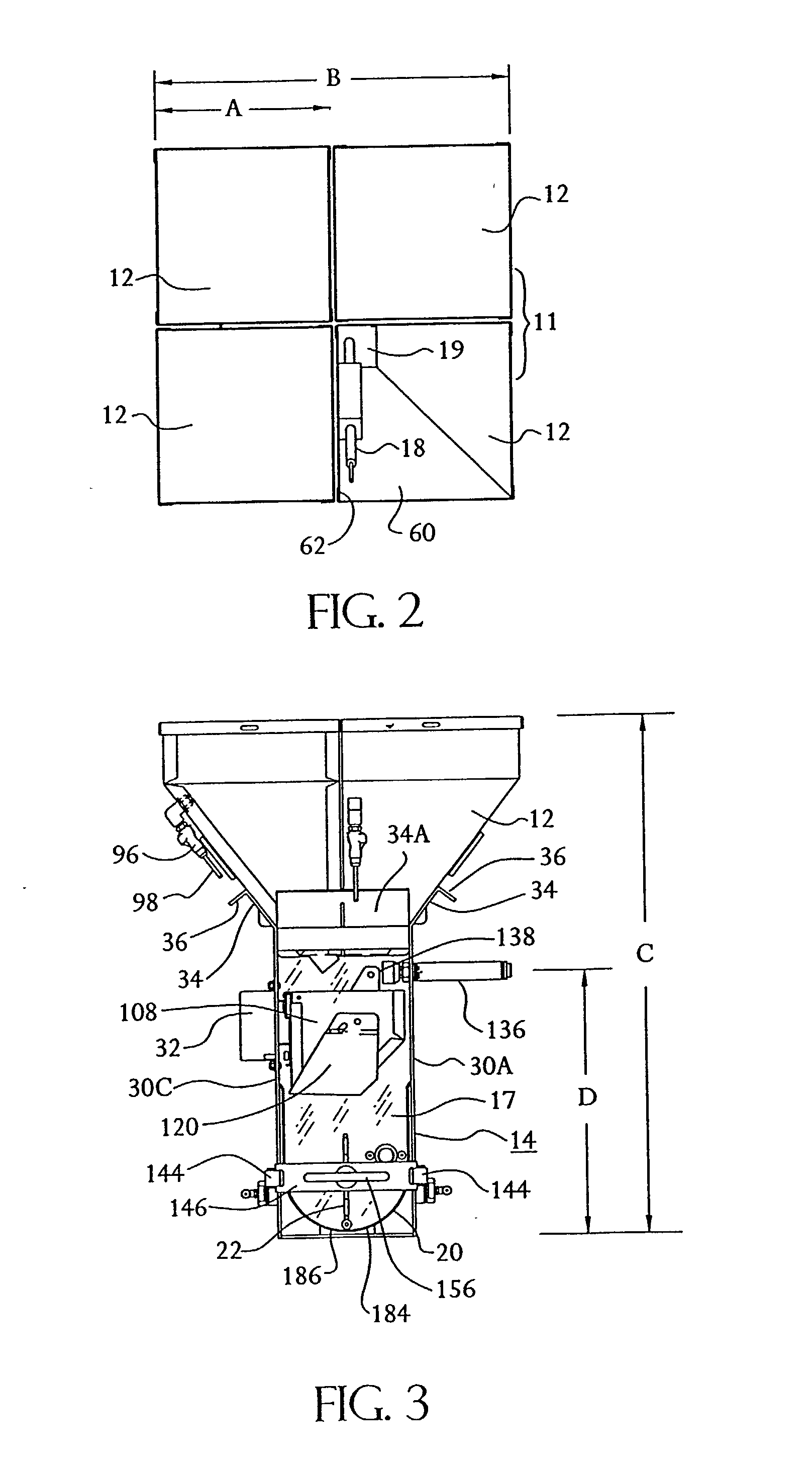

Gravimetric blender with operatively coupled bar code reader

InactiveUS6188936B1Accurate measurementEntered easily and accuratelyDigital data processing detailsRotary stirring mixersBarcodeMicroprocessor

A method for weight blending of granular materials comprises at a remote site generating a command for desired operation of granular material weight blending apparatus; encoding said command into transportable time-stable machine readable tangible storage media; transporting said media to a bar code reader operatively connected to said granular material weight blending apparatus; scanning the tangible media having the command encoded thereon to read the command; and providing the read command as input to a in microprocessor operatively connected to said granular material weight blending apparatus for regulating operation of the same.

Owner:MAGUIRE PROD

Point-of-sale body powder dispensing system

InactiveUS20080047972A1Facilitate customer-interactive processOpening closed containersBottle/container closureBiomedical engineeringPoint of sale

Owner:COSMETIC TECH L L C

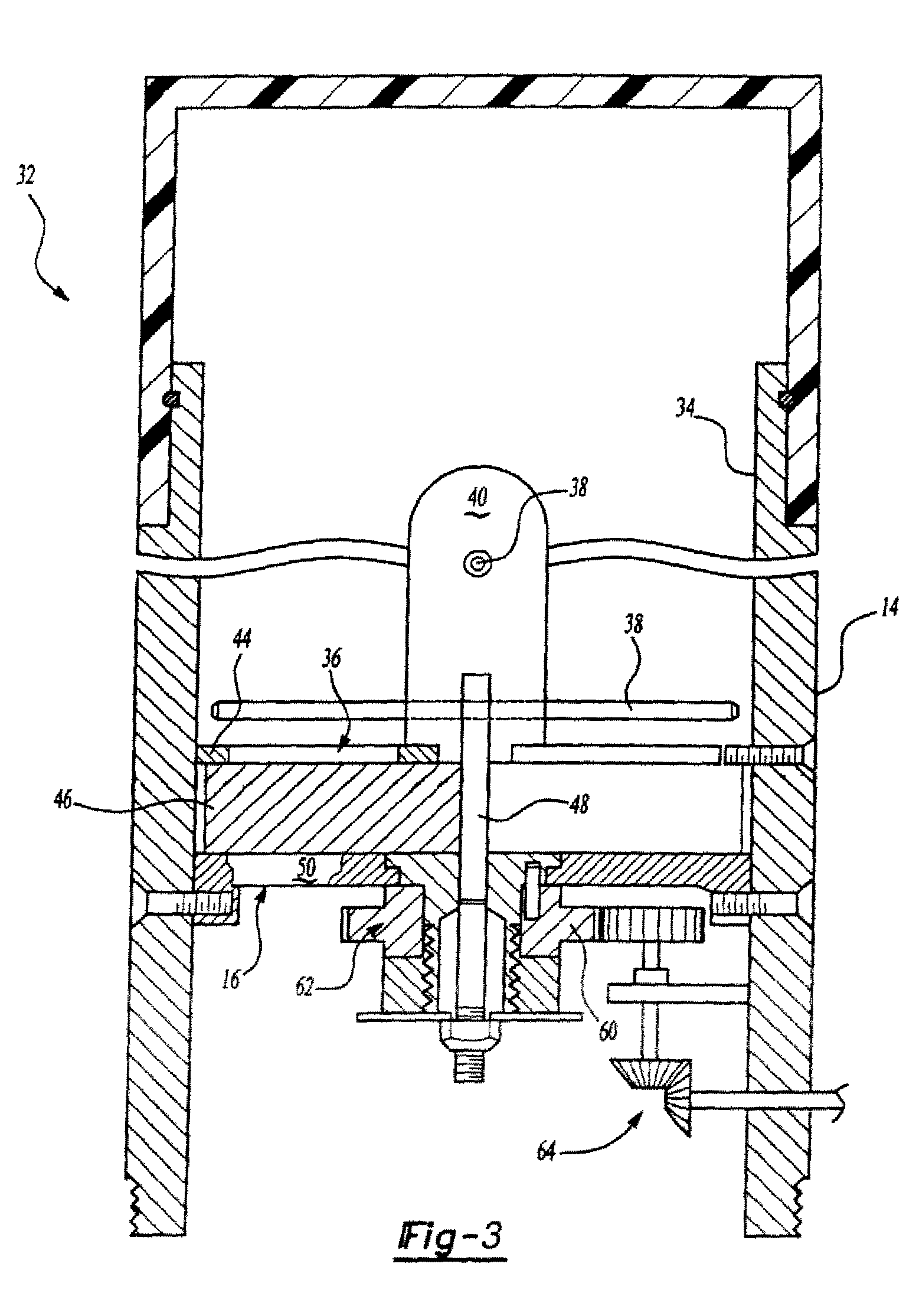

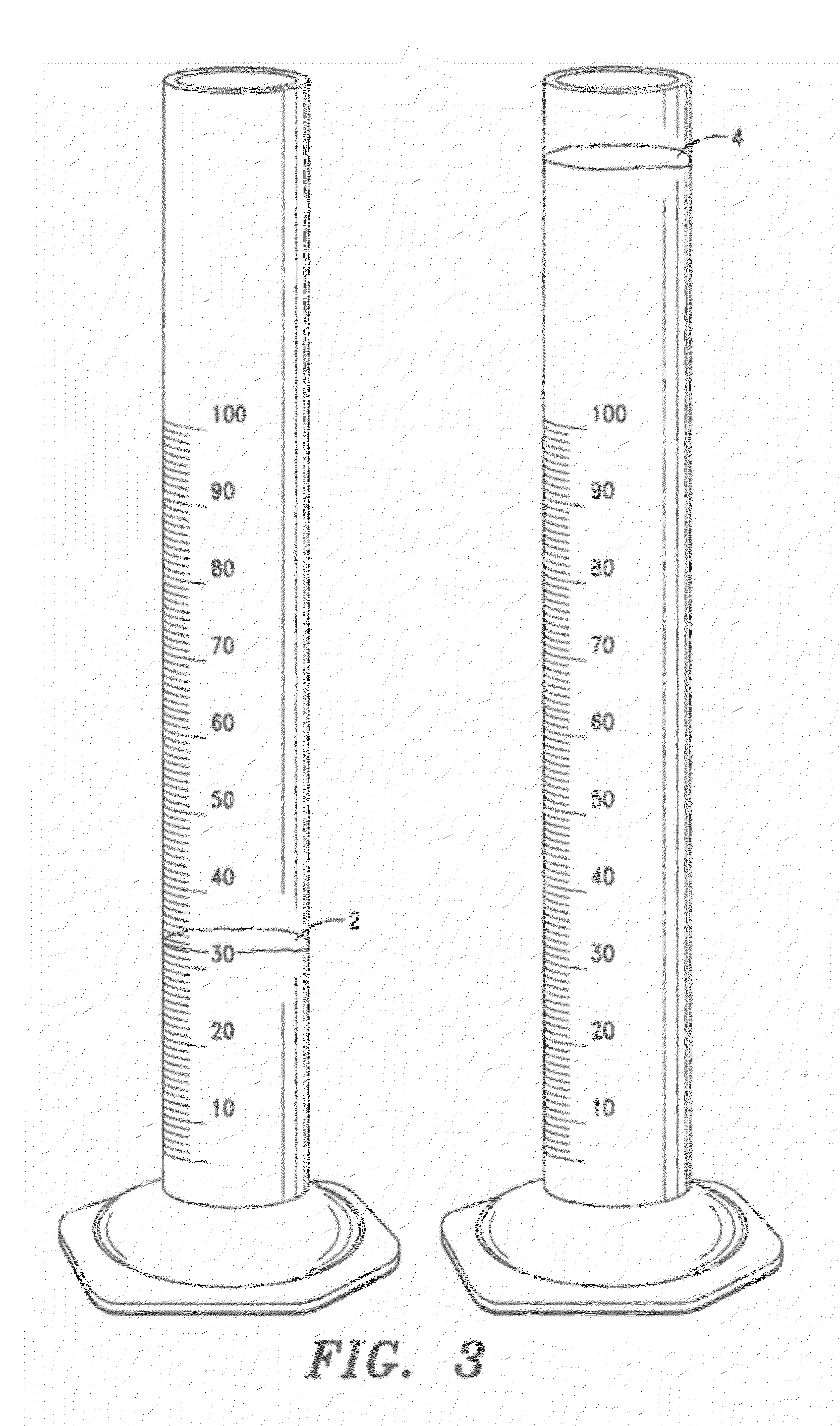

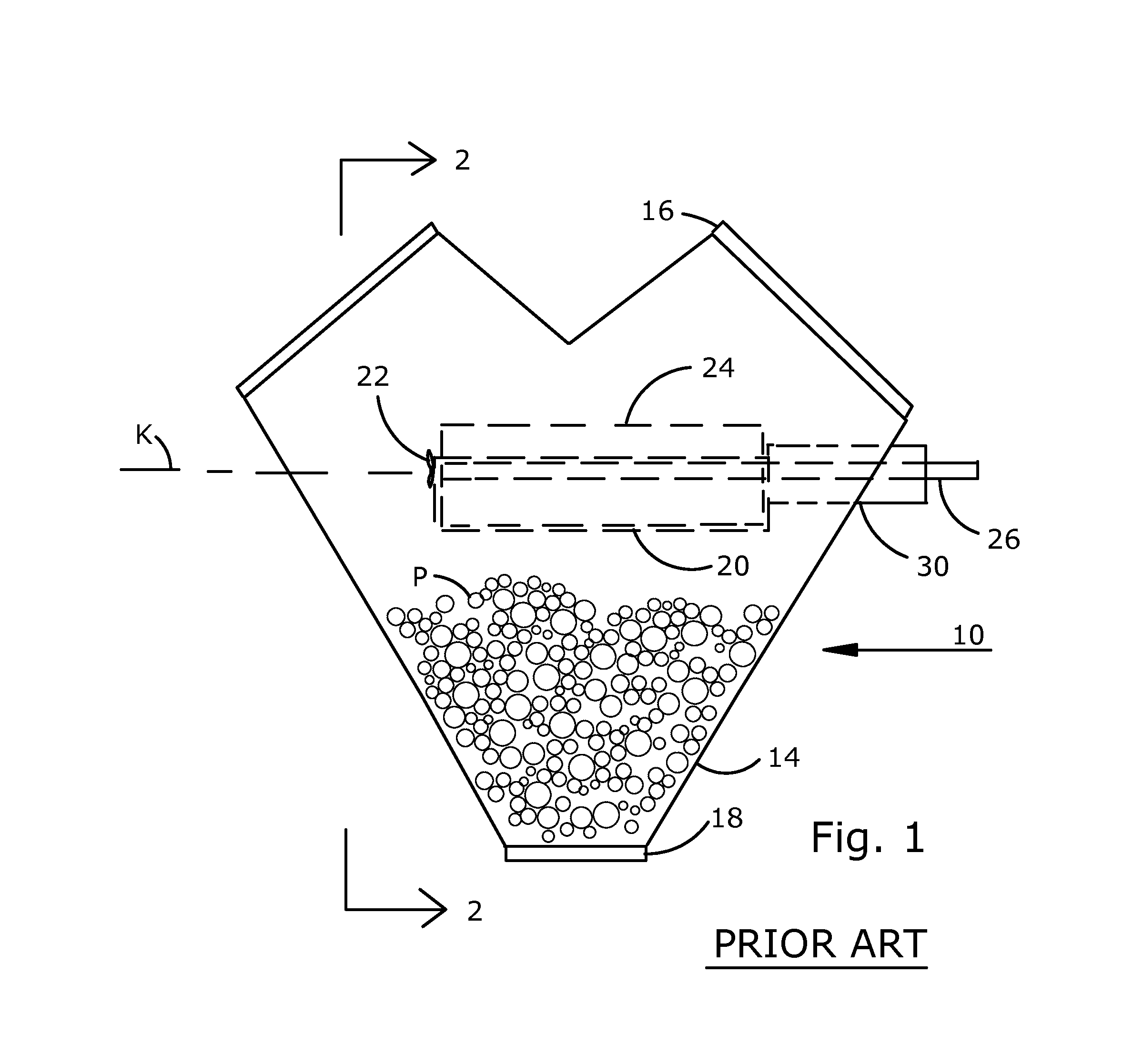

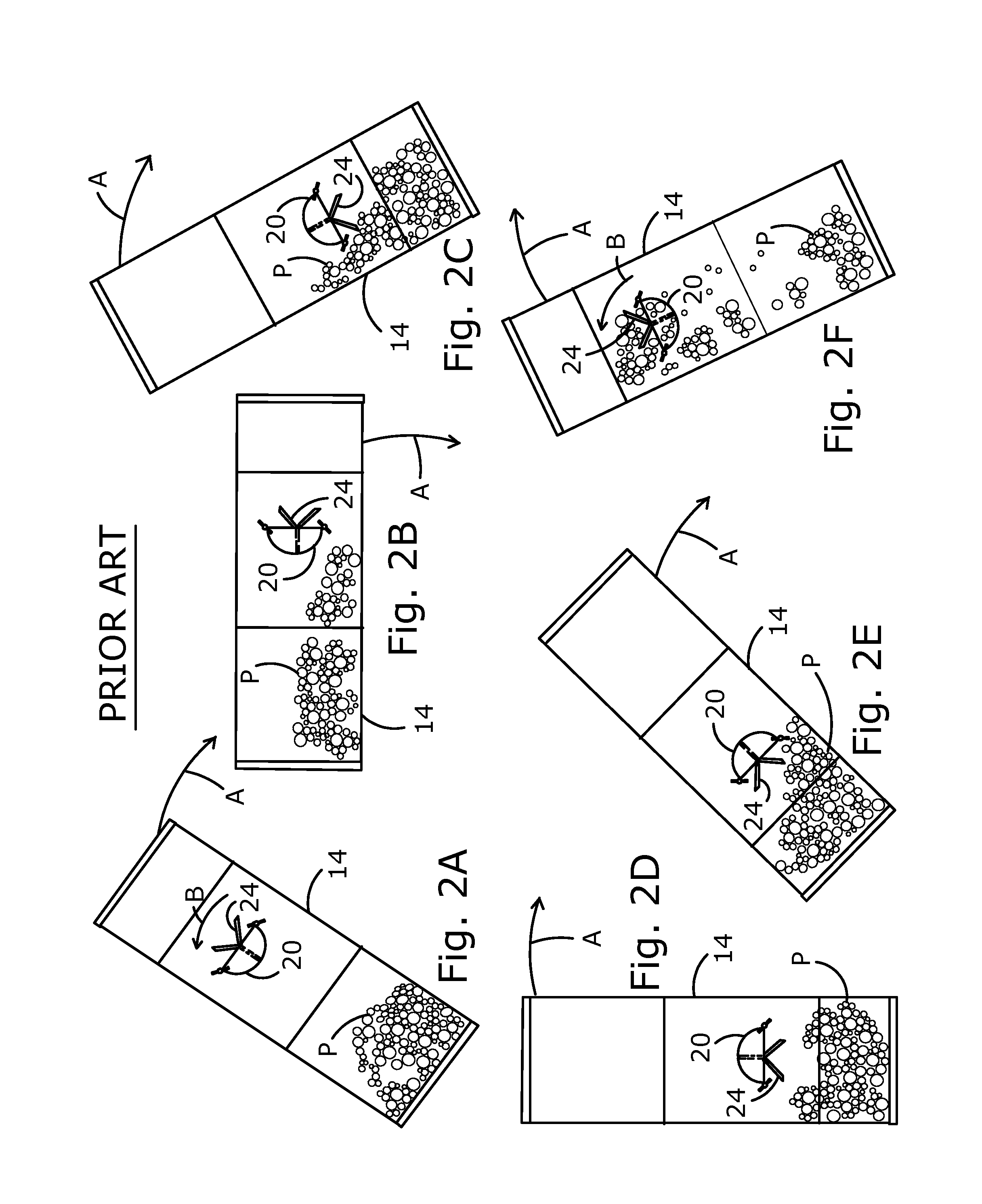

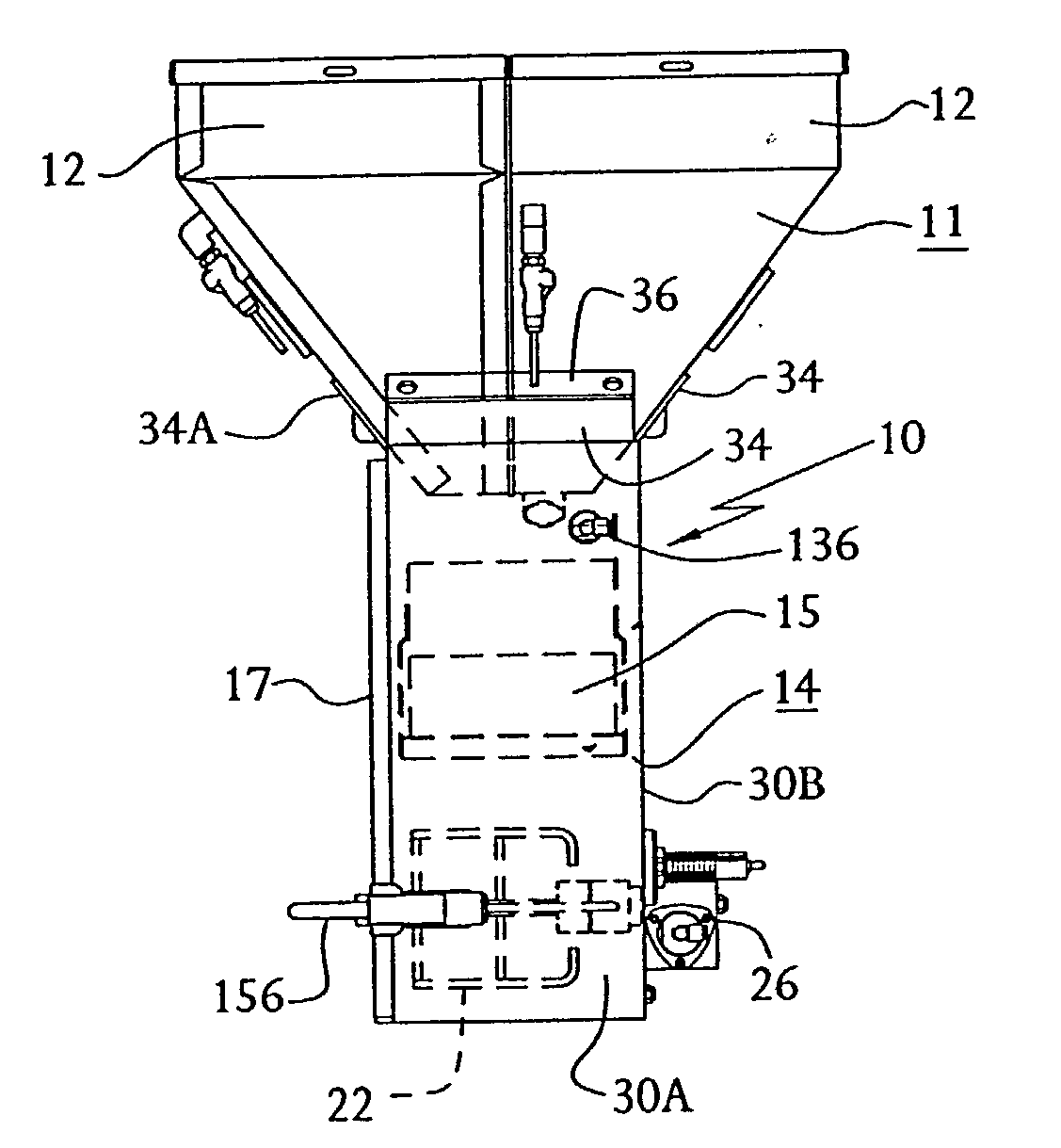

Weigh scale blender

InactiveUS6402363B1Accurate measurementEasy and efficient and accurateControlling ratio of multiple fluid flowsRotary stirring mixersEngineeringLoad cell

A weigh scale blender comprising a frame, a weigh bin, a load cell connected to the frame for sensing weight of the bin and any material contained therein, a mix chamber connected to the frame, including a mixing paddle therewithin, a dump flap for selectably releasing material from the bin into the mix chamber, a bushing intermediate the load cell and the frame for damping transfer of vibration and shock motion therebetween.

Owner:MAGUIRE STEPHEN B

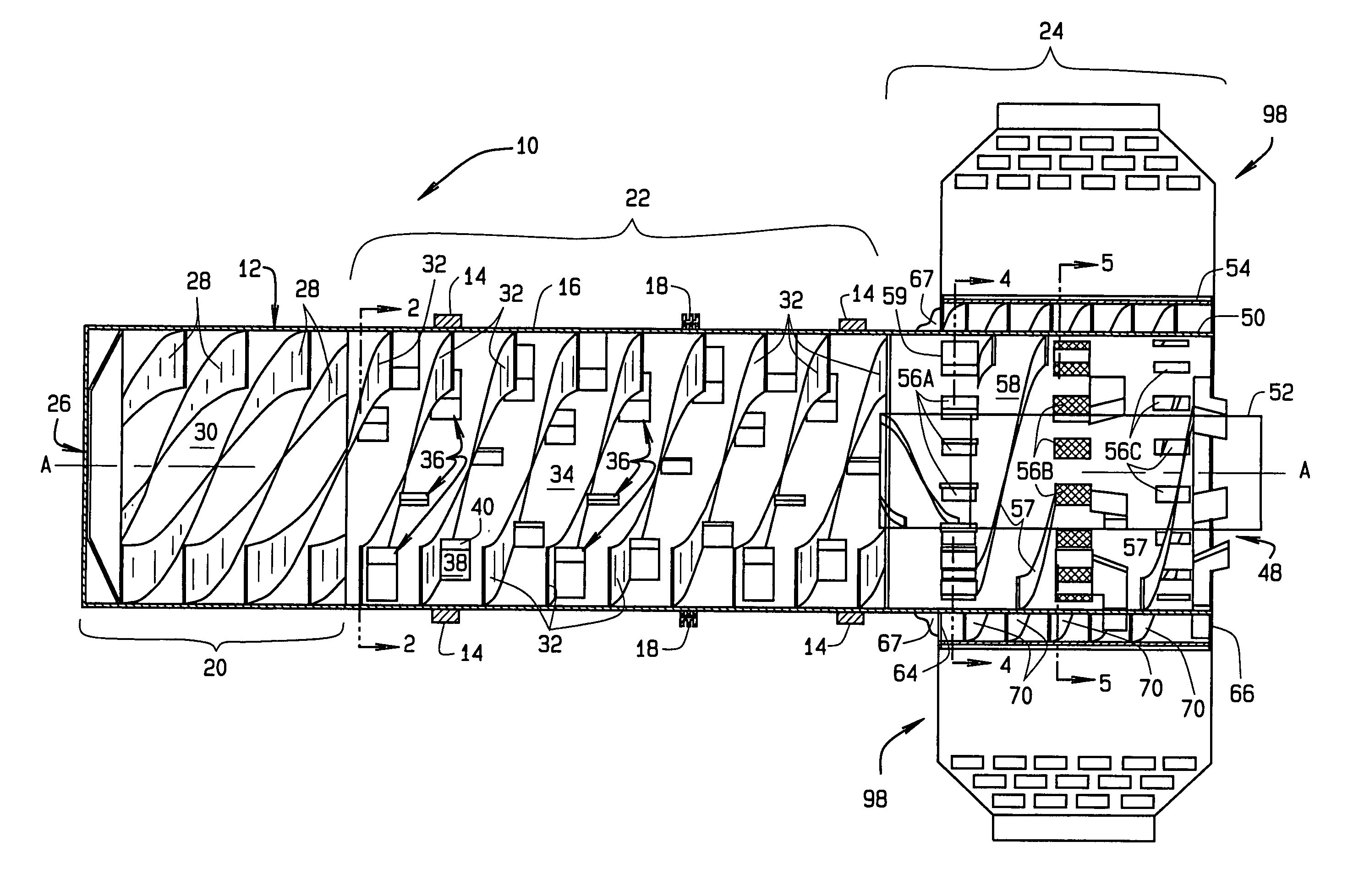

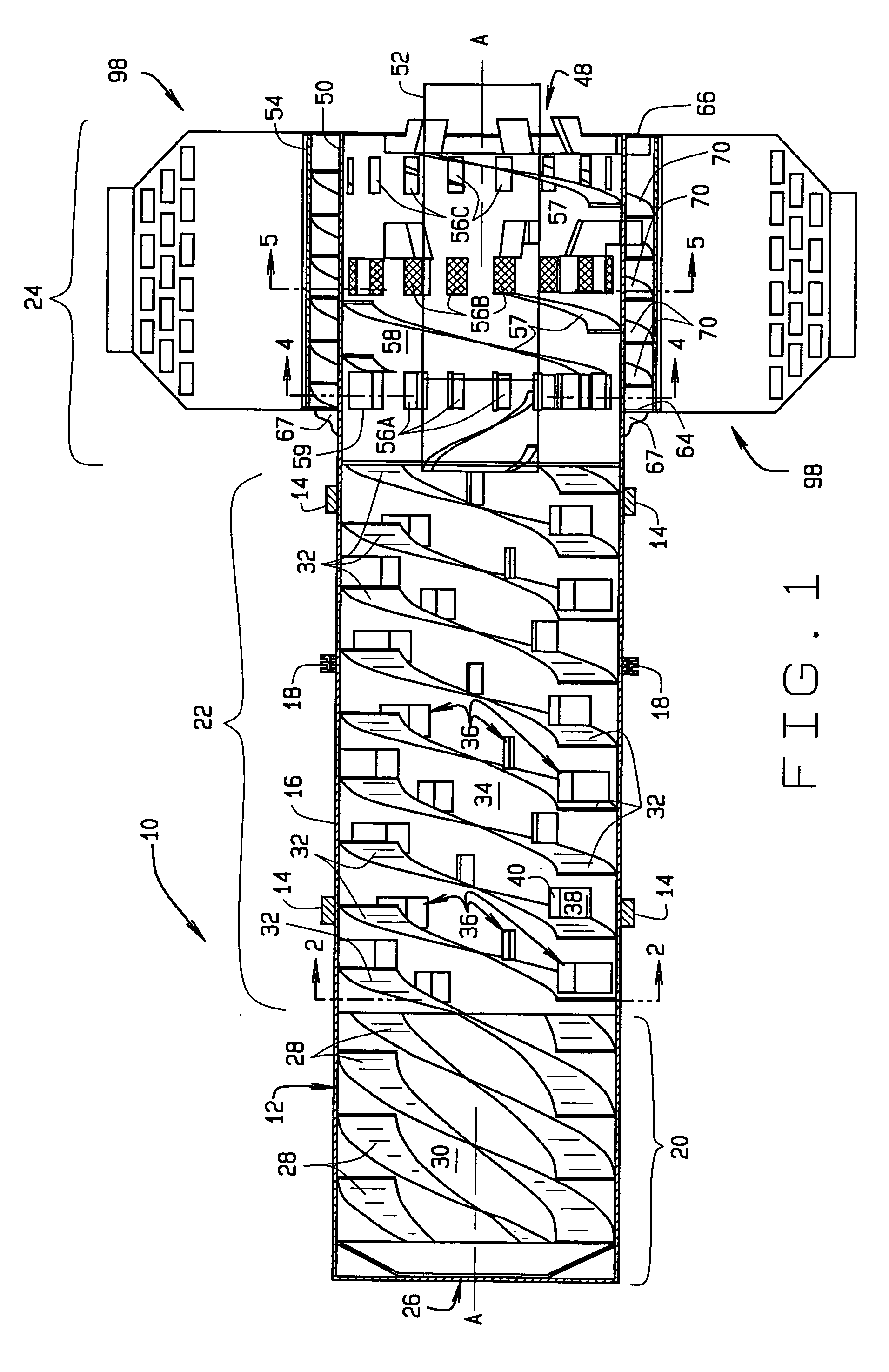

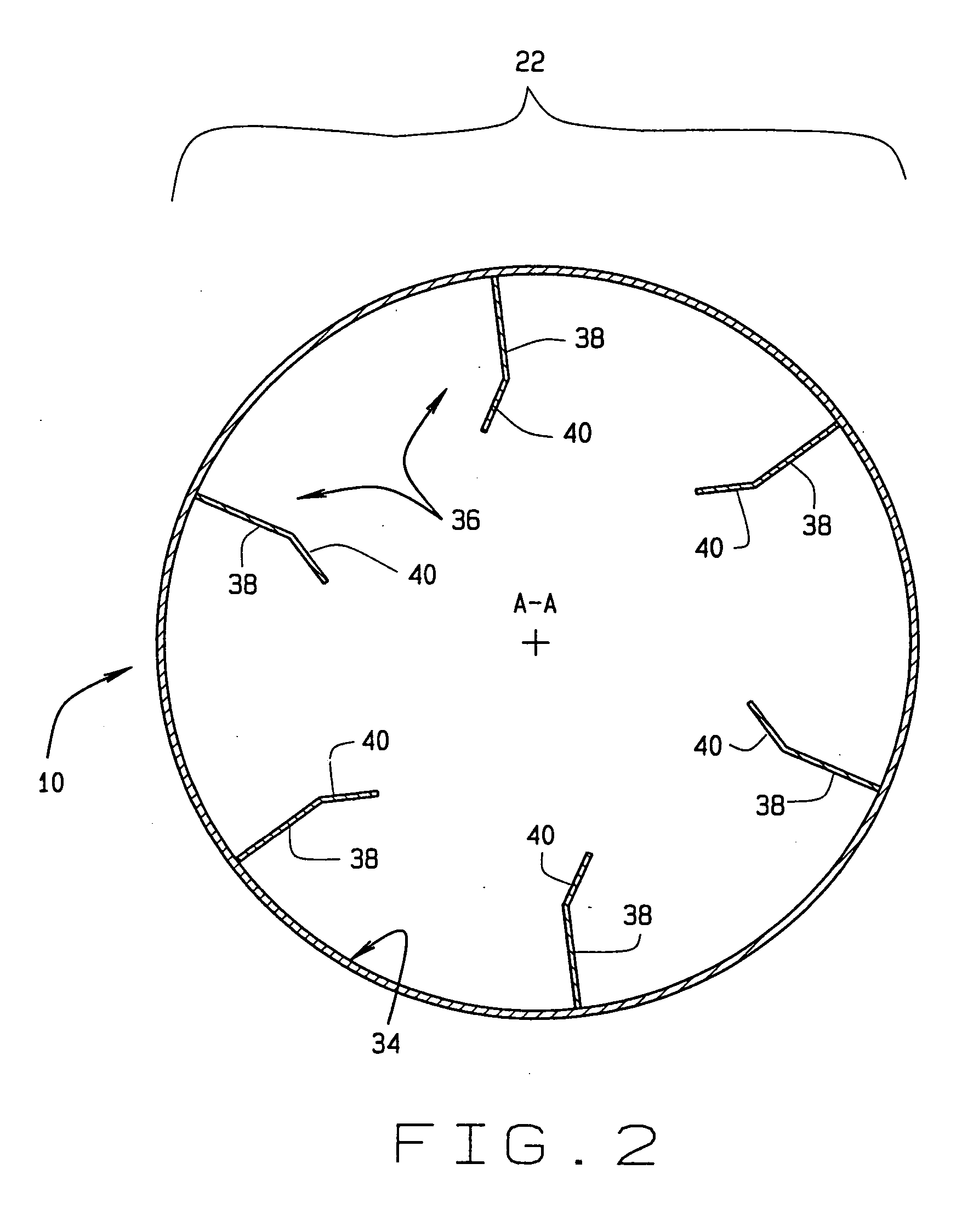

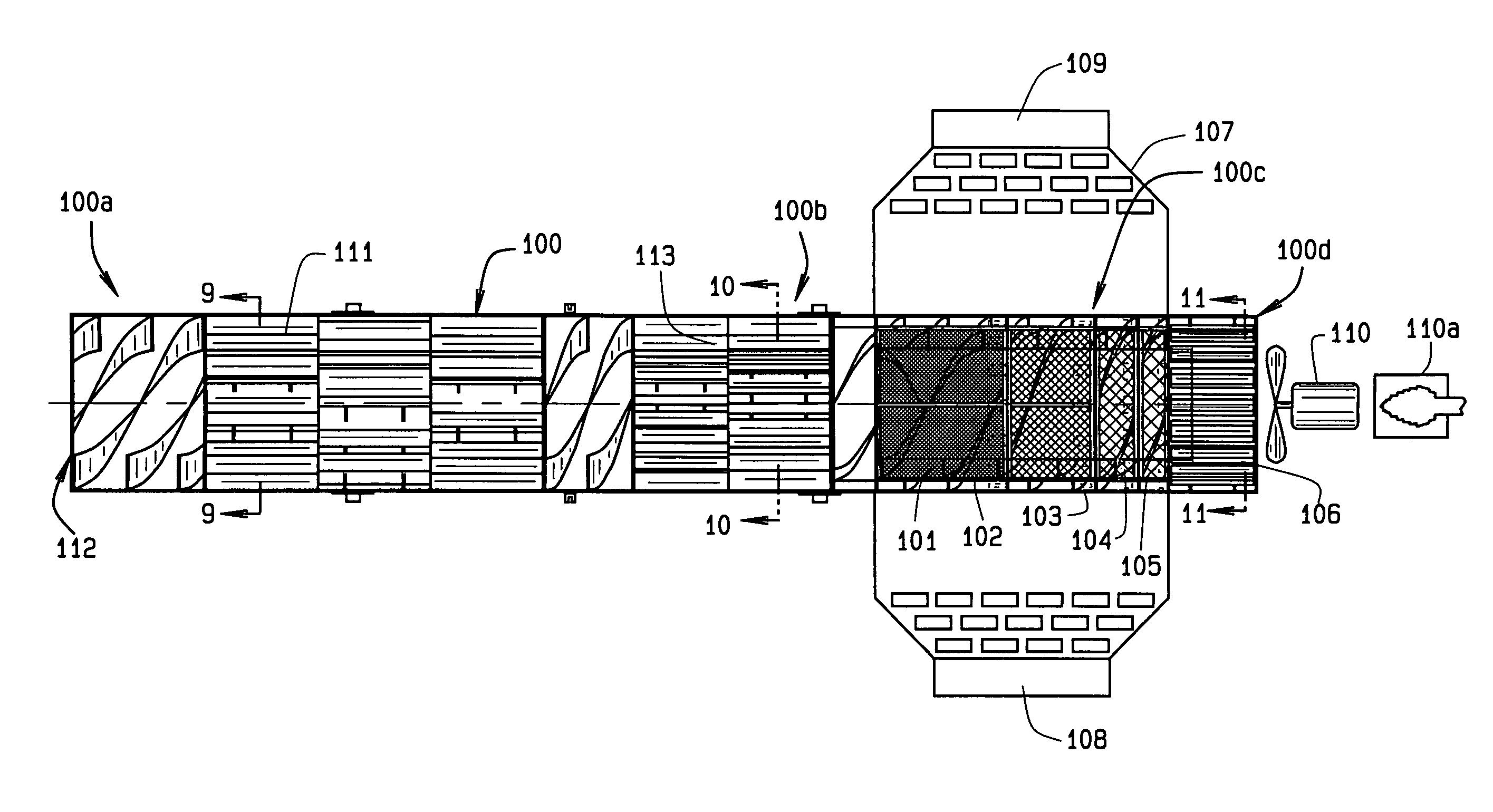

Granular and aggregate blending, cooling and screening rotary drum

InactiveUS20050236320A1Reliable constructionMinimal maintenanceRotating receptacle mixersRotary stirring mixersCounter flowCooling effect

A rotary drum configured for the efficient blending, cooling, and screening of granular products having an outer cylindrical shell, an intake end, and an exit or discharge end. The rotary drum is normally rotated at a predetermined speed by means of a conventional drive package. Disposed on an inner surface of the cylindrical shell is a plurality of compound helical flights and scoops or lifts, configured to blend granular product as it cascades from the intake end to the discharge or exit end of the rotary drum. A coaxially disposed cylindrical air passage adjacent the discharge end of the rotary drum, comprising an inner cylinder, that directs a counter flow of cooling air through the rotary drum towards the intake end, for cooling the cascading granular product as it approaches the screening segment of the rotary drum. The rotary drum having a plurality of discharge ports and grading screens just before its discharge end, provided in the surface of the outer cylindrical shell adjacent to the discharge end, to allow for the passage of air for attaining dust collection, while the counter flowing cooling air passes through the internally arranged inner cylinder to achieve the cooling effect within the rotary drum.

Owner:DIDION TECHNOLOGIES LLC

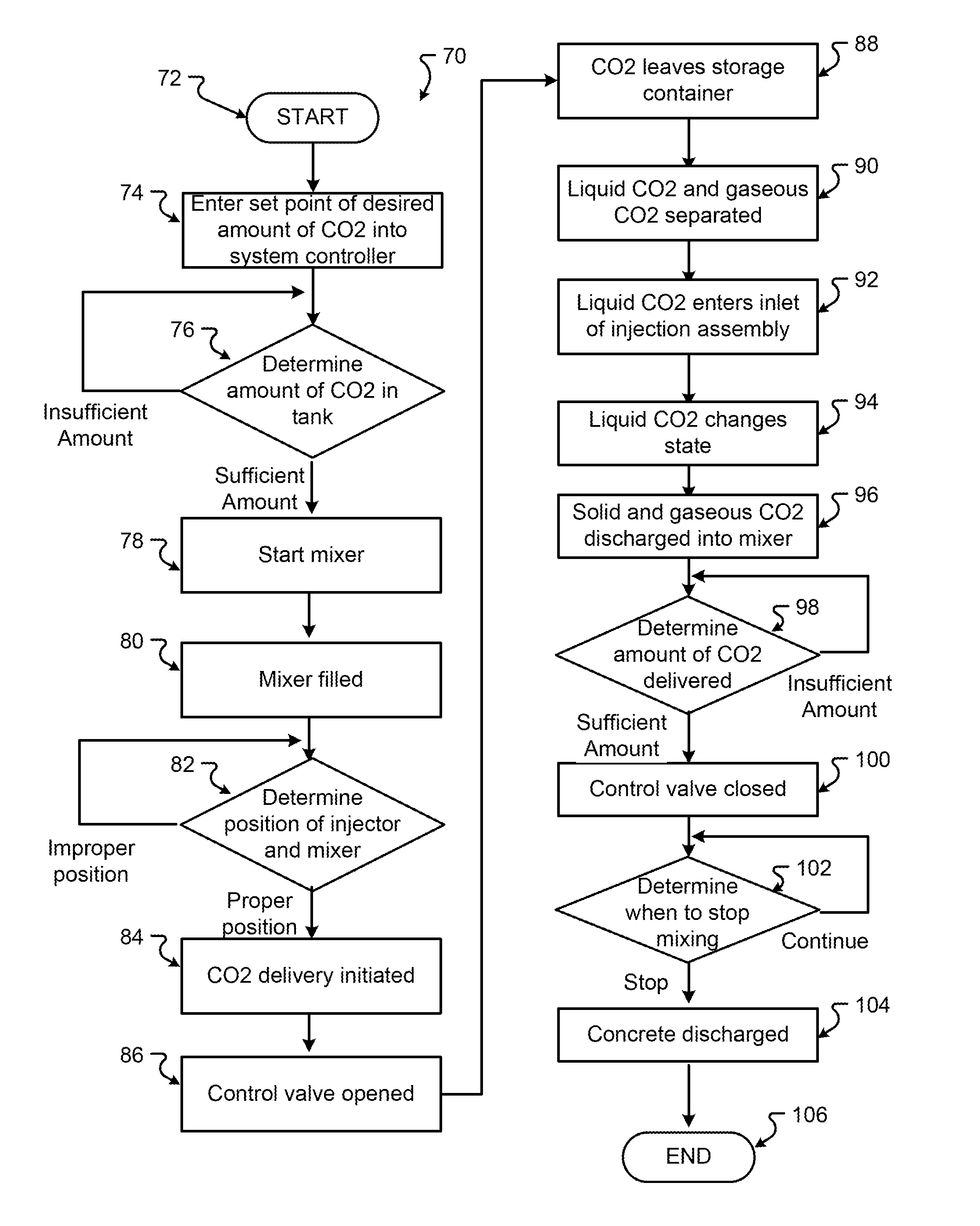

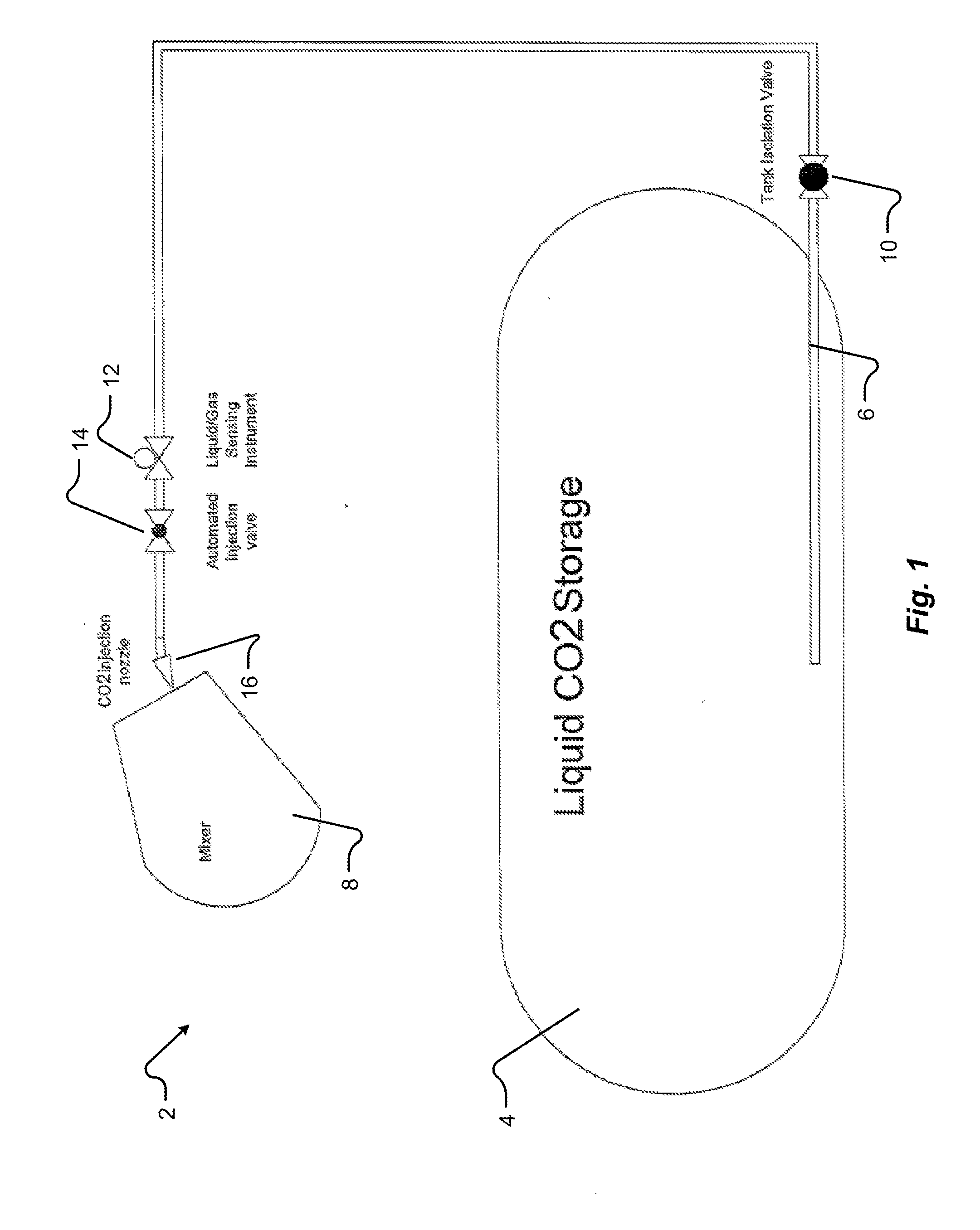

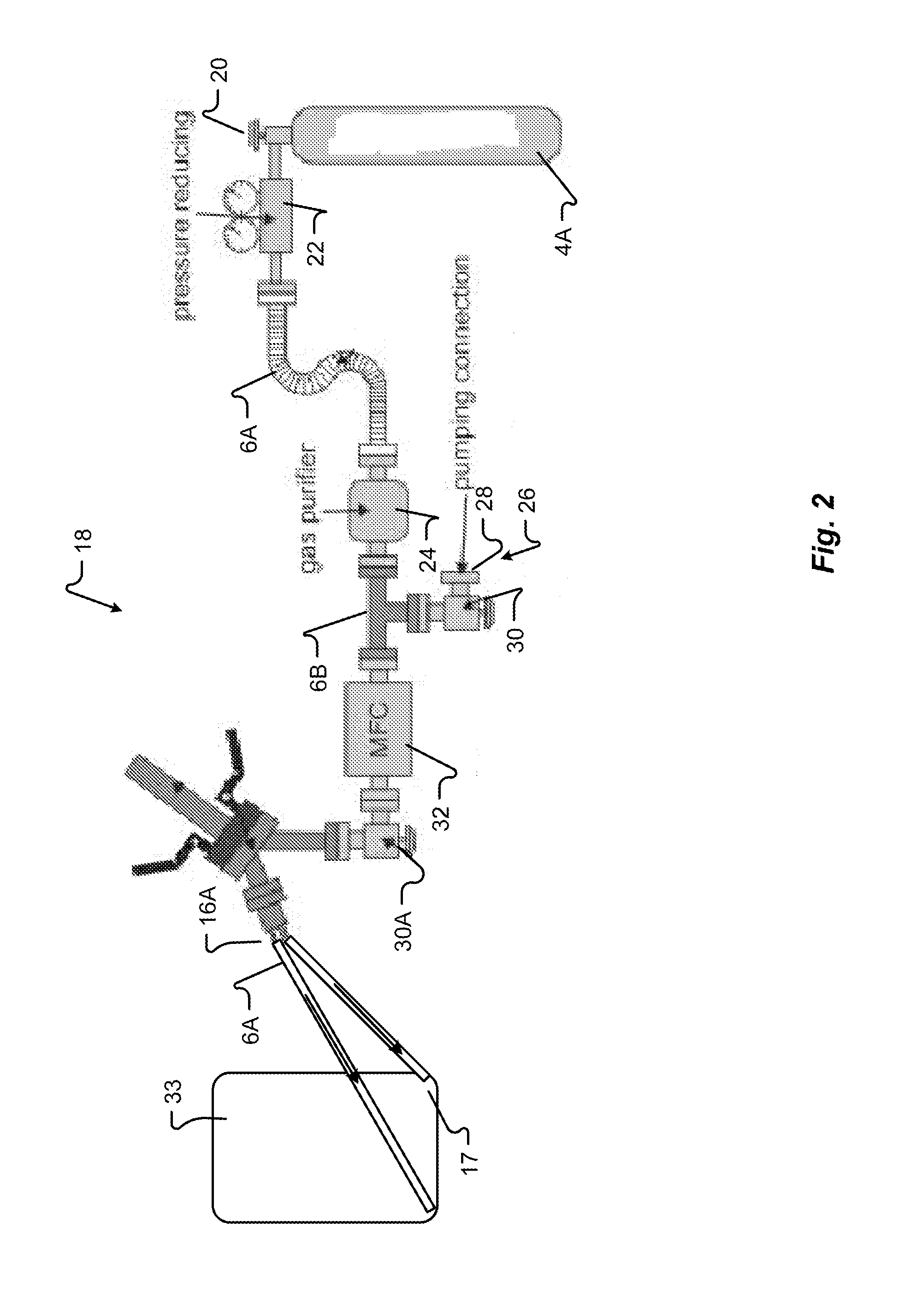

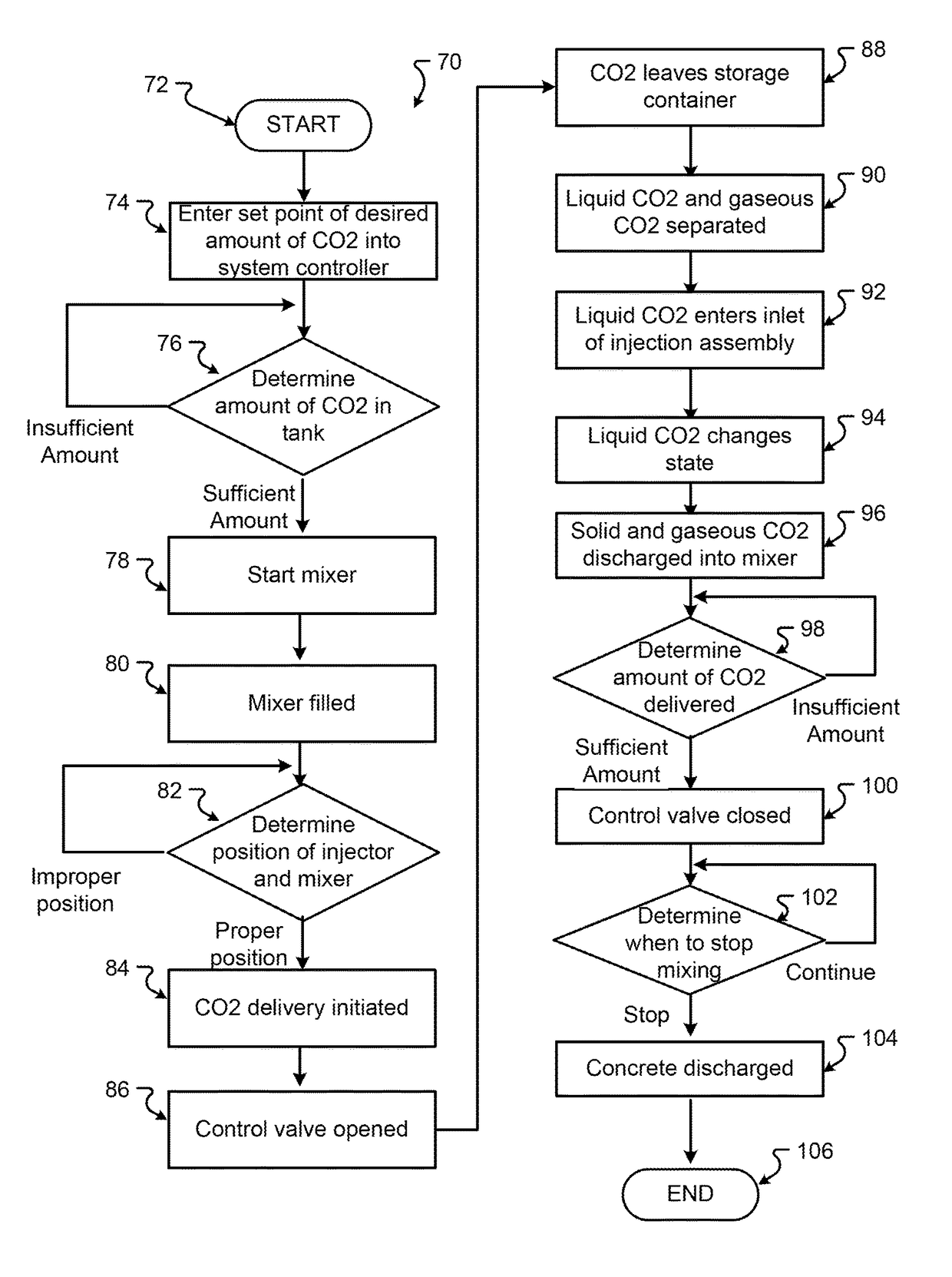

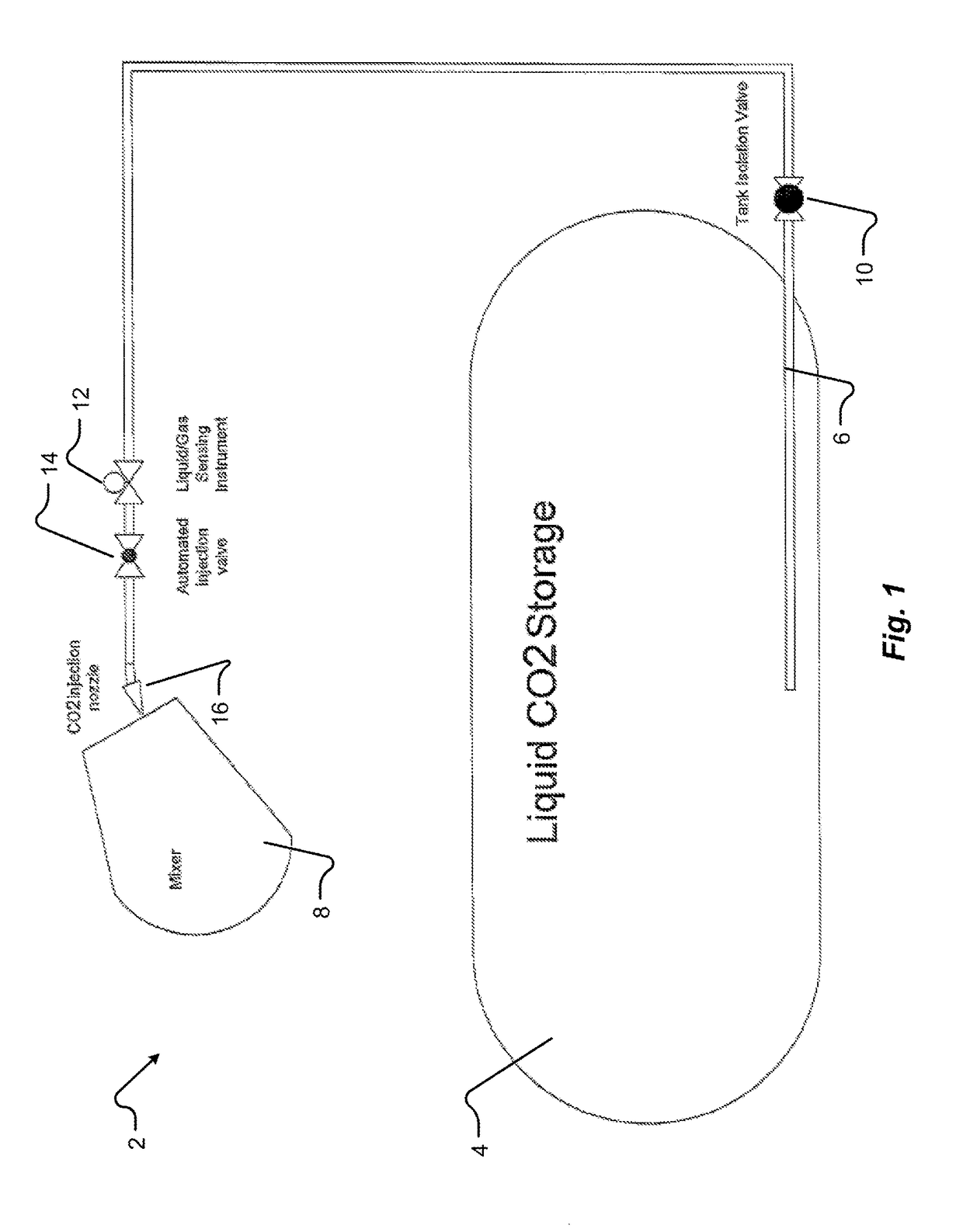

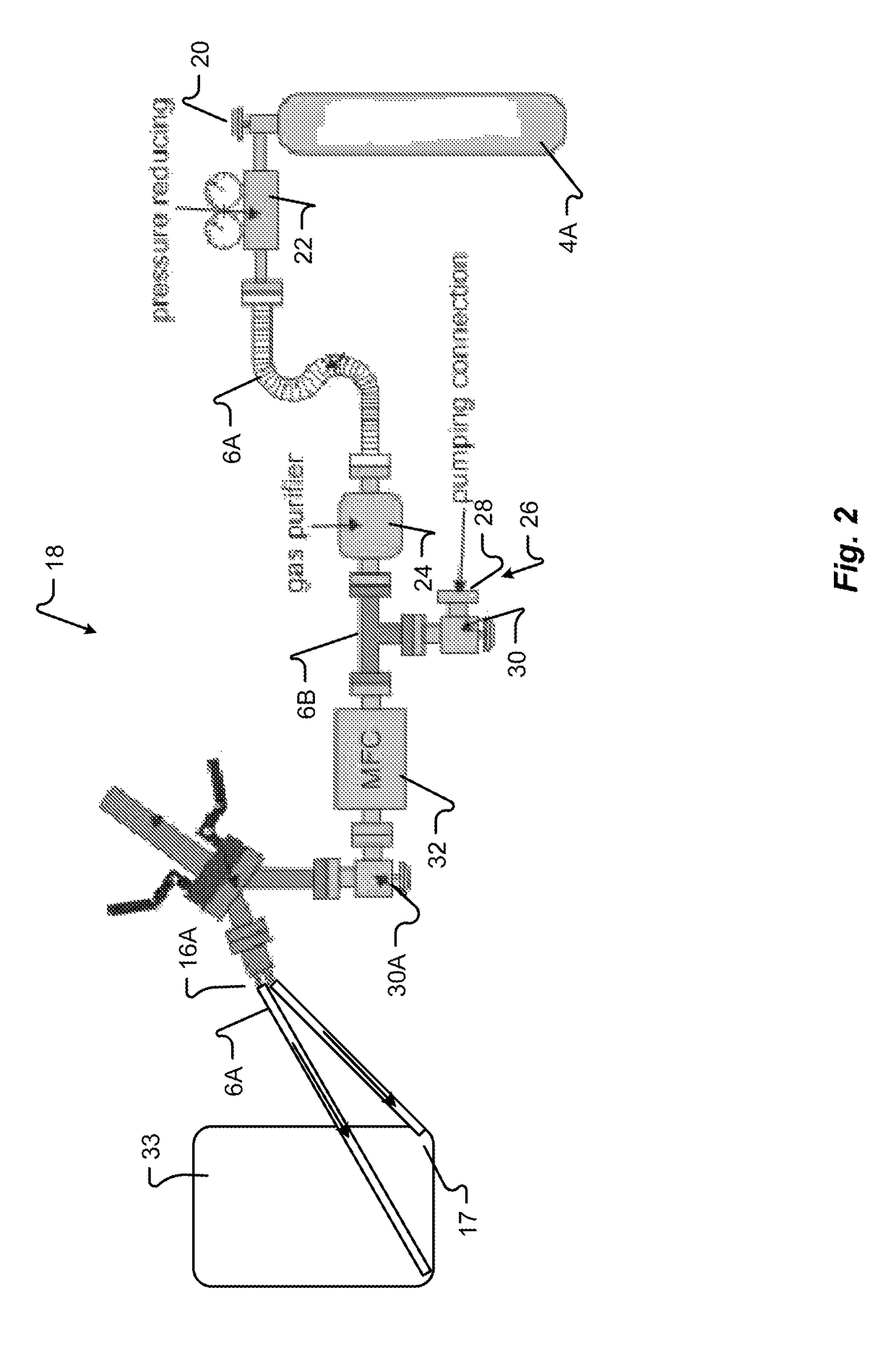

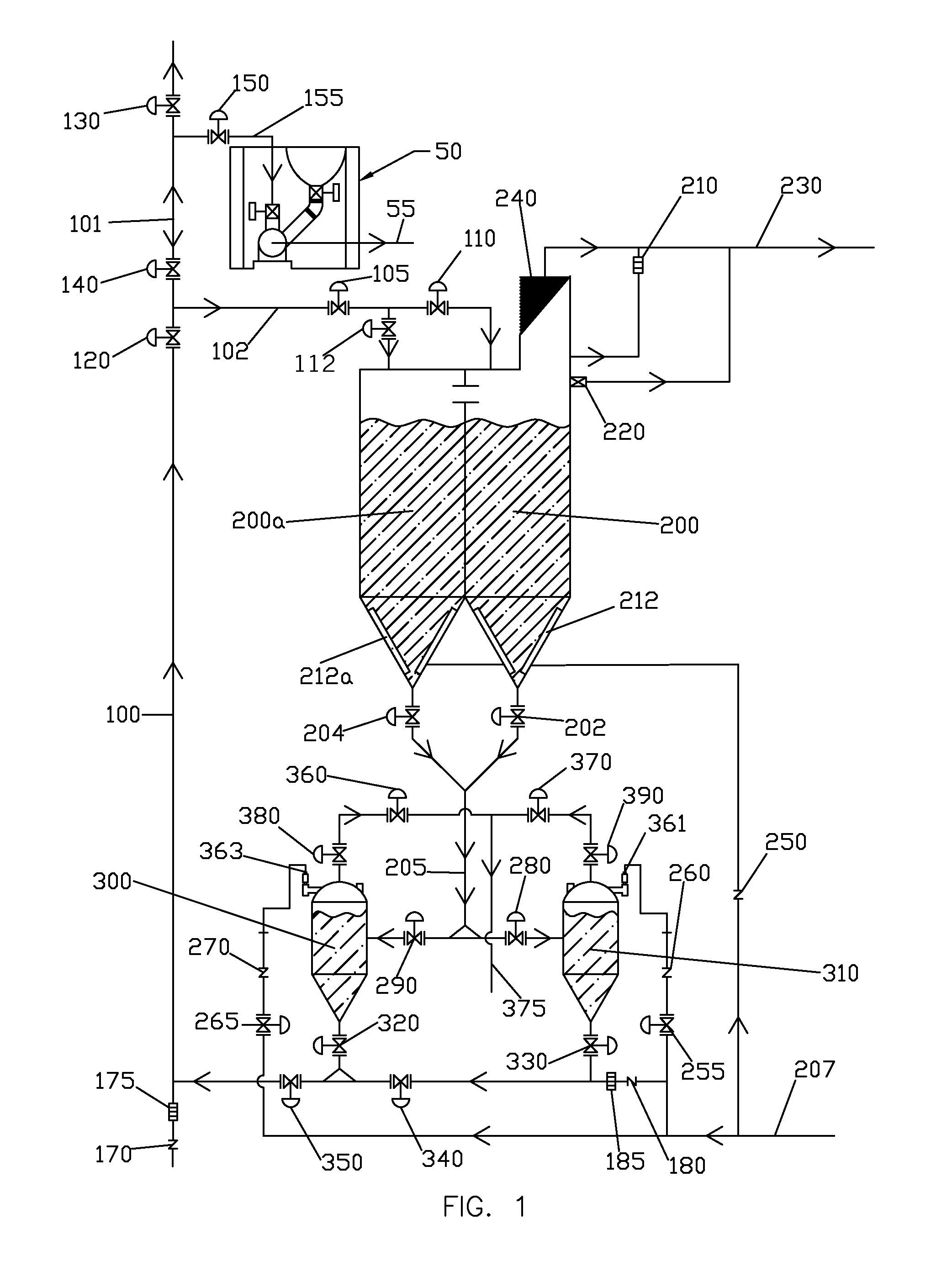

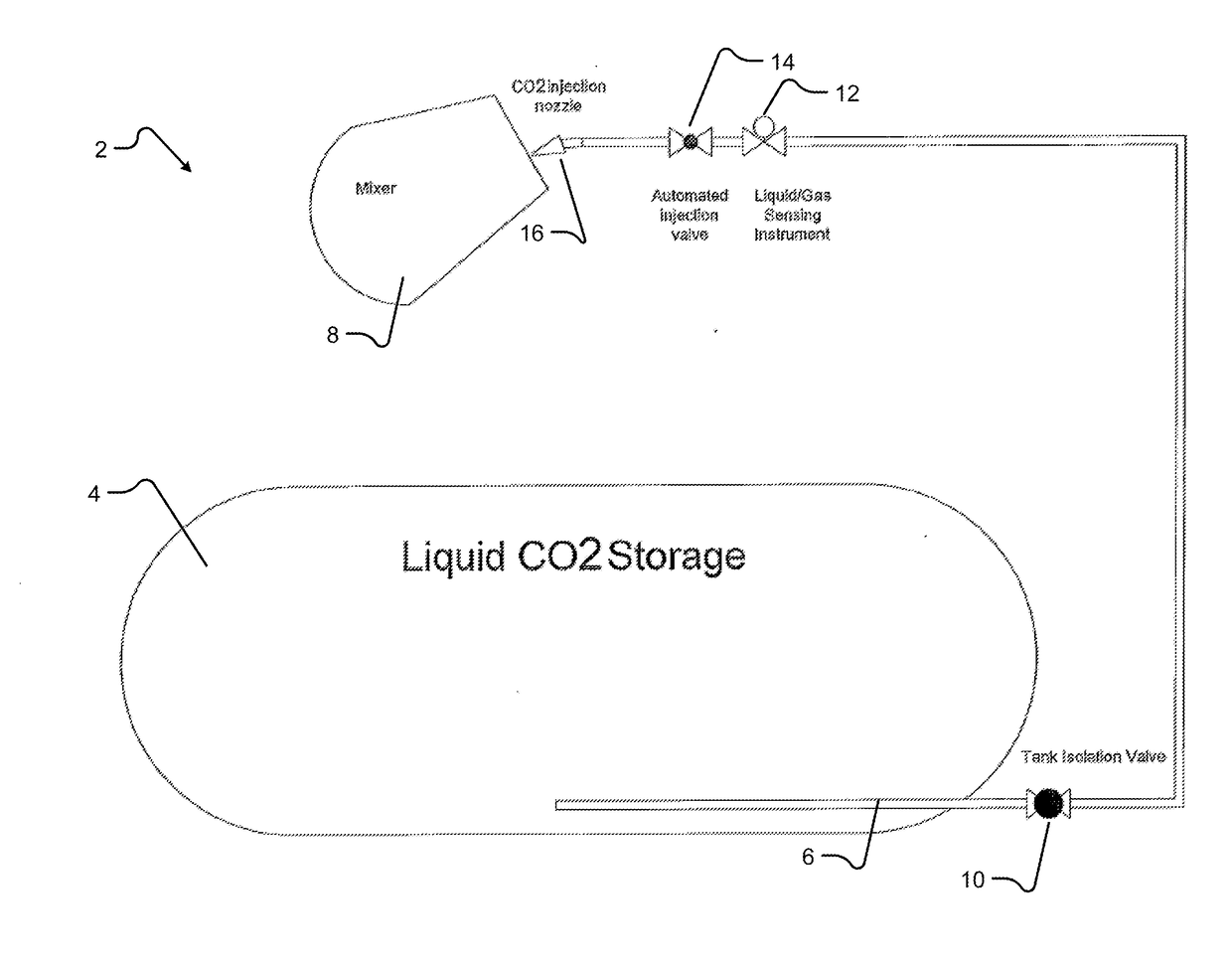

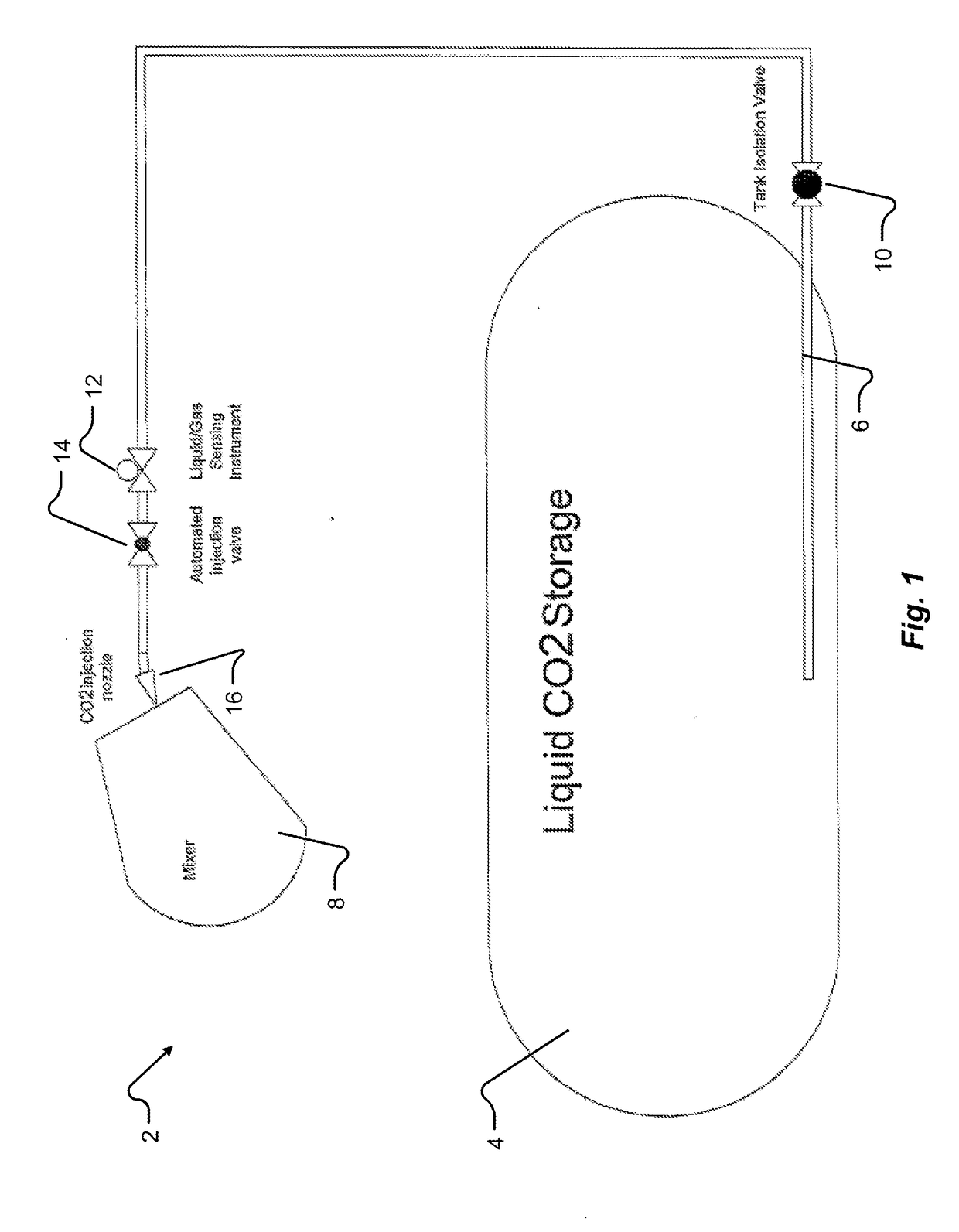

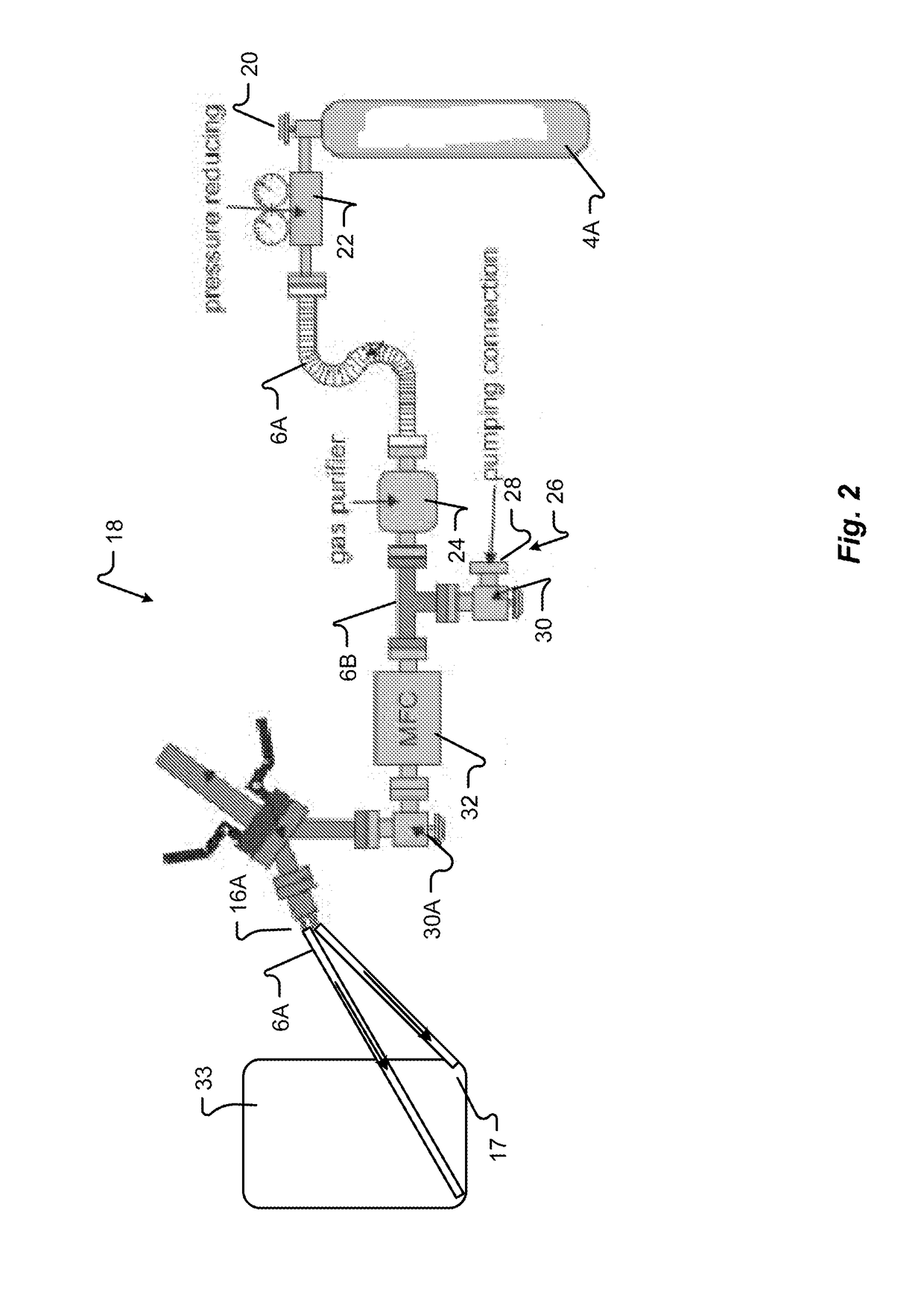

System and method of applying carbon dioxide during the production of concrete

InactiveUS20140216303A1Low costReduce energy consumptionFlow mixersTransportation and packagingMulti materialProcess engineering

The present disclosure involves systems and methods for applying CO2 to concrete, which may be performed in-situ or through a separate, stand-alone process. According to another embodiment disclosed herein, a system and method for applying CO2 to one or more materials used in the production of concrete is also provided.

Owner:CARBONCURE TECH

Granular and aggregate blending, cooling and screening rotary drum

InactiveUS7204636B2Low costSimple materialRotating receptacle mixersTransportation and packagingCounter flowCooling effect

A rotary drum configured for the efficient blending, cooling, and screening of granular products having an outer cylindrical shell, an intake end, and an exit or discharge end. The rotary drum is normally rotated at a predetermined speed by a conventional drive package. Disposed on an inner surface of the cylindrical shell is a plurality of compound helical flights and scoops or lifts, configured to blend granular product as it cascades from the intake end to the discharge or exit end of the rotary drum. A coaxially disposed cylindrical air passage adjacent the discharge end of the rotary drum, comprising an inner cylinder, that directs a counter flow of cooling air through the rotary drum towards the intake end, for cooling the cascading granular product as it approaches the screening segment of the rotary drum. The rotary drum having a plurality of discharge ports and grading screens just before its discharge end, provided in the surface of the outer cylindrical shell adjacent to the discharge end, to allow for the passage of air for attaining dust collection, while the counter flowing cooling air passes through the internally arranged inner cylinder to achieve the cooling effect within the rotary drum.

Owner:DIDION TECHNOLOGIES LLC

Lightweight Clumping Animal Litter and Method Thereof

ActiveUS20120260860A1Reduce staticReduce colorFlow mixersTransportation and packagingCelluloseSodium Bentonite

Animal litter having up to a sixty percent reduction in bulk density can be produced by combining flat-shaped cellulosic materials and sodium bentonite clay. Not only is the resulting litter lighter, but it also maintains a high clump strength as compared to clay-based animal litters that contain greater than ninety percent by weight sodium bentonite clay.

Owner:THE CLOROX CO

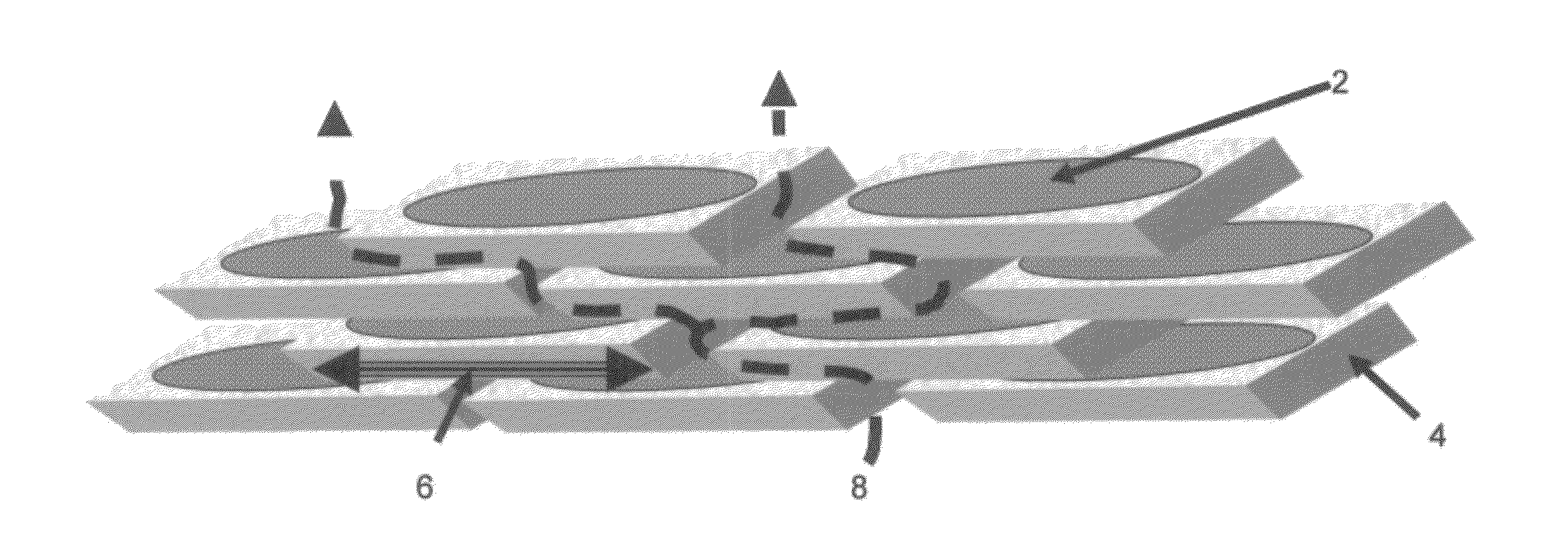

Power-controlled bonding of resin or (co)polymer powder and flake materials

The present invention provides methods of making sticky powder comprising mixing one or more resin or (co)polymer powders in one or more mixing devices without agglomerating the powders and while measuring the power, work or torque drawn by the mixing devices, the mixing continuing until the measure of the power or torque drawn indicates that the powders have become sticky. The mixing further comprises adding to the powders one or more dry materials and mixing to so that the dry materials adhere or “bond” to the sticky powders. Alternatively, the methods further comprise slowing or stopping the mixing, or cooling while mixing once the said sticky powders have been formed, adding one or more dry materials to form a sticky powder mixture, and further mixing to bond the sticky powders and the dry materials together. The dry materials may comprise one or more flake materials, e.g. metallic flakes; layered pigments, clays, catalysts or antimicrobials; resins or (co)polymers; cyroprocessed materials, and materials encapsulated or dispersed in brittle materials. The methods may be automated.

Owner:ONEILL JULIA C +2

Dosing device

InactiveUS6911607B2Simple and elegant constructionAccurate doseFlow mixersTransportation and packagingEngineering

The invention relates to a dosing device for mixing additive into a basic flow, comprising: a passage for the basic flow; an inlet for the additive in the passage; a container for the additive connected to the inlet via a dosing mechanism and having a controllable drive for discharge of the additive into the inlet; weighing means for determining the weight of at least the container with the additive; and a control for the drive which is connected to the weighting means for setting a dosed discharge, wherein the dosing mechanism is arranged on the inlet via the weighing means.

Owner:E H KLIJN BEHEER

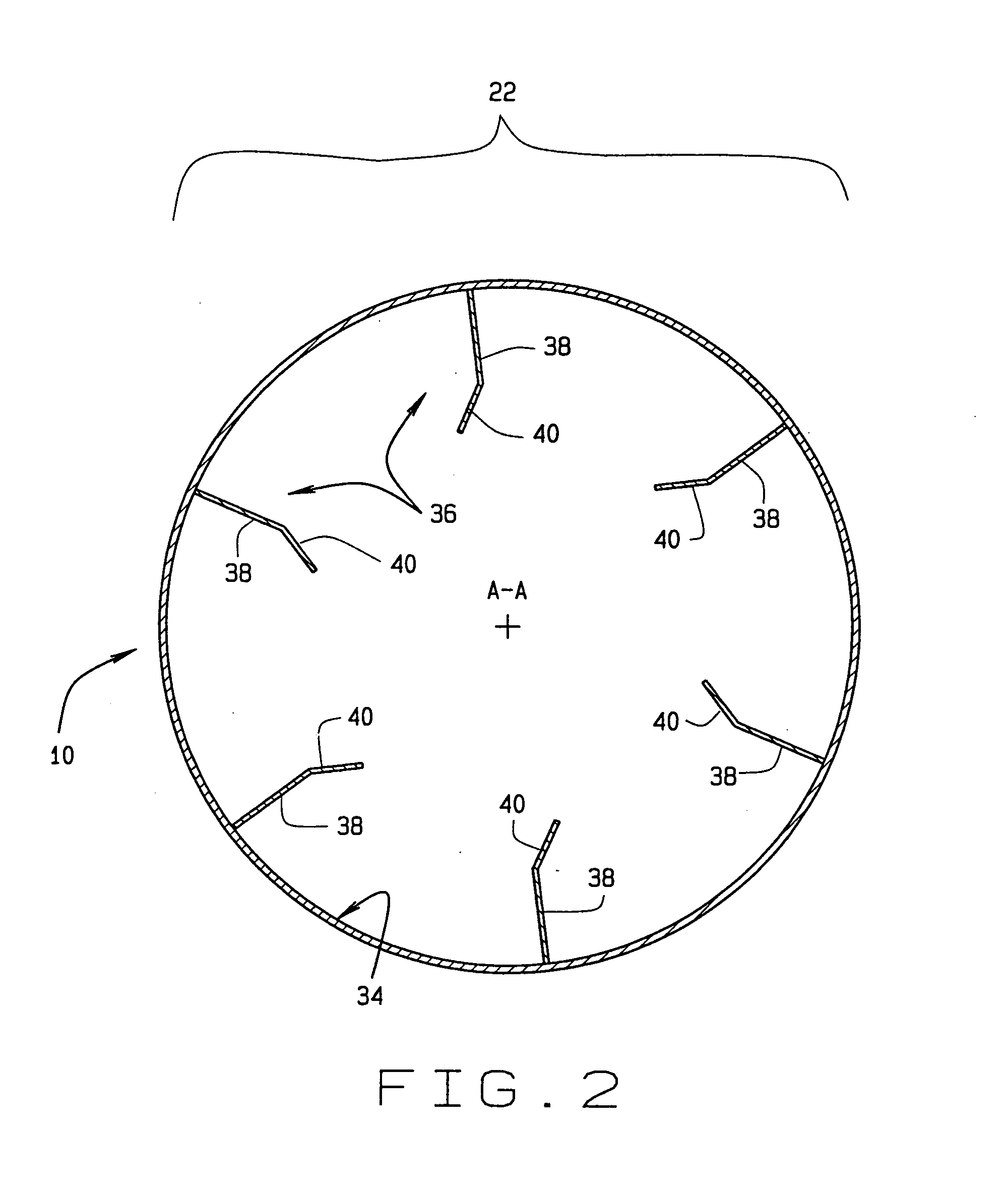

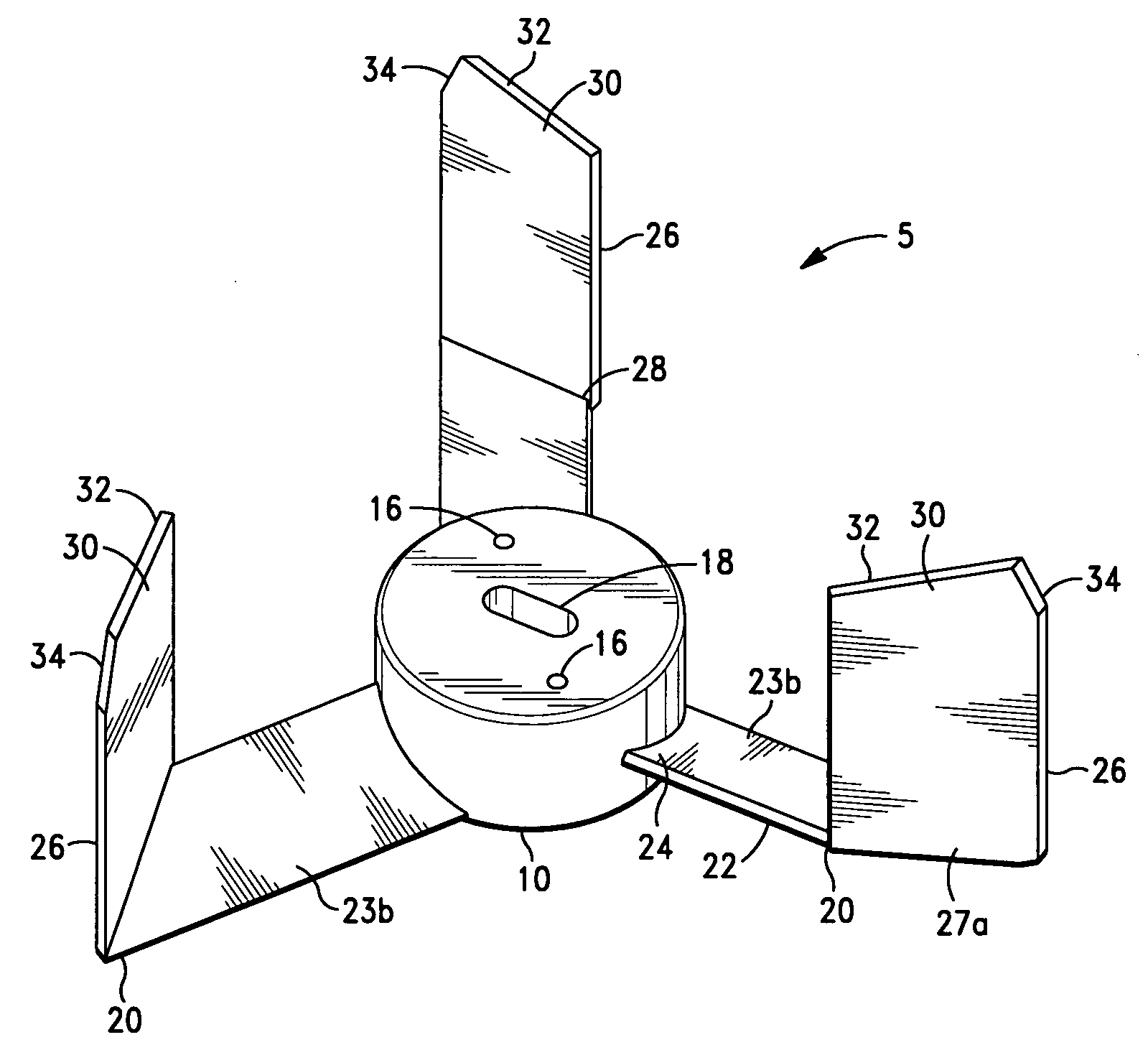

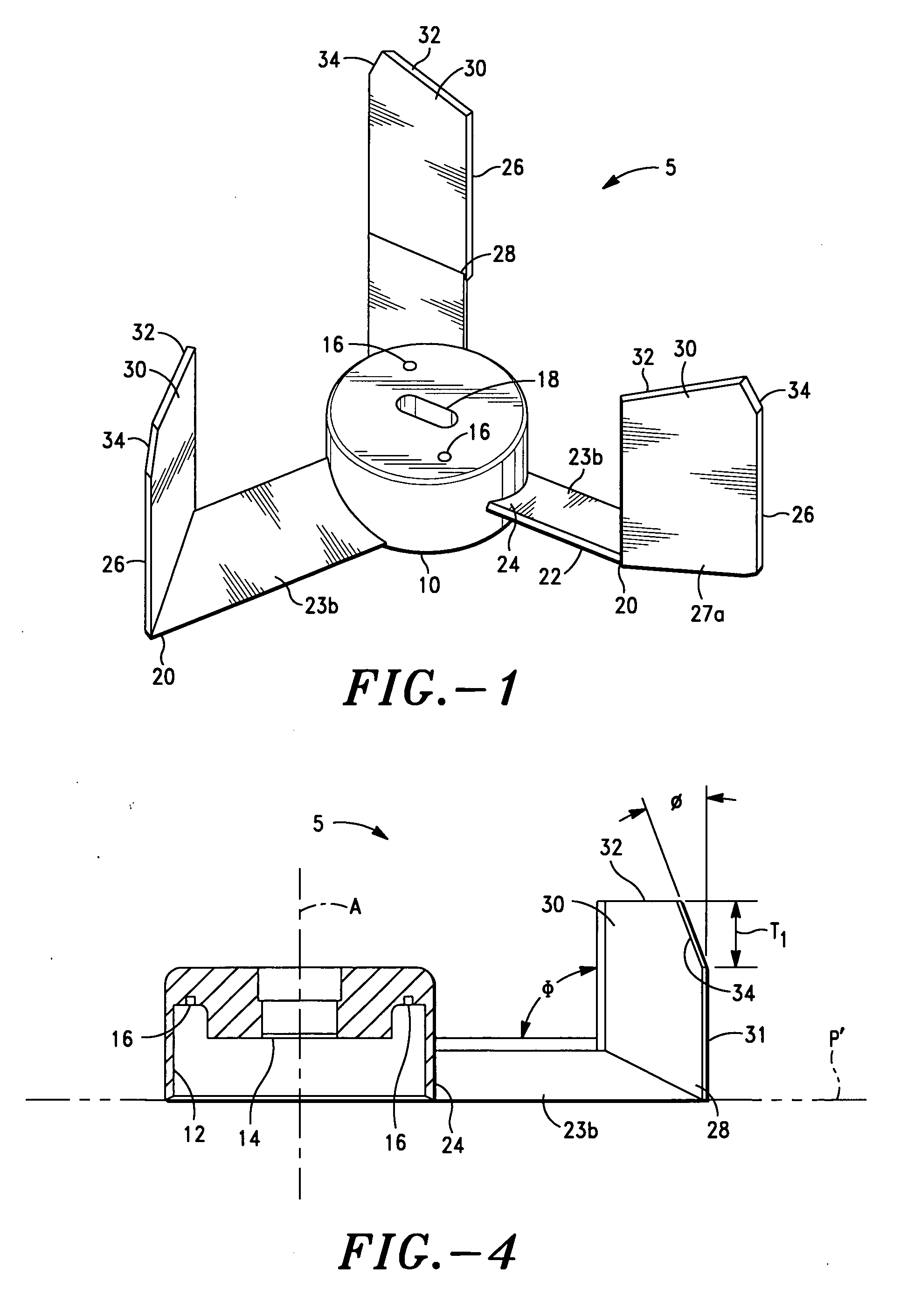

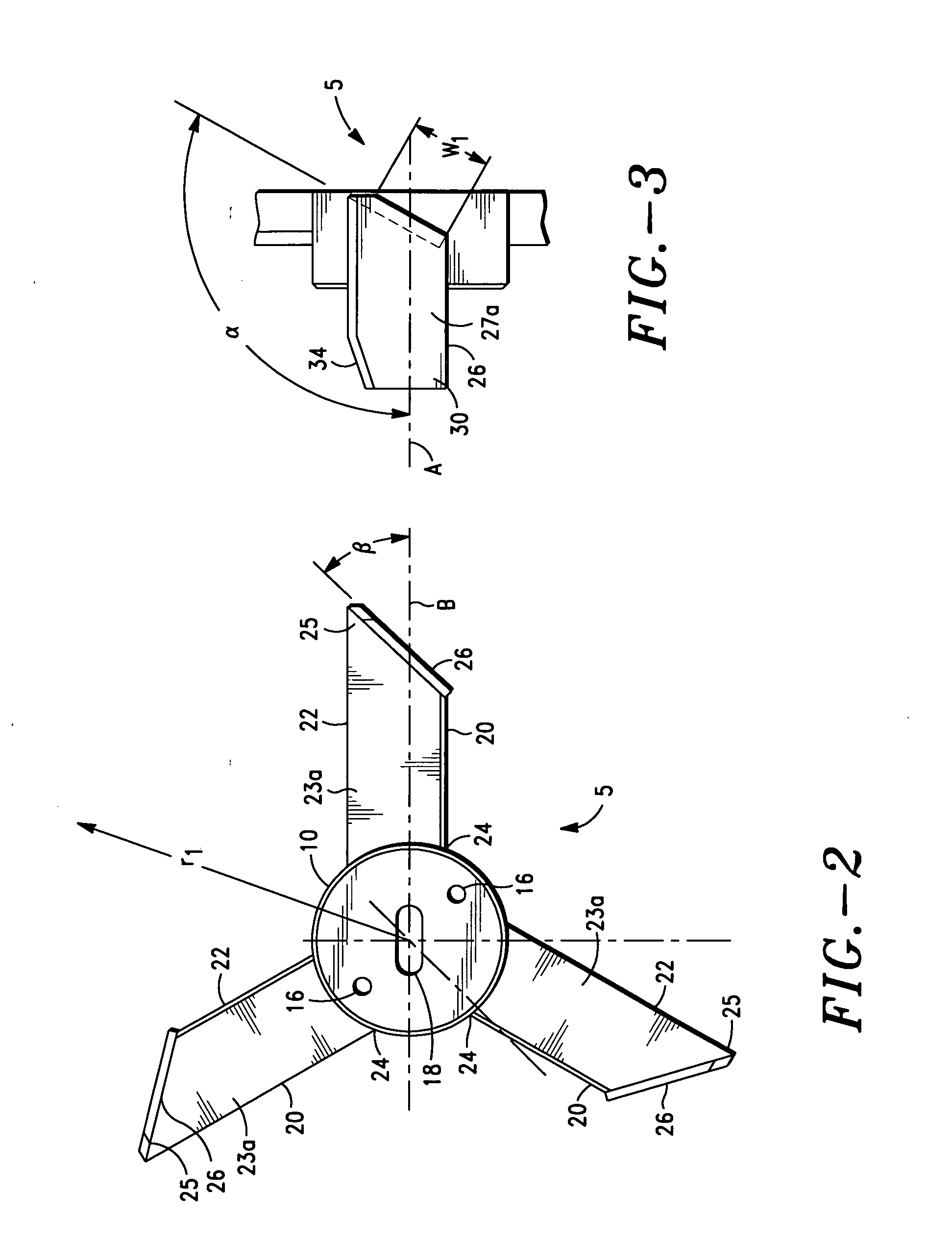

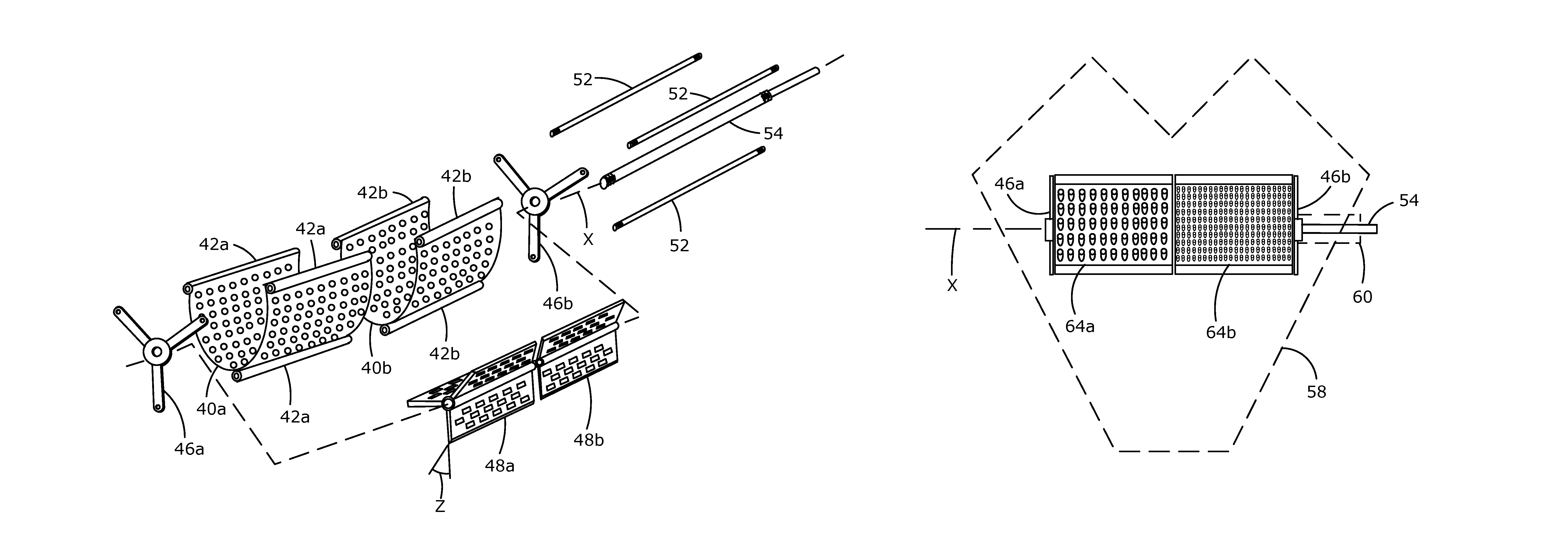

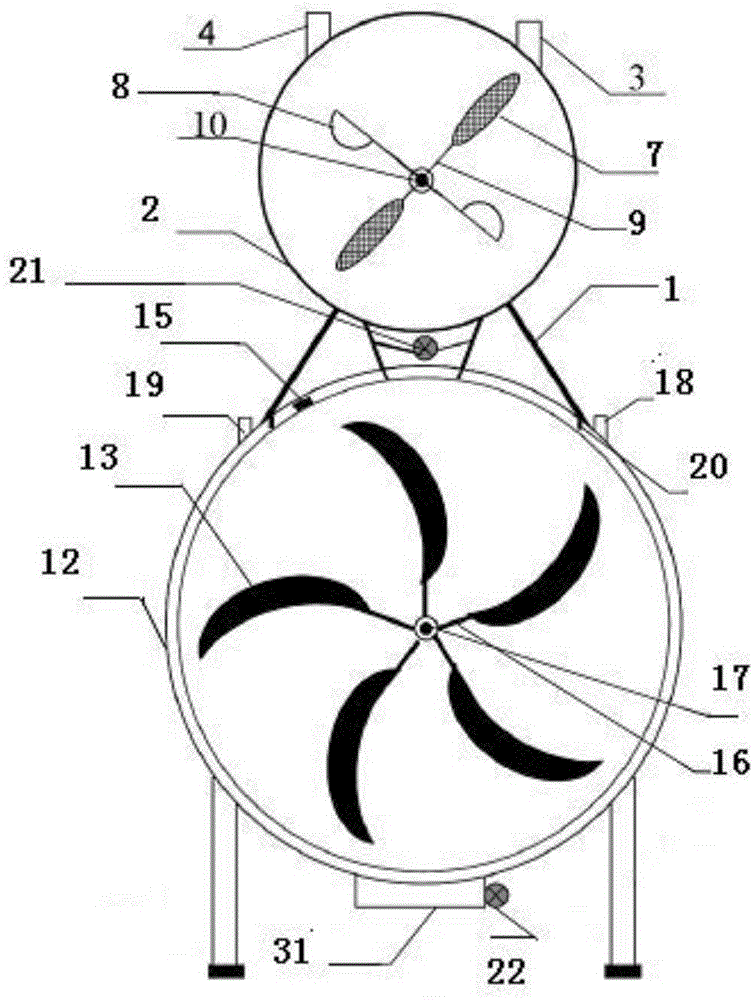

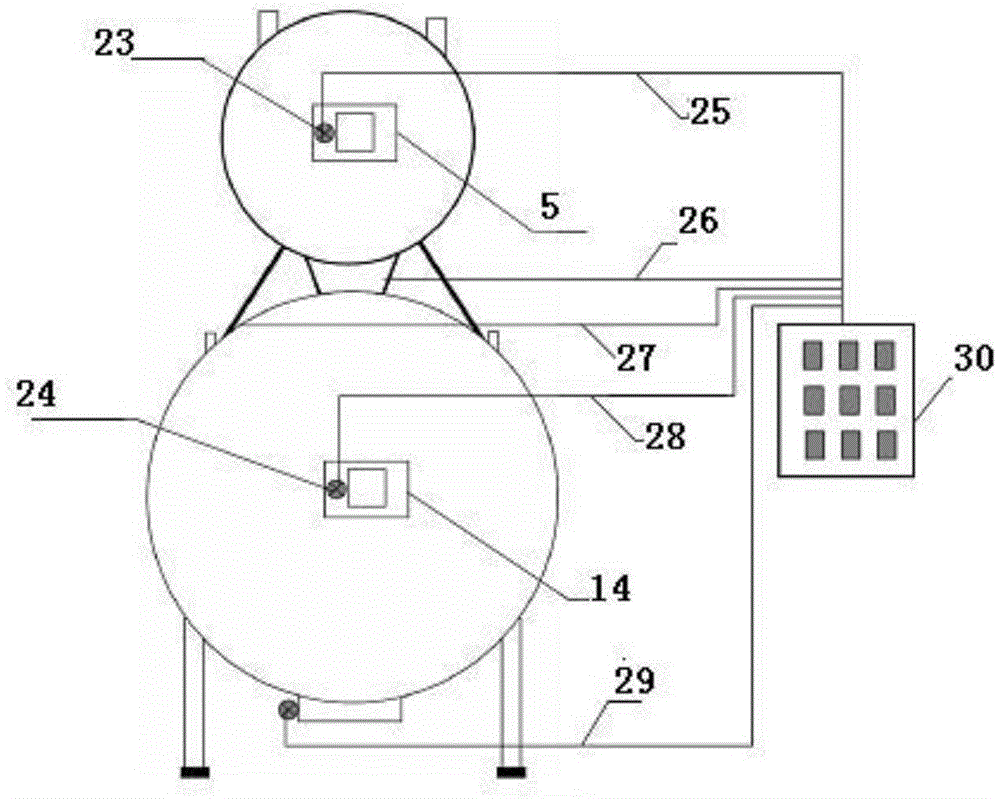

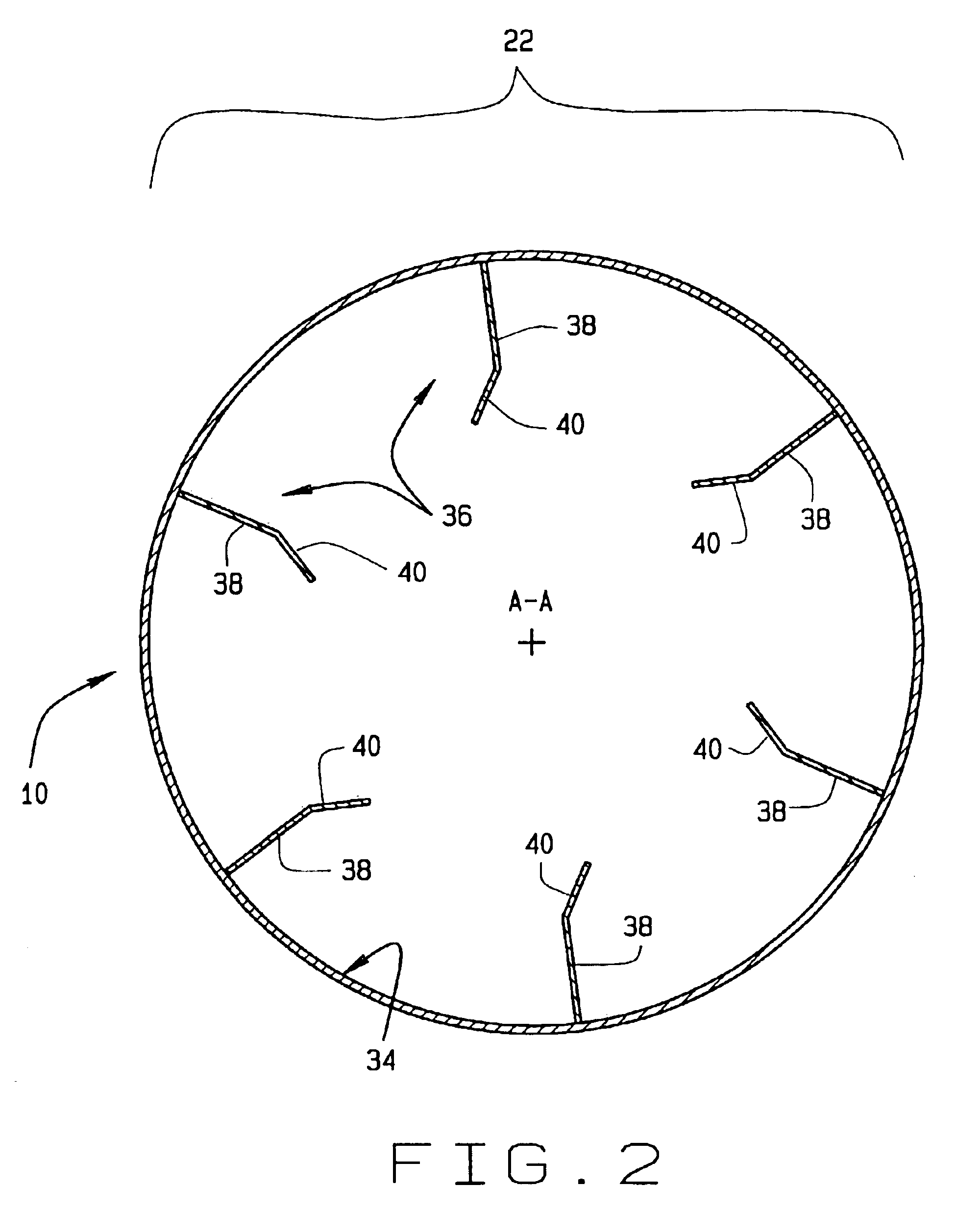

Rotary blending apparatus and system

InactiveUS20060187750A1Uniform particle size distributionHigh degreePropellersFlow mixersImpellerHybrid device

A rotary blending apparatus and system comprising a hub (10) and a plurality of substantially angularly spaced impeller blades (20). The unique, variable configuration of the impeller blades produces optimum flow patterns and, hence, highly efficient mixing of solids and liquids. The blending apparatus is also scalable to multiple sizes without compromising mixing performance.

Owner:GLAXO GRP LTD

System and method of applying carbon dioxide during the production of concrete

ActiveUS9790131B2Reduce energy consumptionLow costFlow mixersTransportation and packagingMulti materialArchitectural engineering

The present disclosure involves systems and methods for applying CO2 to concrete, which may be performed in-situ or through a separate, stand-alone process. According to another embodiment disclosed herein, a system and method for applying CO2 to one or more materials used in the production of concrete is also provided.

Owner:CARBONCURE TECH

Flexible manufacture of polyethylene terephthalate ("PET")

InactiveUS20050059746A1Reduce the possibilityFlow mixersTransportation and packagingPolyethylene terephthalate glycolPolyethylene terephthalate

In at least one embodiment, the present invention relates to a method and system for providing blends of virgin polyethylene terephthalate (VPET) and a VPET property modifying component (PCM). In one embodiment, separate sources of solid VPET and solid PMC are provided. A conduit is provided between the sources and a bulk-container, which is suitable for delivery to an end user. VPET from the source of VPET and PMC from the PMC source are selectively dispensed into the conduit in a desired amount to form a uniform blend of materials comprising a predetermined ratio of VPET relative to PMC. The blend of materials is transported to the bulk-container for delivery to an end user.

Owner:EASTMAN CHEM CO

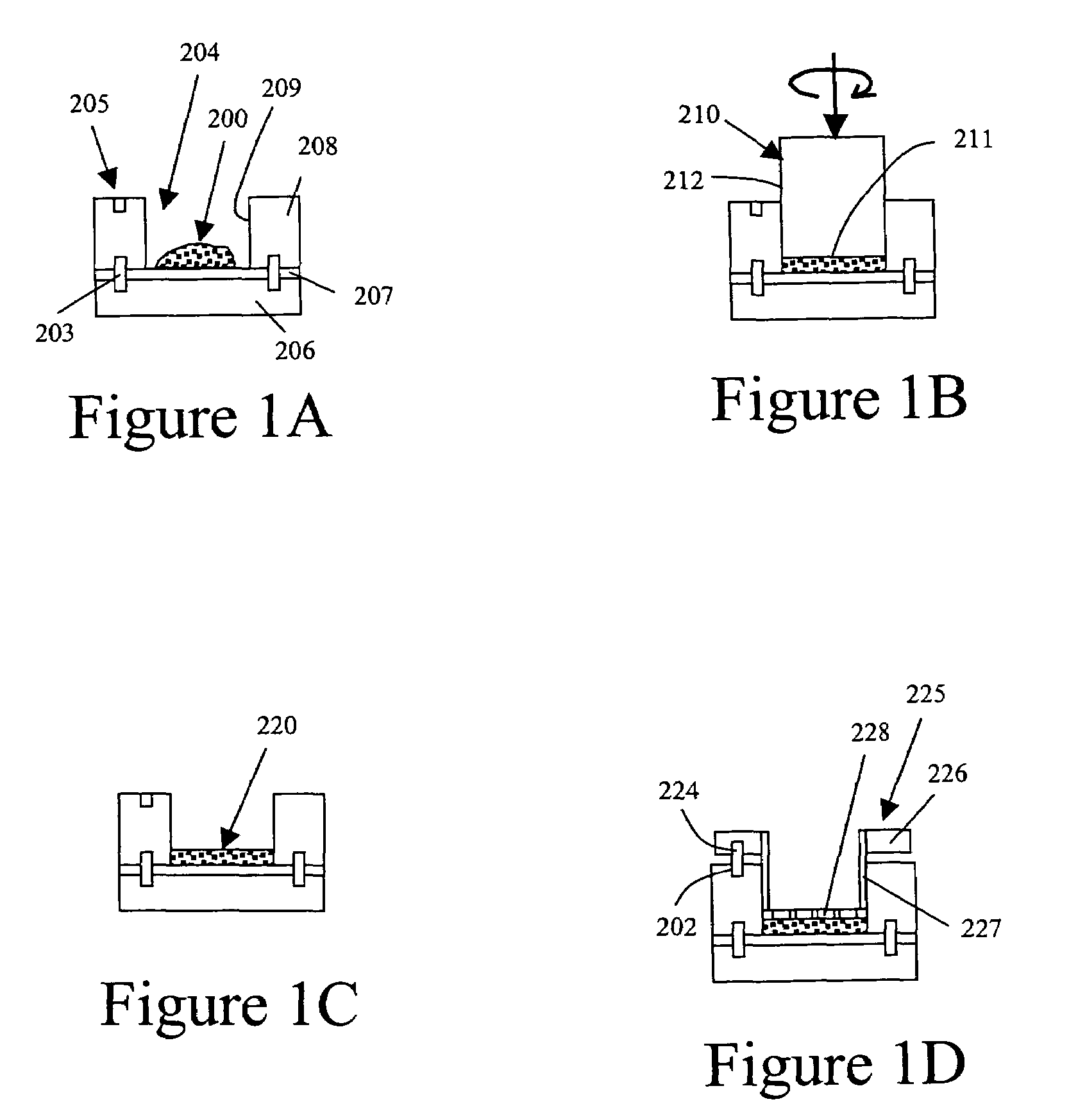

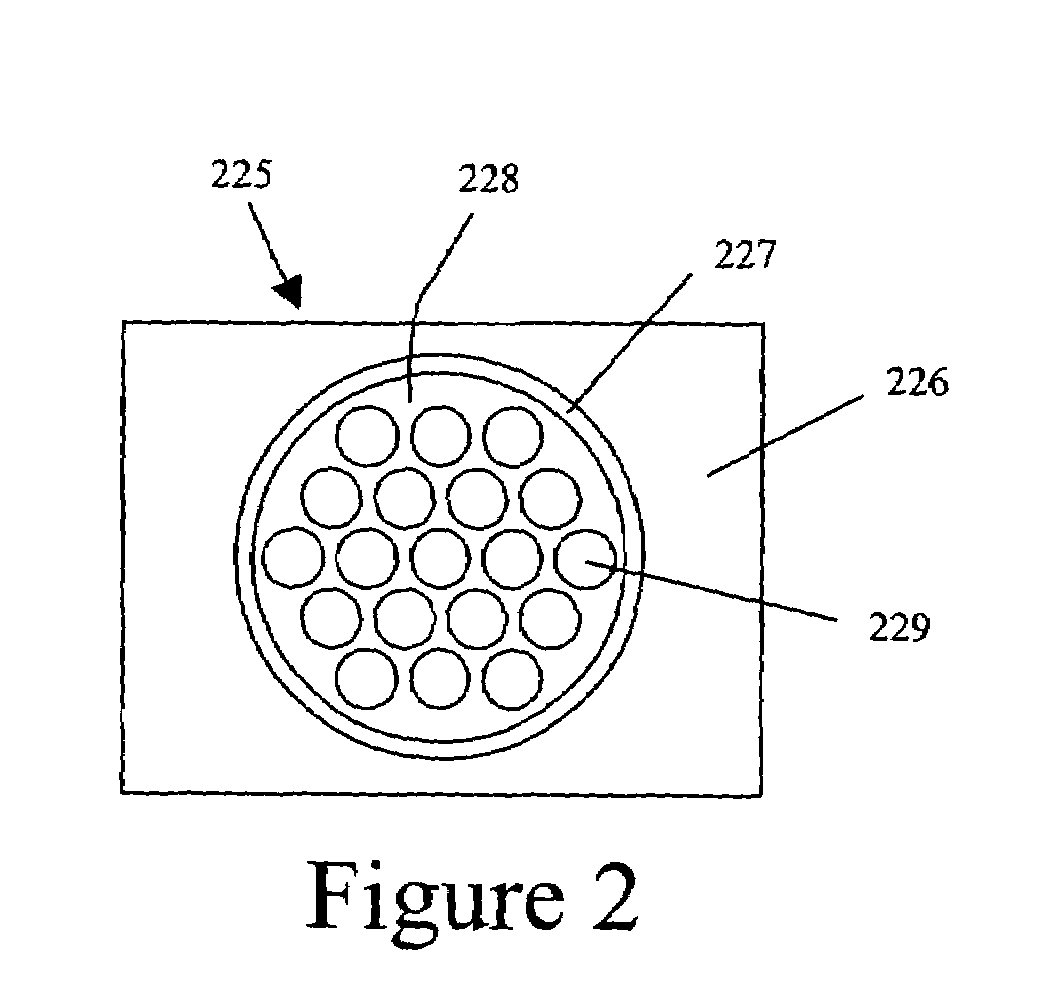

Apparatus for alternately sifting and blending powders in the same operation

ActiveUS8827545B2Efficiently siftingEfficient blendingSievingRotating receptacle mixersMechanical engineeringStructural engineering

A tumbling container is mounted for rotation with a curved screen fixedly mounted within the tumbling container. A multiple vane paddle is mounted to a shaft that is rotatably mounted to the tumbling container. The paddle vanes are formed with angular edges. As the tumbler rotates and the paddle rotates, powder is repeatedly dropped onto the screen to be sifted with the aid of the paddle. Rotating the tumbler further drops unsifted portions of the powder from the screen to mix with additional powder in the tumbler body. Thus, sifting and blending of powders is accomplished in one single operation. The invention utilizes an apparatus having a multiple section screen and a multiple section paddle to enable assembly through the openings in the tumbling container. The screen of a second embodiment has a cowl adjacent to each screen opening to optimize powder lump disintegration.

Owner:KALIDINDI SANYASI R

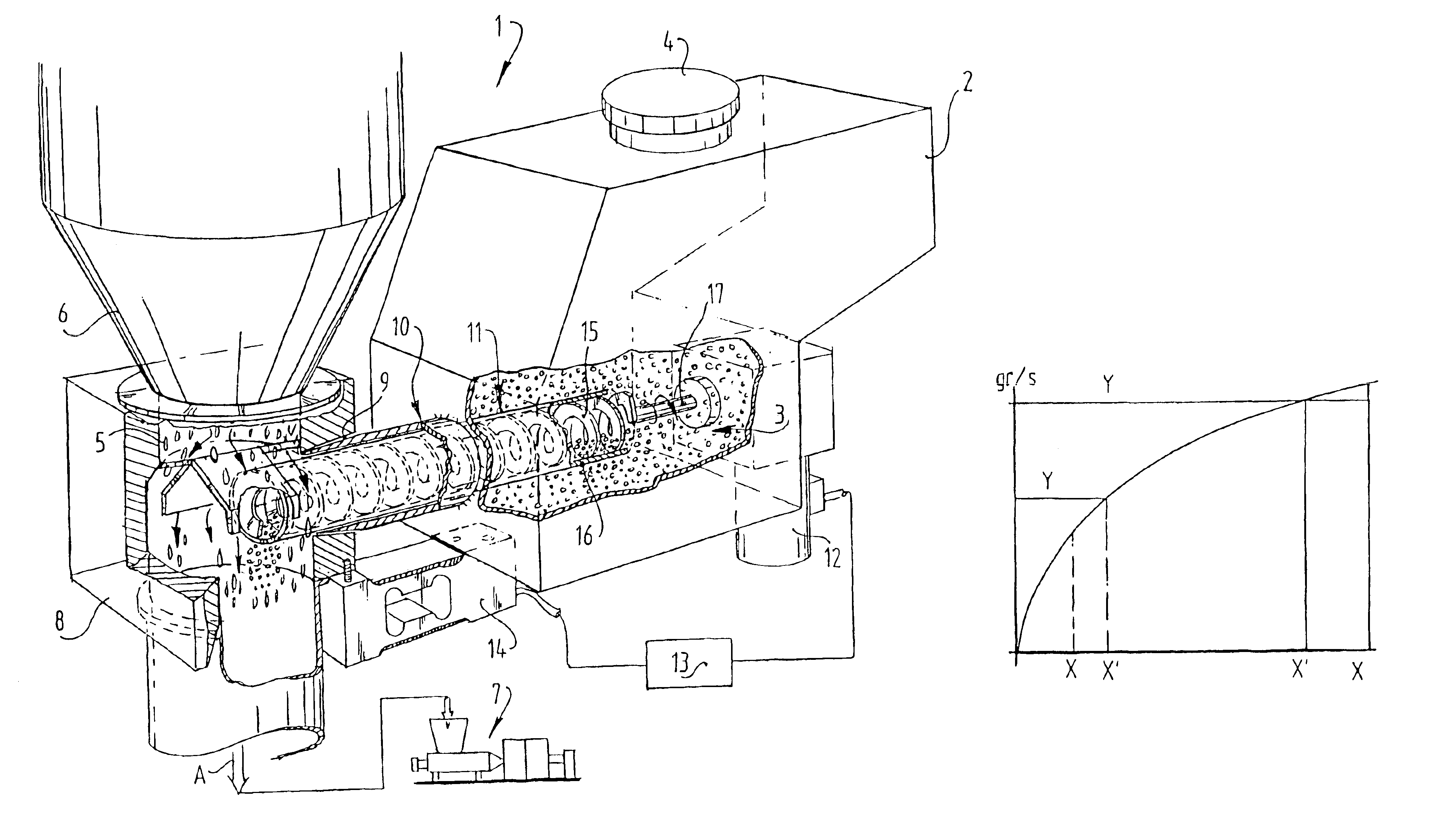

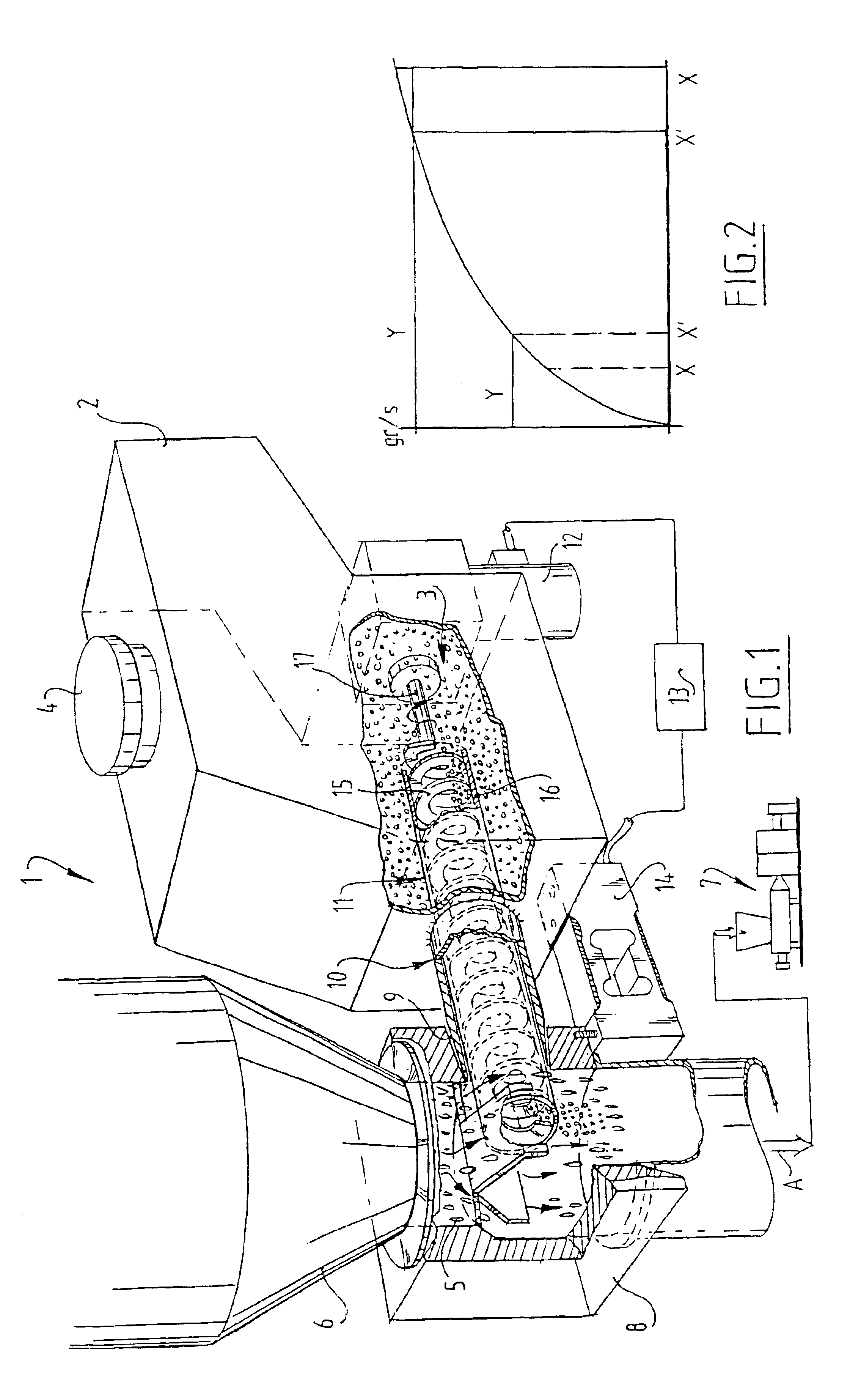

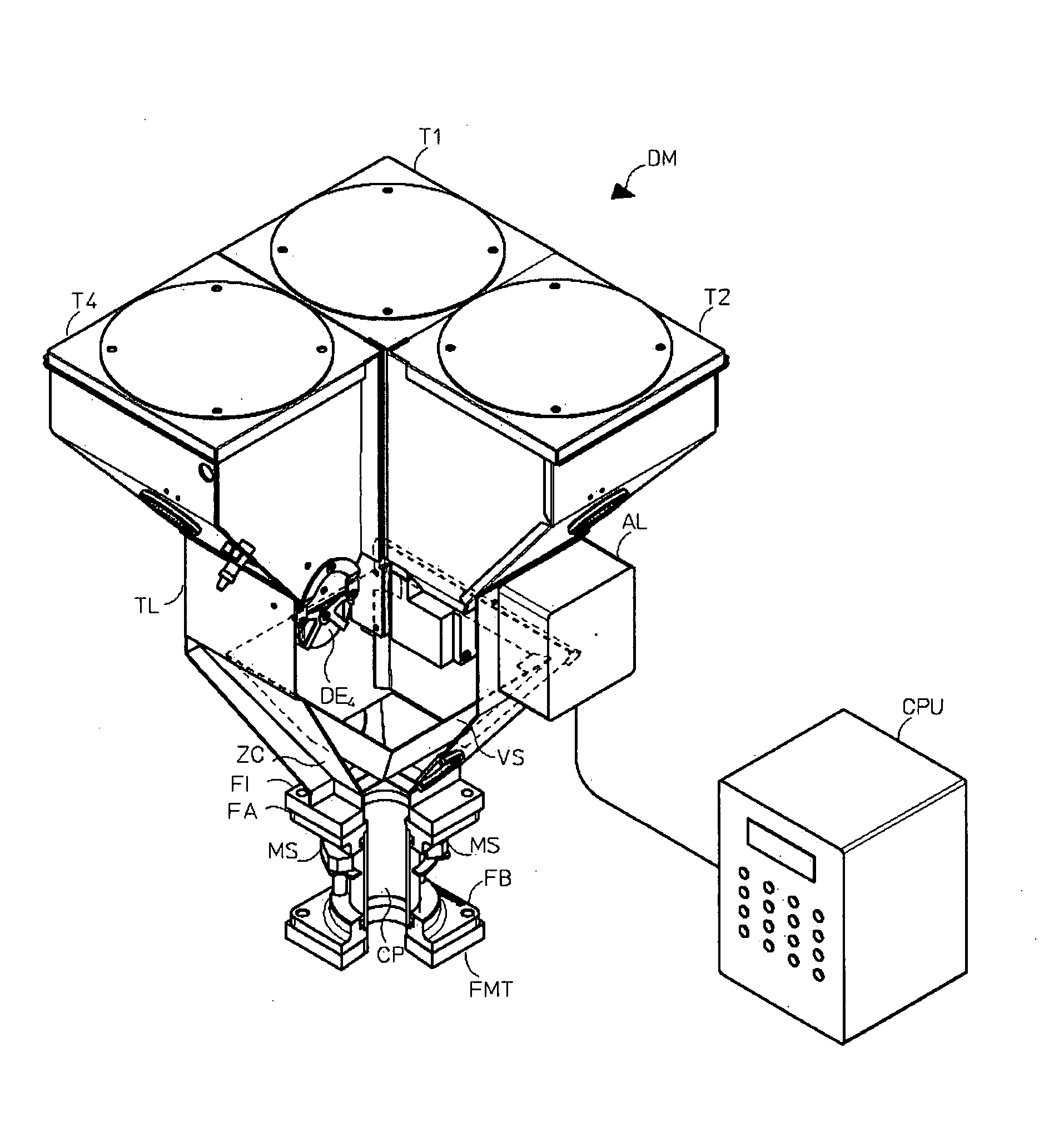

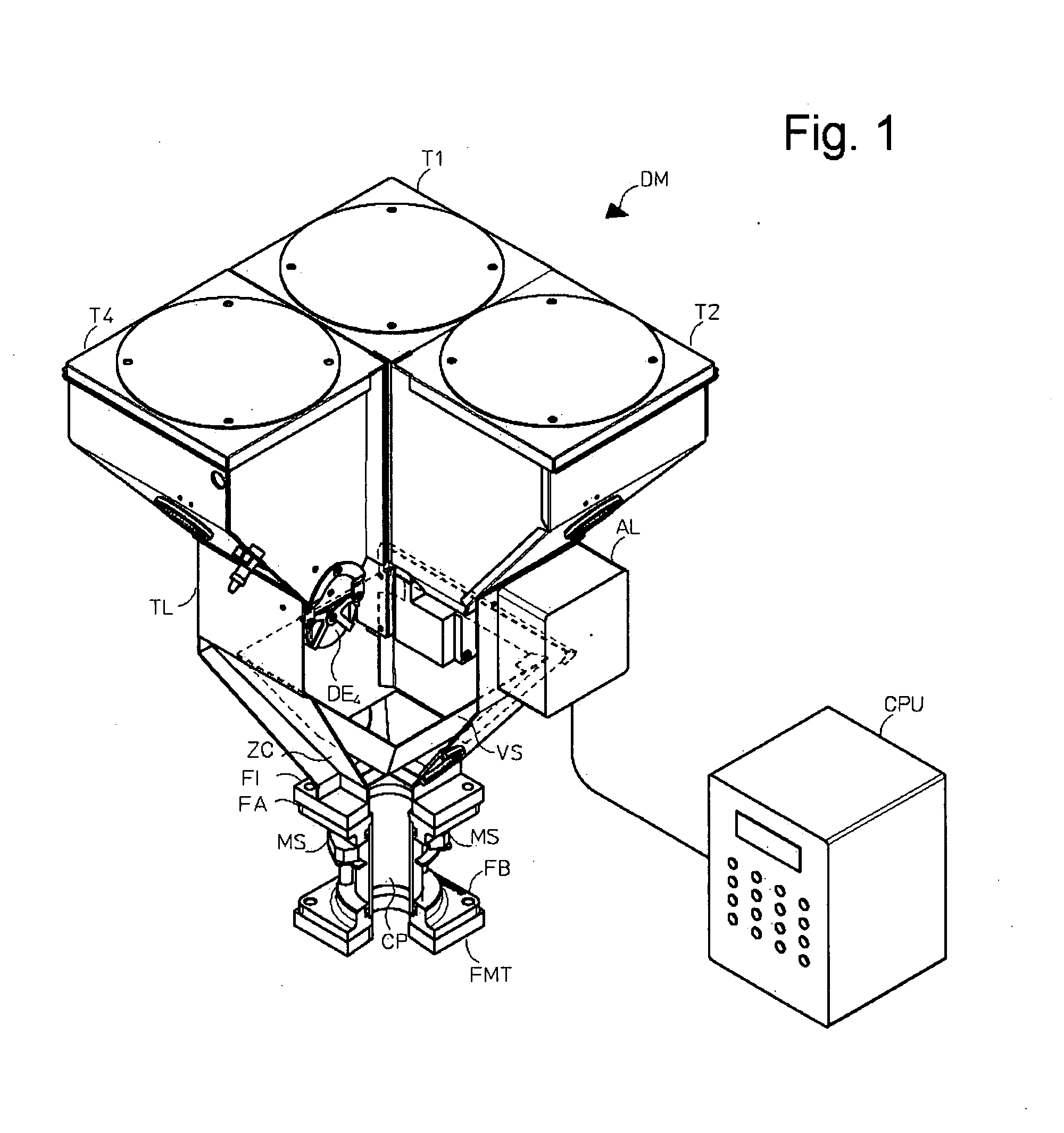

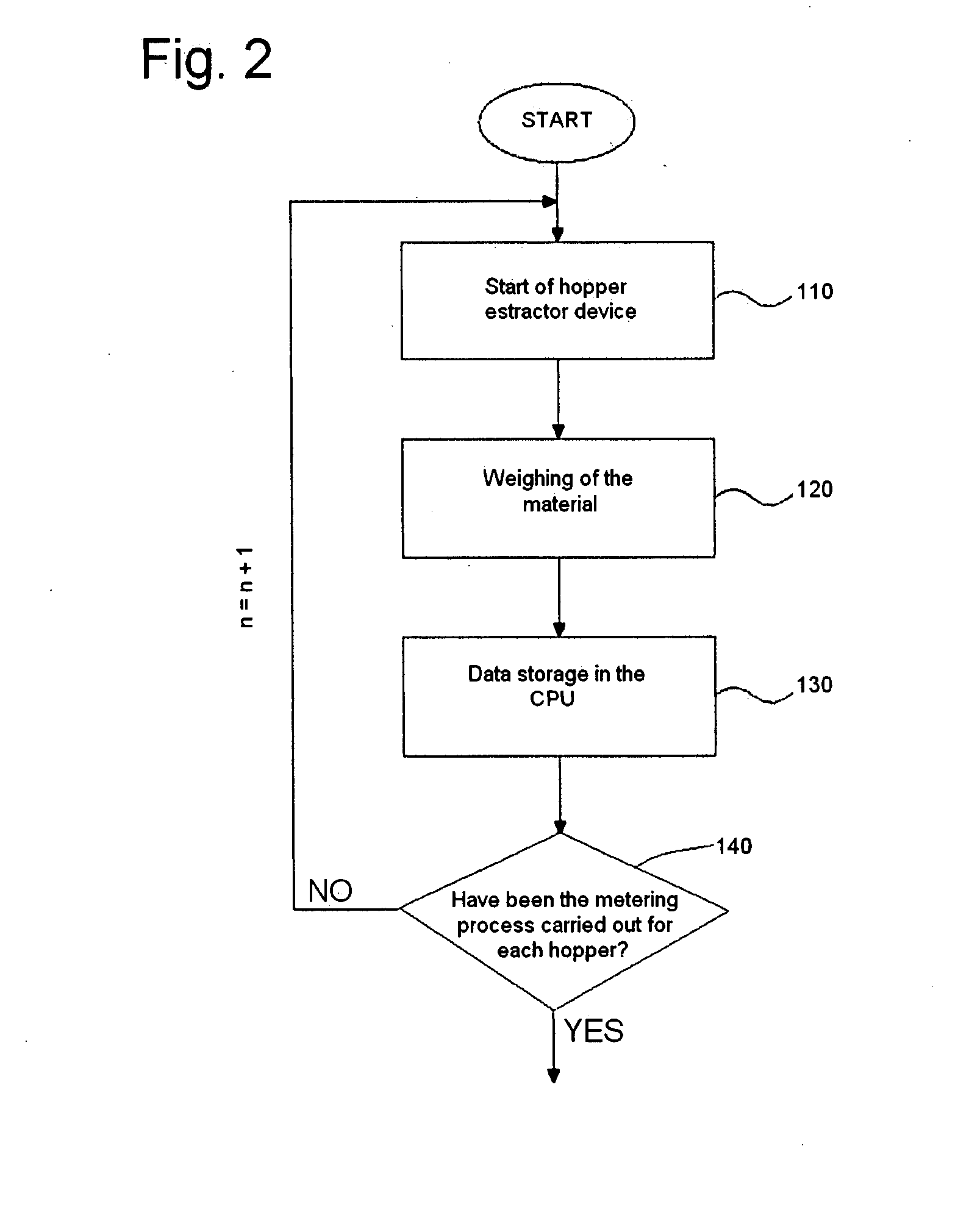

Process and device for processing granular material mixtures

InactiveUS20090039106A1Competitive production costLow percentageTesting/calibration apparatusPower operated devicesControl signalEngineering

The present invention relates to a metering process of a number of granular materials comprising the steps of:a) initial calibration of a multiple metering device (DM) including the steps of:loading a number of granular materials to be metered into respective hoppers or silos (T1, T2, . . . , Tn), each equipped with a respective extractor device (DE1, DE2, . . . , DEn) making up part of the multiple metering device (DM);separately driving each of the extractor devices (DE1, DE2, . . . , DEn), each associated with a respective hopper (T1, T2, . . . , Tn), whereby carrying out a pre-established number of opening-closing steps in the time unit thereby obtaining a corresponding amount of extracted granular material;weighing the amount of granular material extracted by each extractor device (DE1, DE2, . . . , DEn);inserting weight data for each granular material to be metered into a program control unit (CPU) for the calculation of the opening-closing period (P1, P2, . . . , Pn) of each extractor device (DE1, DE2, . . . , DEn) based on desired percentages of each granular material to be metered, for the obtainment of a final mixture with desired composition; and subsequentlyb) cyclic execution of the following sequential steps:sending control signals processed by the program control unit (CPU) as a function of said periods of extractor opening-closing (DE1, DE2, . . . , DEn ) for the extraction of an metered amount of the respective granular material to be treated by at least two extractor devices (DE1, DE2, . . . , DEn);collecting, in a holding container (CP), the metered amounts of each granular material thus extracted; anddetecting, by means of sensor means (MS), a pre-established filling threshold of the holding container (CP) thereby stopping the at least two extractor devices (DE1, DE2, . . . , DEn) upon attainment of the pre-established filling threshold.

Owner:MORETTO SPA

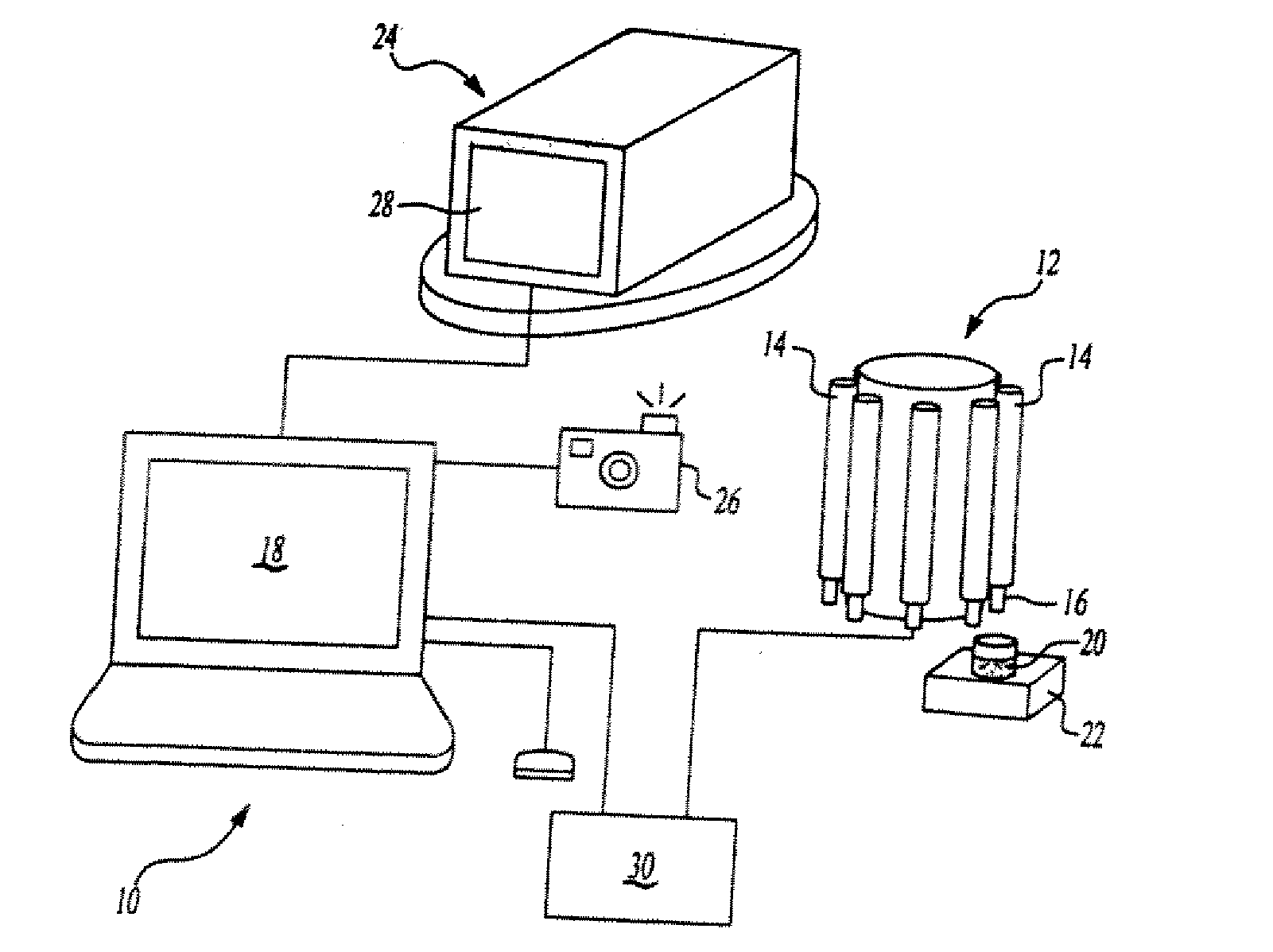

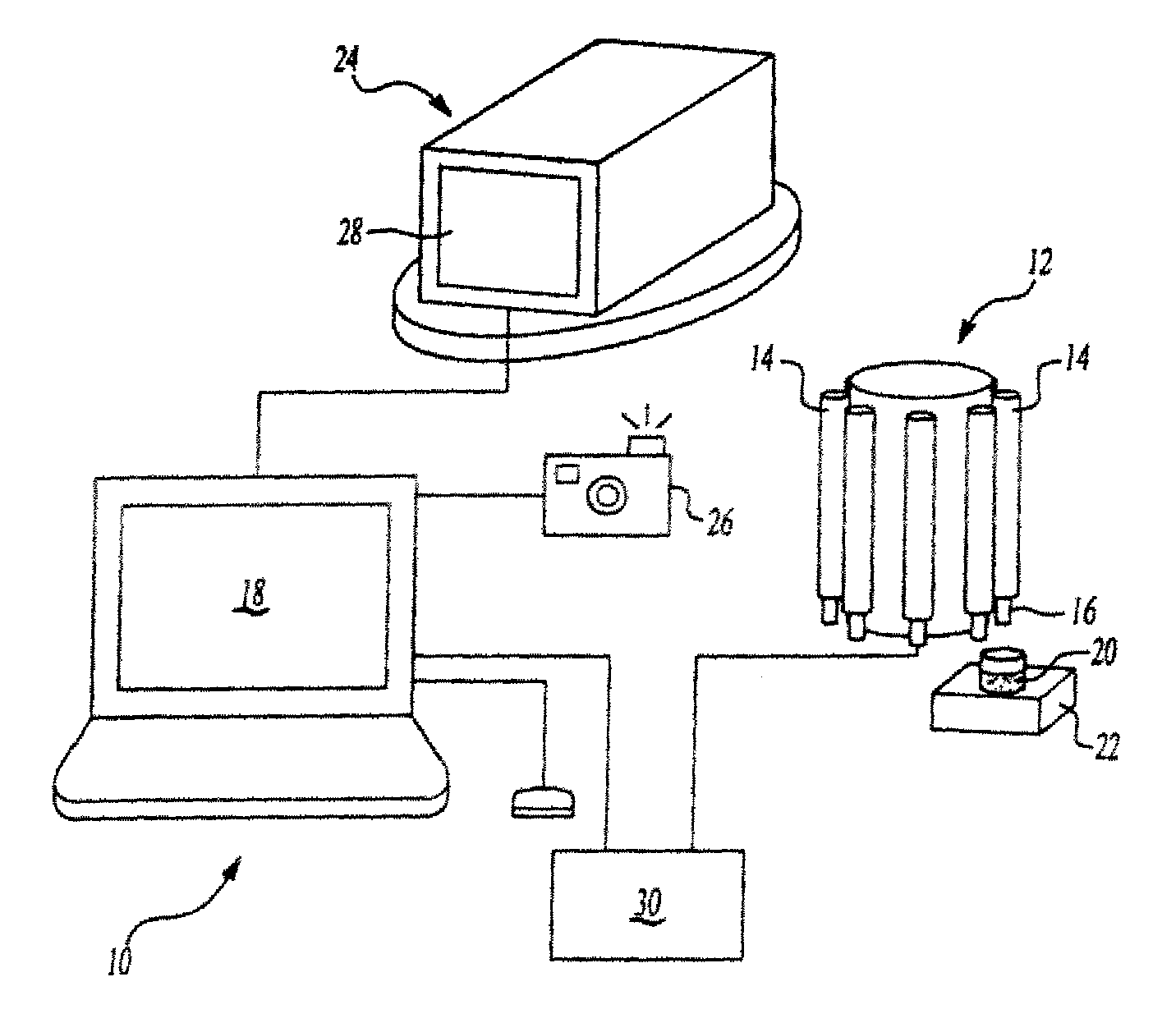

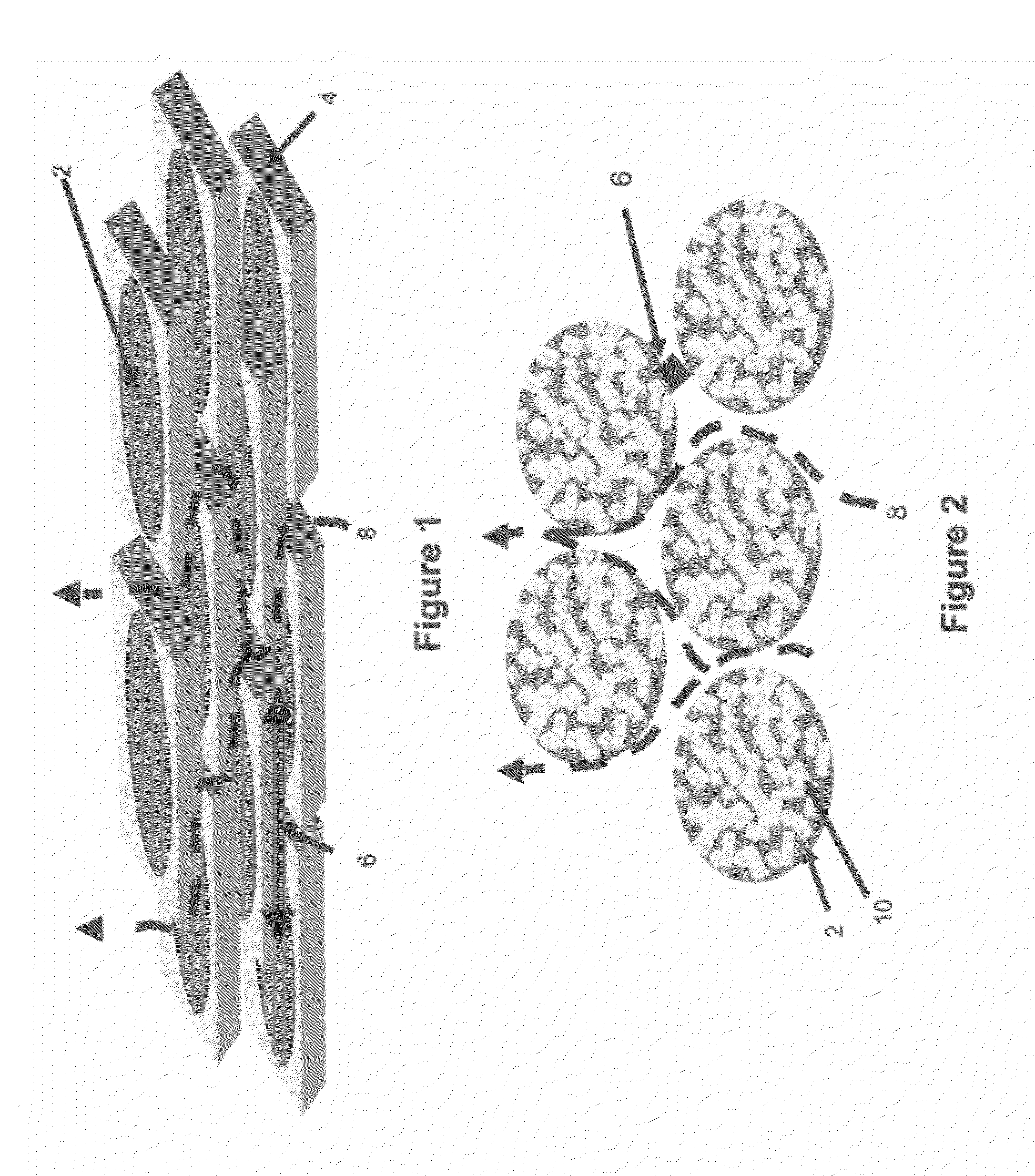

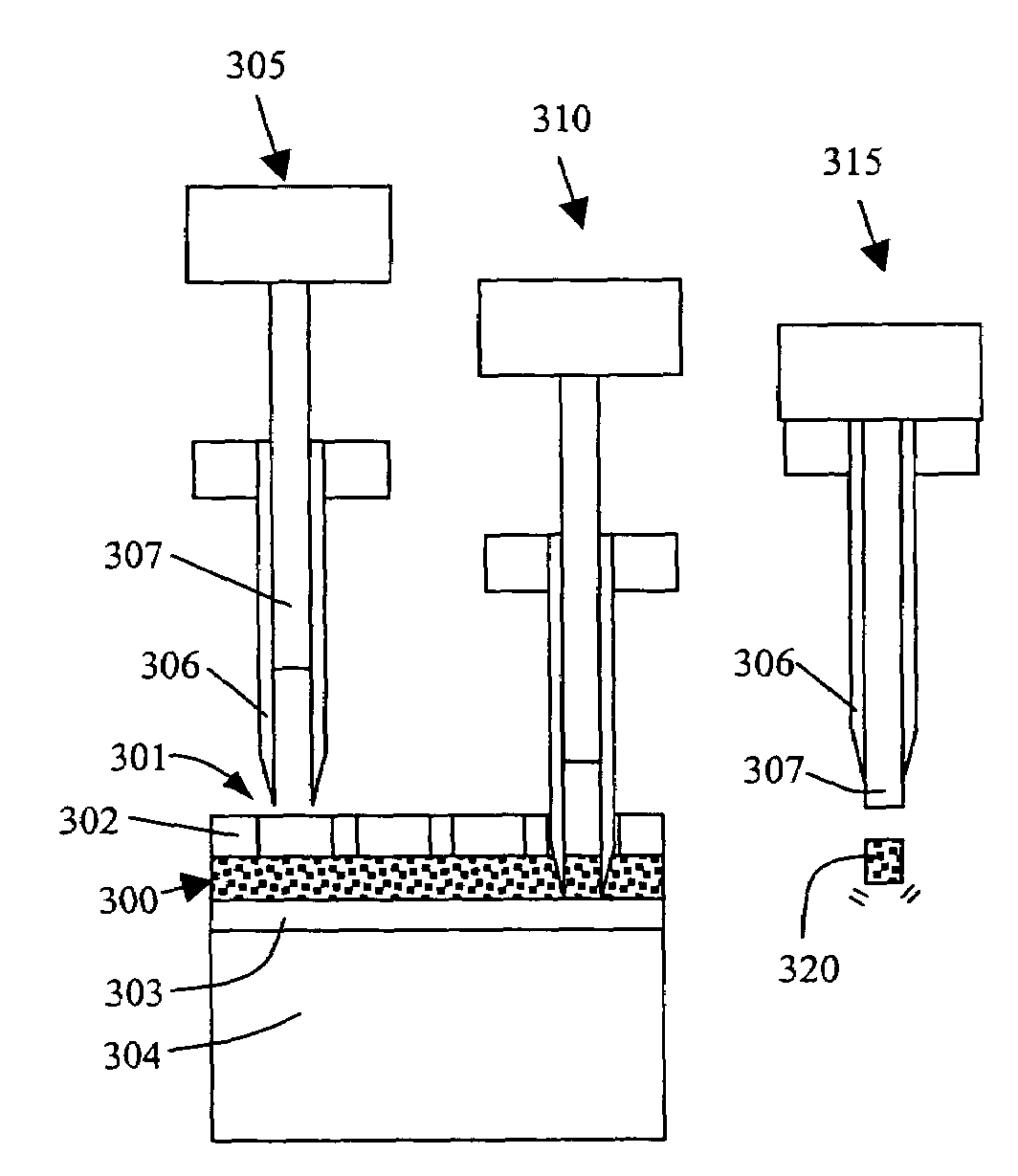

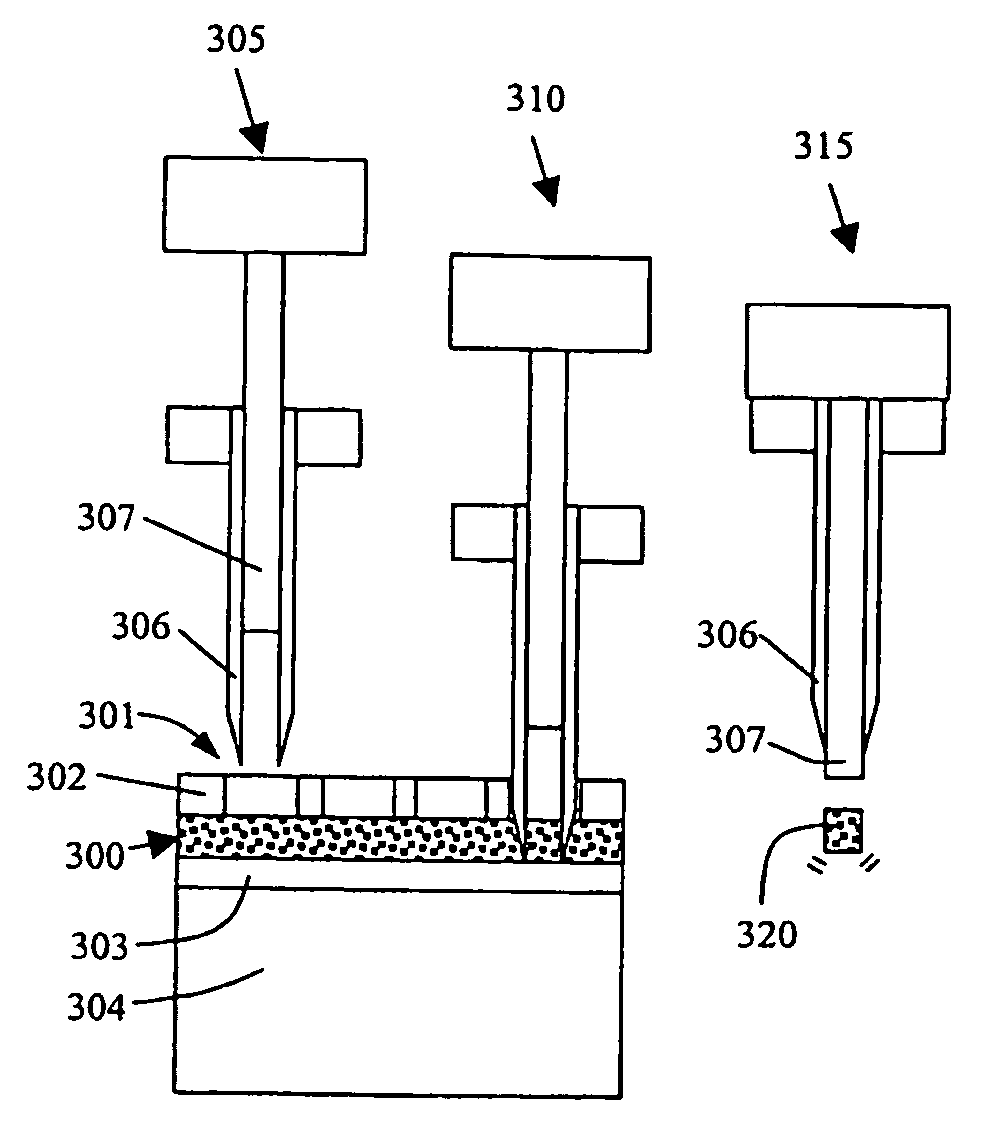

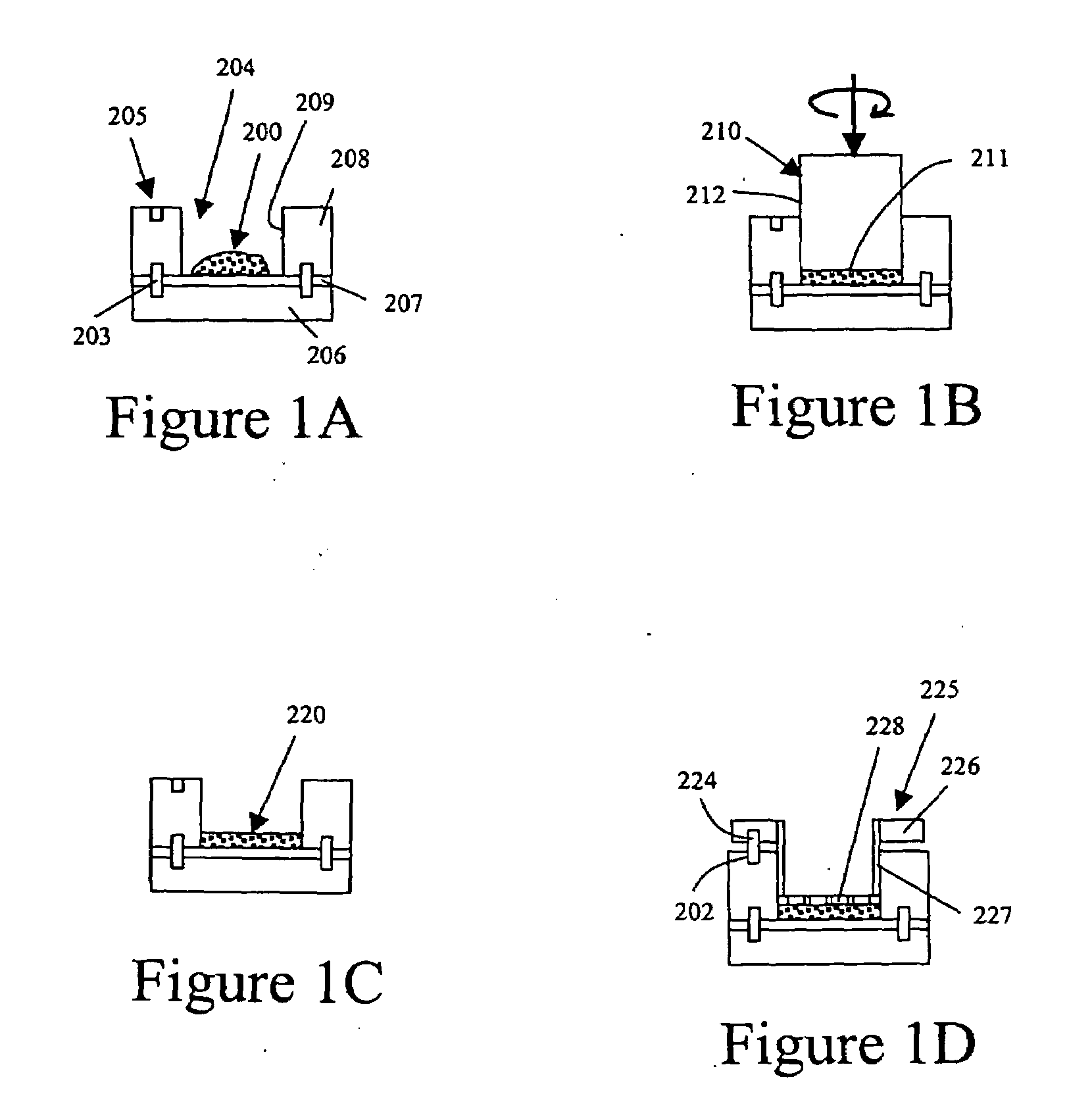

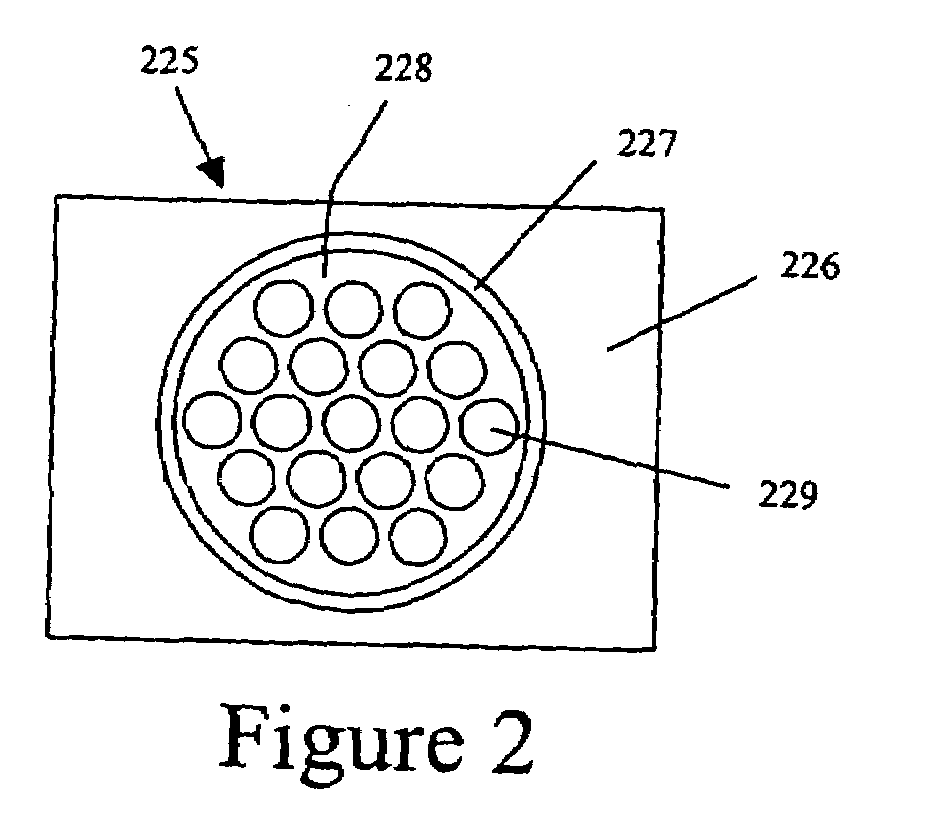

Methods of manipulating small amounts of solids

The invention relates to methods and apparatuses for manipulating small amounts of solids. Specific embodiments of the invention are particularly suited for the automated transfer of small amounts of solids. In one embodiment, a uniform powder bed is lightly compressed into plugs of powder and dispensed. In another embodiment, the solid is placed in a liquid carrier to form a slurry, dispensed, and the liquid component is subsequently removed. In yet another embodiment, solids are manipulated using adhesive surfaces.

Owner:TRANSFORM PHARMACEUTICALS INC

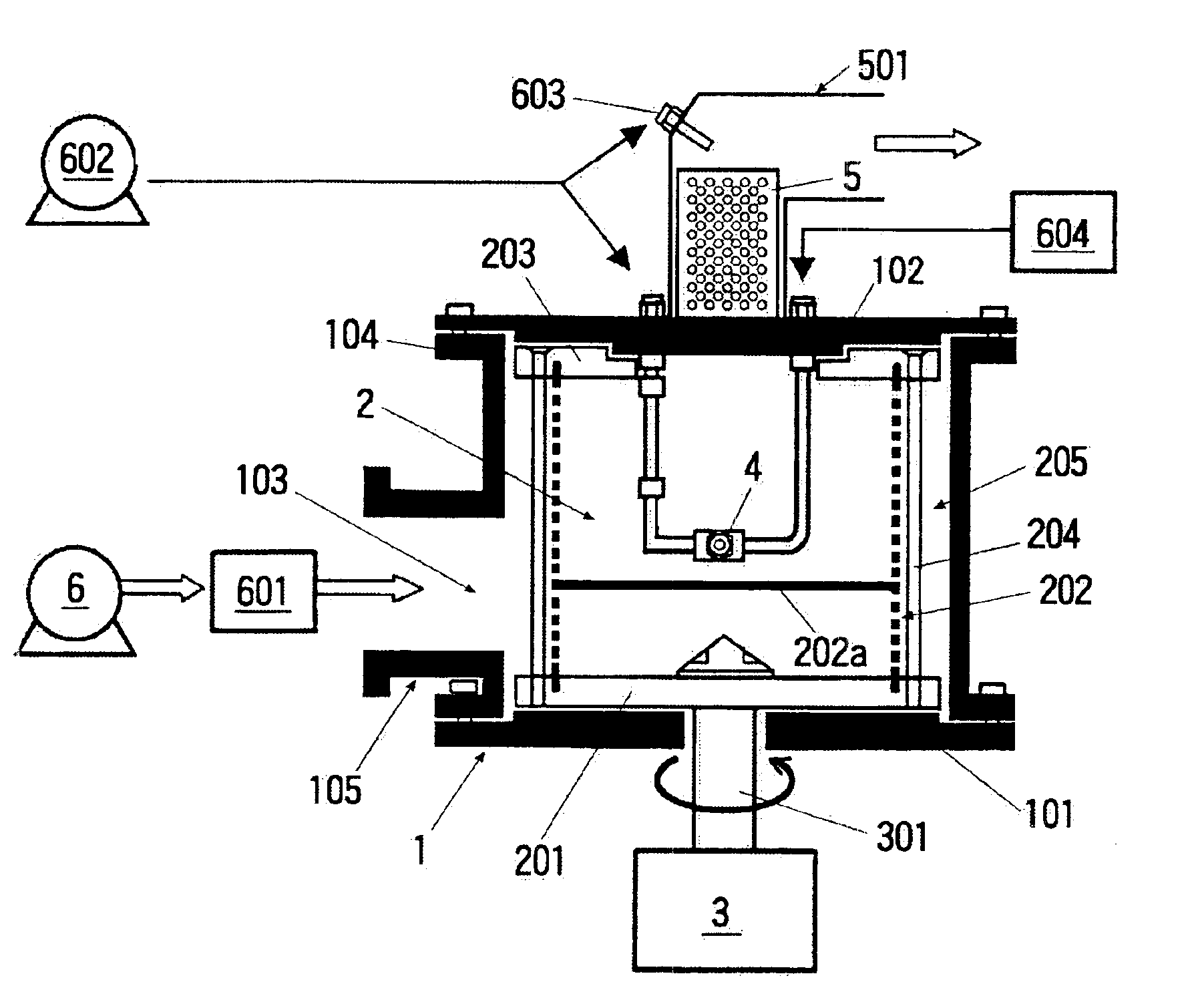

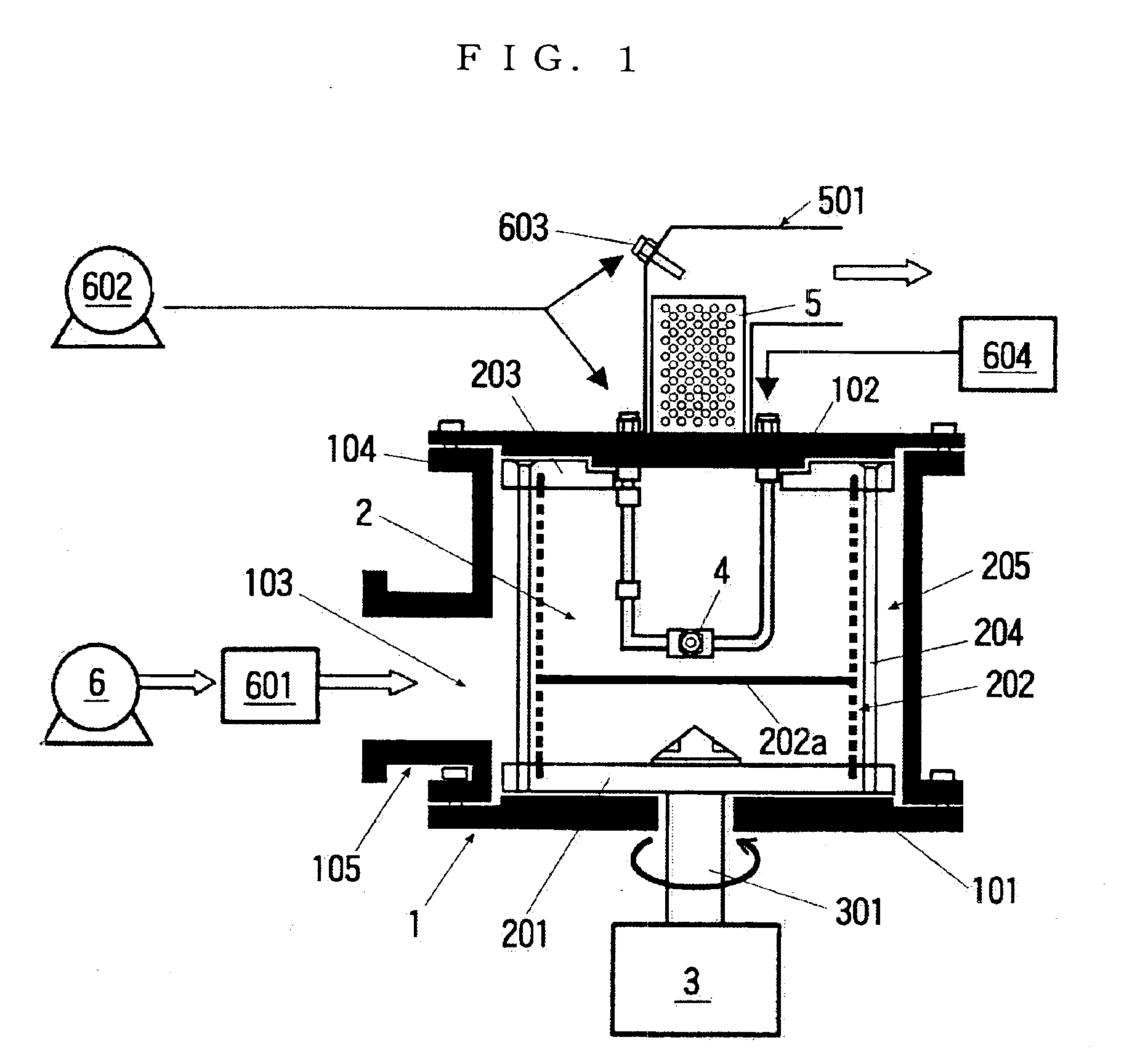

Device for treating powder particles by rotary flow

InactiveUS6892475B2Efficient dischargeEasy to operate and controlRotating receptacle mixersDrying solid materials with heatFluidized bedDischarge rate

The present invention relates to a rotating fluidized bed apparatus for powder particle. A gas circulation path is formed at the periphery of the treatment chamber 2 via the circumferential faceplate 202, 212, and the circumferential faceplate is adapted to rotate around an axis. Behavior of powder particles can be controlled by introducing gas from the periphery of the treatment chamber via the circumferential plate 212 to exert centripetal force on the powder particle, while exerting centrifugal force on the powder particles accompanying rotation of the circumferential plate 212. In another aspect, by making the arrangement proportion of the bag filter 5 inside the treatment chamber 2 wider than the surface width of the dispersion plate 212 or larger than the surface area of the dispersion plate 212, it is possible to cause gas that has flowed into the treatment chamber 2 to be discharged at a lower rate at an axial region inside the treatment chamber 2 where centrifugal force is weak and discharge rate is fast. It is possible to carry out optimal operation control of introduction and discharge of gas for fluidized bed behavior.

Owner:NARA MACHINERY

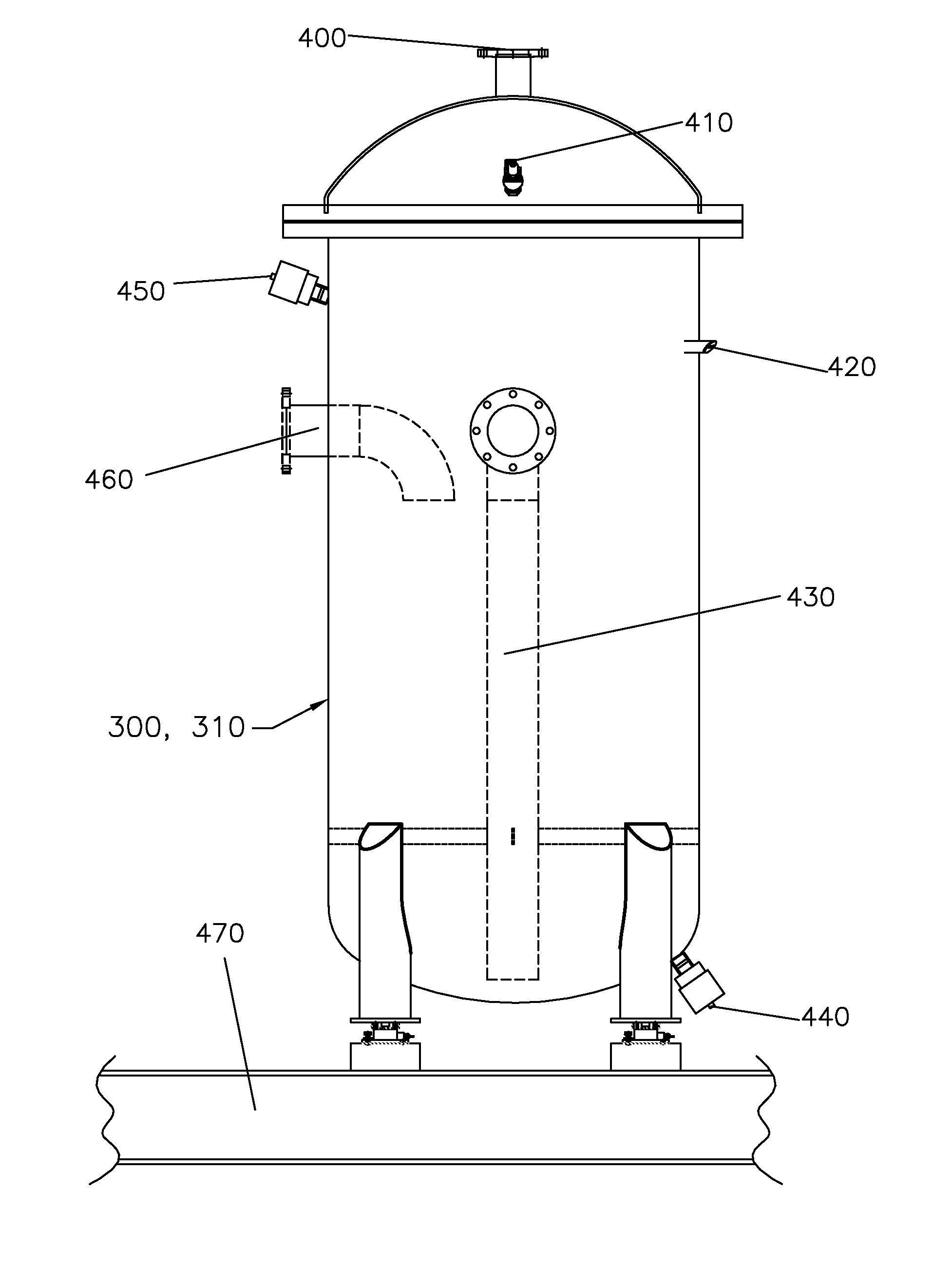

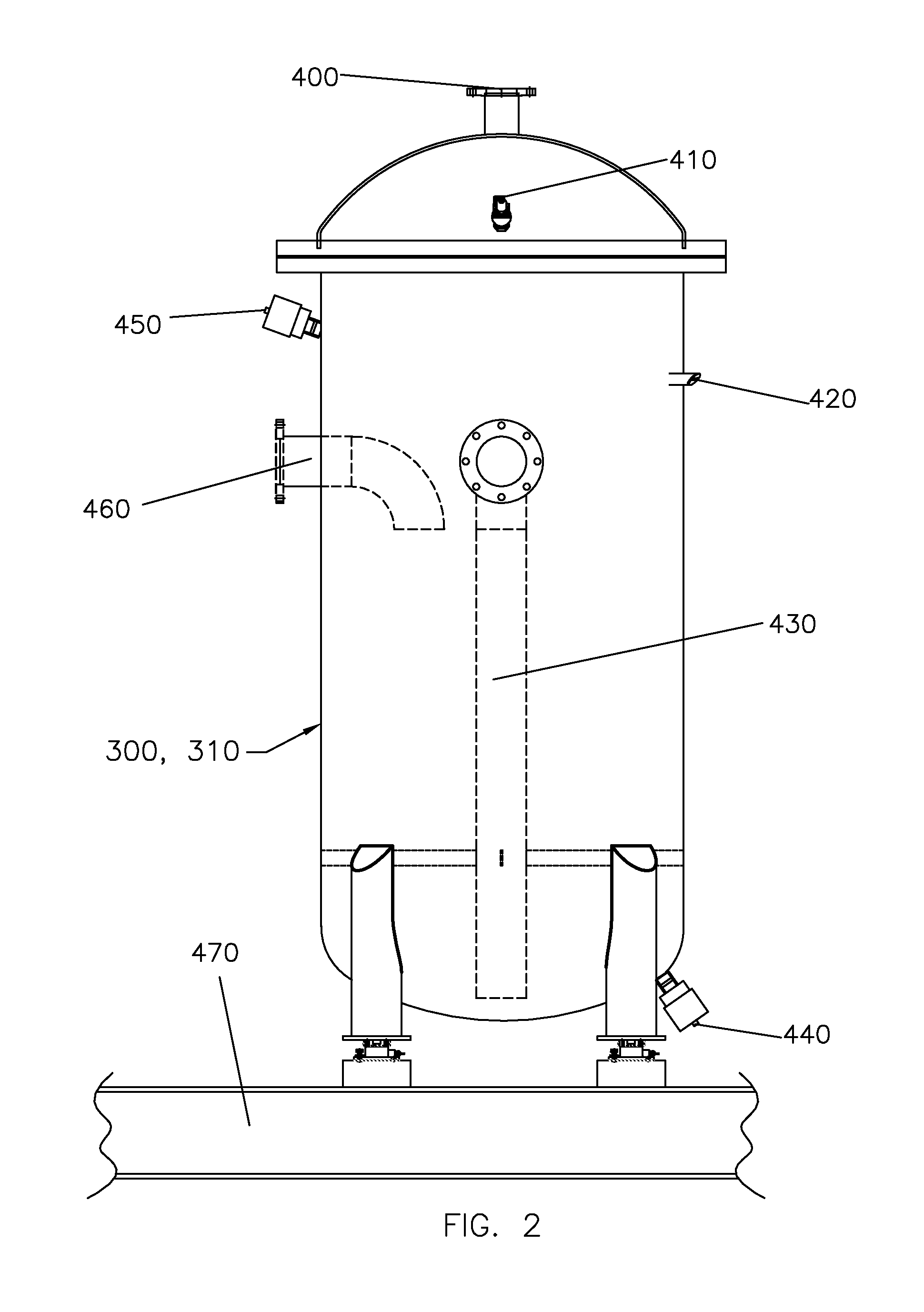

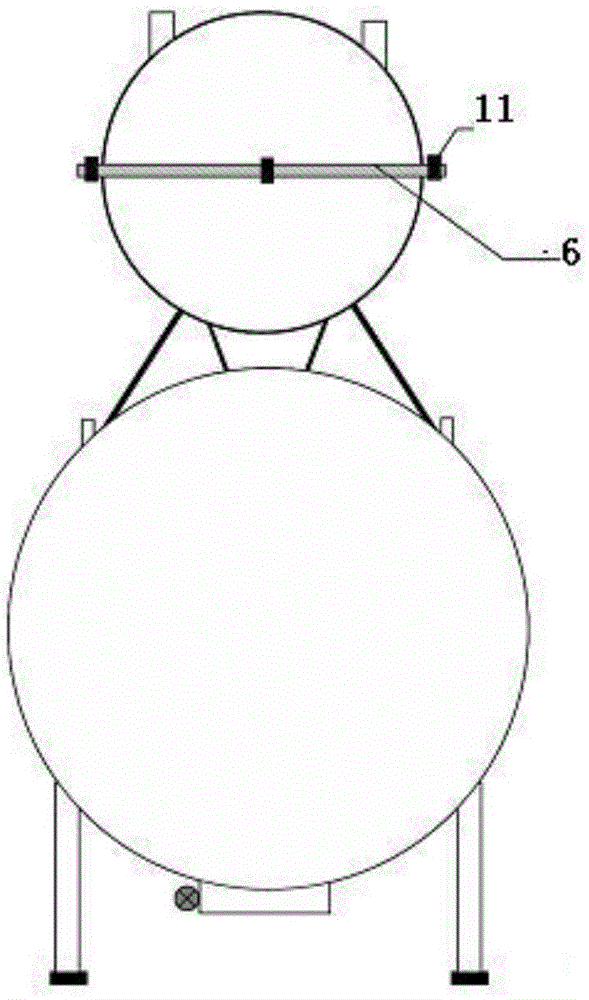

Accurate Dry Bulk Handling System and Method of Use

InactiveUS20140030031A1Minimal of effortMinimal of spaceFlow mixersMixer accessoriesSodium BentoniteFluidized bed

Rapid evacuation and deployment of dry materials is achieved by the dual structure of this device and the method of using it to fill and empty vacuum reloading tanks automatically. This permits materials such a bentonite, barite or cement to be handled easily and without dust on a rig floor and mixed appropriately as needed for well control and completion operations. Dry bulk material is offloaded from an offshore supply vessel into atmospheric tanks, which provide fluidized bed systems to aerate and agitate and move material through piping into the vacuum re-loader tanks. The dual re-loader tank system allows one tank to be emptied while another fills thereby providing sufficient flexibility to expertly manage receiving, storage, transfer, filtration and control of the bulk material on various space-critical platforms, including offshore rigs and service vessels, that require the handling of dry bulk materials in an accurate and dust-free manner.

Owner:PROVEN TECH INC

System and method of applying carbon dioxide during the production of concrete

ActiveUS20170158569A1Reduce energy consumptionLow costFlow mixersTransportation and packagingMulti materialArchitectural engineering

The present disclosure involves systems and methods for applying CO2 to concrete, which may be performed in-situ or through a separate, stand-alone process. According to another embodiment disclosed herein, a system and method for applying CO2 to one or more materials used in the production of concrete is also provided.

Owner:CARBONCURE TECH

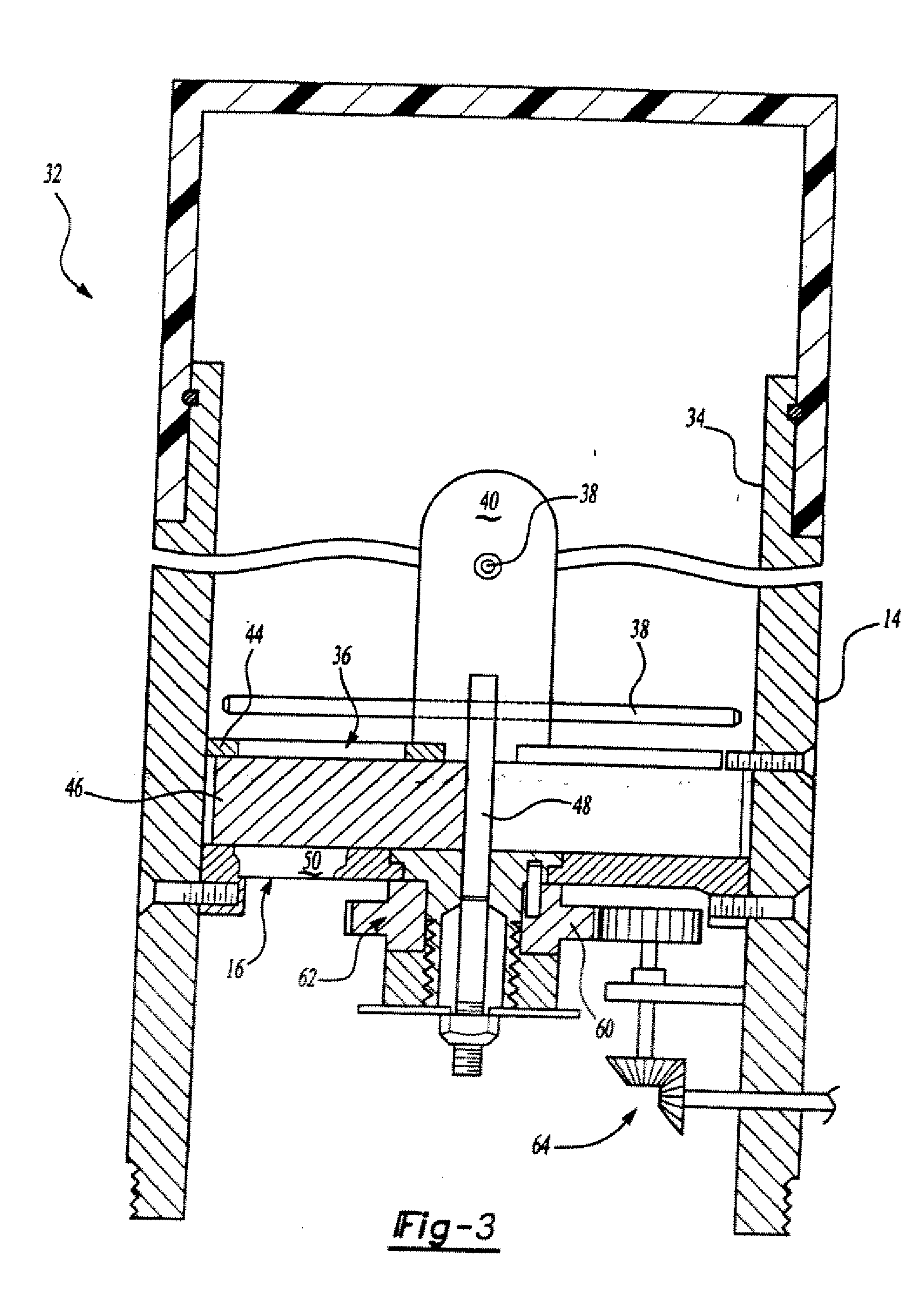

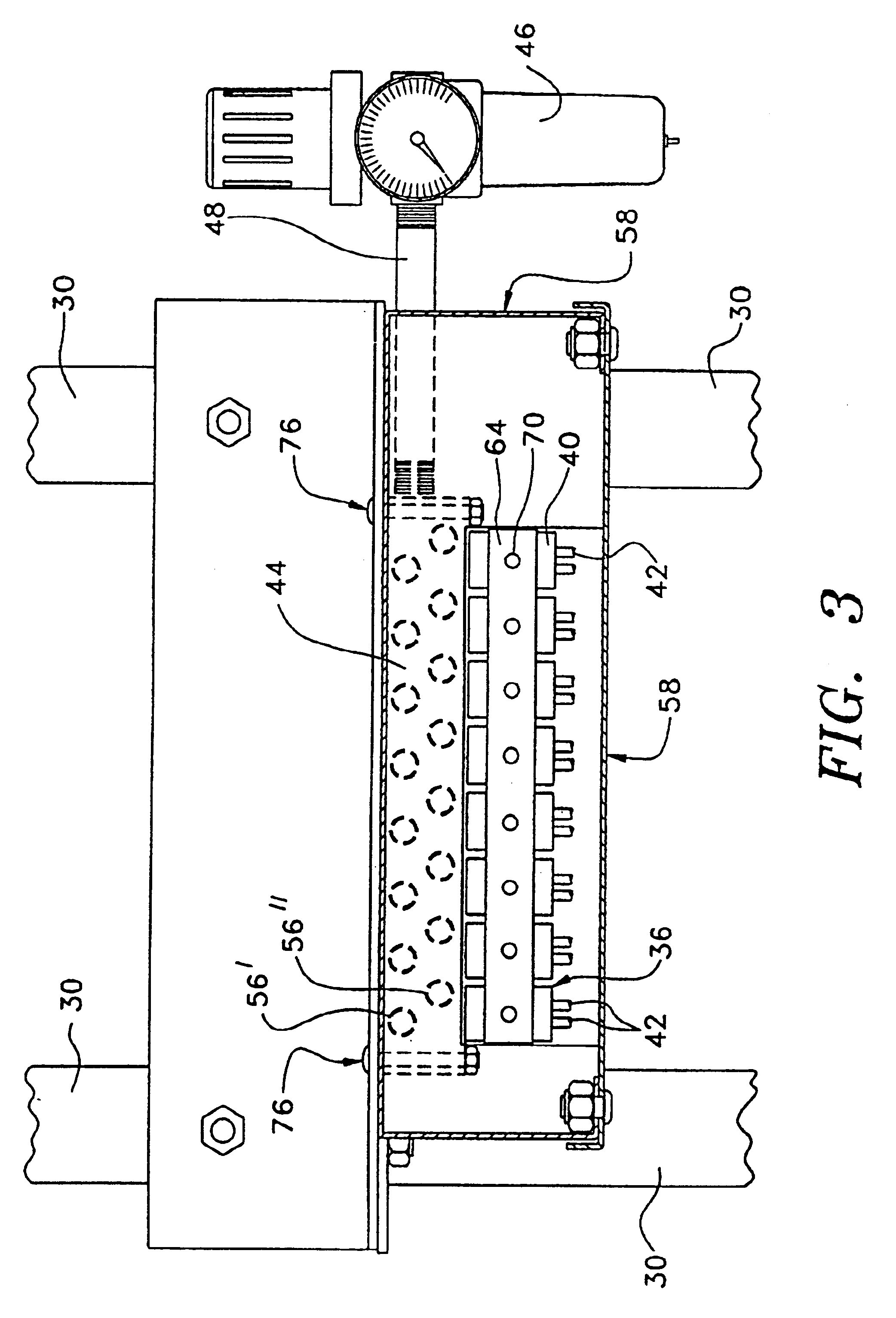

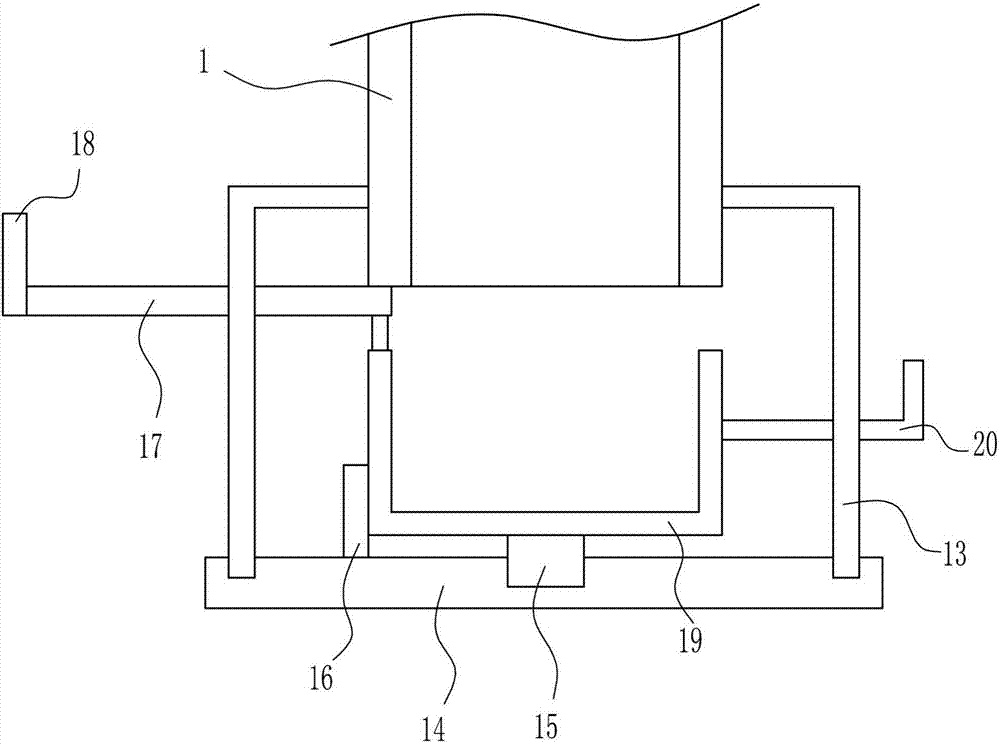

Gravimetric blender with manually removable hoppers having integral interior valves

A valve for downwardly dispensing a precisely controlled flow of granular material from a material storage device has a discharge orifice proximate a lower extremity thereof and includes an axially reciprocable tubular member aligned with and slidable axially upwardly and downwardly within the orifice, having a lateral material intake port formed therein remote from vertical extremities of the member, a lower end member being open to define a discharge orifice for granular material dispensed therby, a chamber at least partially surrounding the tubular member, having an open lower end confronting and spaced above the orifice, the chamber open end affording flow of material from the storage device through the port and into the tubular member when the tubular member is at a first position below the open end, the port being spaced upwardly from the open end when the tubular member is at a second position and a pneumatic piston for moving the tubular member axially between the first and second positions.

Owner:MAGUIRE STEPHEN B

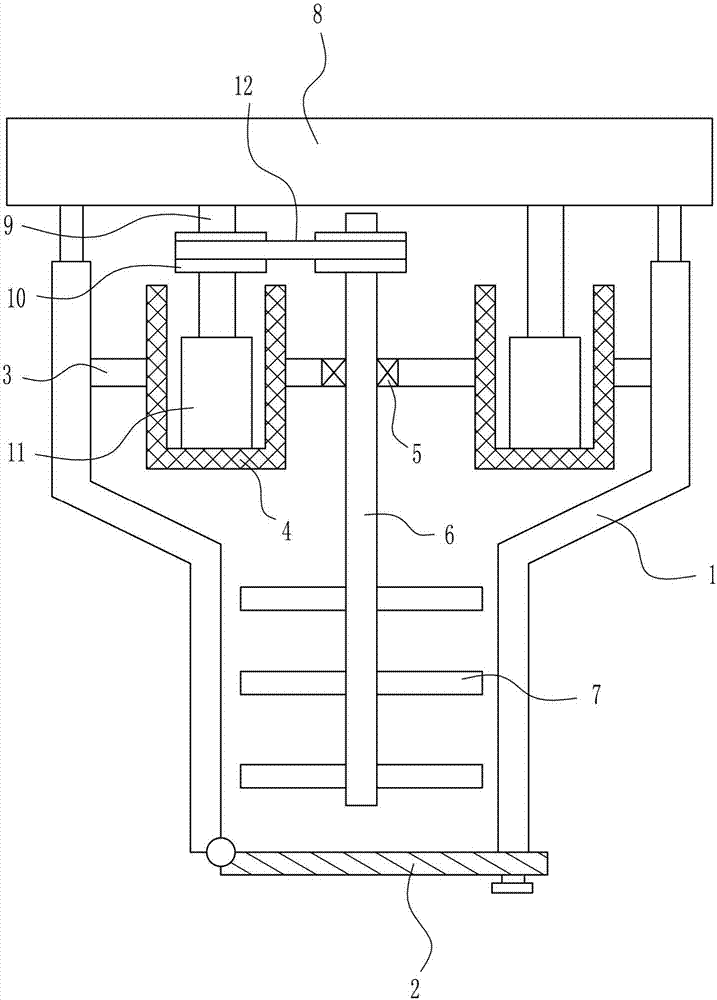

Automatic mixing device for mixed feed additive

ActiveCN105536586AImprove the tightnessQuality improvementFeeding-stuffTransportation and packagingHybrid typeAutomatic control

The invention discloses an automatic mixing device for a mixed feed additive. The automatic mixing device comprises four parts, namely a premixing system, a mixing system, a temperature control system and an automatic control system, wherein the premixing system comprises a premixing bin body, a main and auxiliary material feeding hole, a mixing blade, an adjustable motor and a fixed sealing flange; the mixing system comprises a mixing bin body, a mixing blade, an adjustable motor and a vibrator; the temperature control system comprises an internally inlet / outlet, a seal sheet and an interlayer; and the automatic control system comprises a relay switch gear, a connecting circuit and an automatic control board. The automatic mixing device has the characteristics of high automation, convenience in use, high main / auxiliary material mixing strength and obviously improved mixing degree, is high in device sealing degree, is capable of lowering the pollution rate and the material loss rate, reducing damage to human bodies, decreasing heat produced by machine operation and improving the activity and heat-labile component quality of the mixed feed additive, and is beneficial to quality stability of products in different batches.

Owner:FUJIAN BRADY PHARMA CO LTD

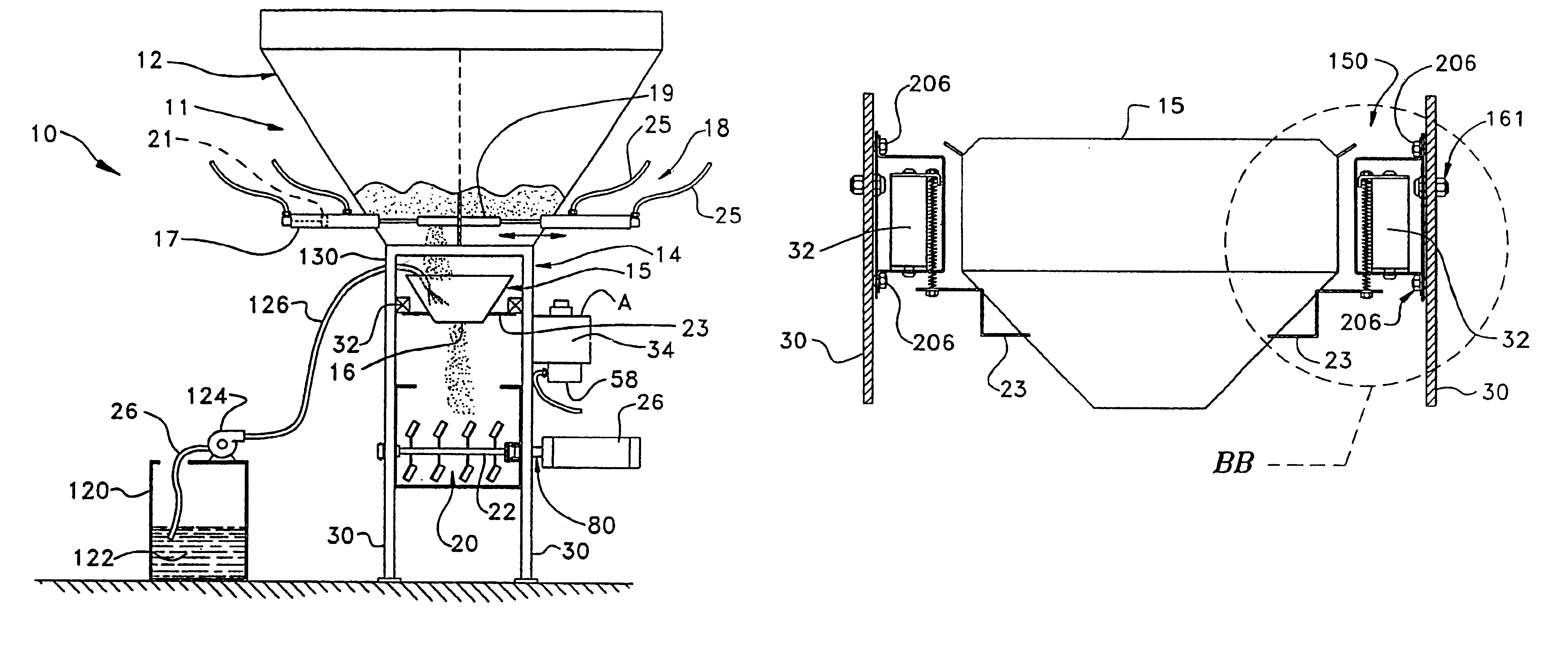

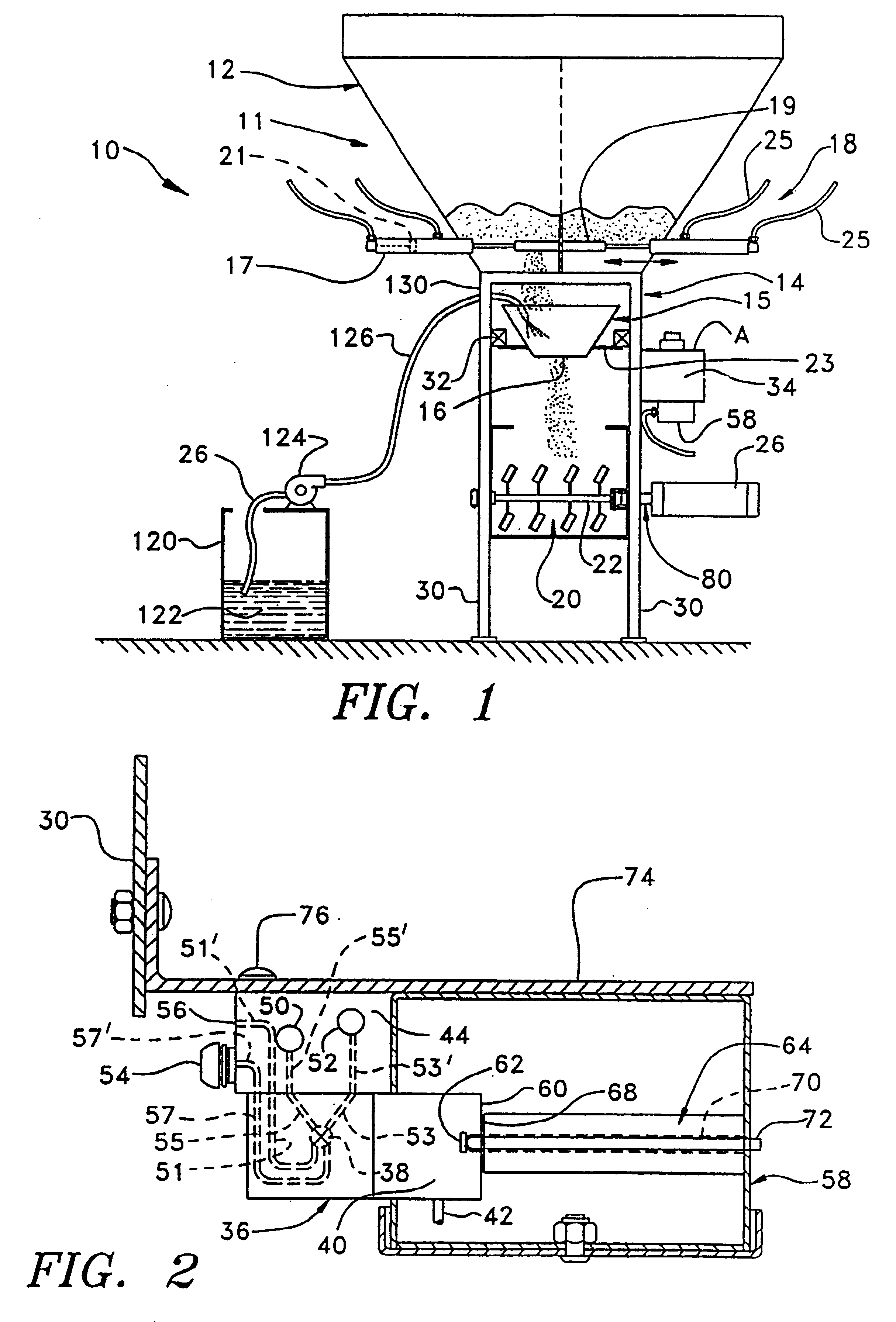

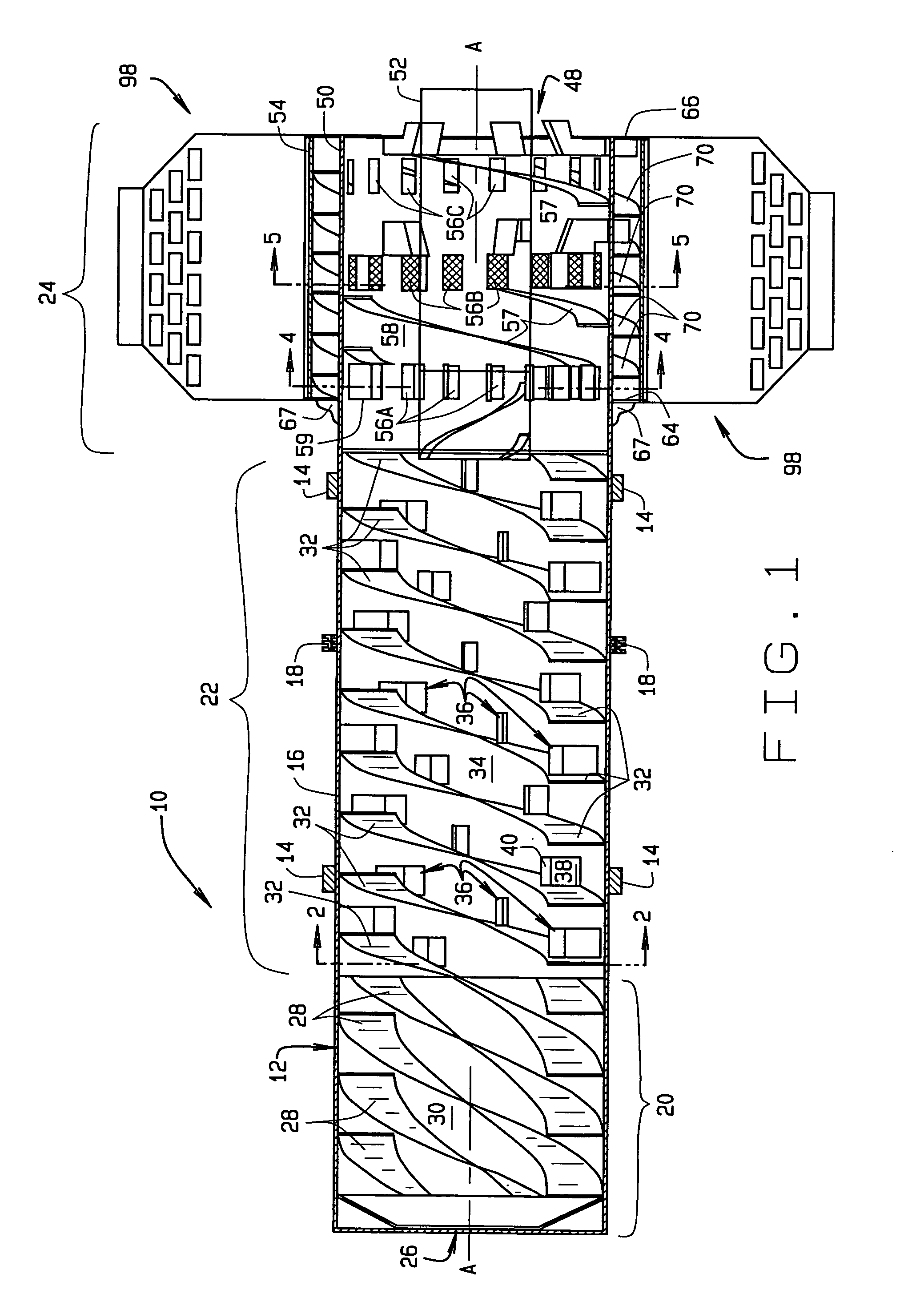

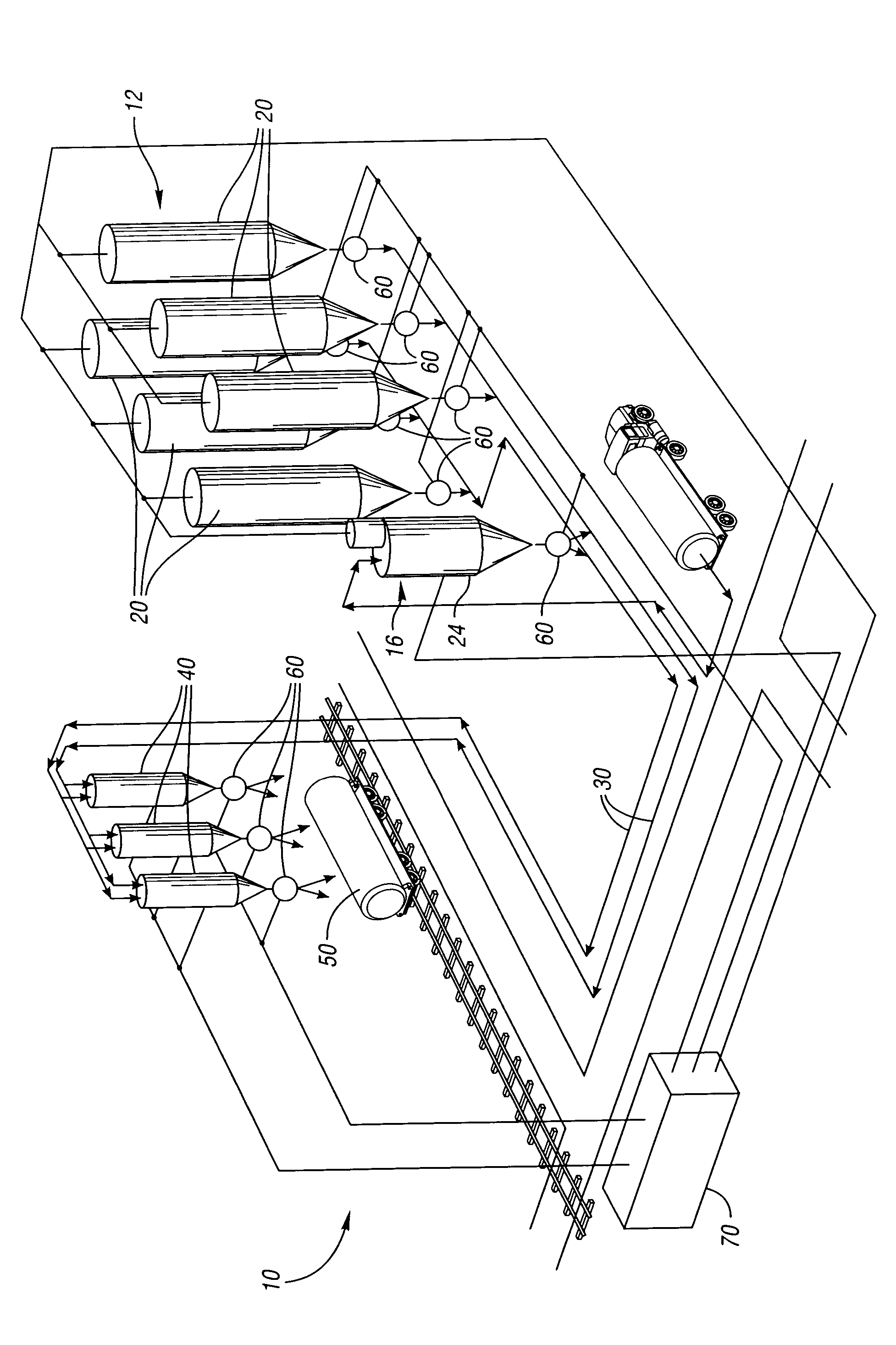

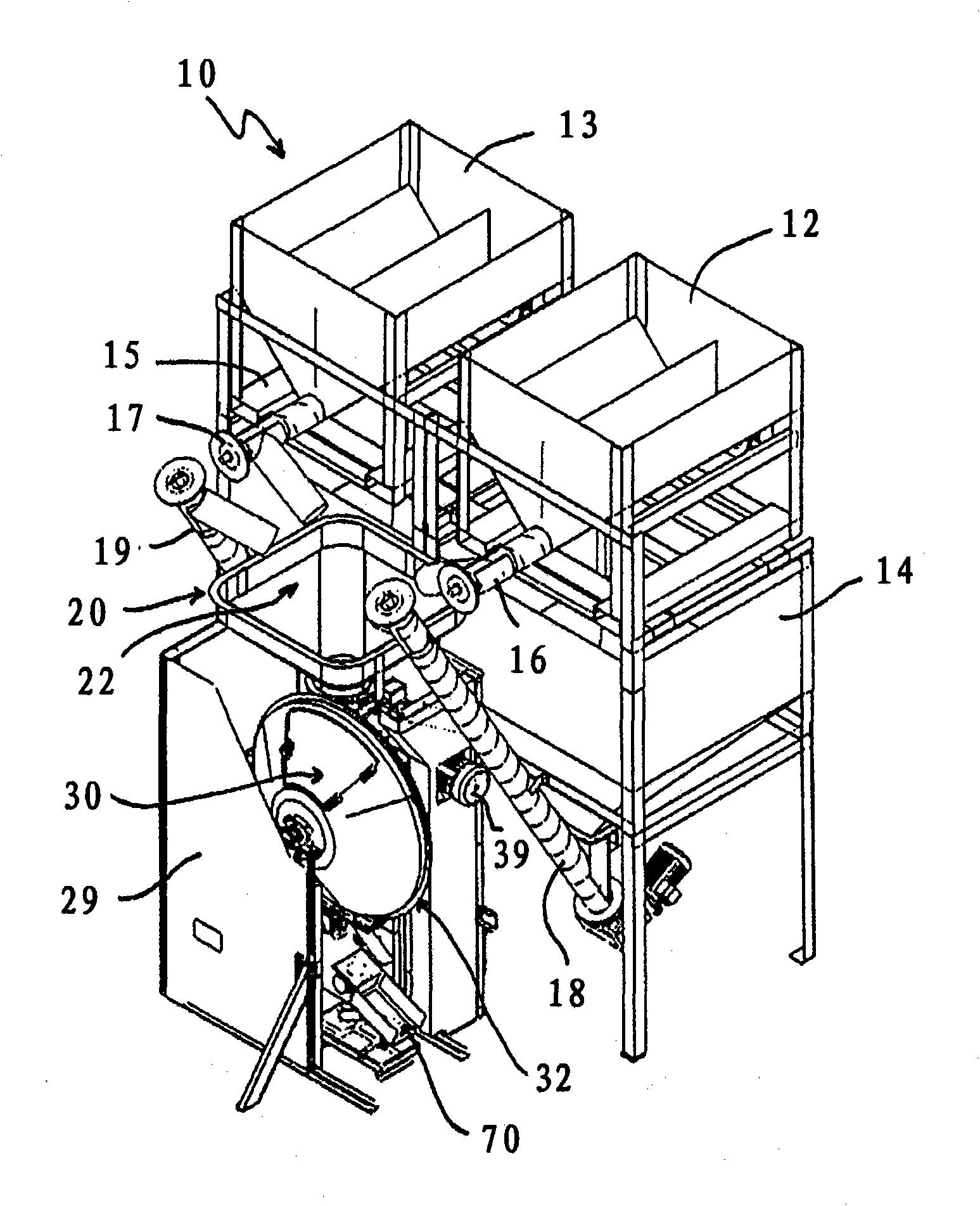

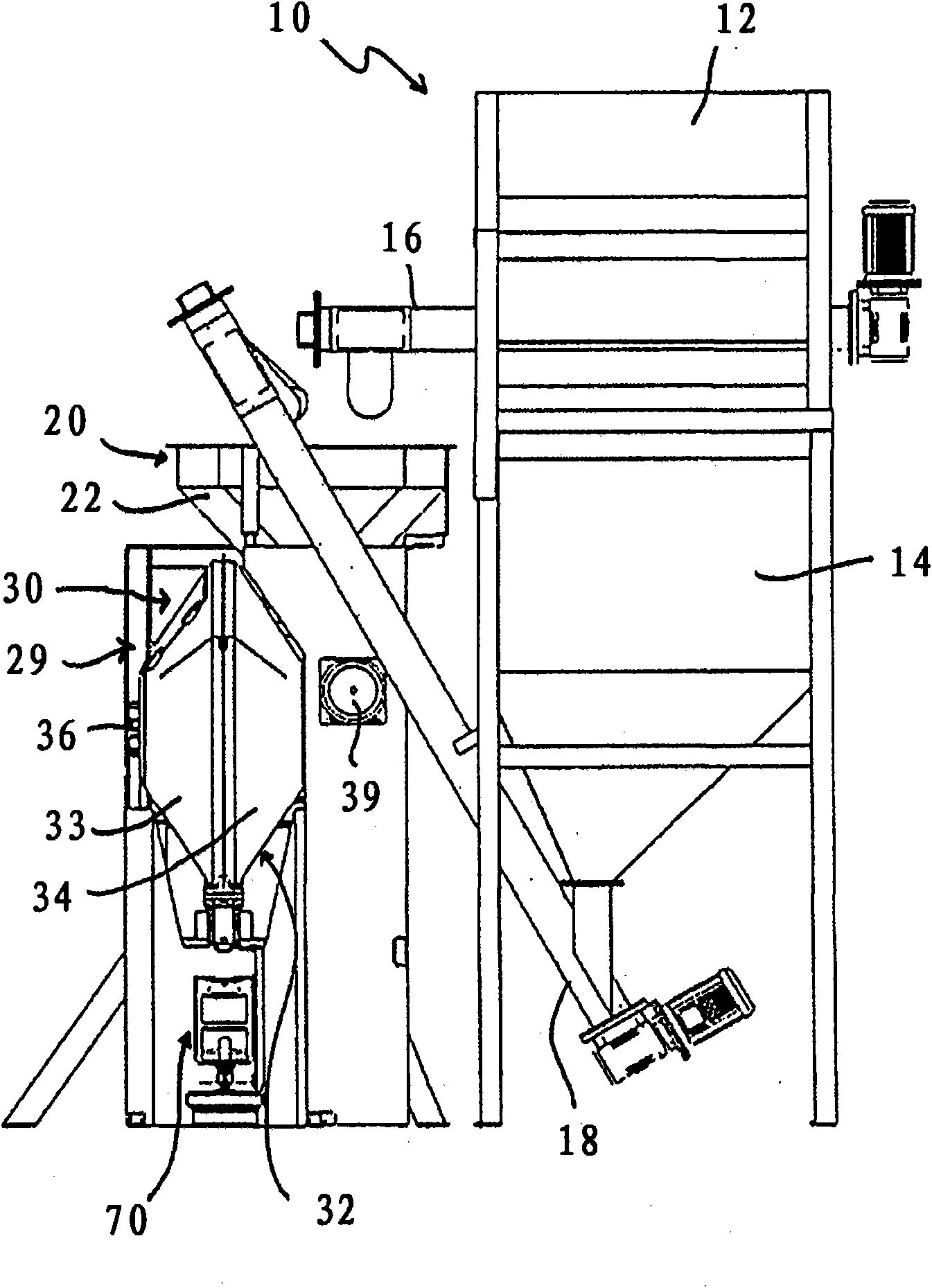

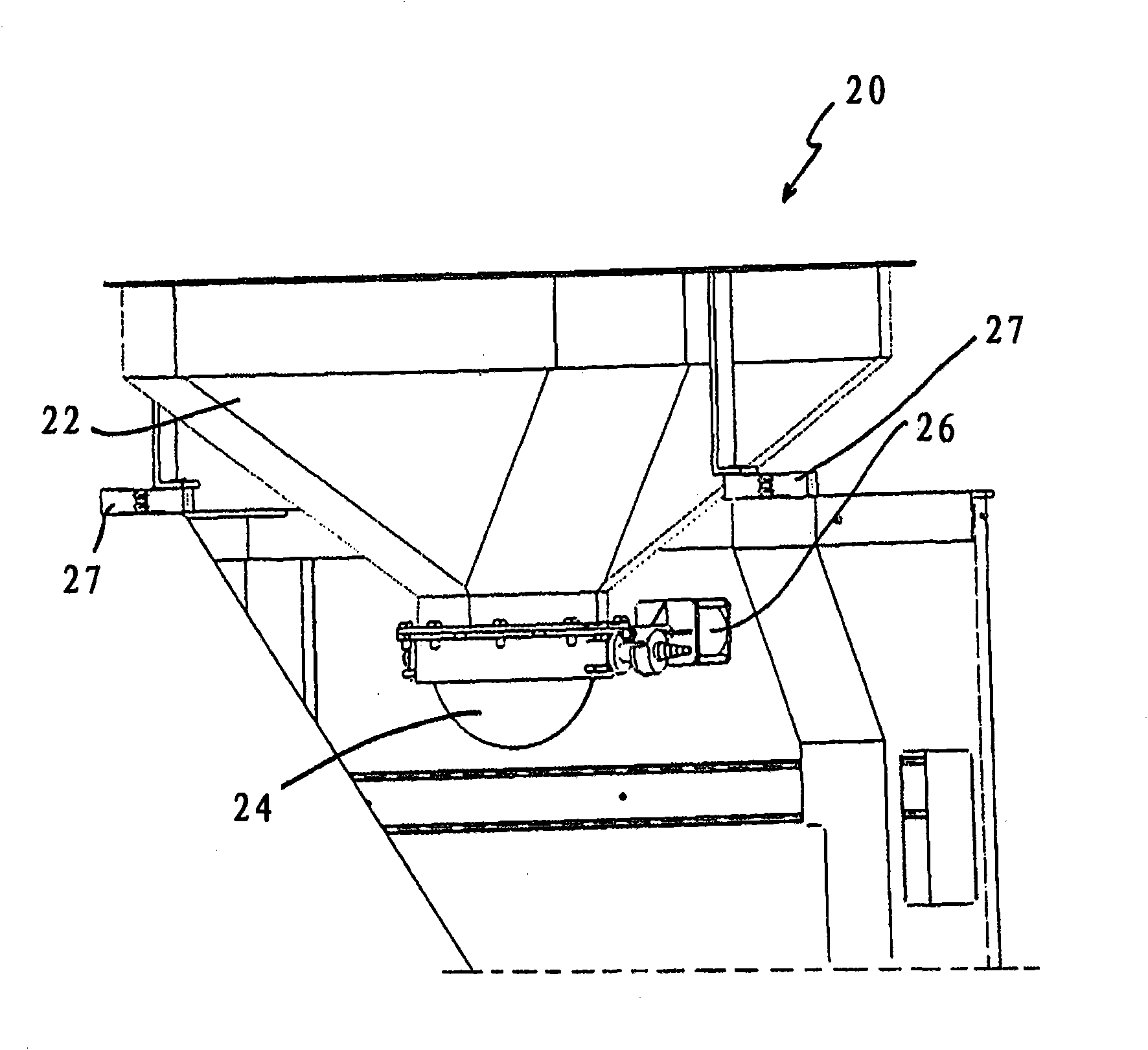

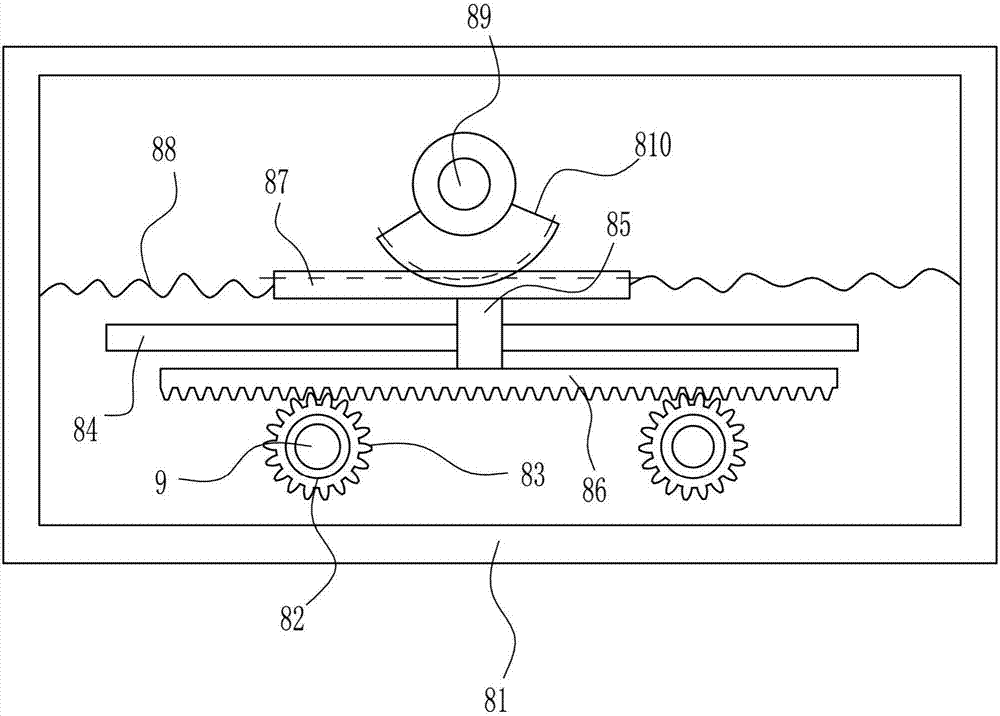

Apparatus and method for metering, mixing and packaging solid particulate material

ActiveCN101790414AEasy to produceIncrease production capacityControlling ratio of multiple fluid flowsRotary stirring mixersParticulatesSolid particle

The present application relates to a method and an apparatus to produce solid particulate material from solid particulate components. The components are metered and mixed according to a desired recipe. After having been mixed the material is metered and packaged in a suitable form, e.g. in bags. The apparatus (10) comprises a stationary casing (32) provided with a rotating mixing tool (40), a discharge valve (50) mounted on the bottom of said mixer (30) and a metering and packaging unit (70). The method is particularly suitable to manufacture solid particulate material by mixing low-value components available in any site and high-value components, such as materials for use in the building and construction field.

Owner:PERSONAL FACTORY

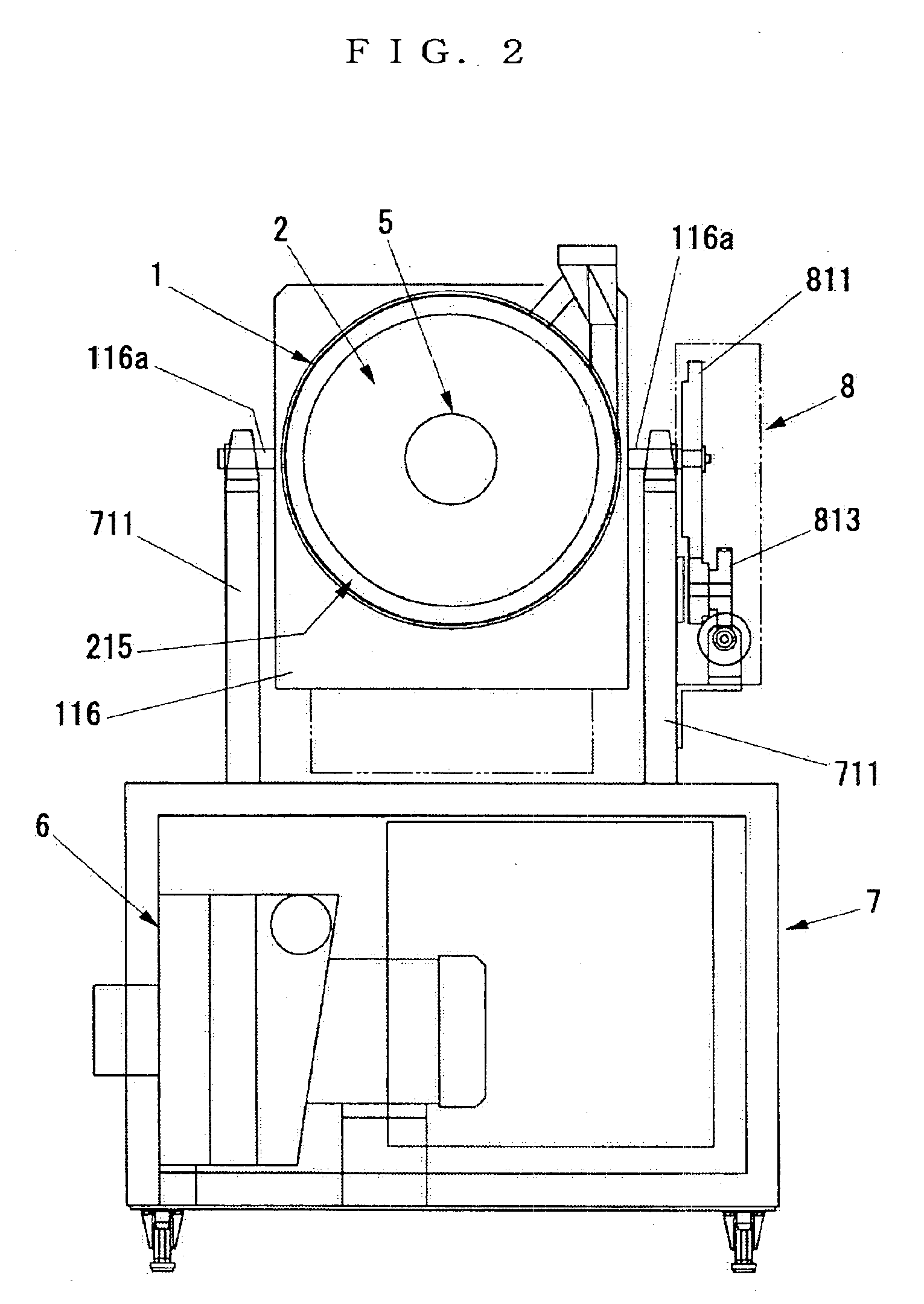

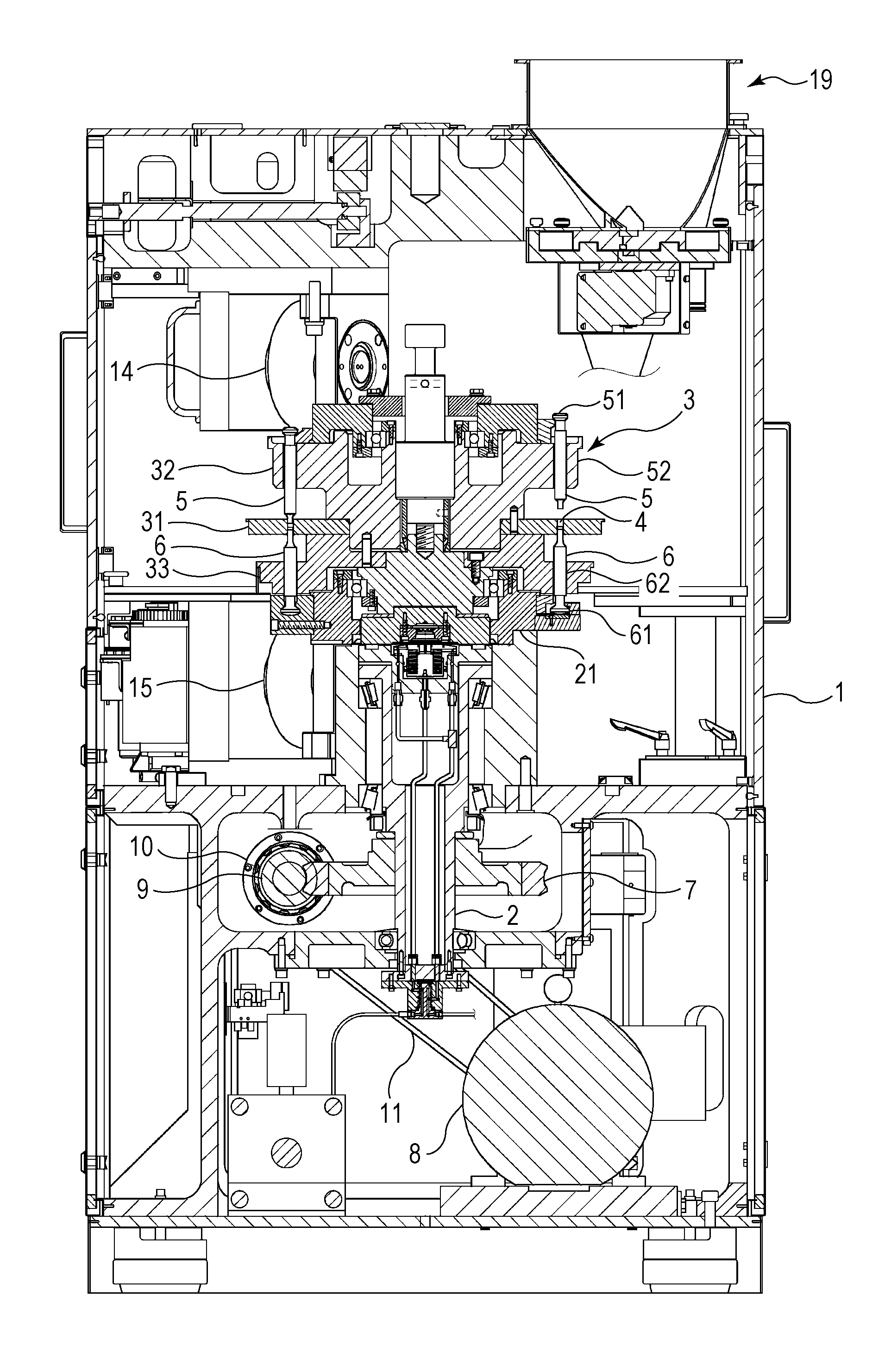

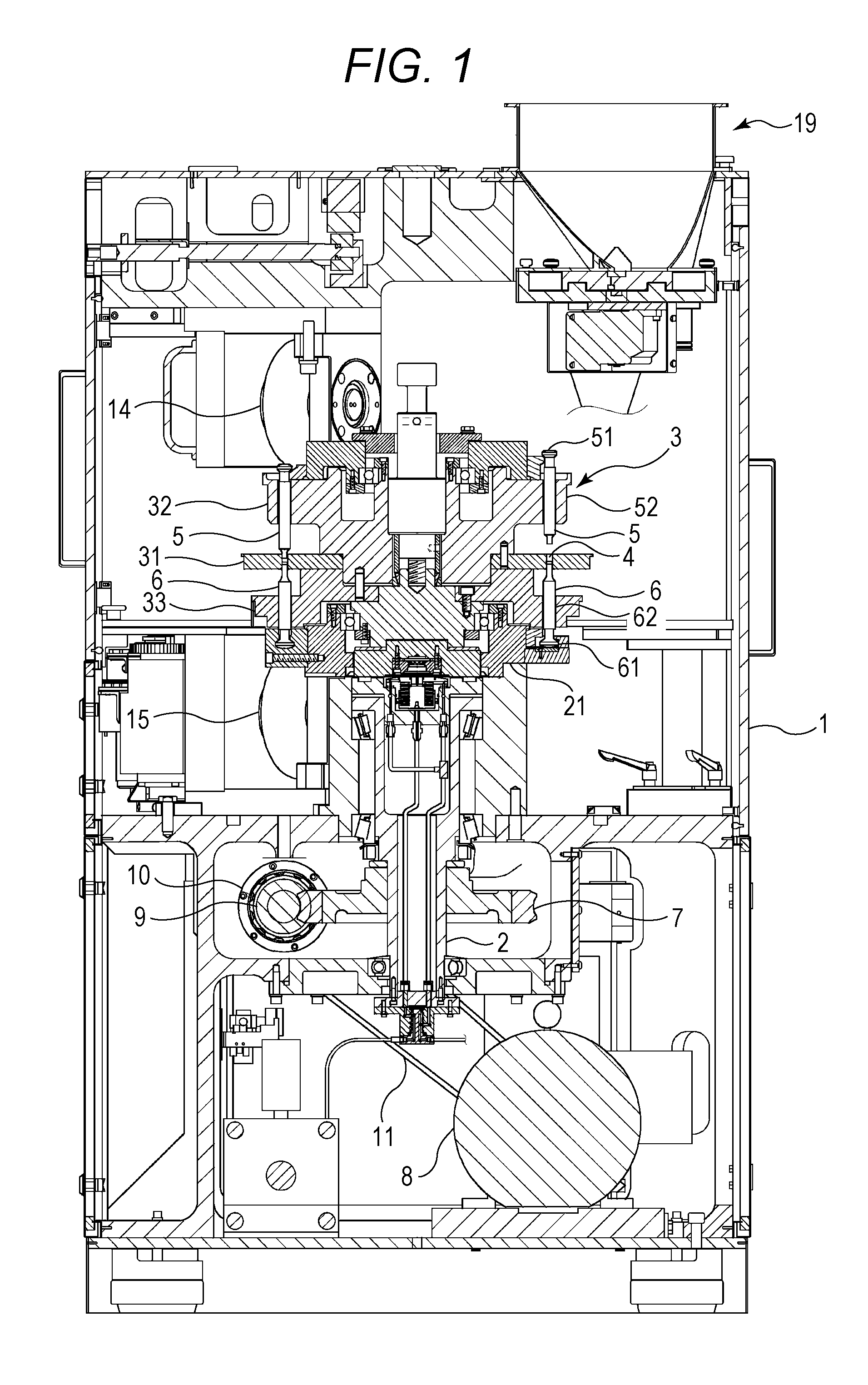

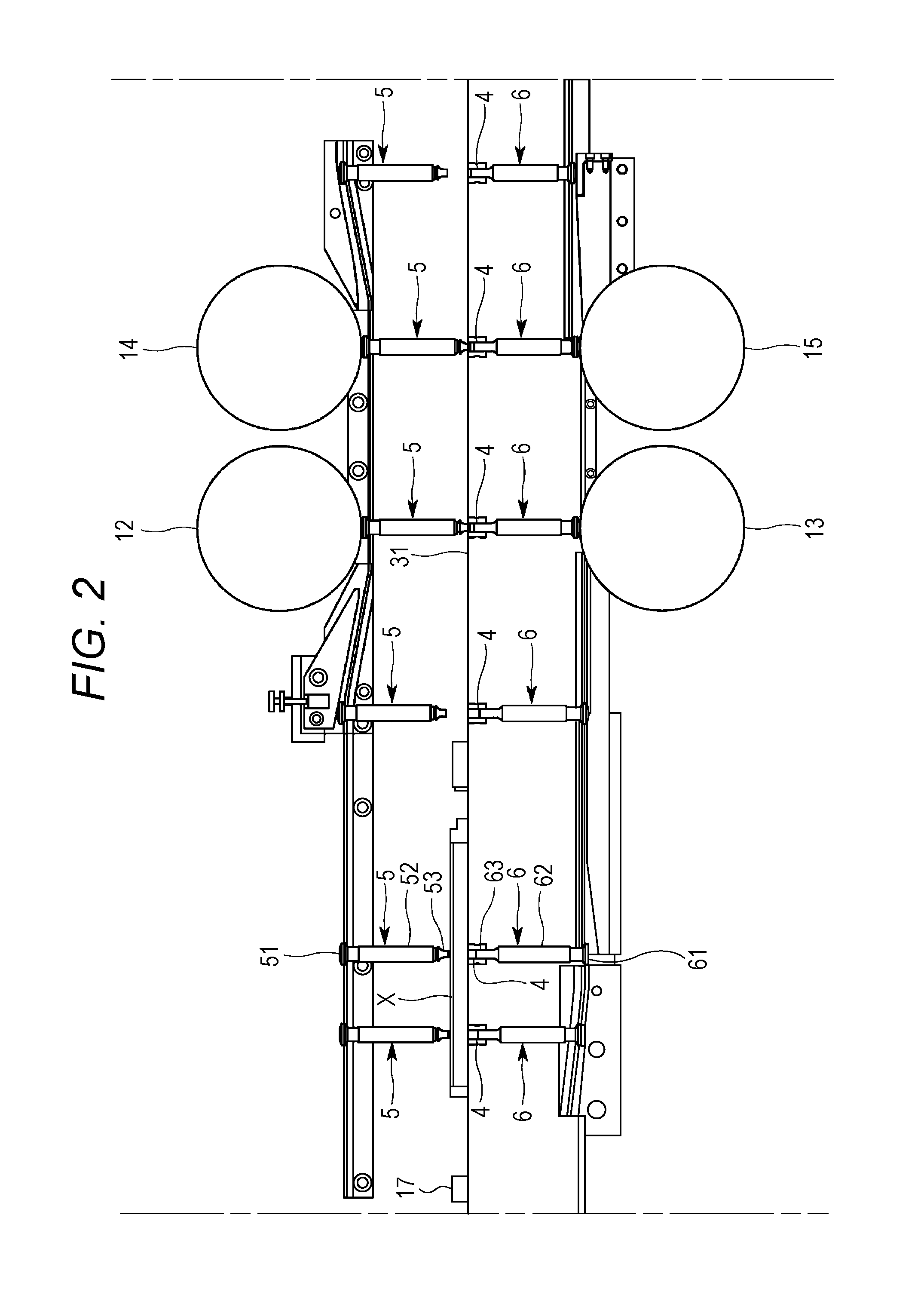

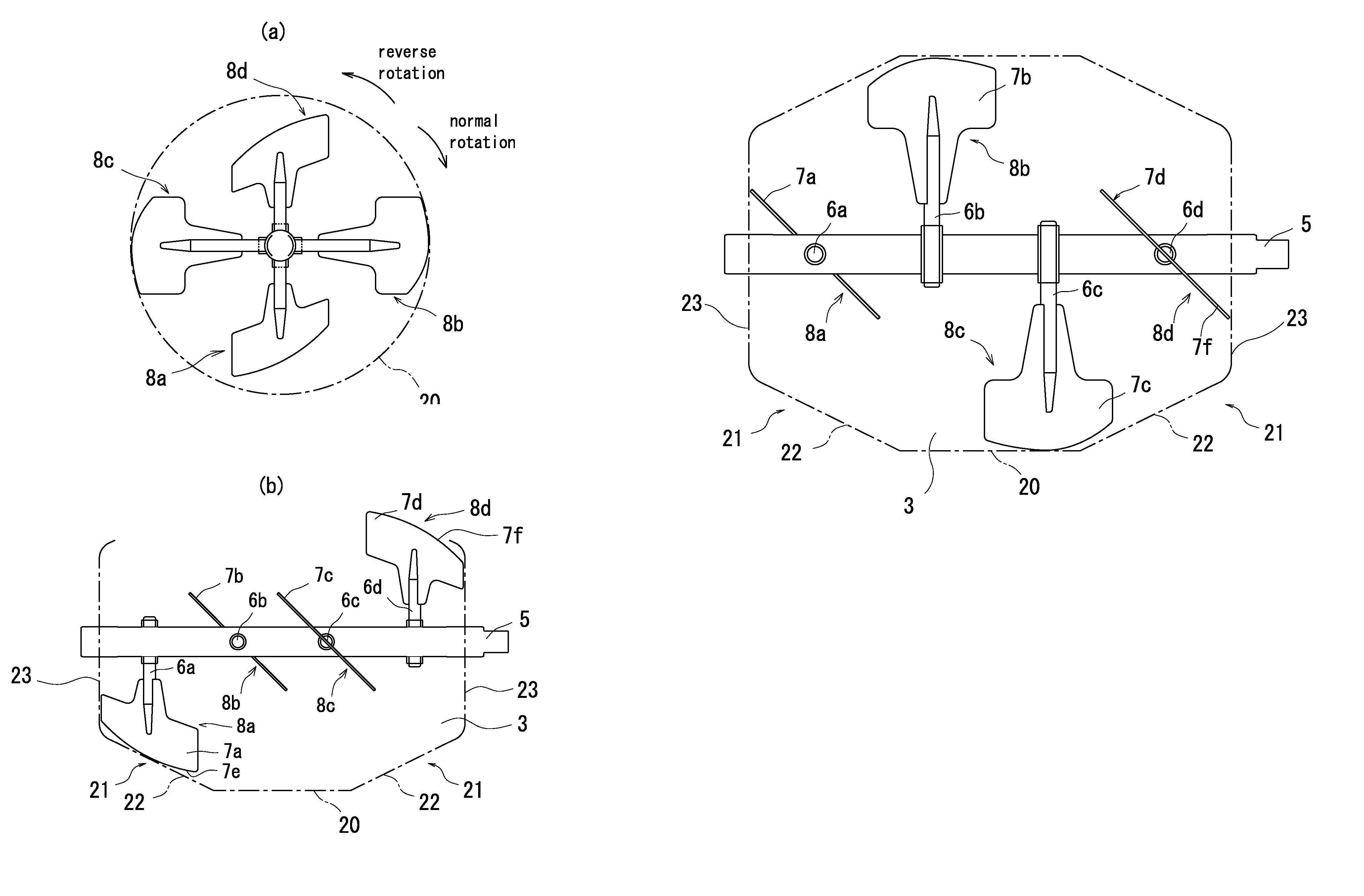

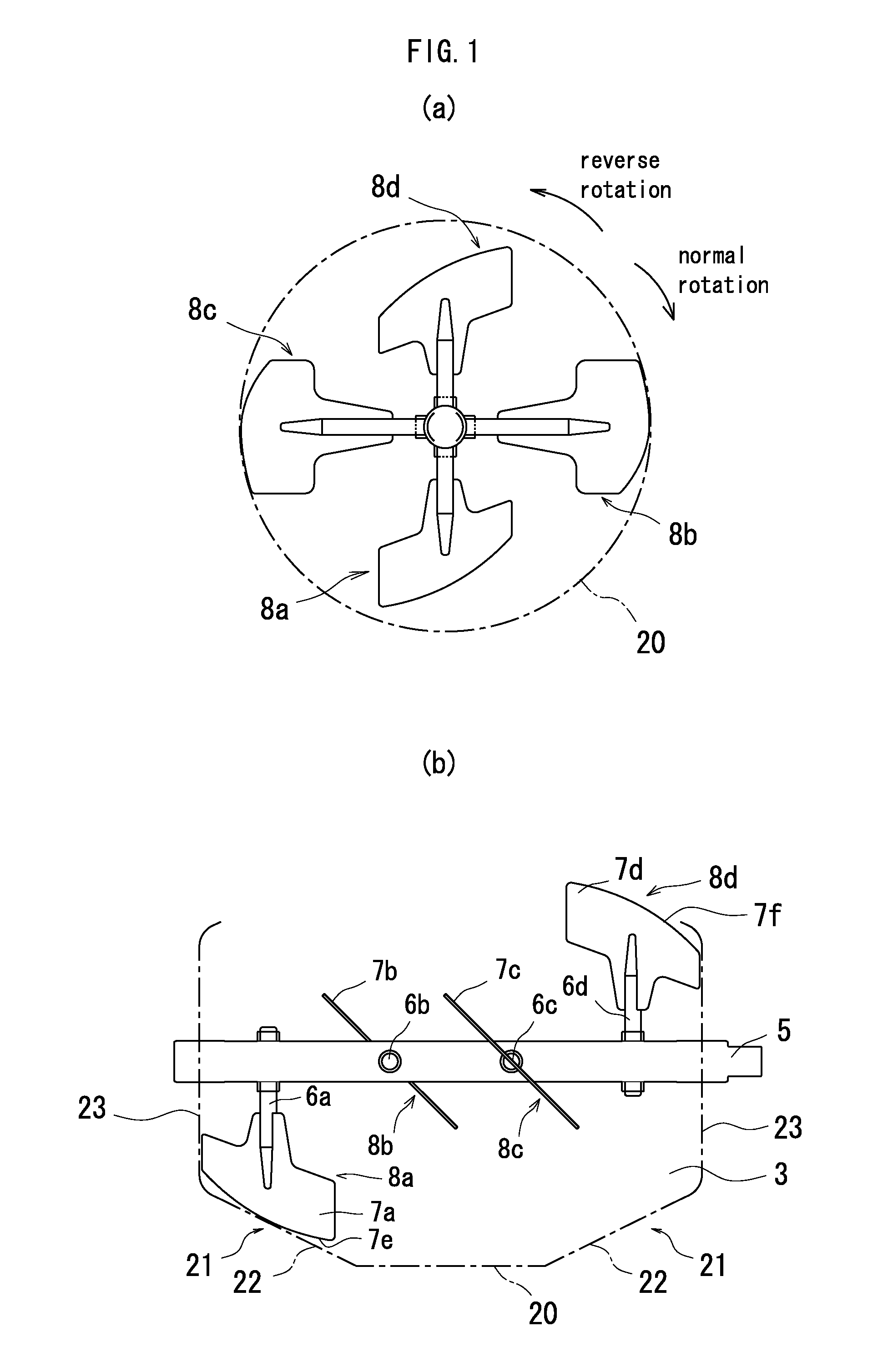

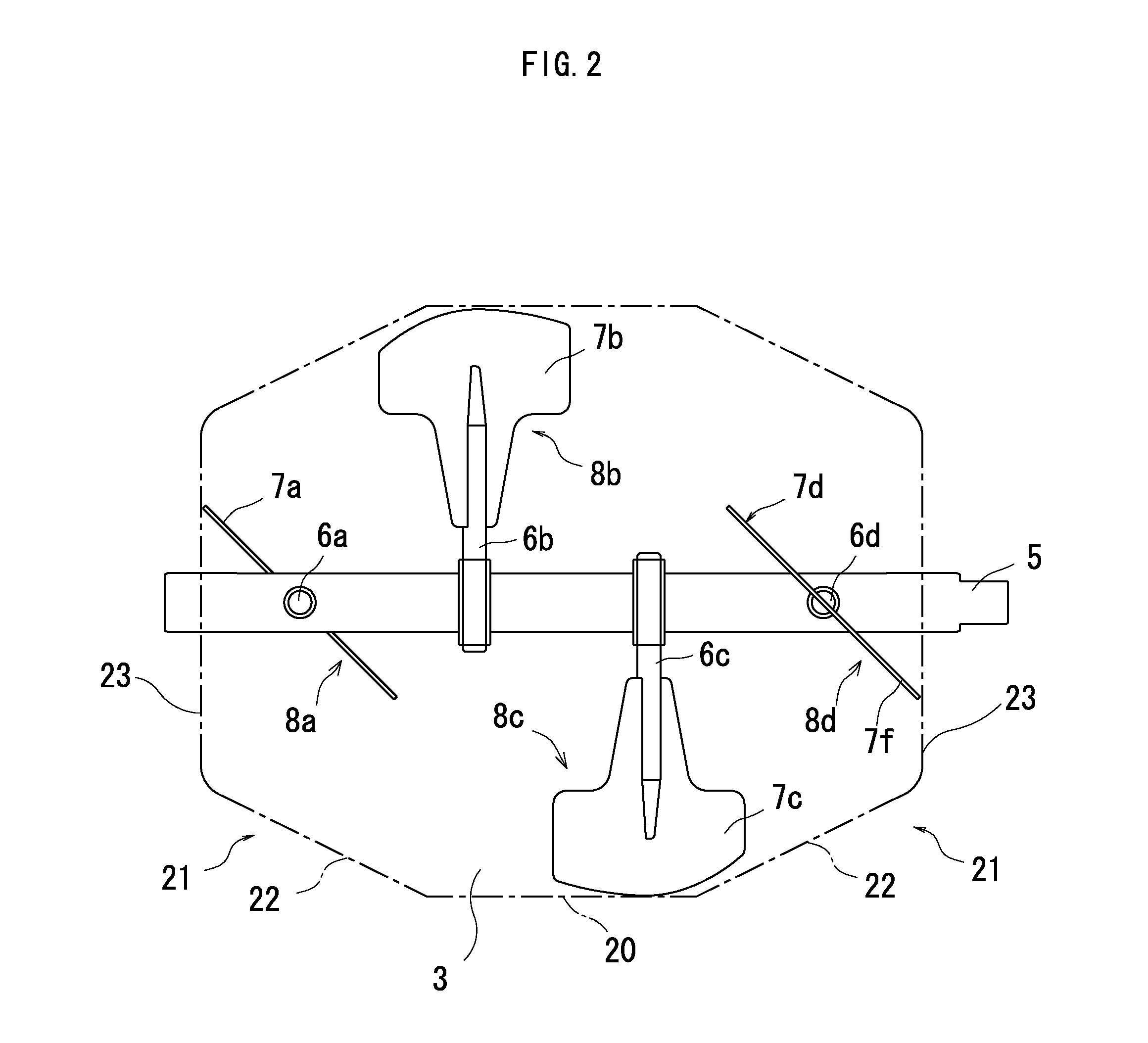

Powdery material mixing and feeding device and compression-molding machine including the same

ActiveUS20160361885A1Enhanced mixing processIncrease the degree of mixingRotary stirring mixersTransportation and packagingCompression moldingEngineering

A powdery material mixing and feeding device is configured to mix at least two types of powdery materials and to feed a compression-molding machine with the mixed powdery materials. The powdery material mixing and feeding device includes a first mixer configured to rotate about a substantially vertical shaft and to mix the powdery materials, and a reservoir configured to reserve at least a part of the powdery materials, and a second mixer configured to rotate about a substantially horizontal shaft and to mix the powdery materials.

Owner:KIKUSUI SEISAKUSHO LTD

High-viscosity lithium ion battery slurry blending technology

InactiveCN107086292ACheap manufacturingSimple processCell electrodesTransportation and packagingAdhesiveEngineering

A high-viscosity lithium ion battery slurry blending technology is used for stirring of positive and negative slurries for a lithium ion battery and comprises the following steps: admixing an adhesive, a conductive agent, a thickening agent and an active substance into a stirring barrel, dry-blending, adding a solvent, wetting and kneading and dispersing, and finally filtering by the use of a filter screen so as to obtain slurry. Through dry-blending and kneading stirring process and by application of high-speed shearing force and mechanochemical force, the conductive agent covers around the granular active substance, and the adhesive is uniformly distributed in the active substance so as to obtain the uniformly-dispersed and stable slurry placed for a long time. By the technology, stirring time is shortened, production efficiency is raised, and cost is reduced. The preparation technology is simple and flexible, is suitable for large-scale slurry blending for lithium ion batteries, especially applicable to materials with small particle size and large specific surface area, and is a high-viscosity slurry mixing technology with a high-solid-content formula.

Owner:湖北猛狮新能源科技有限公司

Particulate mixer having paddles of different lengths

ActiveUS7458716B2Increase the circulation areaShorten discharge timeRotary stirring mixersTransportation and packagingParticulatesLower face

The particulate mixer is part of a blender that includes a cylindrical drum with a particulate mixing chamber. A rotating shaft is arranged in a horizontal direction in the particulate mixing chamber. Four arms project in a radial direction from the rotating shaft and include four paddles with respective stirring blades spaced from each other in an axial direction on the rotating shaft. The drum has a cylindrical center portion and side portions that communicate with the cylindrical center portion. Each of the side portions has a lower face and a vertical face. The drum is in the form of a truncated cone with the rotating shaft as its axis. The stirring blades have a driving end face and a driven end face with slopes corresponding to the slopes of the lower face of the side portions.

Owner:TSUKASA

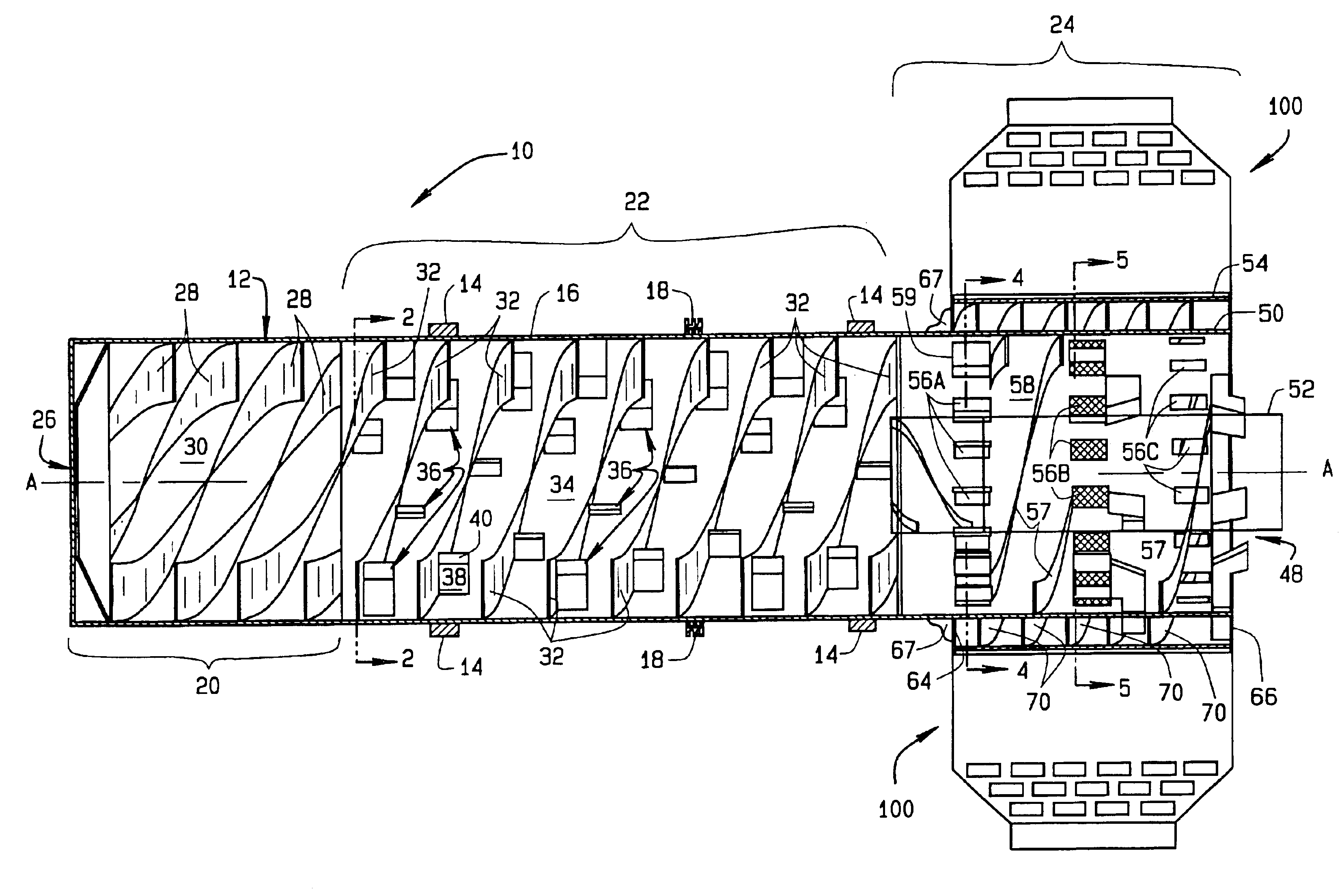

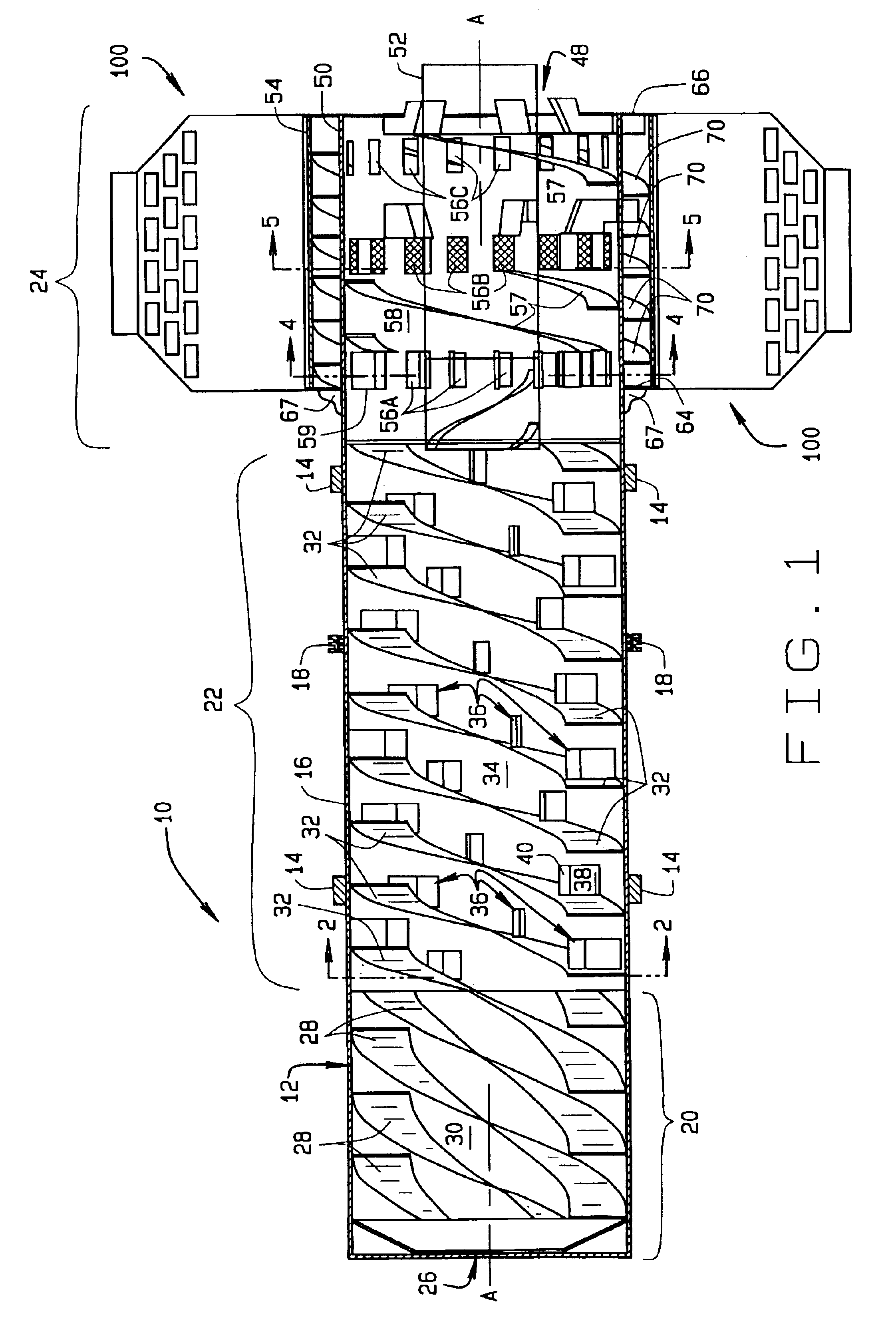

Granular product blending and cooling rotary drum

InactiveUS6896400B2Efficient blendingEffective coolingRotating receptacle mixersTransportation and packagingCounter flowMechanical engineering

A rotary drum configuration for the efficient blending, cooling, and screening of granular products having an outer cylindrical shell, an intake end, and a discharge end. The rotary drum is normally rotated at a predetermined speed by means of a conventional drive package. Disposed on an inner surface of the cylindrical shell are a plurality of compound helical flights and scoops, configured to blend granular product as it cascades from the intake end to the discharge end of the rotary drum. A coaxially disposed cylindrical air passage adjacent the discharge end of the rotary drum directs a counter flow of cooling air through the rotary drum towards the intake end, cooling the cascading granular product as it approaches the discharge end, and plurality of discharge ports and grading screens in the surface of the outer cylindrical shell adjacent the discharge end provide a entrance for a second counter flow of cooling air while simultaneously providing passage for the granular product to drop downwards towards a outer coaxial discharge passage.

Owner:DIDION TECHNOLOGIES LLC

Manufacturing device for automobile brake pad

InactiveCN106964423AImprove work efficiencyEasy to collectSievingRotary stirring mixersSilicon oxideMillstone

The invention relates to a manufacturing device, in particular to a manufacturing device for an automobile brake pad. The invention aims to solve the technical problem of providing the manufacturing device for the automobile brake pad, through the manufacturing device, silicon oxide powder and silicon nitride can be subjected to crushing and mixing at the same time. In order to solve the above technical problem, the manufacturing device for an automobile brake pad, provided by the invention, comprises a mixing box, a first baffle, first connecting rods, a cylindrical filter screen frame, a first bearing support, a first rotating rod, a stirring rod, a rotating mechanism, a second rotating rod and the like, wherein the first baffle is connected to the bottom of the mixing box in a rotating manner; the mixing box is in bolt connection to the right part of the first baffle plate; and the first connecting rods are respectively connected to the left side and the right side of the upper part in the mixing box. According to the manufacturing device disclosed by the invention, firstly, the rotating mechanism is arranged, so that the silicon oxide powder and the silicon nitride are crushed by the reciprocating rotation of a cylindrical millstone driven by the rotating mechanism.

Owner:来安县华鹏摩擦材料厂

Methods of manipulating small amounts of solids

InactiveUS20080253935A1Shaking/oscillating/vibrating mixersTransportation and packagingEngineeringSlurry

The invention relates to methods and apparatuses for manipulating small amounts of solids. Specific embodiments of the invention are particularly suited for the automated transfer of small amounts of solids. In one embodiment, a uniform powder bed is lightly compressed into plugs of powder and dispensed. In another embodiment, the solid is placed in a liquid carrier to form a slurry, dispensed, and the liquid component is subsequently removed. In yet another embodiment, solids are manipulated using adhesive surfaces.

Owner:TRANSFORM PHARMACEUTICALS INC

Method for manufacturing powder coatings

InactiveUS20090201759A1Good dispersionEliminating non-homogeneitiesShaking/oscillating/vibrating mixersTransportation and packagingAdditive ingredientImproved method

An improved method for manufacturing powder coatings for applications where uniform dispersion of one or more additives is critical to the function of the final coating. The method comprises ultrasonic post-blending of powder coating of one or more additives into a base powder coating material prepared by ordinary means. In one example, an antimicrobial powder coating containing a silver zeolite additive is prepared using the ultrasonic post-blending method. The resulting powder exhibits superior antimicrobial efficacy compared to an analogue powder manufactured using identical constituent ingredients, but according to conventional premix / extrusion methods. Powder manufactured using ultrasonic post-blending allows a wide range of stock powder coatings to be modified to exhibit new properties at improved cost and efficiency than conventional preparation methods. The method is suitable for powder coating formulations requiring incorporation of a small percentage of additives, especially additives with relatively small particle sizes such as nano- and sub-micron additives.

Owner:MILLS PAUL

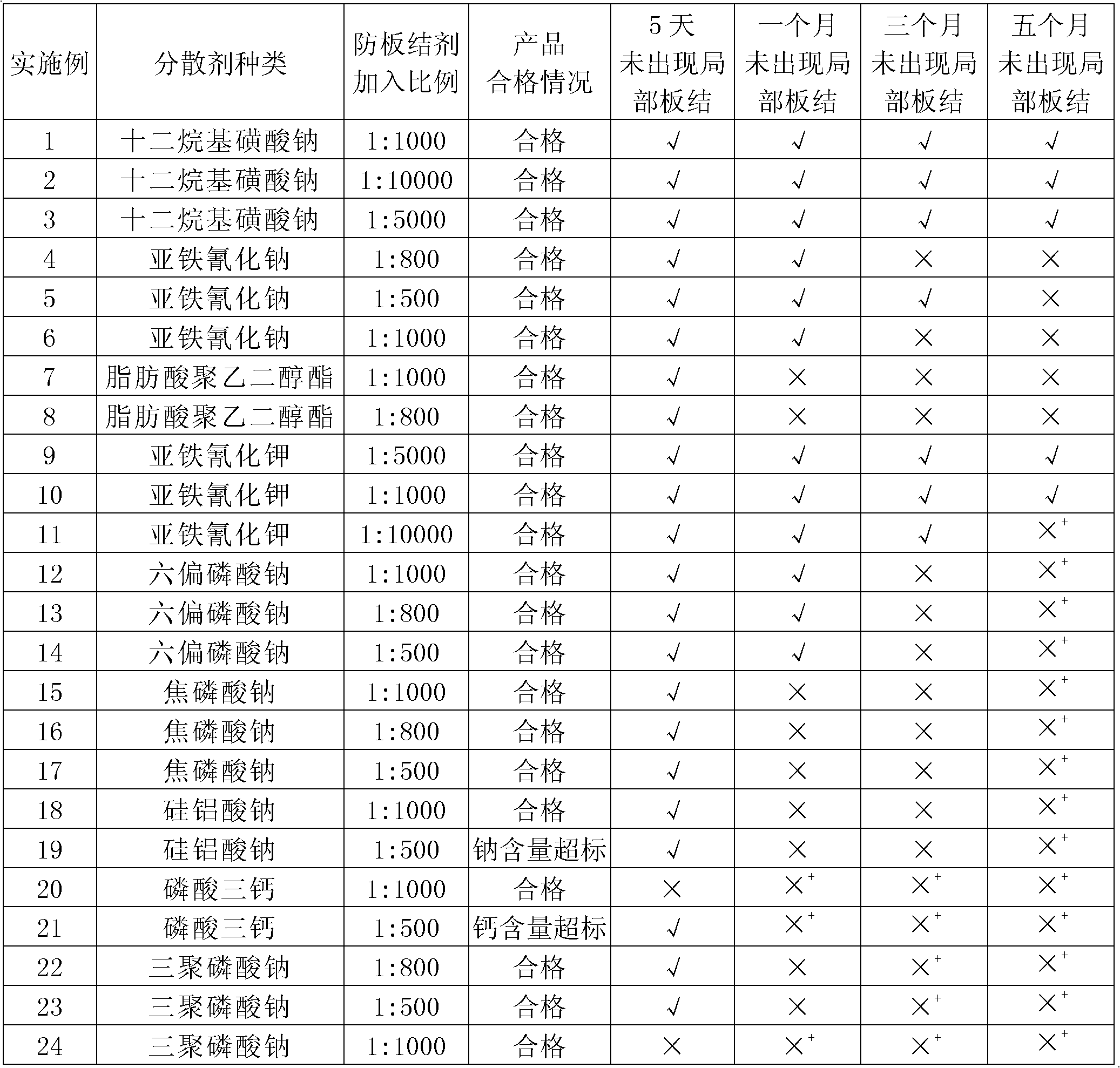

Lithium hydroxide monohydrate and preparation method thereof

ActiveCN102020294ANo flyingMeet the qualityTransportation and packagingLithium oxides/hydroxidesCalcium hydroxideDust explosion

The invention refers to a dust-free lithium hydroxide monohydrate and a preparation method thereof, belonging to the technical field of lithium hydroxide. The technical problems to be solved by the invention are that wet LiOH.H2O has a problem of hardening and dry LiOH.H2O has a problem of dust explosion in the prior art. The invention provides a novel LiOH.H2O, that is, dust-free lithium hydroxide monohydrate without hardening. The lithium hydroxide monohydrate is a loosened granular wet product, wherein the content of water is less than or equal to 3.5%, and the surface of the lithium hydroxide monohydrate is coated with a little anti-hardening agent. The dust-free lithium hydroxide monohydrate is prepared by the following methods: (1) preparing a LiOH solution having a Li2O concentration of 70+-5g / l, and the concentration of SO42- is less than or equal to 15g / l; (2) evaporating the LiOH solution obtained in the step (1) until the ratio of liquid to solid is 1: (0.8-1.5); adding a little anti-hardening agent; uniformly stirring; separating and washing the mixture to obtain dust-free wet LiOH.H2O; and carrying out vacuum seal and packing the wet product, wherein the obtained product is not hardened within 3-5 months.

Owner:TIANQI LITHIUM CORP

Popular searches

Weighing apparatus for materials with special property/form Weighing apparatus with automatic feed/discharge Special data processing applications Chemical/physical processes Numerical control Mixing solids with solids Sampled-variable control systems Computer control Mixing operation control apparatus Simulator control

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com