Lithium hydroxide monohydrate and preparation method thereof

A technology of monohydrate lithium hydroxide and moisture content, applied in lithium oxide;/hydroxide, chemical/physical process, solid and solid mixing, etc., can solve problems such as dust flying, achieve low equipment investment, lithium ion The effect of high recovery rate and low product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1 Battery-grade dust-free LiOH·H 2 Preparation of O

[0047] (1) Preparation of Li 2 LiOH solution with an O concentration of 70±5g / l

[0048] Take Li 2 Li with an O concentration of 38 g / L 2 SO 4 Leach solution 10000ml, add Ca(OH) to it 2 Adjust pH=7, filter, then add 1080g sodium hydroxide to the filtrate, stir well to make it dissolve completely, then cool it to -3°C while stirring, when the SO in the solution 4 2- When the concentration is 35g / L, it is separated by filtration to obtain LiOH solution and Na 2 SO 4 10H 2 O solid; when the obtained LiOH solution was evaporated to a liquid-solid volume ratio of about 0.8:1, it was filtered and centrifuged to obtain LiOH·H 2 O primary crude product; add deionized water, stir to dissolve it completely, and make Li in the solution 2 O concentration is 70g / L, add 7.8g refining agent Li 1.3 Ti 0.8 Ce 0.4 Zr 0.5 al 0.3 (PO 4 ) 3 , the temperature was 45°C, stirred and reacted for 120 minutes, and the...

Embodiment 2-24

[0051] Example 2-24 Battery-grade dust-free LiOH·H 2 Preparation of O

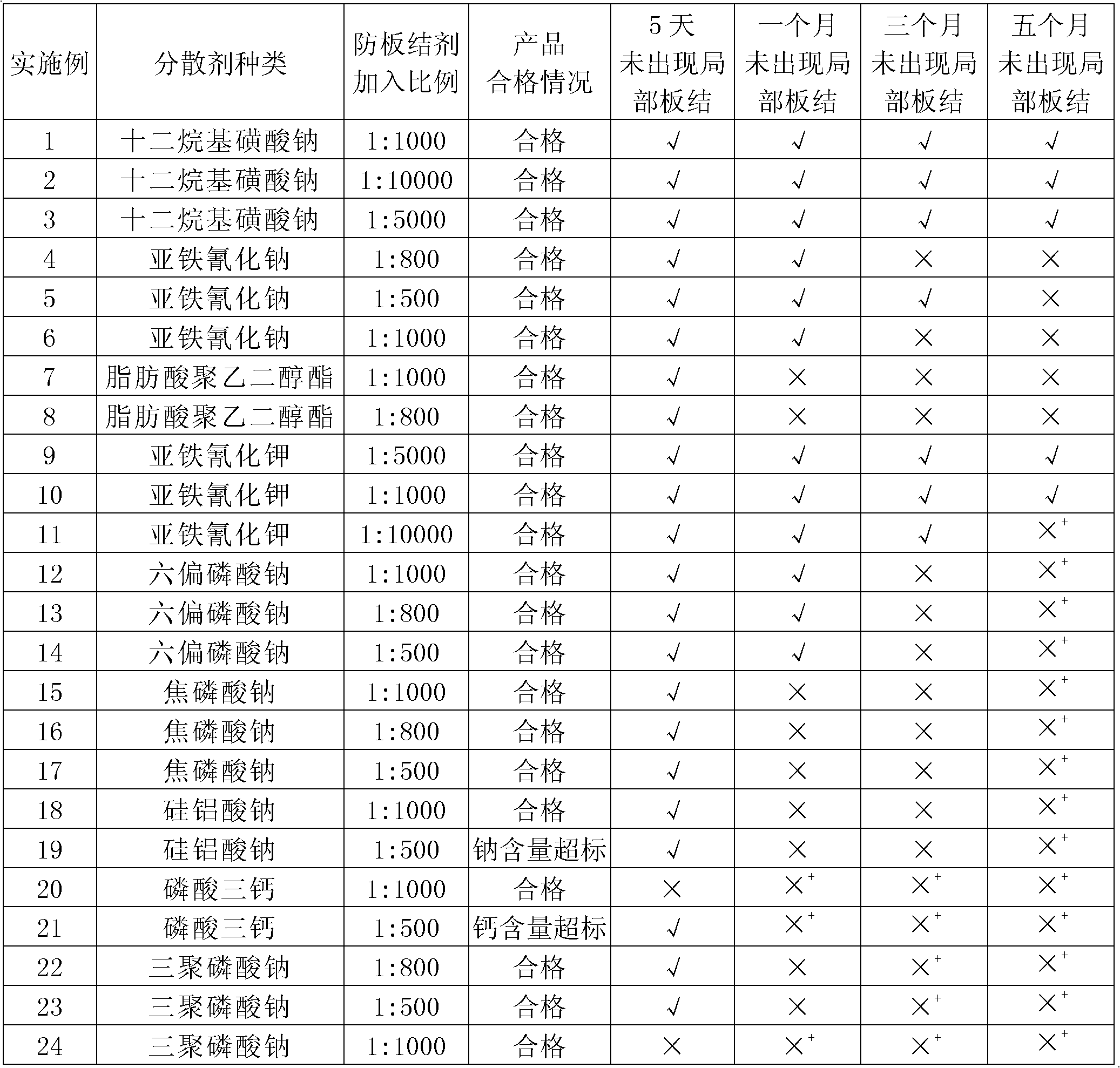

[0052] The preparation process is the same as in Example 1, except that the amount of anti-caking agent used and the type of anti-caking agent are different. The specific results are shown in Table 1.

[0053] Table 1

[0054]

[0055] In Table 1, √ means no hardening, × means hardening, × + Indicates that the agglomerate is very hard.

[0056] Qualification in Table 1 refers to compliance with battery-grade product standard indicators:

[0057] Fe%

[0058]As can be seen from the results in Table 1, the selection of dispersants should pay attention to the impact of the substances brought into the product on the impurity content of the product. At the same time, some dispersants will produce a large amount of foam during use, which seriously affects the production. Sodium hexametaphosphate, sodium hexametaphosphate, potassium ferrocyanide, and sodium ferrocyanide are preferred. Insoluble ...

Embodiment 25-48

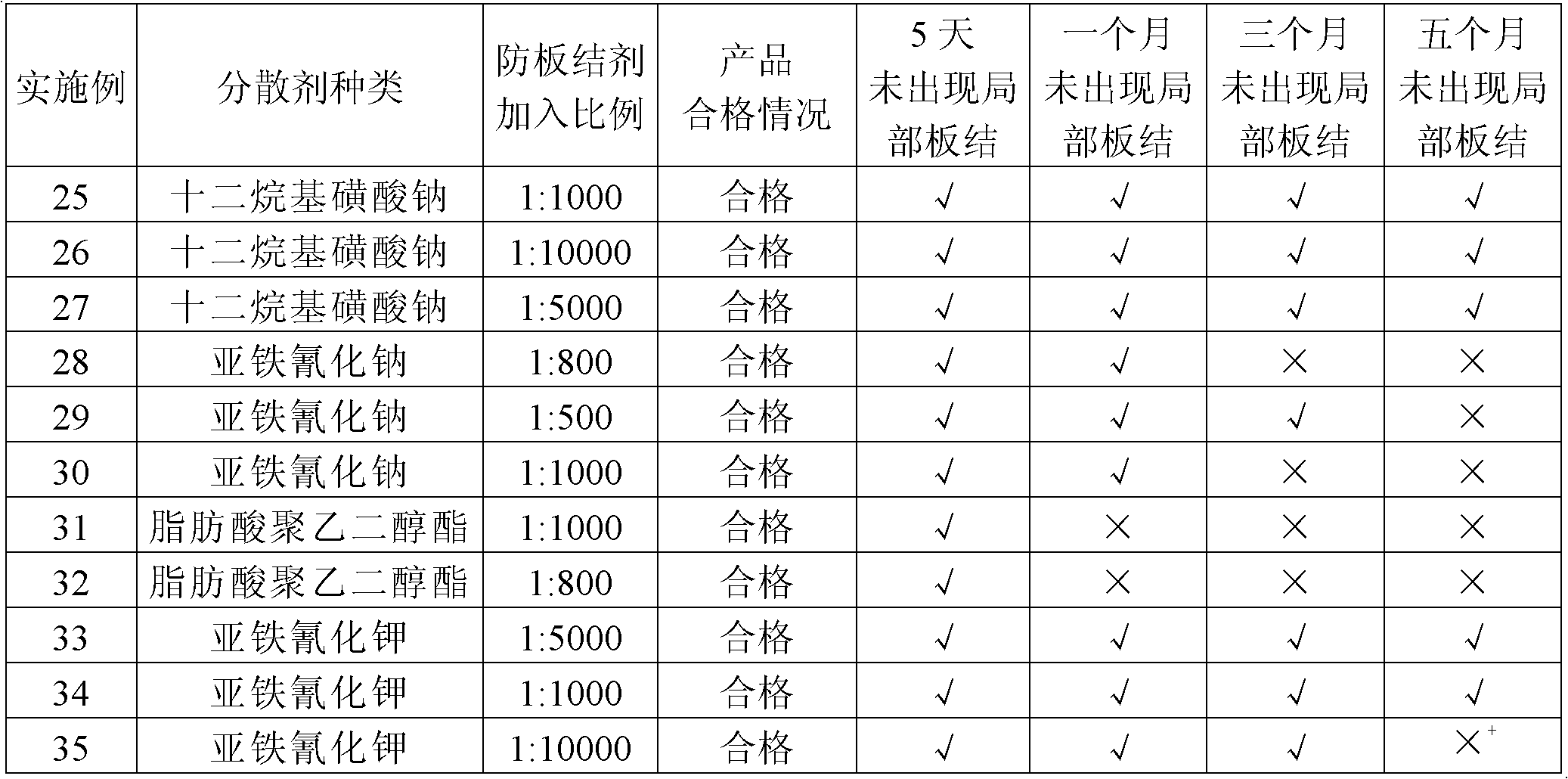

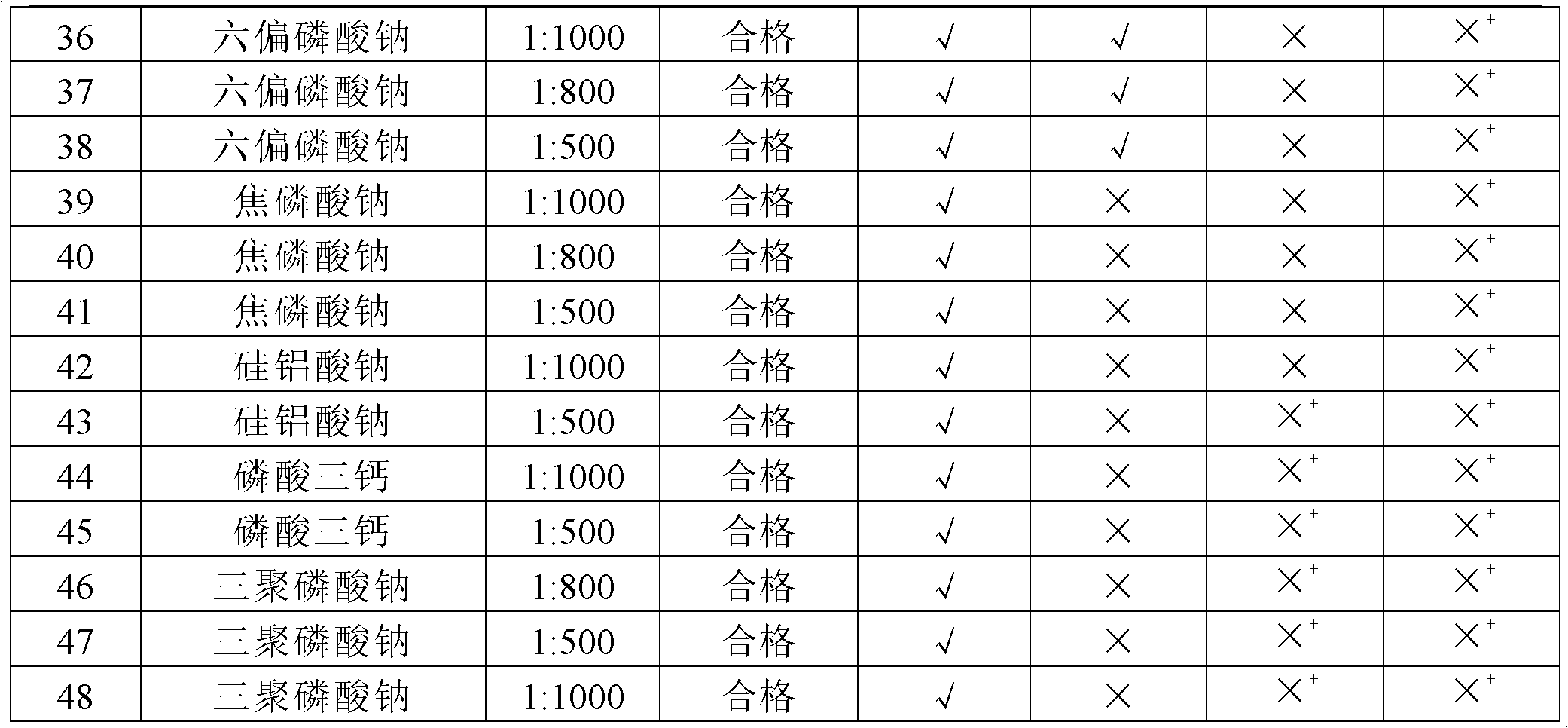

[0059] Example 25-48 Industrial-grade dust-free LiOH·H 2 Preparation of O

[0060] (1) Preparation of Li 2 LiOH solution with an O concentration of 70±5g / l

[0061] Take Li 2 Li with an O concentration of 38 g / L 2 SO 4 Leach solution 10000ml, add Ca(OH) 2 Adjust pH=7, filter, then add 1080g sodium hydroxide to the filtrate, stir well to make it dissolve completely, then cool it to -3°C while stirring, when the SO in the solution 4 2- When the concentration is 35g / L, it is separated by filtration to obtain LiOH solution and Na 2 SO 4 10H 2 O solid; when the obtained LiOH solution was evaporated to a liquid-solid ratio of about 0.8:1, it was filtered and centrifuged to obtain LiOH·H 2 O primary crude product; add deionized water, stir to dissolve it completely, and make Li in the solution 2 O concentration is 70g / L, it is separated by filtration, and the filtrate is LiOH pure liquid; Wherein Li 2 LiOH solution with an O concentration of 70 g / l, SO 4 2- Concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com