Patents

Literature

35results about How to "Easy to wash and dry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

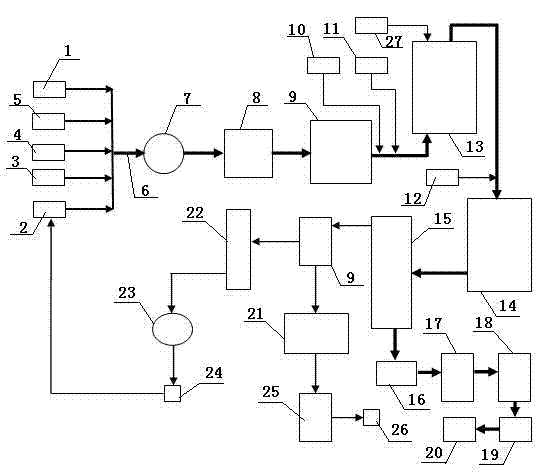

Nitrile rubber production process

The invention relates to the technical field of rubber production, aiming to provide an improved nitrile rubber production process, which comprises polymerization, degassing and condensation. Raw materials including acrylonitrile, butadiene, desalinated and deoxidized water, condensed water and molecular weight regulators are fed into a polymerization position, convergence is carried out in a header pipe at the polymerization position, the converged mixture is pre-emulsified sequentially through a pipe pump and a pipe mixer, heat exchange is carried out through an ammonia-cooling heat exchanger for cooling, the cooled mixture, initiator emulsion and activator solution are sequentially fed into a plurality of reactors for polymerization to produce latex, the latex taken out of the reactorsand terminating defoamer solution are fed into a maturing reactor and are fully mixed when the rate of polymerization and conversion reaches 70 plus or minus 5 percent, and the mixture is then fed into a degassing tower to be degassed and into a condensation reactor for condensation. The problem of blockage of the heat exchanger can be avoided, the process is simple, the production process is stable and economical, the Mooney of rubber can be controlled easily, and the produced nitrile rubber has high quality.

Owner:NINGBO SHUNZE RUBBER

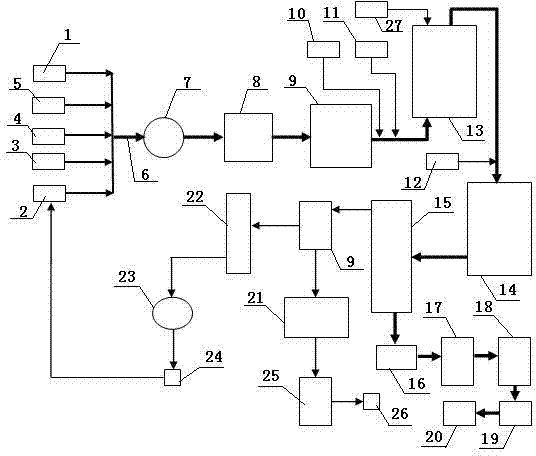

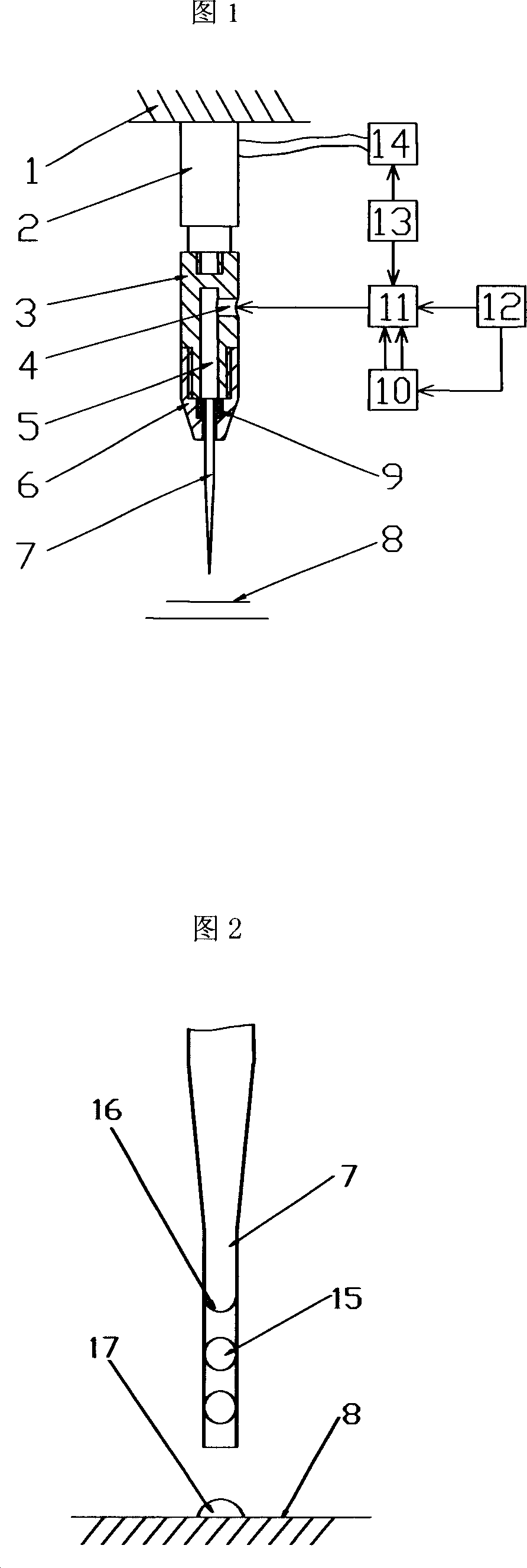

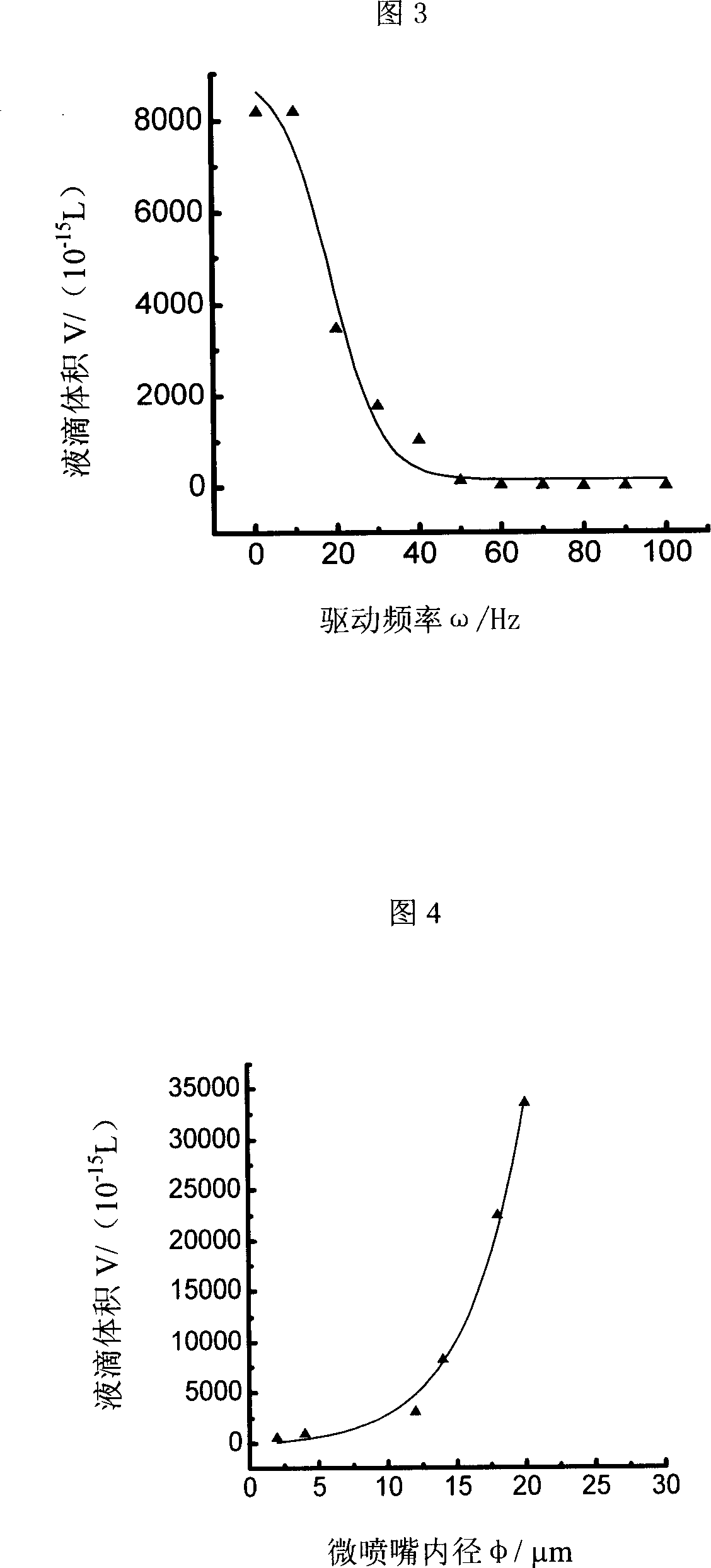

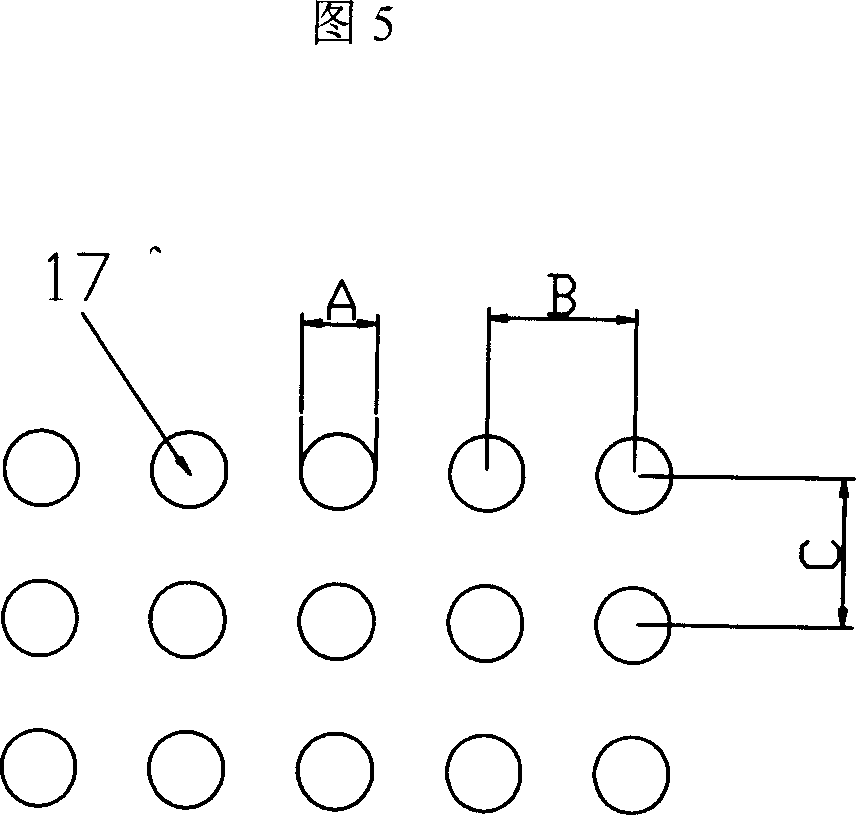

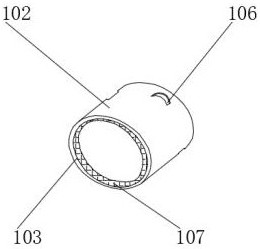

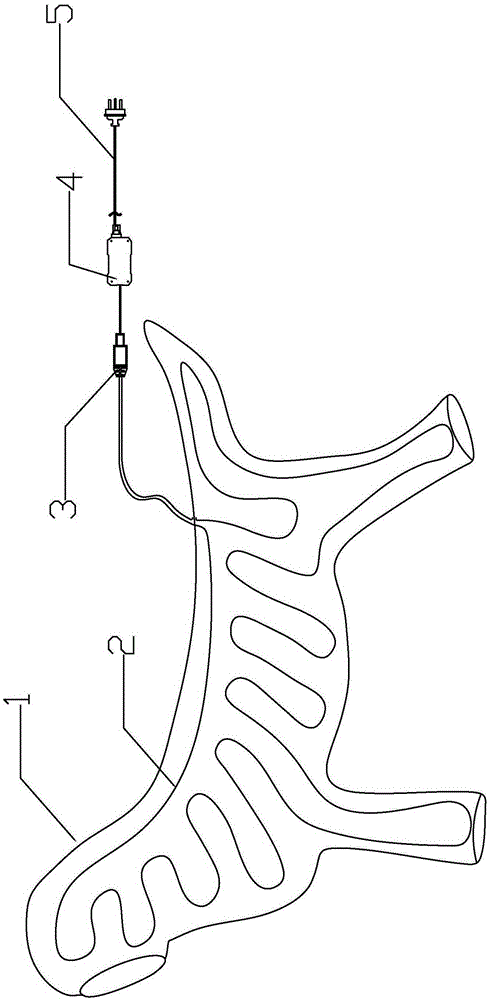

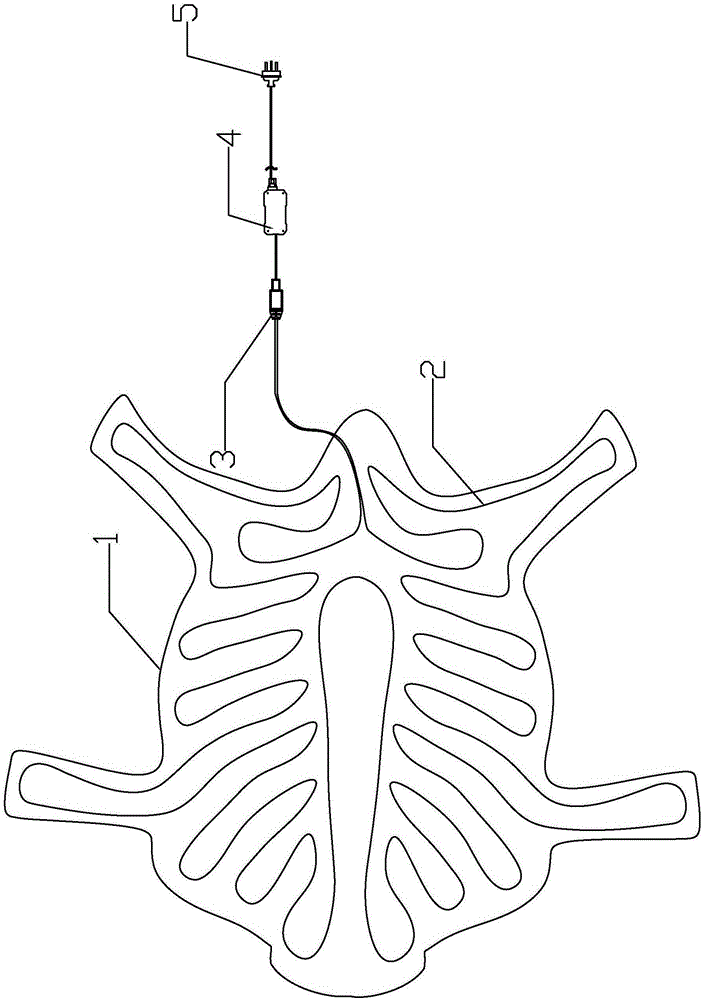

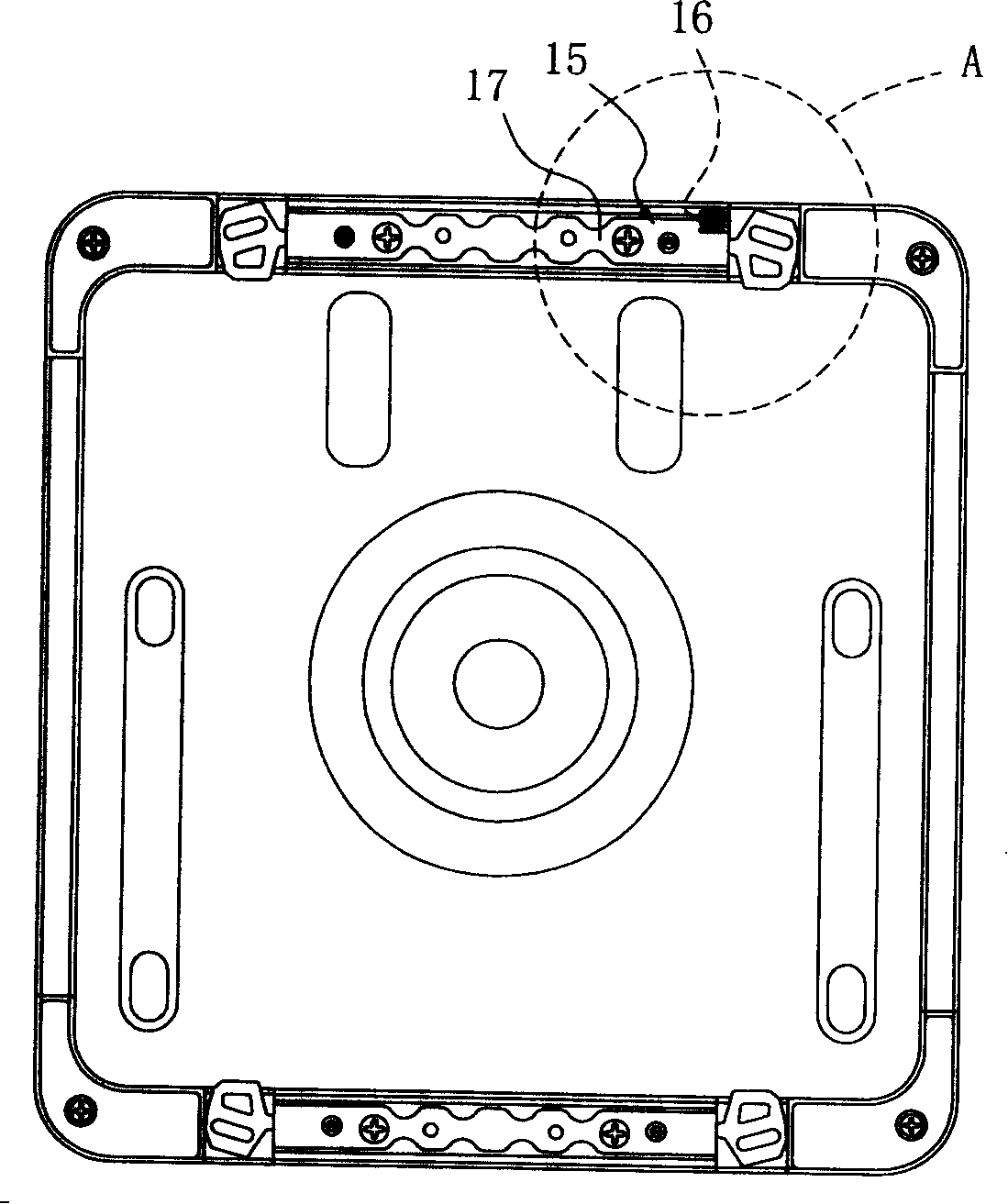

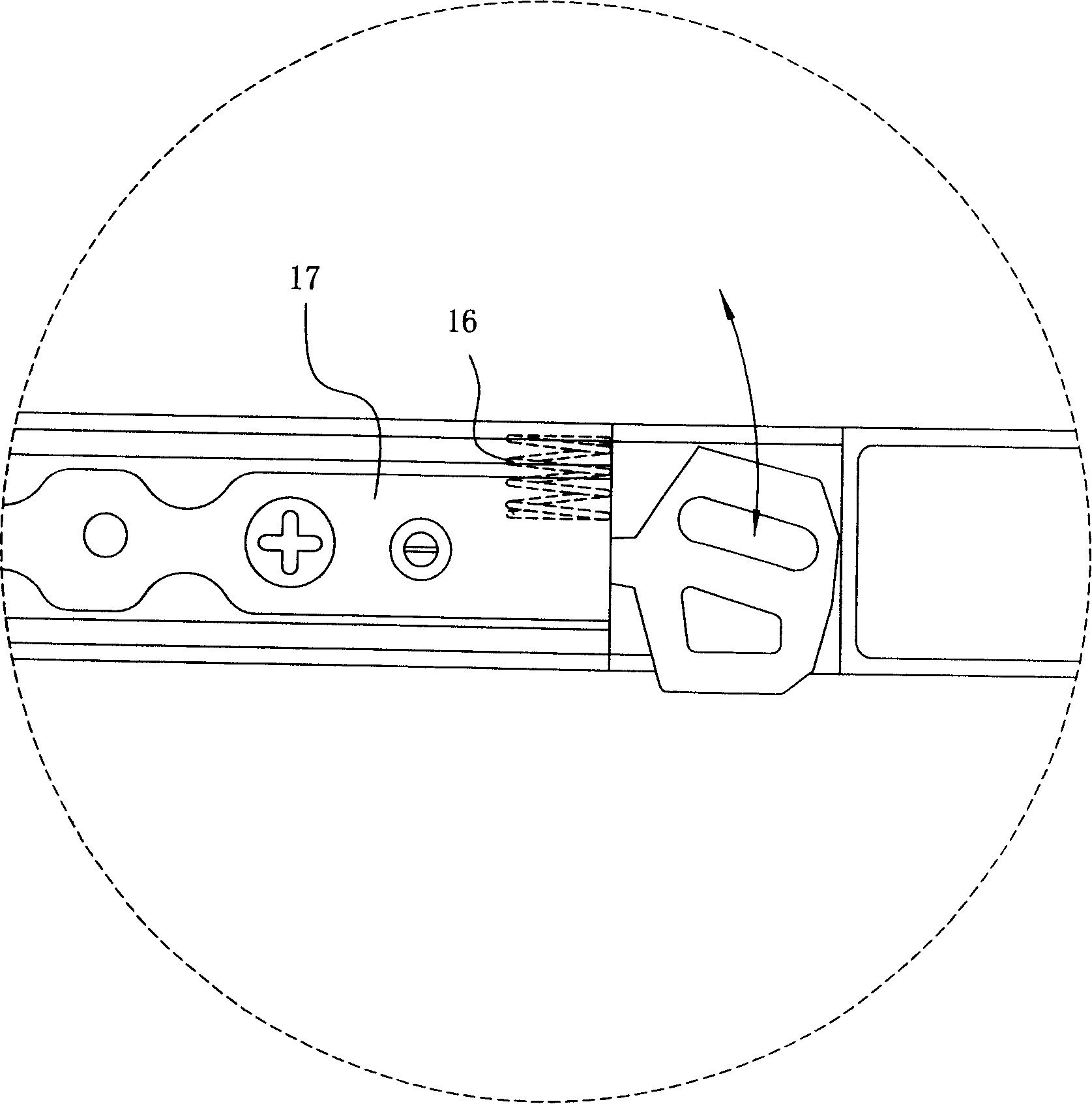

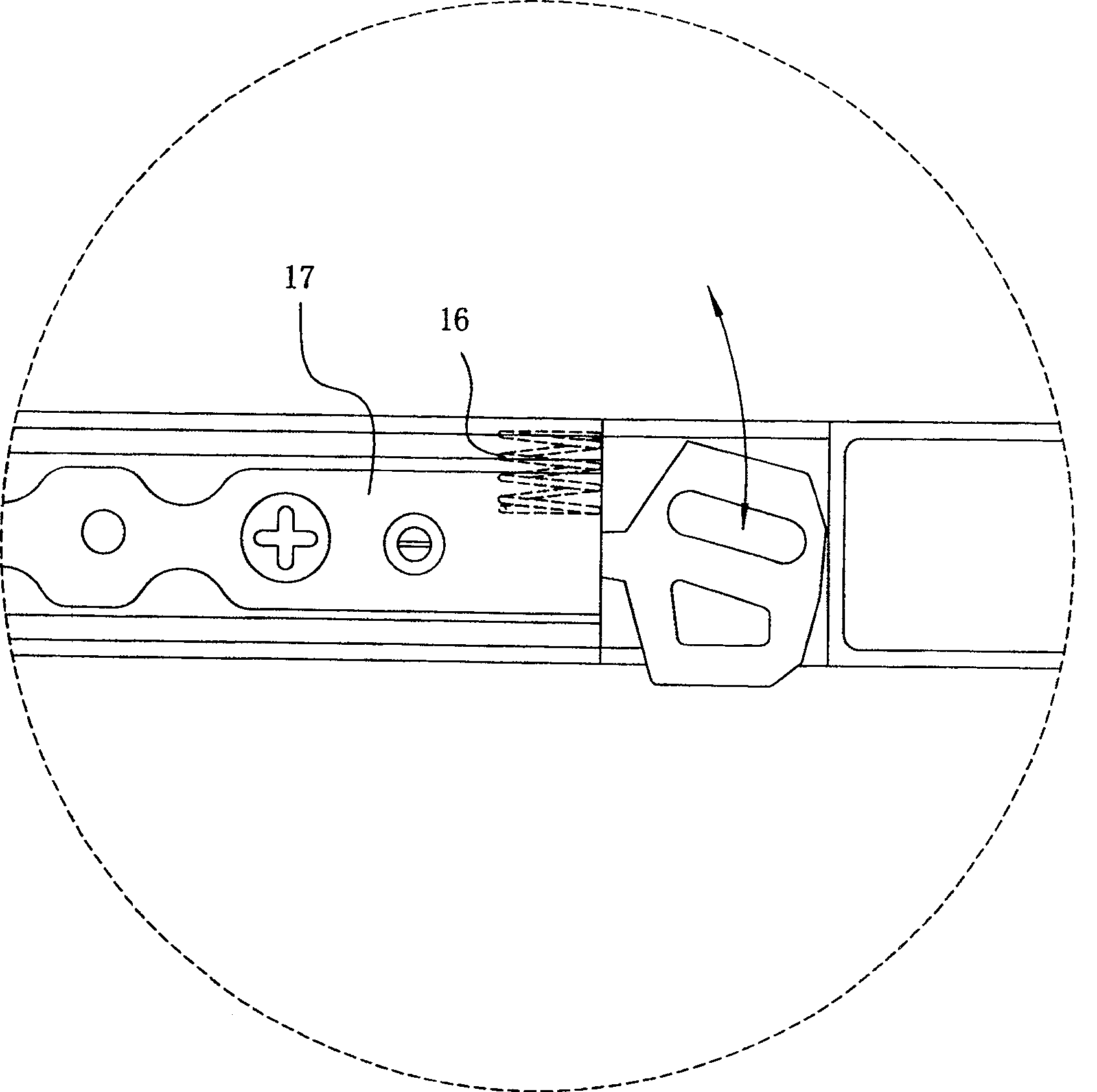

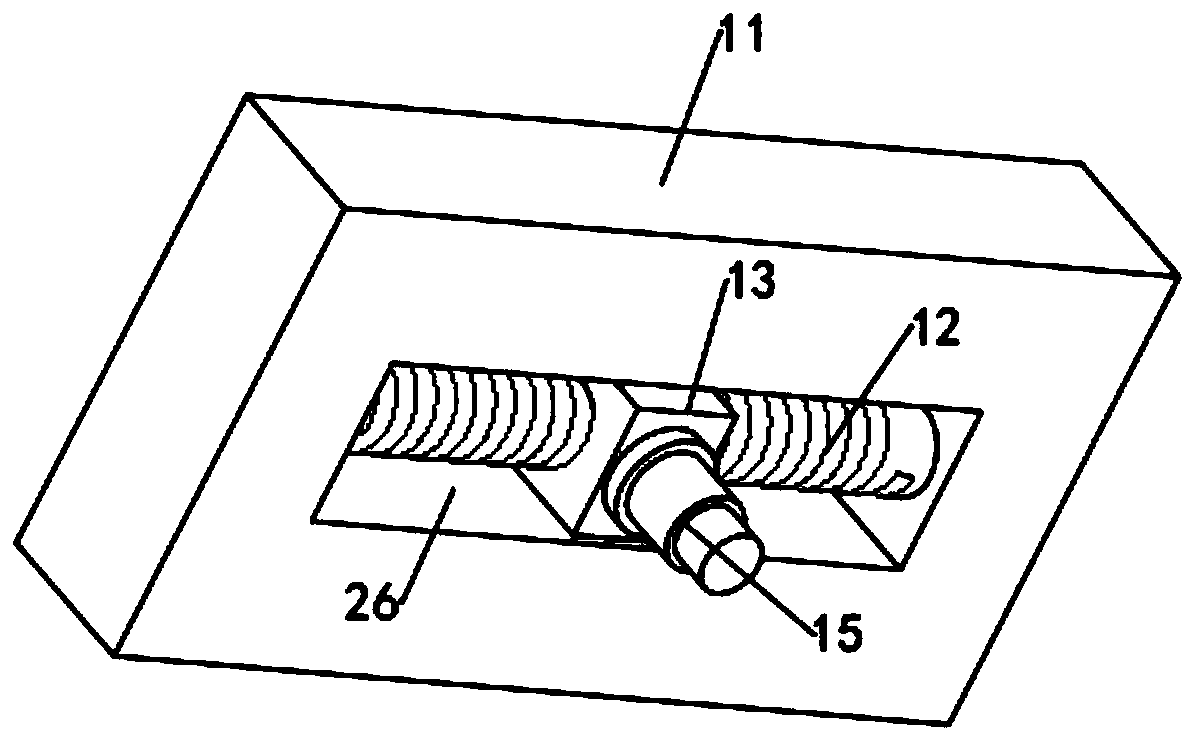

Gene chip sample applying nozzle

InactiveCN1986229AEasy to wash and dryEliminates particle cloggingPrintingEngineeringInstrumentation

The gene chip sample applying nozzle includes a micro nozzle, a holding fixture, a piezoelectric ceramic driver, a driving power source, a control valve and a control computer. The micro nozzle is connected to one end of the piezoelectric ceramic driver directly by means of the holding fixture, and the other end of the piezoelectric ceramic driver is connected to the instrument. The present invention has simple structure and easy manufacture, and may be used to obtain micro liquid drop of volume in 10<-15>-10<-12> liter for making high density gene chip micro array.

Owner:章维一 +2

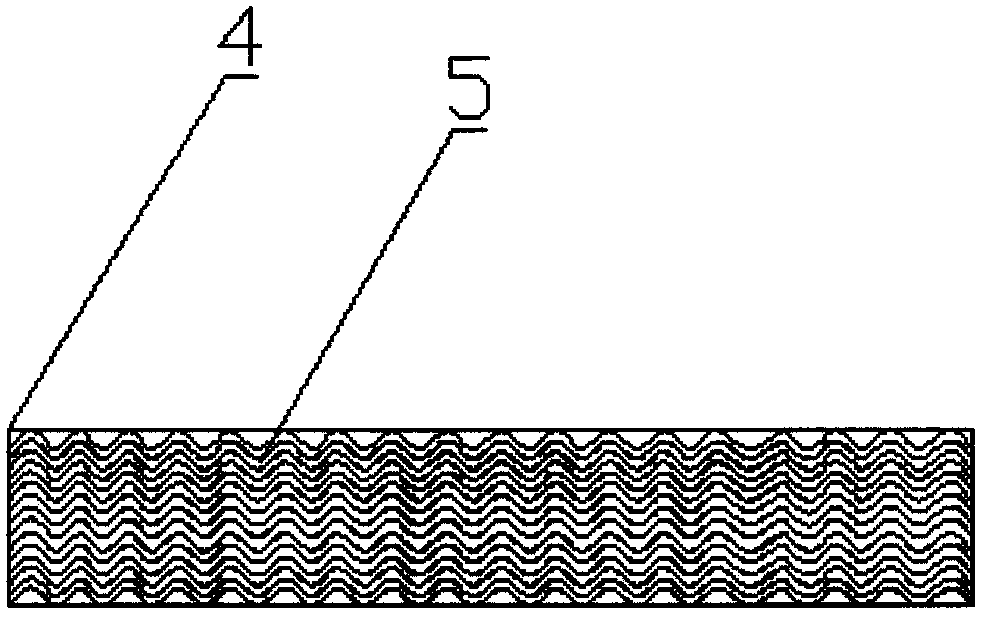

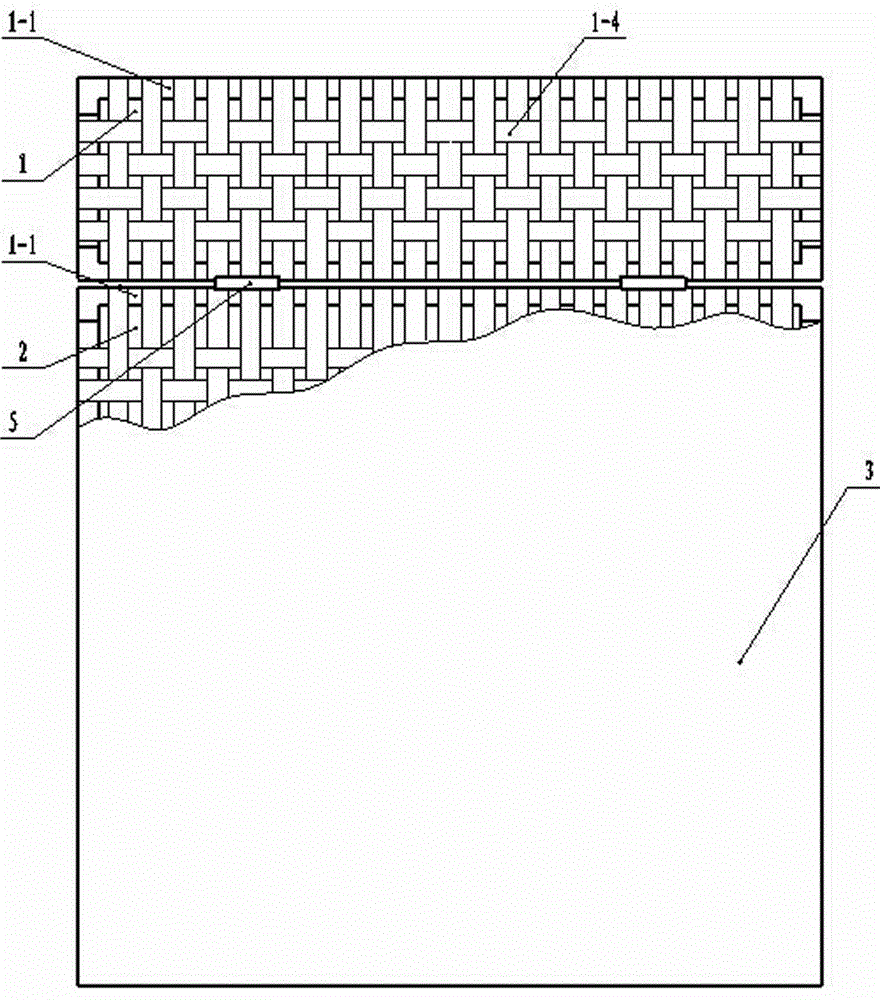

Four sides elasticity chamois flannel

InactiveCN101191273AEasy to stretchEasy to replyMonocomponent polyurethanes artificial filamentWoven fabricsFiberExtensibility

The invention relates to a neoprene suede nap and belongs to the textile fabric technical field. The invention is mainly characterized in that: warp threads are wrapped yarns taking sea-island filament as urethane elastic fiber core yarns, and the sea-island filament is made to become elastic sea-island filament; weft yarns are wrapped yarns taking PTT polyester as urethane elastic fiber core yarns, thereby the PTT is made to have good tension and restoring force and advanced performances like softness, fluffiness, easy dyeing, easy washing and so on are fully displayed; because a little urethane elastic fiber is arranged inside the PTT, resilience of the PTT is strengthened. The invention utilizes stain resistance better than chinlon fiber, antistatic property better than nylon, fluffiness, resilience, chromaticity, good stain removal and antifouling properties, easy dyeing, soft hand feeling, abundance in elasticity, and extensibility same as urethane elastic fiber of the PTT fiber to prepare the suede nap through coating according to mixture ratio; advantages of the two fibers are given full play; due to addition of the PTT fiber, the cost of raw materials and processing costs like energy consumption and so on can be reduced; due to addition of the urethane elastic fiber, the resilience can be guaranteed; by weaving of the suede nap, disadvantages of thin fabrics are avoided.

Owner:YANGZHOU JIYUAN TEXTILE

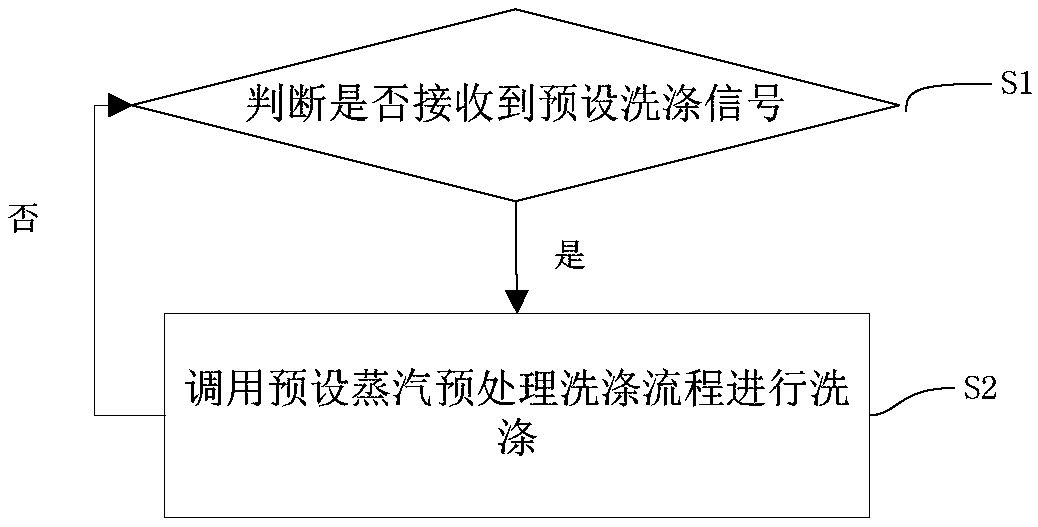

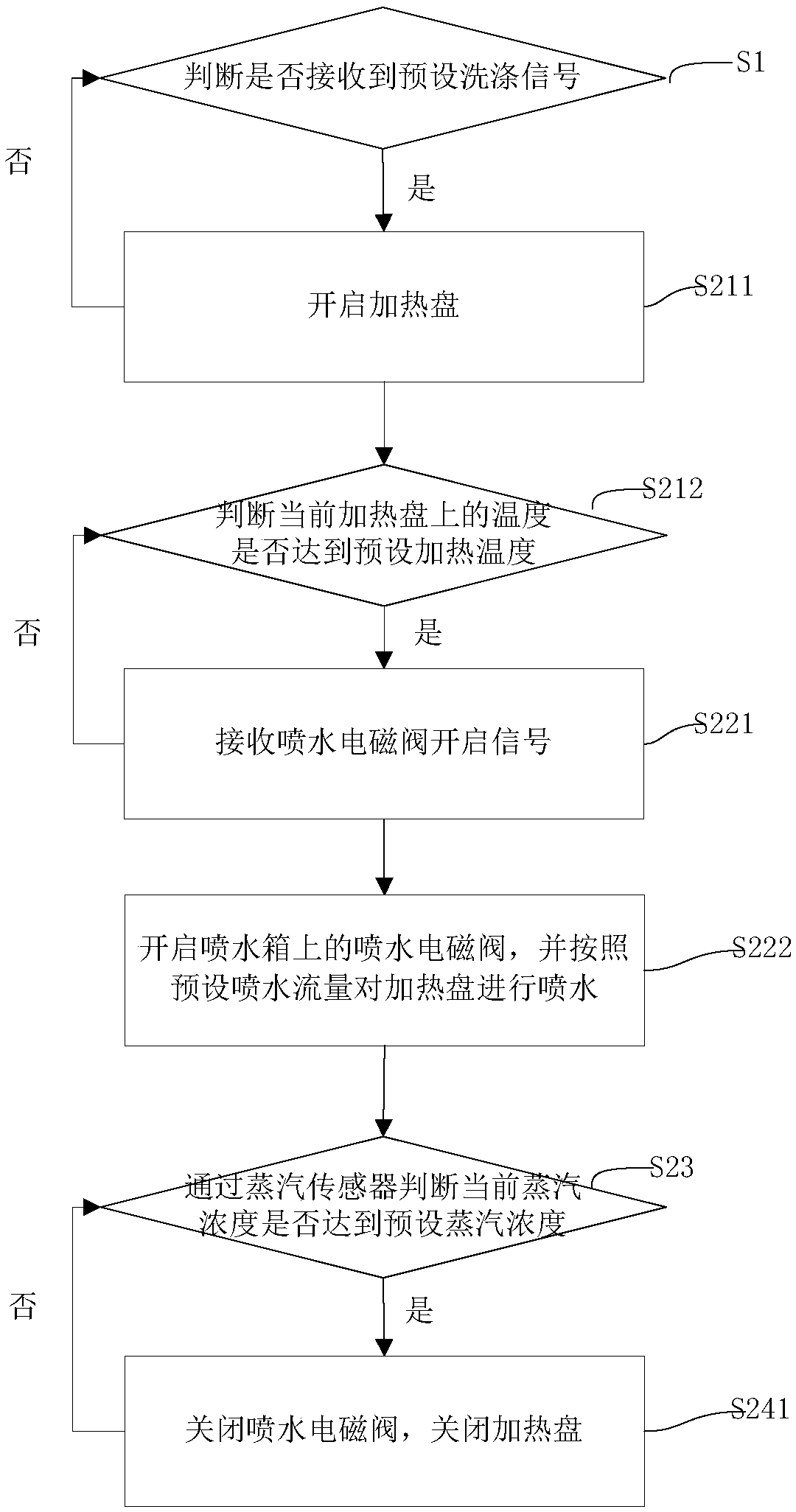

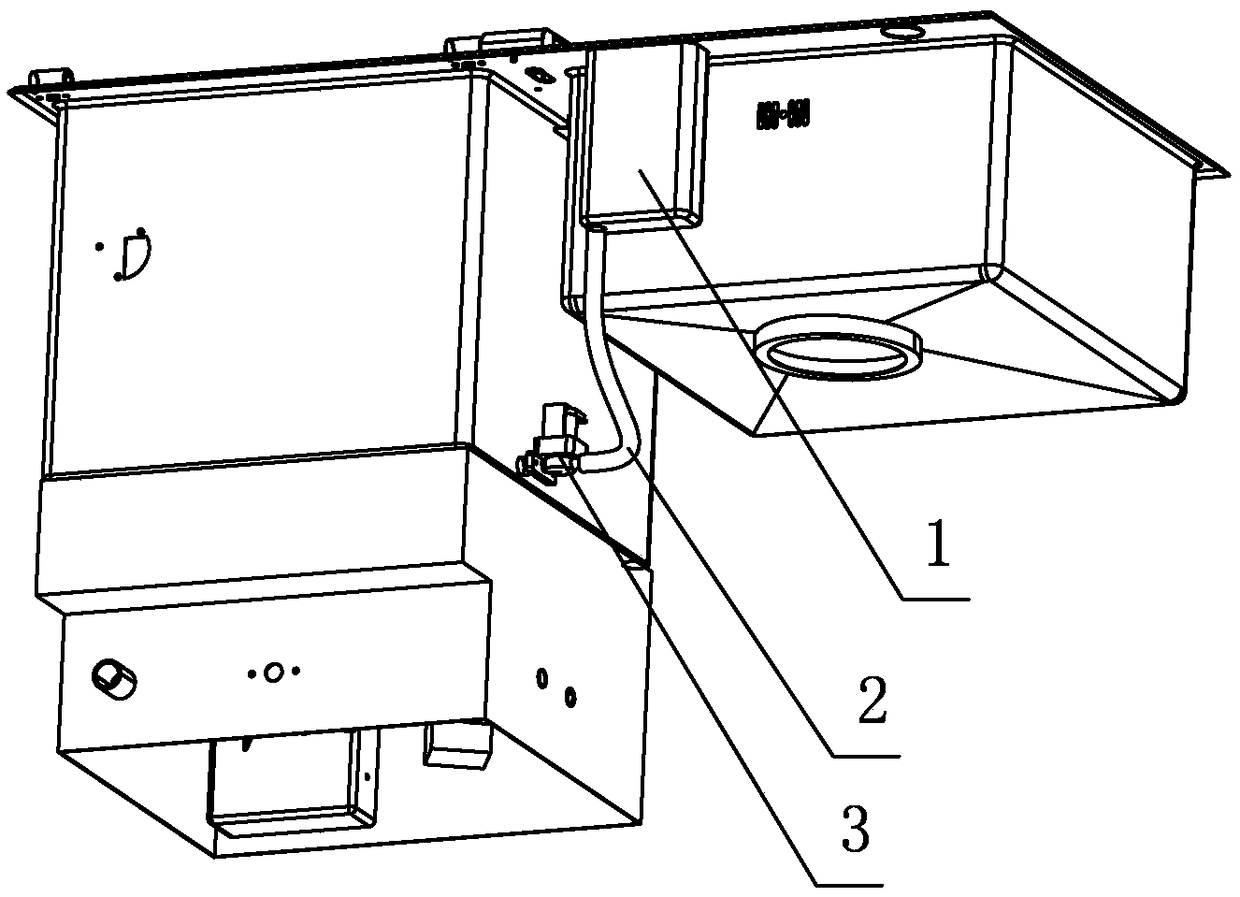

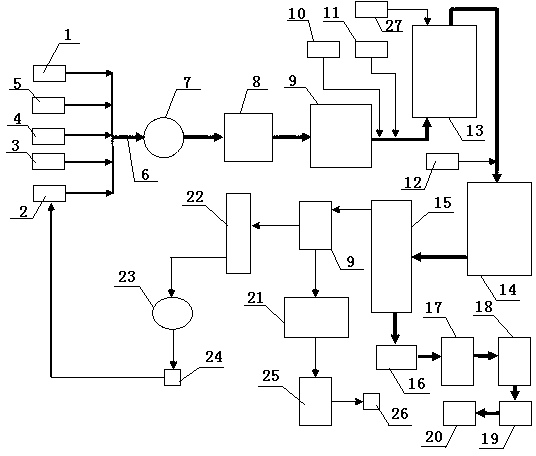

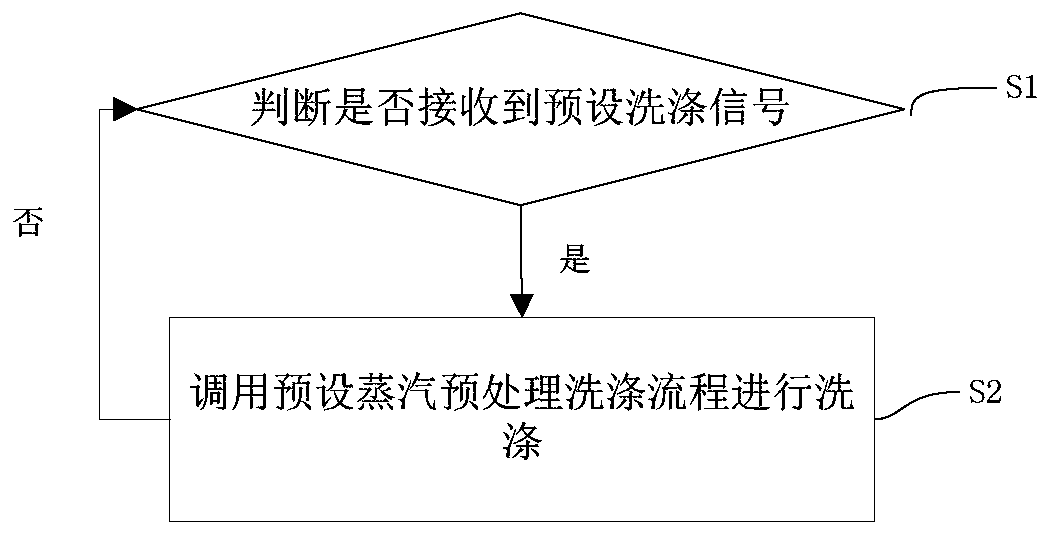

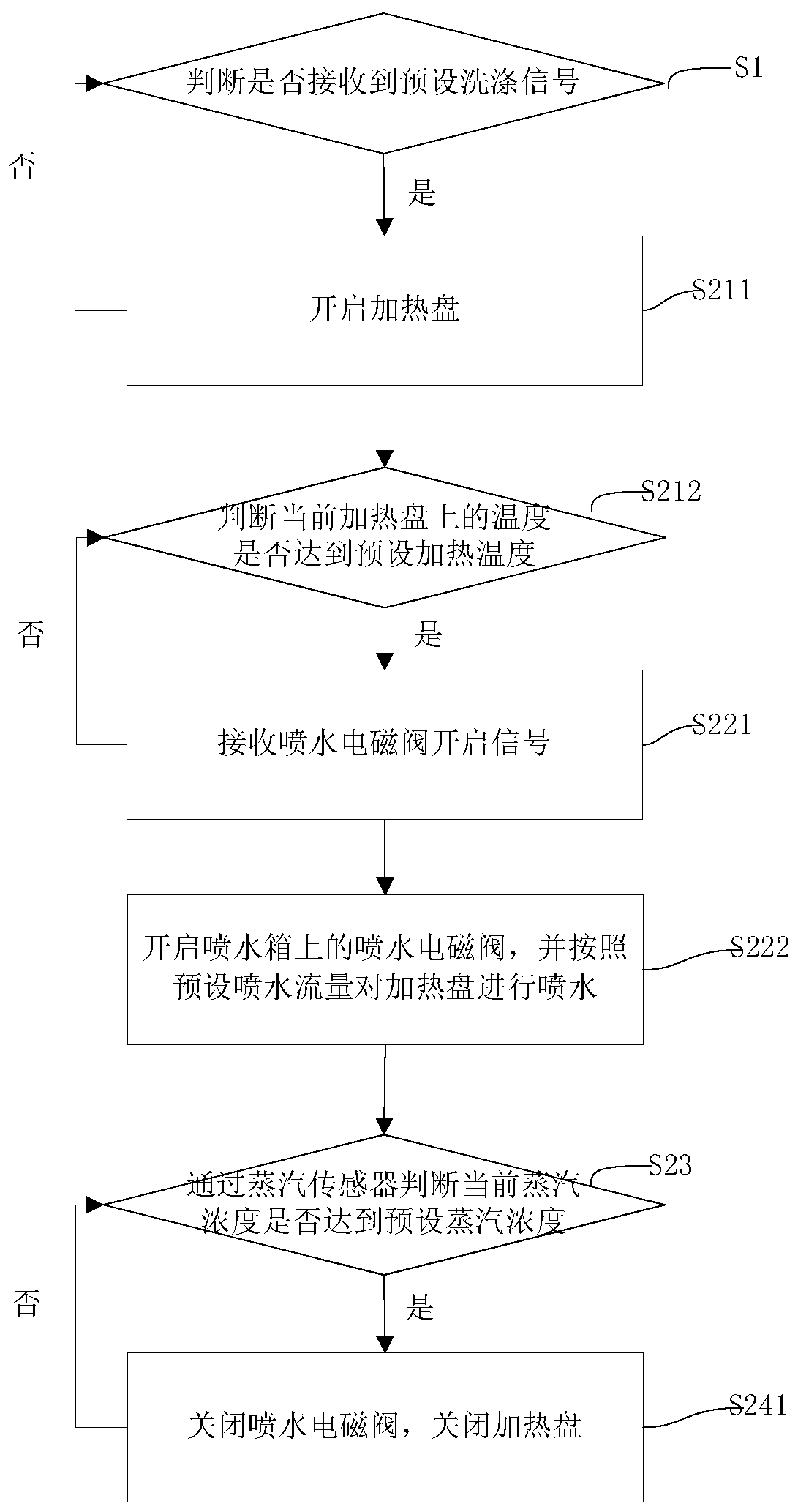

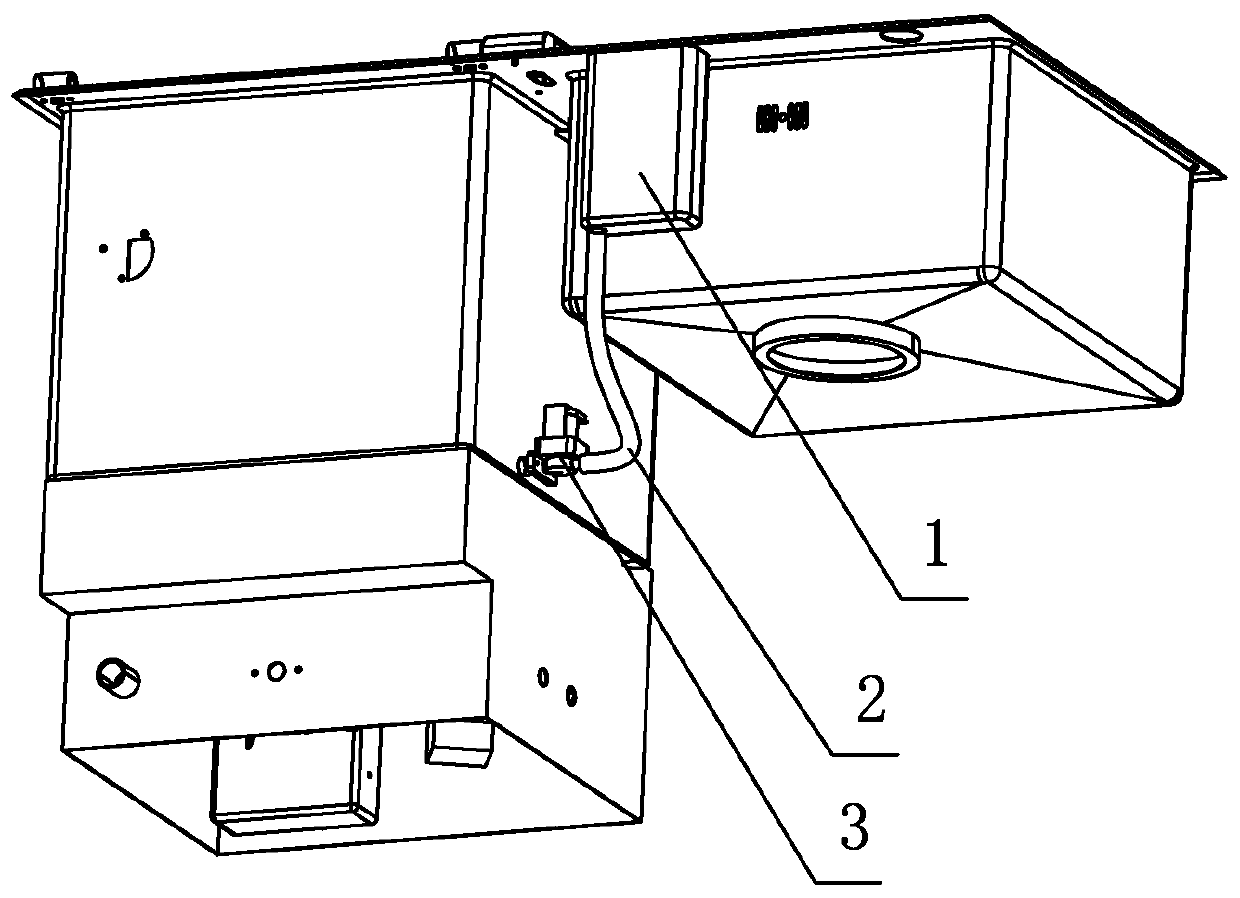

Method and a system for steam pretreatment of a sink of a dishwasher

ActiveCN109124513AImprove cleanlinessImprove cleaning efficiencyTableware washing/rinsing machine detailsWashing processesEngineeringOil pollution

The invention provides a method for steam pretreatment of a sink of a dishwasher, which is used for solving the problem that the dishwasher is not cleaned due to the solidification of the oil dirt ona dinner plate and a dish chopsticks in the prior art. The method for steam pretreatment of the sink of the dishwasher comprises the following steps: S1, judging whether a preset washing signal is received; S2: If yes, the preset steam pretreatment washing process is called for washing. The method pretreats the dishwasher with steam before the preset washing process, and softens the oil stains onthe dish and the dishchopsticks through the steam pretreatment, thereby improving the cleanliness of the dishwasher and ensuring the cleaning effect of the dishwasher.

Owner:NINGBO OULIN IND CO LTD

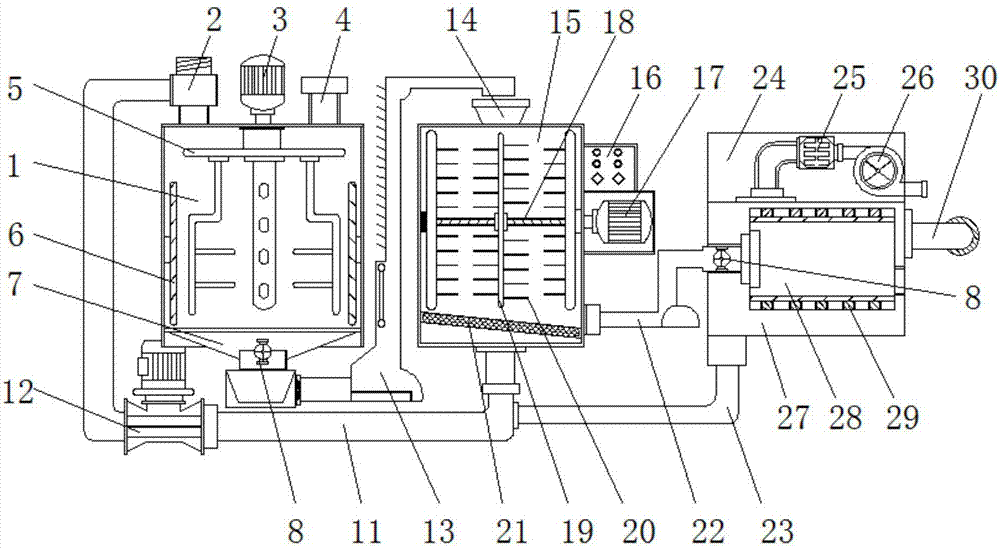

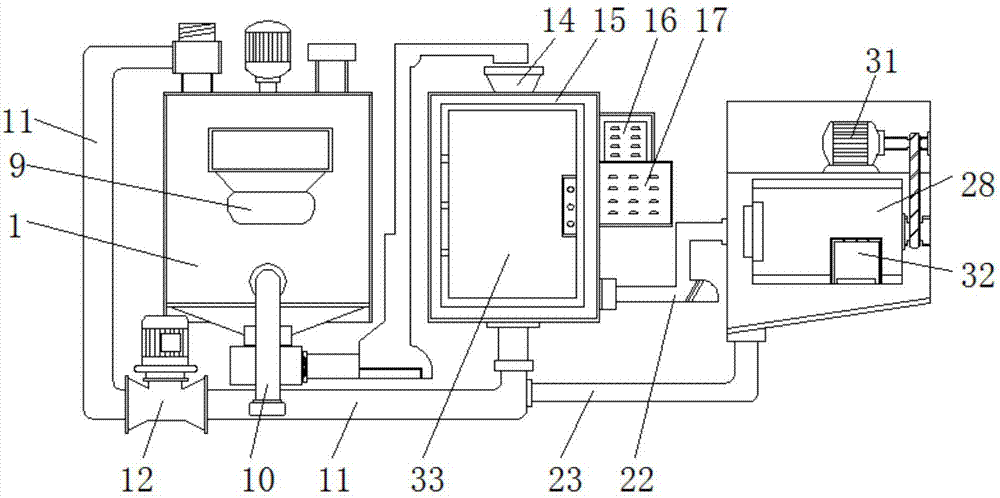

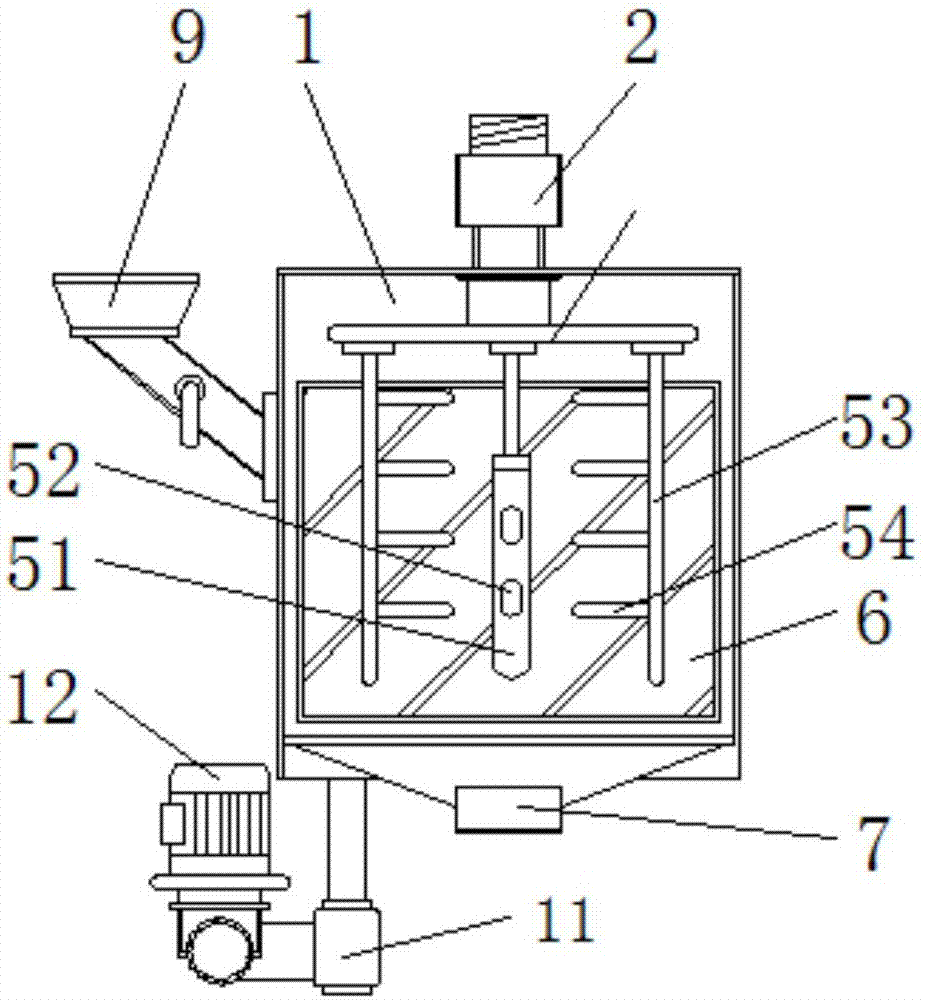

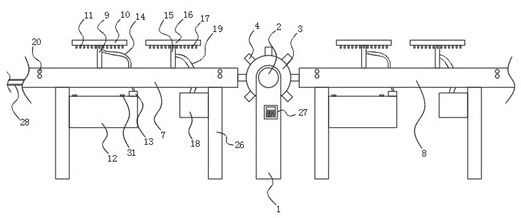

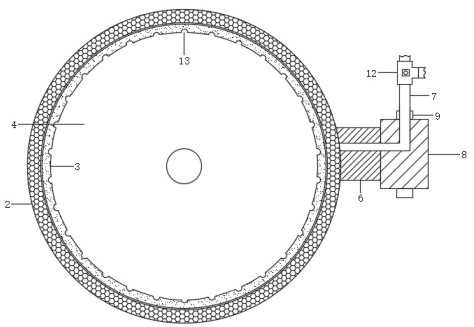

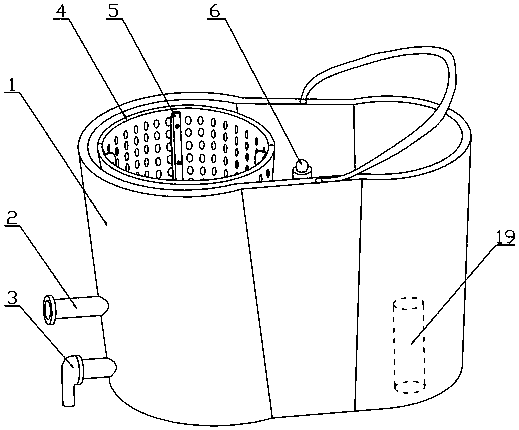

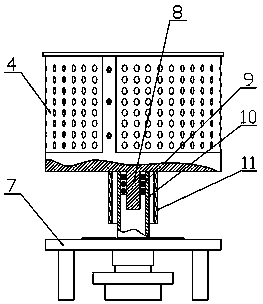

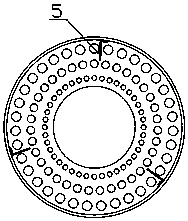

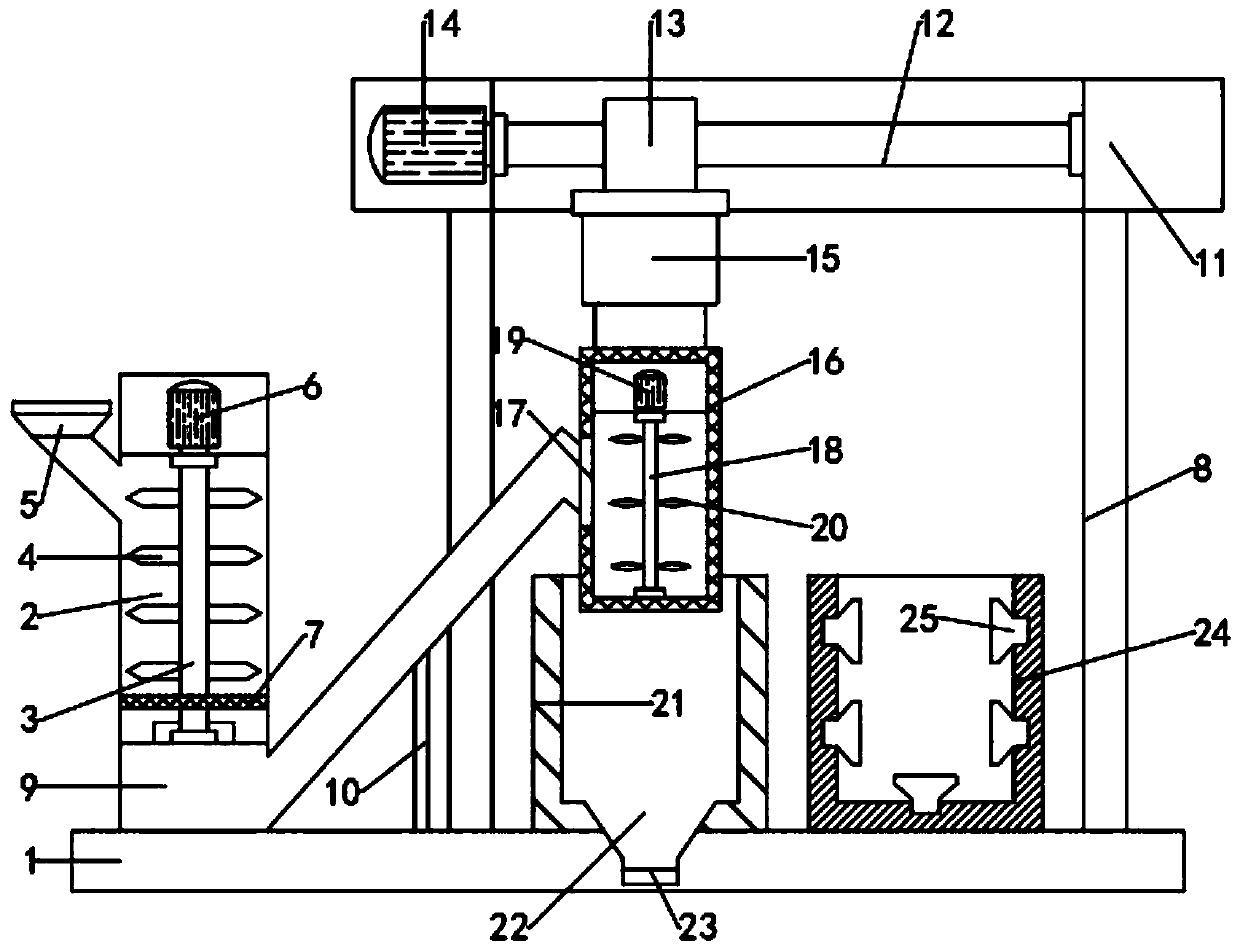

Black carp washing and drying integrated device

ActiveCN107439666AEasy to cleanEasy to wash and dryFish washing/descalingClimate change adaptationIntegrated devicesBlack carp

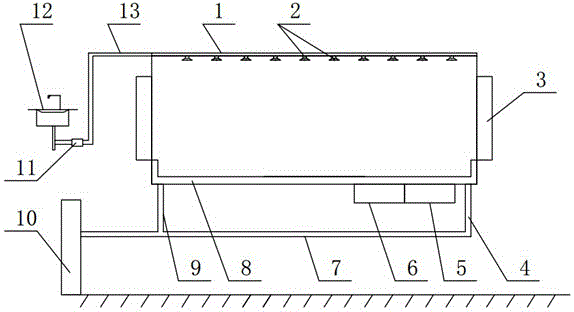

The invention relates to a black carp washing and drying integrated device. The black carp washing and drying integrated device comprises a No.1 washing cavity, a rotating disk, a water inlet pipeline, bristles and a heating furnace, wherein the water inlet pipeline is fixed to the upper part of the No.1 washing cavity; a No.1 motor is arranged on the right side of the water inlet pipeline; a discharge opening is formed in the lower part of the No.1 washing cavity; a water pump is connected to the left side of the water inlet pipeline; the No.1 washing cavity is connected with a No.2 washing cavity through a No.1 elevator on the right side of the No.1 washing cavity; a rotating cavity is connected with the water inlet pipeline through a drainage pipeline under the rotating cavity; ventilating holes are formed in the outer side of the rotating cavity; a No.3 motor is mounted behind the heating cavity; a material taking door is fixed to the rear surface of the drying cavity; and a sealing hatch door is mounted on the rear surface of the No.2 washing cavity. According to the black carp washing and drying integrated device disclosed by the invention, black carp meat is thoroughly washed by the bristles; the heating area of the black carp meat is uniform through the continuous rotation of the rotating cavity; and in the process of washing and drying, clean water is reused.

Owner:WUHU TAIQING ELECTRONICS TECH CO LTD

Manufacturing method of beaded polytrifluorochloroethylene resins

The invention relates to a manufacturing method of beaded polytrifluorochloroethylene resins, which comprises the following steps of: taking trifluorochlor oethylene, high-purity water, an organic dispersant and an initiator under the condition that the mass ratio of the trifluorochlor oethylene, the high-purity water, the organic dispersant and the initiator is 100:(500-1000): (50-200): (0.1-1); placing the high-purity water, the organic dispersant and the initiator in a reaction kettle, and at a stirring speed of 400-500 rmp, feeding the trifluorochlor oethylene into the reaction kettle; carrying out reaction on the obtained mixture for 4-6 hours under the conditions of 0.2-1 Mpa and 20-30 DEG C; and then continuing to react for 2-4 hours at a temperature of 50 DEG C and at a stirring speed of 100-200 rmp; and carrying out washing and drying on the obtained product so as to obtain a beaded polytrifluorochloroethylene resin with a diameter of 0.5-5 mm. The method disclosed by the invention is stable in polymerization rate and narrow in molecular weight distribution, no dust flying occurs in the process of production, and no further granulation treatment is required; the obtained polytrifluorochloroethylene resin is excellent in performances, and can be prepared into tubes, bars and profiles with more complicated shapes through melt injection molding; and no yellowing phenomenon occurs, therefore, the method has good social, economic and environmental benefits.

Owner:山东森福新材料有限公司

Dental appliance cleaning disinfecting device

InactiveCN109419562AAvoid damageSolve cleaningDentistryCleaning using liquidsMegasonic cleaningContact force

The invention belongs to the technical field of medical technology, and discloses a dental appliance cleaning disinfecting device. The dental appliance cleaning disinfecting device comprises a tank body; the internal bottom end of the tank body is provided with a slide groove; the internal part of the slide groove is connected with slide blocks through slide connection; one end of each slide blockis fixedly connected with a washing tank; the internal bottom end of the washing tank is fixedly connected with a ultrasonic cleaning device; the top of the ultrasonic cleaning device is provided with a rotating plate; the surface of the rotating plate is fixedly connected with a washing support; the two sides of the rotating plate are fixedly connected with bearings; one side of each bearing ismovably connected with a rotating rod; and one end of each rotating rod is fixedly connected with an output terminal of a motor. According to the dental appliance cleaning disinfecting device, the ultrasonic cleaning device is adopted, ultrasonic vibrators are adopted to generate strong vibration on washing solvent in the washing tank, the contact force of the solvent with dental appliance is enlarged, the motor is used for driving the rotating plate to rotate, and the dental appliance is driven to rotate, so that the contact force of the solvent with the dental appliance is enlarged further,and cleaning is convenient.

Owner:许利静

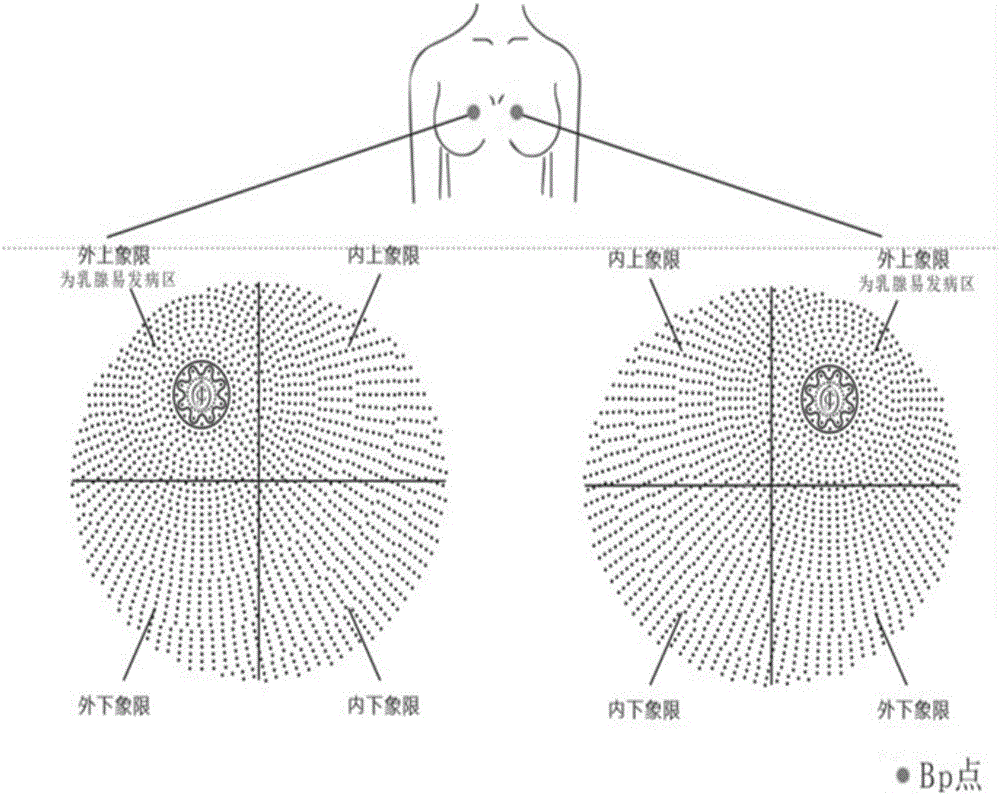

Making method of graphene-containing breast-conditioning health care bra

A making method of a graphene-containing breast-conditioning health care bra comprises the following steps: uniformly mixing warm water, graphene and hot-melt silica gel to prepare a graphene glue; uniformly printing a sandwich fabric with the mixed graphene glue for multiple times according to a template, air-drying, and fitting with a non-woven fabric sticky glue; carrying out positioning cold pressing and mold pressing of the fitted material at the temperature of 190 DEG C or less; then trimming into cups; seaming the cups combined with surface cups, back wings, flanks, shoulder straps, hook buckles, decorations and other traditional components, wherein the flanks adopt arc-shaped side plastic bones, the graphene-containing breast-conditioning health care bra is obtained through machine sewing. The graphene-containing breast-conditioning health care bra manufactured by applying the graphene high technology composite raw material provides a safest and comprehensive care for female breasts.

Owner:广州美乔新材料科技有限公司

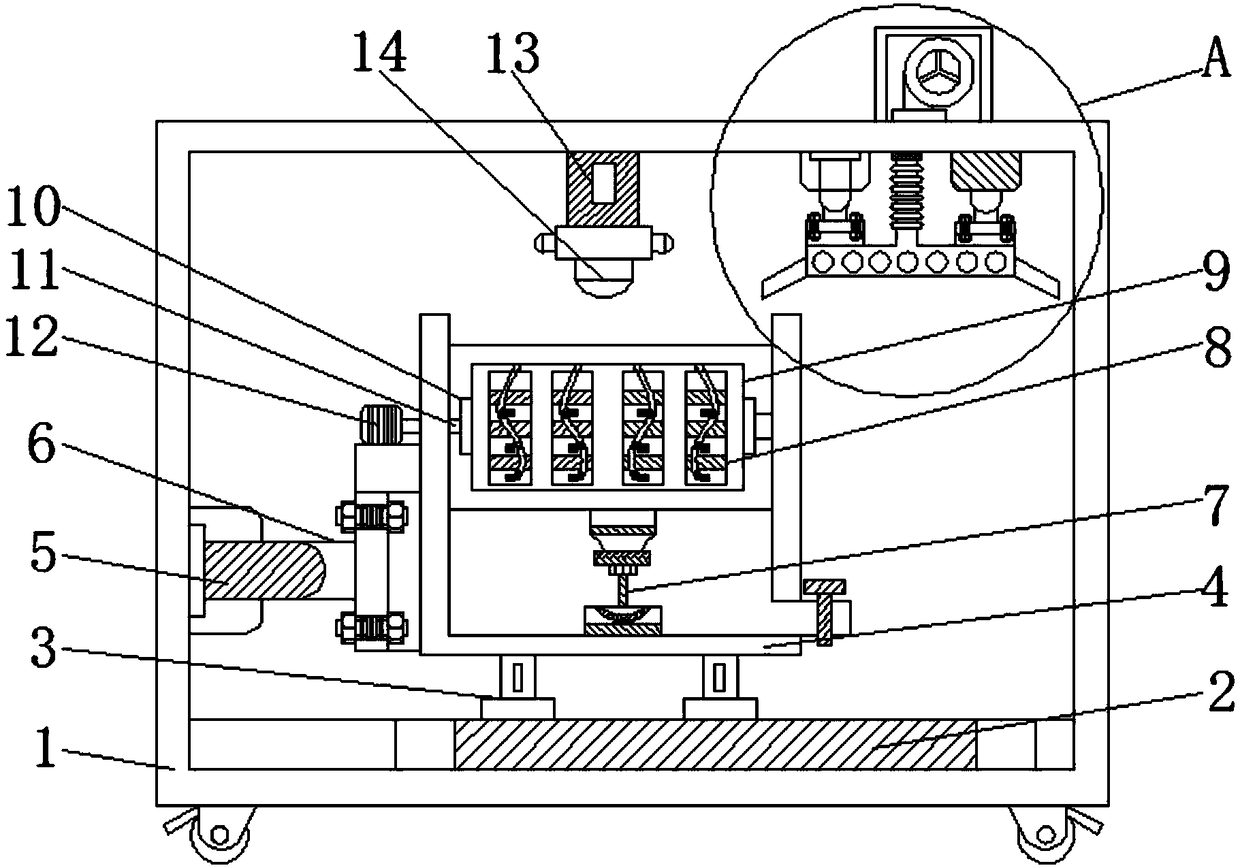

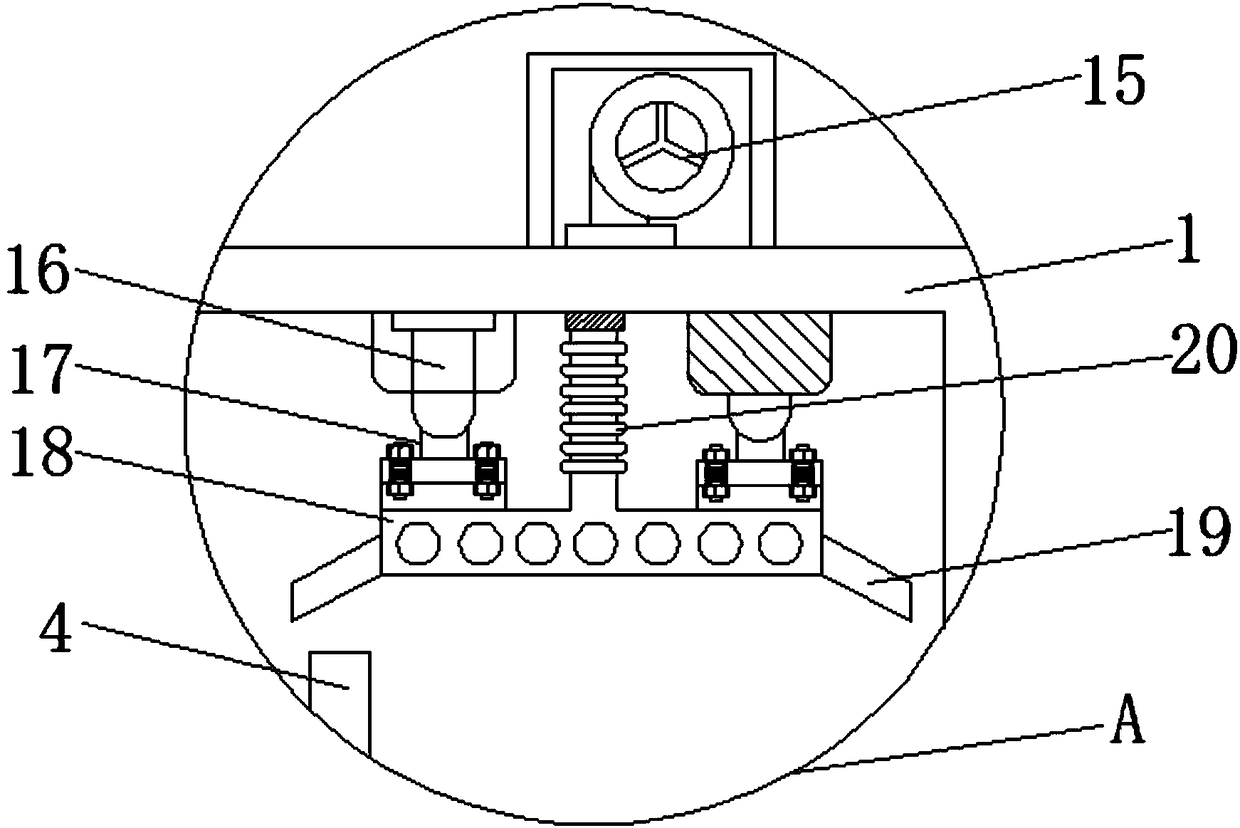

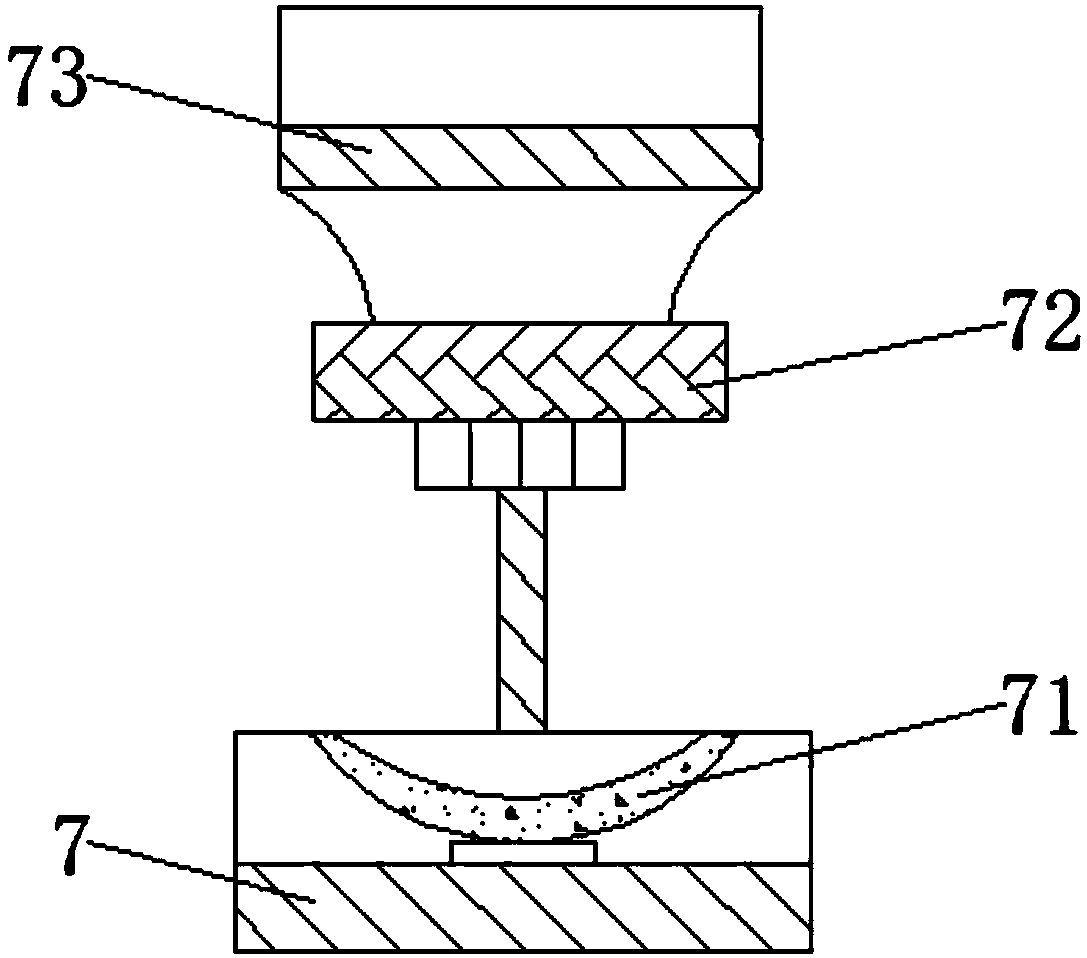

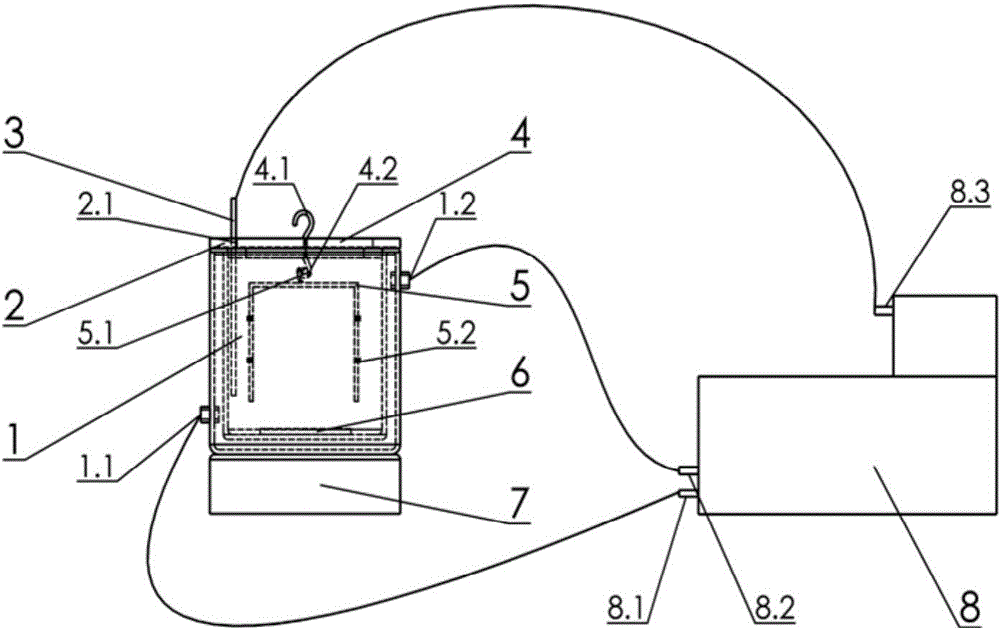

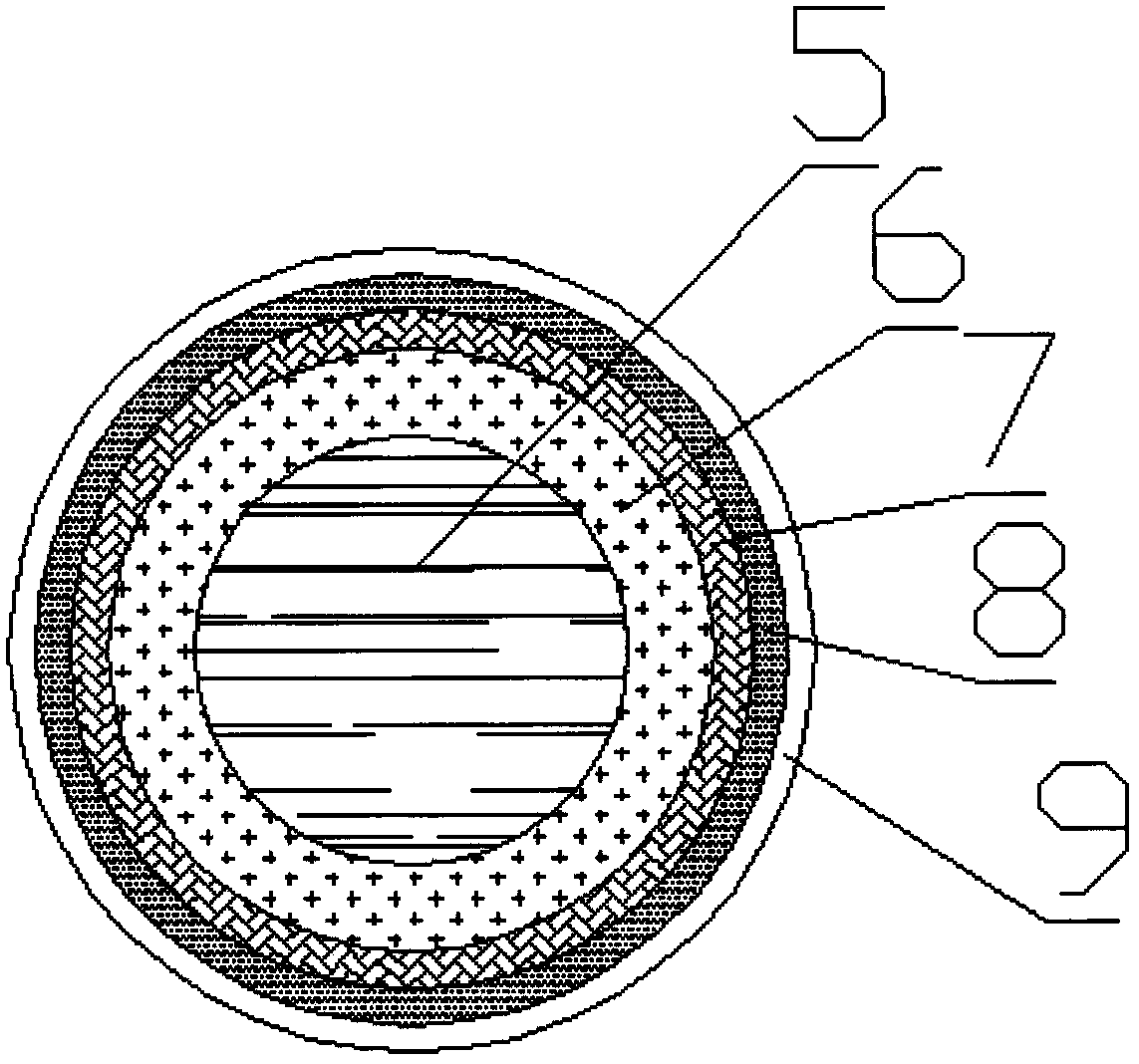

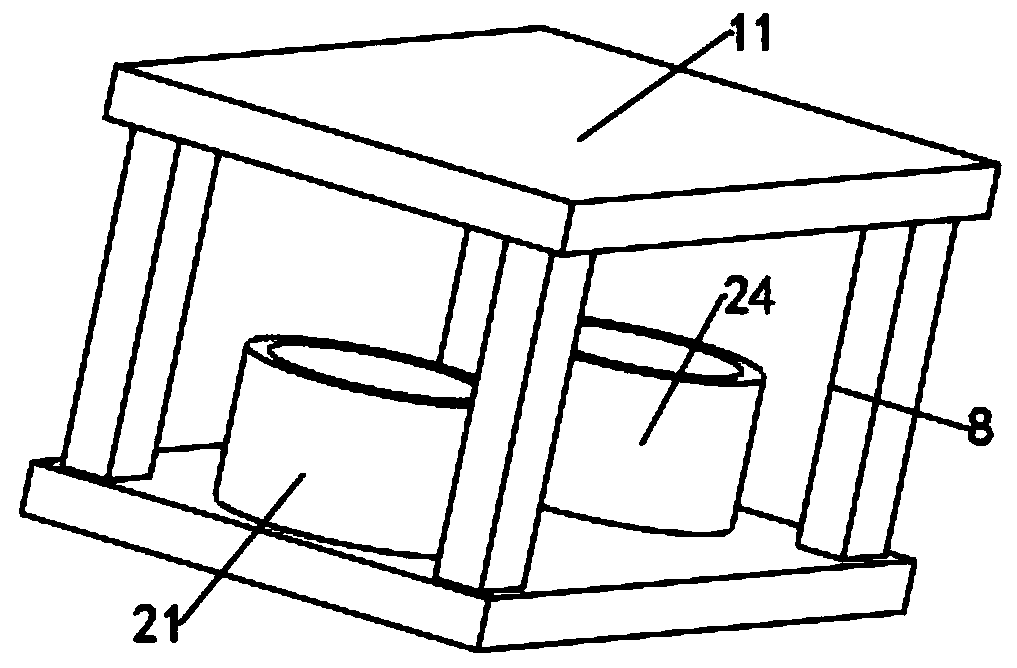

Nuclear pore membrane small sample etching apparatus

InactiveCN104977198AUniform temperaturePrecise temperature controlPreparing sample for investigationLiquid temperatureSmall sample

The present invention relates to a nuclear pore membrane small sample etching apparatus, which is mainly characterized by comprising an etching cup, wherein a sealed upper cup cover is arranged above the etching cup, an inner cover performing secondary sealing on the etching cup is arranged below the upper cup cover, a membrane bracket is arranged below the inner cover, a thermal-sensitive probe is arranged inside the etching cup, the etching cup has the double-layer hollow cup wall, the upper side and the lower side are respectively provided with a water inlet and a water outlet, the water inlet and the water outlet are respectively communicated with the water outlet end and the water inlet end of a constant temperature circulation system, and magnetic transmission stirring comprising a magneton and a magnetic stirring device is arranged below the etching cup. According to the present invention, with the magnetic stirring, the etching liquid maintains the uniform state; with the circulating water heating of the etching cup interlayer, the etching liquid temperature is uniform; the built-in thermal-sensitive probe and the etching liquid are connected, such that the etching liquid temperature can be accurately controlled; the whole etching cup maintains the sealed state, such that the solution evaporation can be reduced; and the sample is fixed through the sample clamp, such that the sample maintains the flat state, the sample taking is convenient, and the cleaning and air-drying are easy.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

Cleaning equipment for medical equipment

InactiveCN111871948AEasy positioningEasy cleaning connection operationDrying machines with local agitationDrying machines with materials at restMedical equipmentCleansing Agents

The invention discloses cleaning equipment for medical equipment. The cleaning equipment comprises a cleaning equipment main body, the cleaning equipment main body comprises a cleaning box, a positioning pipe, an inflation sealing air cushion, a placement box, an observation window, a buckle groove and a sealing gasket, the observation window is formed in one side of the cleaning box, and the positioning pipe and the placement box are arranged on the outer surface of the rear end of the cleaning box; and the buckle groove is formed in the outer wall of the positioning pipe, the inflation sealing air cushion is fixedly connected to the inner wall of the positioning pipe, and the sealing gasket is fixedly connected to the inner surface of the inflation sealing air cushion. The cleaning equipment for the medical equipment is provided with the cleaning equipment main body, a water inlet tank, an airing cover plate and a mounting plate convenient to disassemble and assemble, cleaning connection operation is facilitated, disassembling and assembling are easy, the sealing effect is excellent, water adding operation can be better conducted conveniently, cleaning agents can be mixed conveniently, regulation and control can be conducted, and cleaning and airing operation is facilitated; and the installation effect is more excellent, and the protection performance is good.

Owner:孝感市优达城市环保科技有限责任公司

Rotary cleaning and drying device for experimental apparatuses for senior high school students

InactiveCN107497770APlace stableFully contactedDrying gas arrangementsCleaning using liquidsAir pumpEngineering

The invention discloses a rotary cleaning and drying device for high school students' experimental equipment, which comprises a top cover, a cooling block, a heat conduction sheet and a fixing rod. The lower end of the screw is fixed with a screw rod, and a heat conduction column is placed under the screw rod, a heat supply chamber is installed on the right side of the heat conduction column, and an air pump is arranged inside the heat supply chamber, and an electric heating wire is installed inside the air pump, A heat conduction sheet is fixed above the heat dissipation block, and the heat dissipation block is located inside between the heat conduction columns, and a rotating sheet is arranged below the heat conduction sheet. The rotary cleaning and drying device for high school students' experimental equipment is equipped with a heat conduction column, and the hollow inside can transport hot air very well, so that the heat dissipation block and the heat conduction sheet can heat up rapidly, which is beneficial to improve the drying effect.

Owner:朱石明

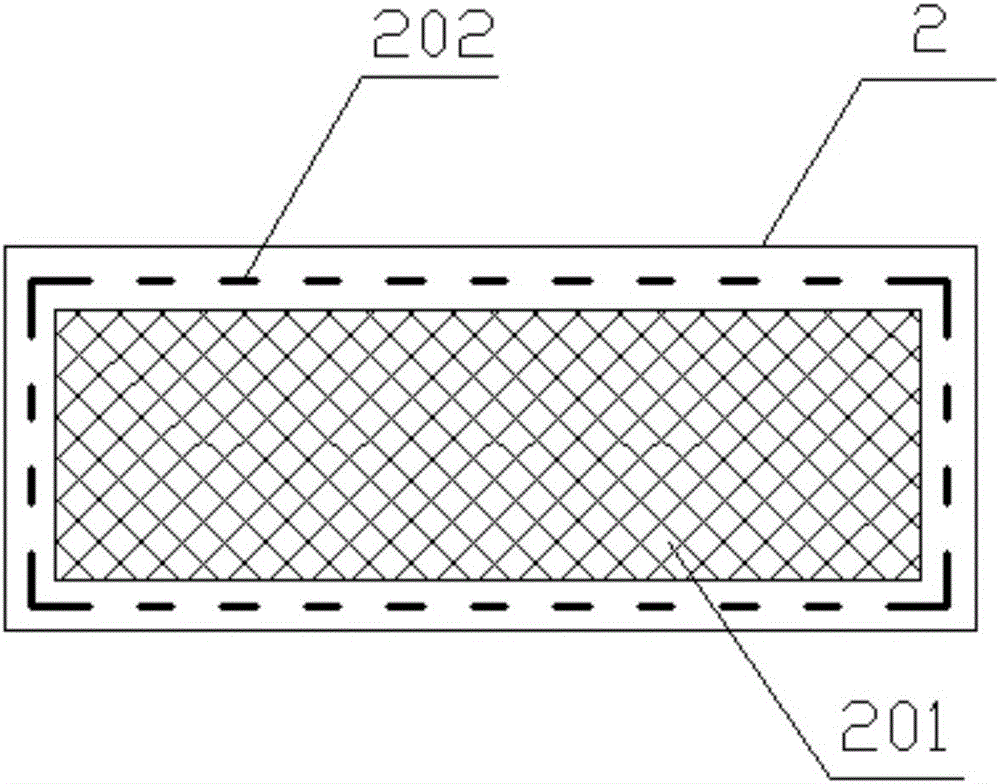

Automatic moisture absorption and drying clothes for pets

PendingCN106577341AGood moisture absorption and drying effectAccelerated moisture absorption drying effectGrooming devicesMoisture absorptionProcess engineering

The invention provides a piece of automatic moisture absorption and drying clothes for pets, and relates to the field of pet clothes. The automatic moisture absorption and drying clothes for pets includes a clothes body, a heat generating line and a power supply device for supplying power for the heat generating line, wherein the heat generating line is arranged at the inner side surface of the clothes body. The automatic moisture absorption and drying clothes for pets has the advantages of quickly and automatically drying the clothing hair of pets and being convenient for usage.

Owner:史静

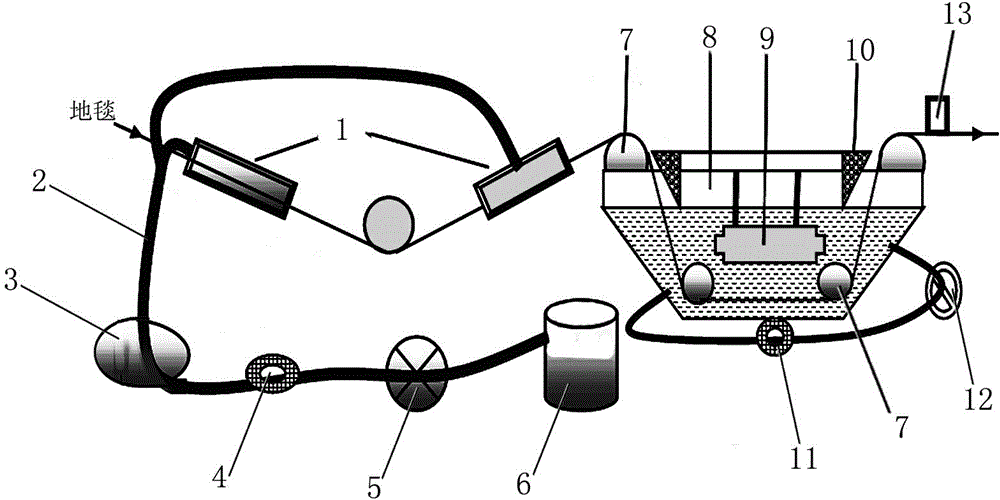

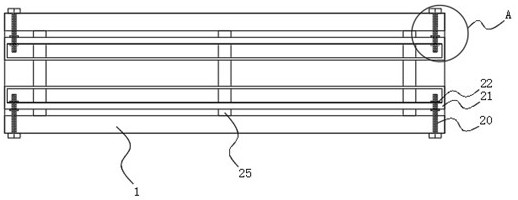

Device and process for washing carpets

ActiveCN104404751AEasy to wash and dryImprove qualityMechanical cleaningPressure cleaningWater resourcesWater flow

The invention relates to a device and a process for washing carpets in digital inkjet printing procedures. The device for washing the carpets comprises a paste recycling device, a washing tank, four guide rolls, a first water spraying device, a second water spraying device, a water flow flushing device and a vacuum water sucking device. The paste recycling device comprises two sucking barrels, a pumping pipeline, a vacuum pump, a filter device, a centrifugal water removing device and a mixing barrel; the washing tank is a trapezoidal tank with the length of 2 meters, the width of 4.3 meters and the depth of 1.3 meters, and the water flow flushing device and two guide rolls are mounted in the washing tank. The device and the method have the advantages that residual paste in the carpets can be thoroughly removed by the aid of the method, and accordingly the carpets are high in quality; water can be recycled in washing procedures, so that water resources can be saved; the paste can be recycled, so that the printing and dyeing waste water disposal difficulty can be lowered, and the benefit can be increased.

Owner:威海德瑞合成纤维有限公司

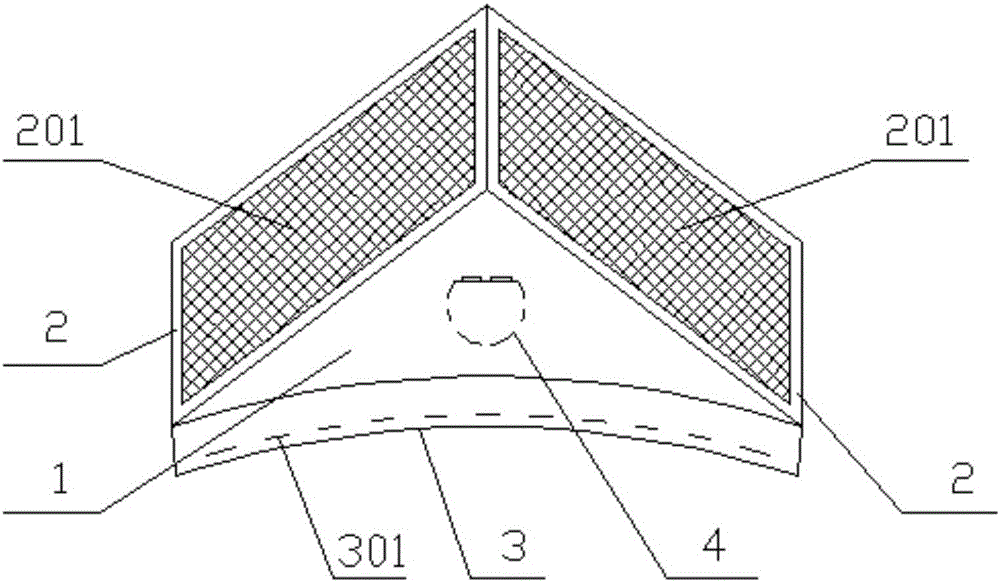

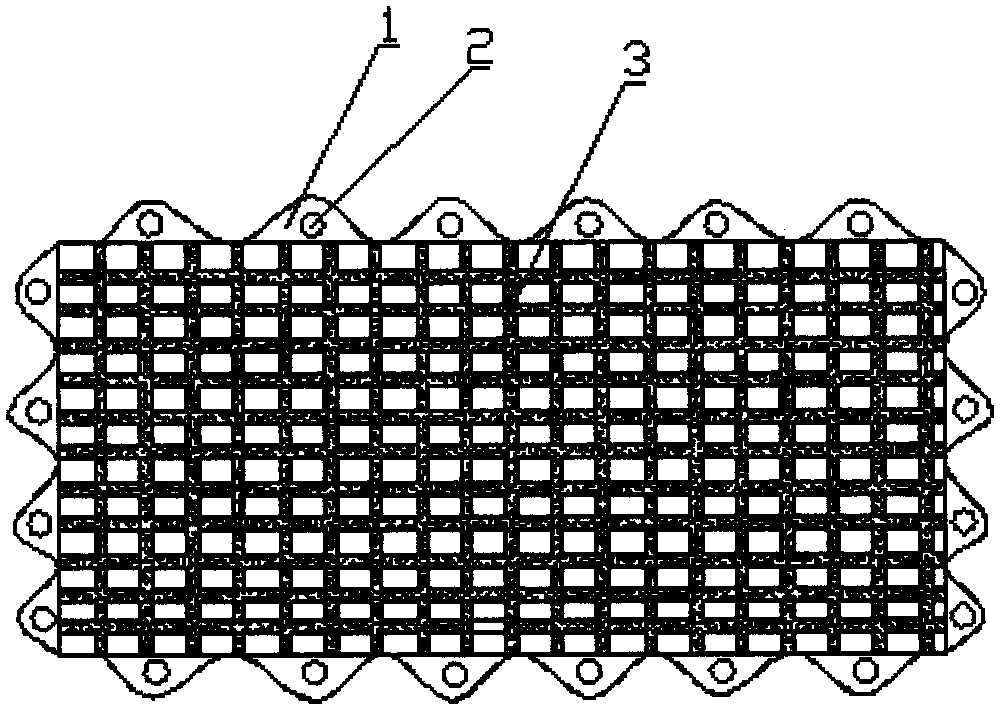

Basin filter screen

InactiveCN105126407AEasy to dryEasy to wash and dryStationary filtering element filtersRight triangleWater flow

The invention provides a basin filter screen. The basin filter screen comprises a bottom plate and vertical plates, wherein the bottom plate is a right-angle triangular plate with an inclined side which is downward and arc-shaped, the radian of the inclined side of the bottom plate is fit with the radian of the edge of the mouth of the basin, the vertical plates perpendicular to the bottom plate are respectively arranged on the two straight sides of the bottom plate, the two vertical plates are in a V shape, hollowed-out surfaces are arranged on the vertical plates, the hollowed-out surfaces are covered with filter screens, a vertically downward arc-shaped clamping groove is formed along the arc-shaped side of the bottom plate, and a convex edge for fastening the filter screens on the edge of the basin is arranged on the inner side surface of the arc-shaped clamping groove. The basin filter screen has the beneficial effects that the basin filter screen can be clamped on the edge of the basin through the arc-shaped clamping groove, water flows through the two V-shaped vertical plates during washing of food materials, thereby the water is filtered, the food materials are remained in the basin or the basin filter screen without being taken away by the water, and the food materials can be quickly and conveniently cleaned.

Owner:李传义

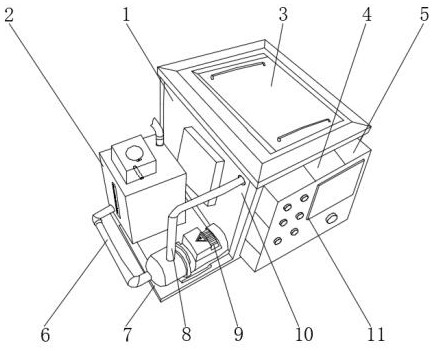

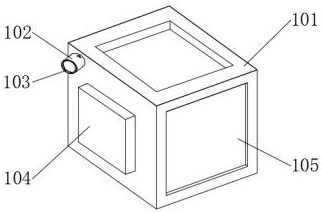

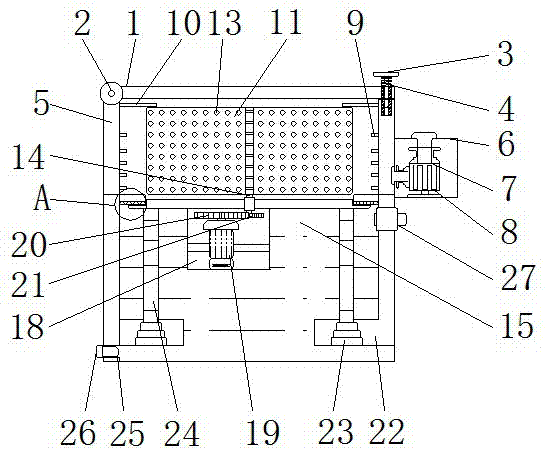

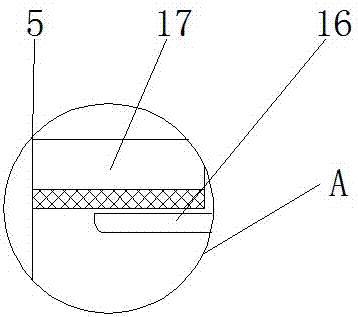

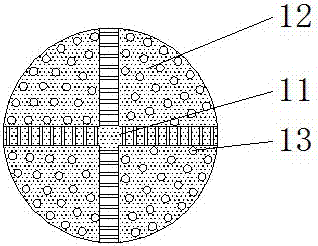

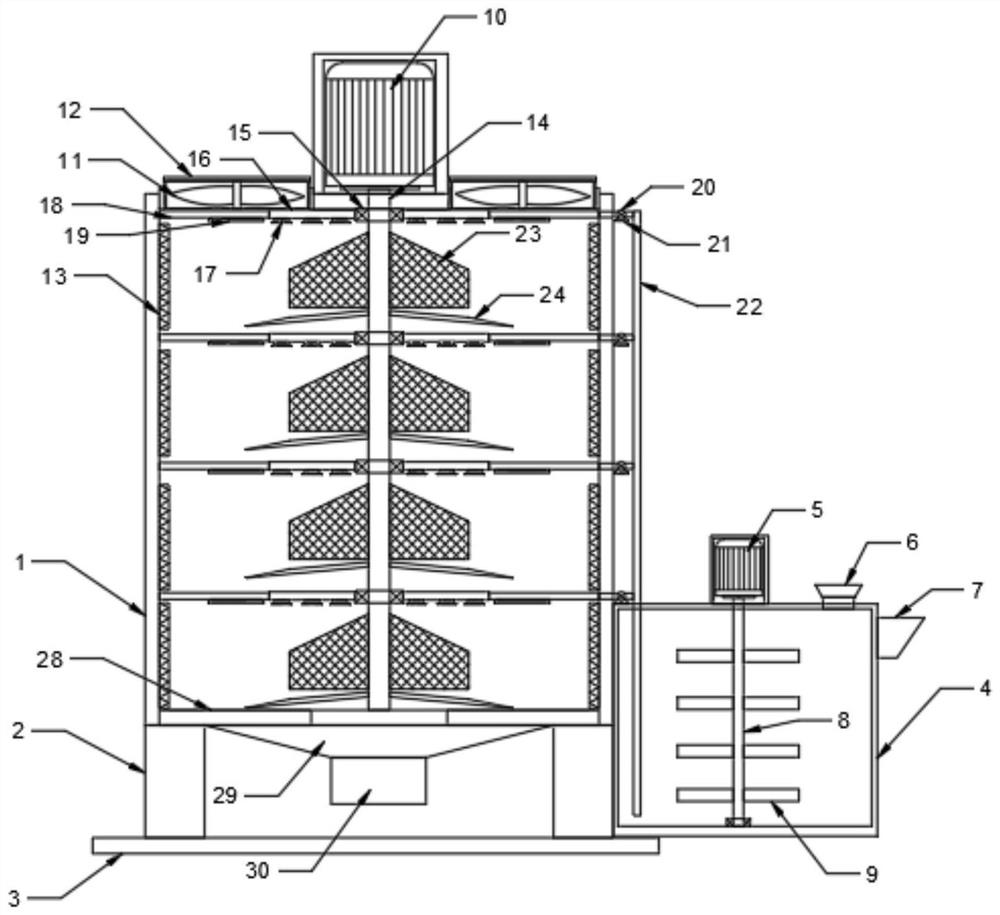

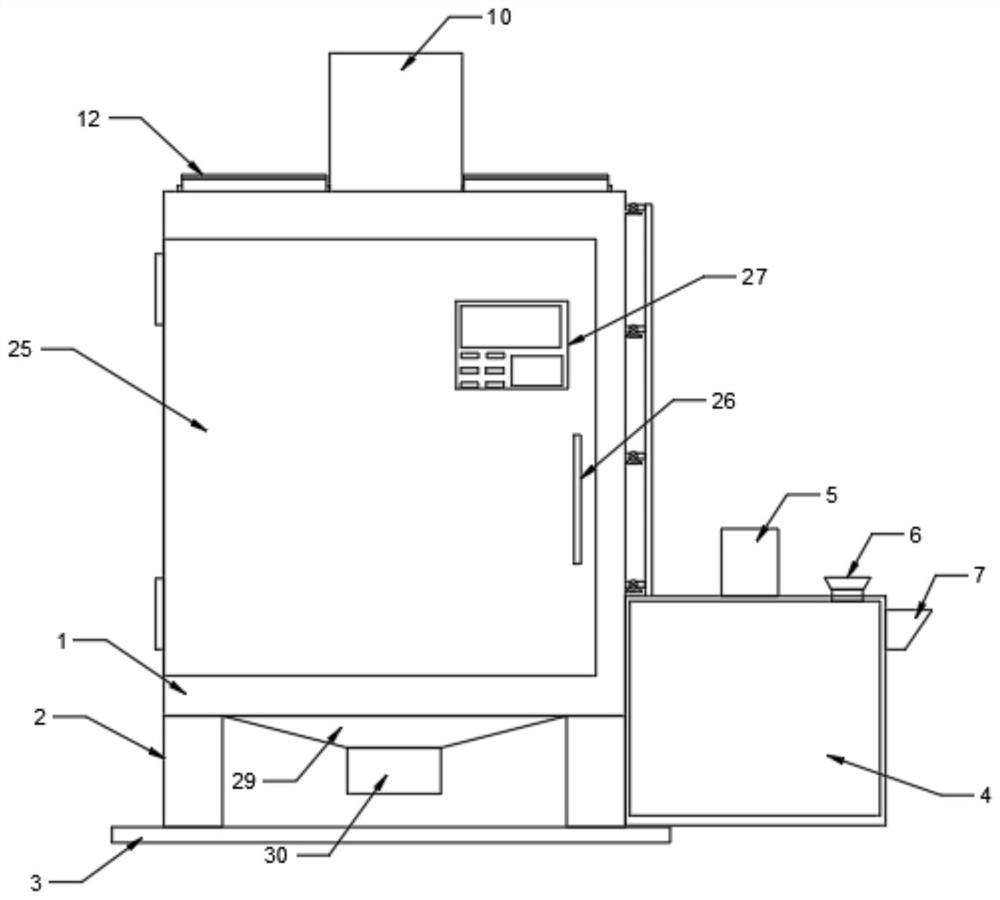

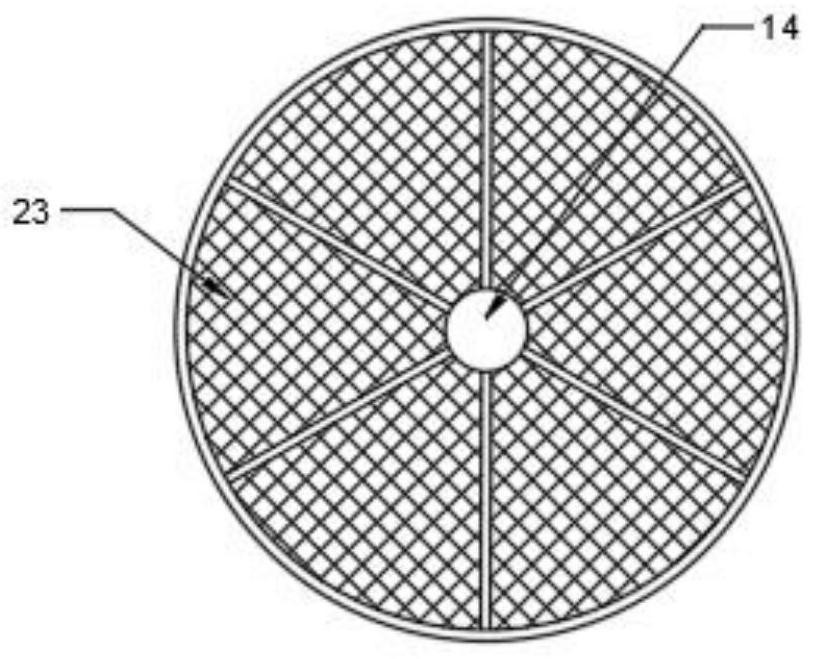

Medical instrument cleaning and drying equipment

InactiveCN111811231AEasy to wash and dryEasy to rinseDrying gas arrangementsDrying solid materialsUltraviolet lightsElectric machinery

The invention discloses medical instrument cleaning and drying equipment. The medical instrument cleaning and drying equipment comprises a box body, a placement frame and a nozzle, wherein a water tank is arranged on the right side of the box body, a water inlet and a feeding port are formed in the right side of the top end of the water tank, a first motor is installed in the middle of the top endof the water tank, a stirring rod and stirring blades are installed at the front end of a rotating shaft of the first motor, a second motor is installed in the middle of the top end of the box body,a rotating rod is installed at the front end of a rotating shaft of the second motor, the placement frame is installed on the outer side of the rotating rod, a flow guide plate is arranged at the bottom end of the placement frame, a fan is arranged at the top end of the box body, a heating net is installed on the inner wall of the box body, a rolling bearing is arranged above the placement frame,a spraying pipe is installed on the outer side of the rolling bearing, the nozzle is installed at the bottom end of the spraying pipe, a connecting pipe is installed at the end, away from the rollingbearing, of the spraying pipe, an ultraviolet lamp is installed at the bottom end of the connecting pipe, a water outlet is formed in the bottom end of the box body, a funnel is installed at the bottom end of the water outlet, and a drain outlet is formed in the bottom end of the funnel. The medical instrument cleaning and drying equipment is reasonable in structure, medical instruments can be conveniently cleaned and dried, and the medical instrument drying efficiency is improved.

Owner:王清弘

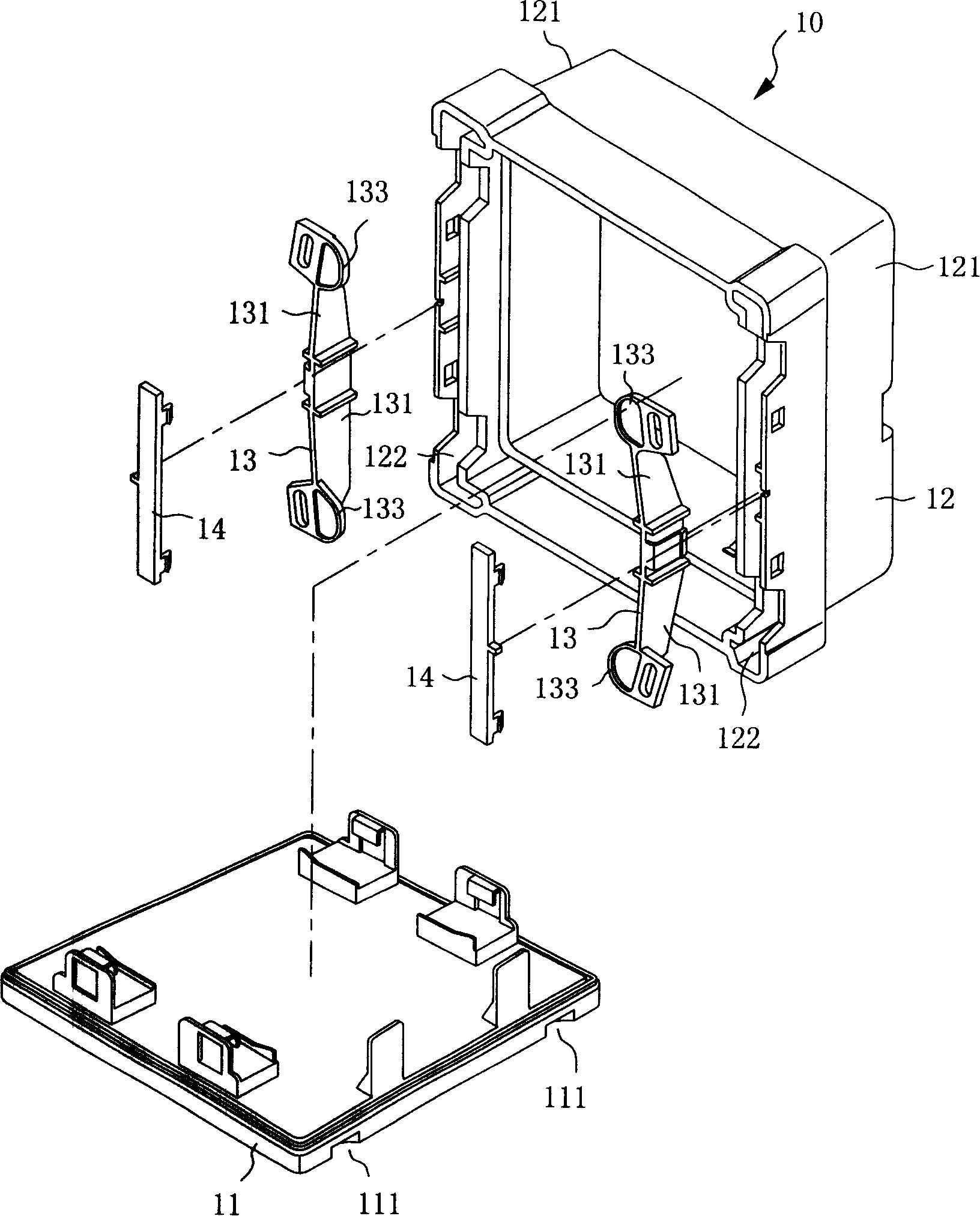

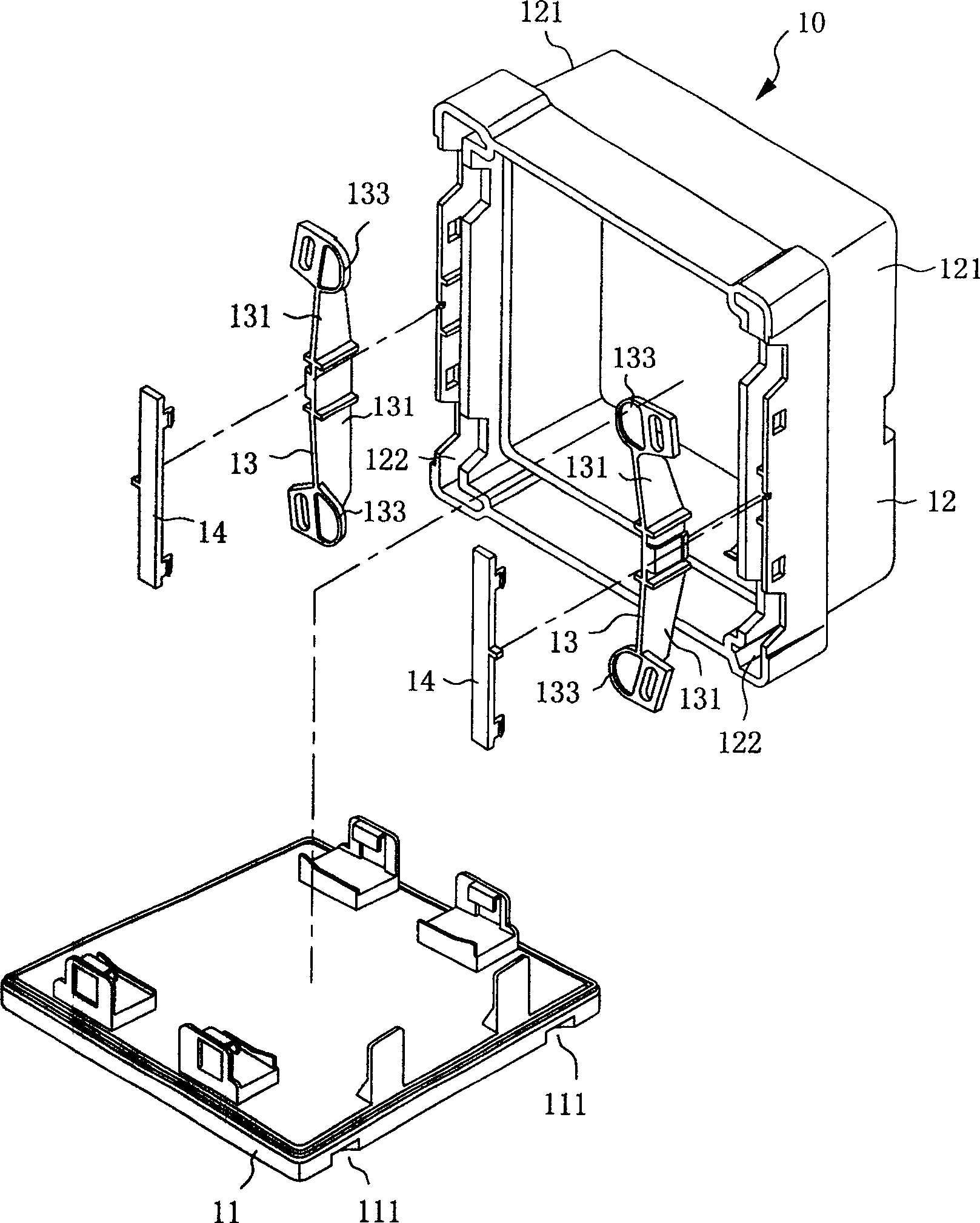

Clean container latching structure

InactiveCN101209761ACombined fasteningSecure lockoutSemiconductor/solid-state device manufacturingRemovable lids/coversElastic componentSelf locking

The invention discloses a cleaning container buckling structure which is combined on a cover body of a cleaning container through a demountable buckling part to lead the cover body to close or open in a seat body of the cleaning container. The buckling part comprises an integrated forming main body, a locating part and an elastic buckling arm. The locating part extends along one side of the main body to form an elastic slice; and the elastic slice is provided with a flange, so as to fasten the buckling part on the cover body. The elastic buckling arm is provided with an elastic arm and the end part of the elastic buckling arm is provided with a lateral flange. The lateral flange extends into the seat body to from a buckling state. The buckling part can comprise an elastic auxiliary arm formed between the elastic arm and the main body used for improving the elastic intensity of the elastic buckling arm. By adopting the cleaning container buckling structure of the invention, the quantity of the buckling parts can be reduced, can be directly positioned on the cover body and form self-locking after buckling the seat body and increase elastic components.

Owner:IND TECH RES INST

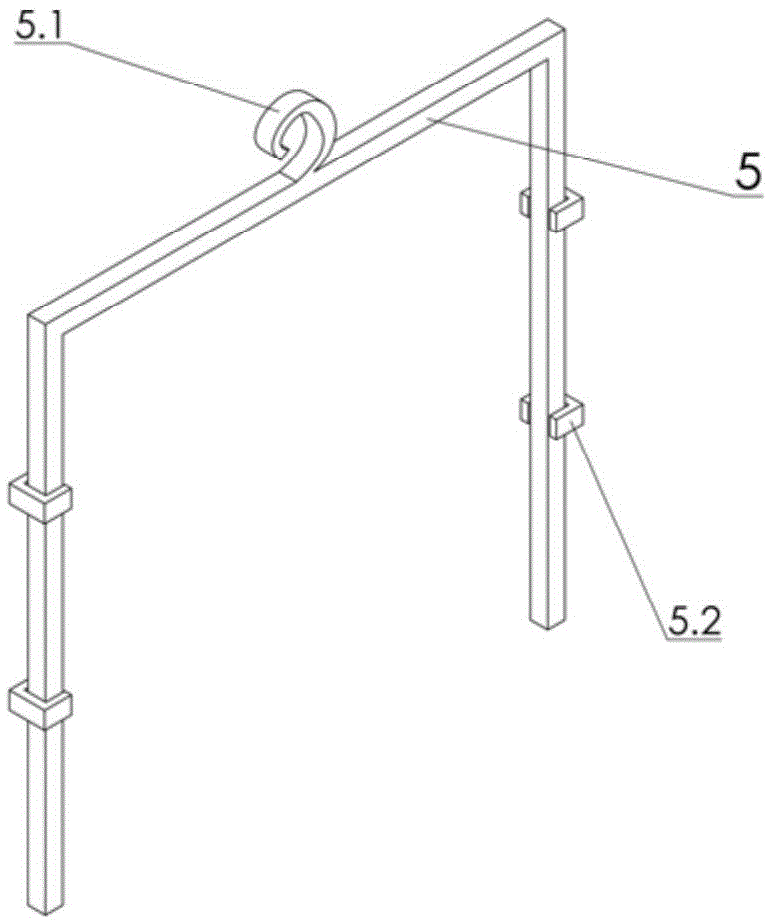

Part overturning device for new energy vehicle production

InactiveCN112775082AEasy to wash and dryEasy to produceDrying gas arrangementsCleaning using liquidsNew energyControl engineering

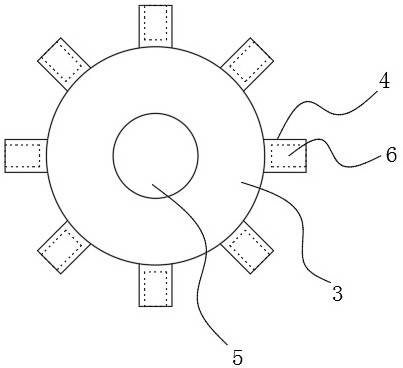

The invention discloses a part overturning device for new energy vehicle production. The part overturning device comprises a support, a servo motor is installed on one side of the top end of the support, a rotating wheel is installed in the middle of the top end of the support, a plurality of rotating teeth are arranged on the edge of the rotating wheel, workpiece grooves are formed in the middles of the rotating teeth, a first conveying chain is installed on one side of the support, a second conveying chain is installed on the other side of the support, a first installation frame is installed on one side edge of the top of the first conveying chain and one side edge of the top of the second conveying chain, a first flow dividing box is installed at the top end of the first installation frame, a plurality of first nozzles are evenly installed at the bottom end of the first flow dividing box, liquid storage hoppers are installed on one side of the bottom of the first conveying chain and one side of the bottom of the second conveying chain, and a water pump is installed at the top of one end of each liquid storage hopper. The part overturning device is novel in structure and ingenious in conception, new energy vehicle parts can be cleaned and dried conveniently, cleaning liquid can be recycled, energy conservation and environmental protection are achieved, the new energy vehicle parts can be overturned, cleaned and dried, and production of the new energy vehicle parts is facilitated.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

Quick and automatic water cleaning and air drying platform

InactiveCN105750251ANo dustStructural Design ScienceDrying gas arrangementsCleaning using toolsWater pipeClean water

The invention discloses a quick and automatic water cleaning and air drying platform. The platform comprises a platform body, wherein a transverse water pipe 1 is arranged at the top of the platform body, and a plurality of nozzles 2 are arranged on the bottom surface of the transverse water pipe 1; the right pipe opening of the transverse water pipe 1 is closed, the left pipe opening of the transverse water pipe 1 is connected with an external water pipe 13, the external water pipe 13 is communicated with a water inlet pipe connected to the bottom of a cleaning water tank outside the platform body, and a filter 11 is arranged on the external water pipe; dryers 3 are arranged on left and right sides of the platform body correspondingly; a U-shaped water receiving tank 8 is arranged at the bottom of the platform body. The water pipe provided with the plurality of nozzles 2 is arranged on the platform body, the dryers are arranged on the two sides of the platform body, so that quick water cleaning and air drying of objects can be realized, dust is not produced, several purposes are achieved, the platform is scientific in structural design, facilitates water cleaning and air drying and is free of dust and environment-friendly, and the environmental health is guaranteed.

Owner:XIAN YIMU SOFTWARE TECH

Clean container latching structure

InactiveCN100542904CCombined fasteningSecure lockoutSemiconductor/solid-state device manufacturingRemovable lids/coversSelf lockingFlange

Owner:IND TECH RES INST

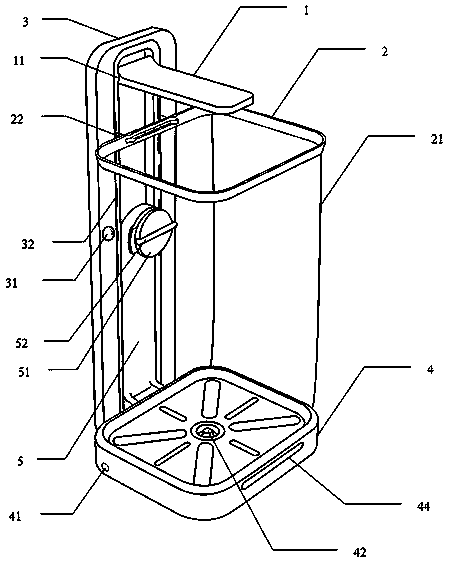

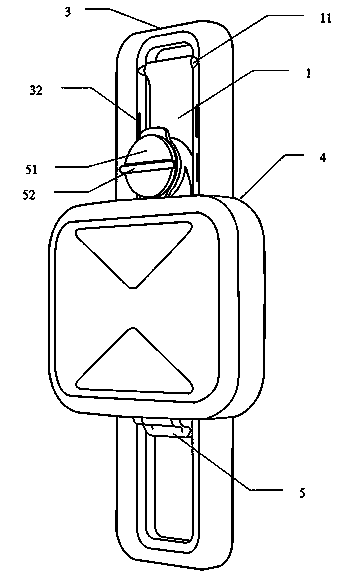

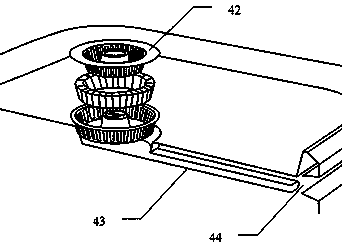

Environment-friendly and water-saving folding shower room

An environment-friendly and water-saving folding shower room comprises a shower nozzle, a shower curtain support, a portal and a water tank base. The shower nozzle is connected to the top end of the portal in a rotating-shaft mode. The shower curtain support is arranged in a slot in the inner side of the portal in an insertion-shaft mode and is provided with four shower curtains. A cold and hot water mixing valve faucet communicated with the shower nozzle is further arranged on the front face of the portal. The middle of the portal is provided with a lifting column, wherein the bottom of the lifting column can be connected with the water tank base in a 90-degree folding mode. The lifting column is provided with a self-locking hand winch with a folding handle. The side face of the water tank base is provided with a water outlet with a valve. The surface of the top of the water tank base is arranged to be in an inward-concave type with anti-skid lines. The side face of the water tank base is further provided with an overflow opening. The center of the water tank base is provided with a filter communicated with the interior of the water tank base. The bottom of the filter is provided with an overflow pipe, wherein an outlet of the overflow pipe points to and is close to the front end of the water tank base. The whole shower room can be folded and compressed to be in a wall-mounted state in a detachable mode, the occupied space is quite small, and clean water resources formed when a user takes a shower can be stored to be reused for other household activities.

Owner:WUXI X RES PROD DESIGN & RES

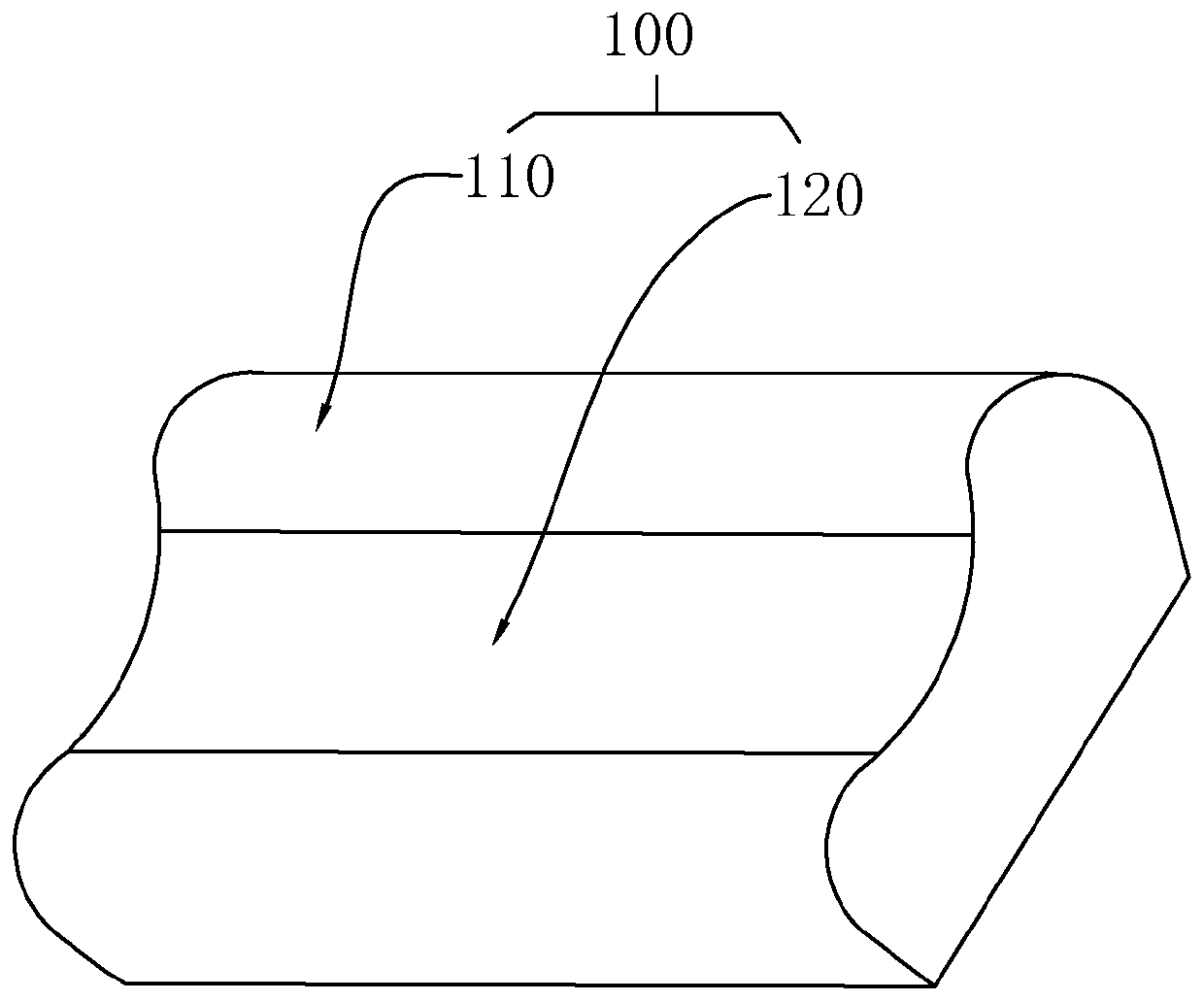

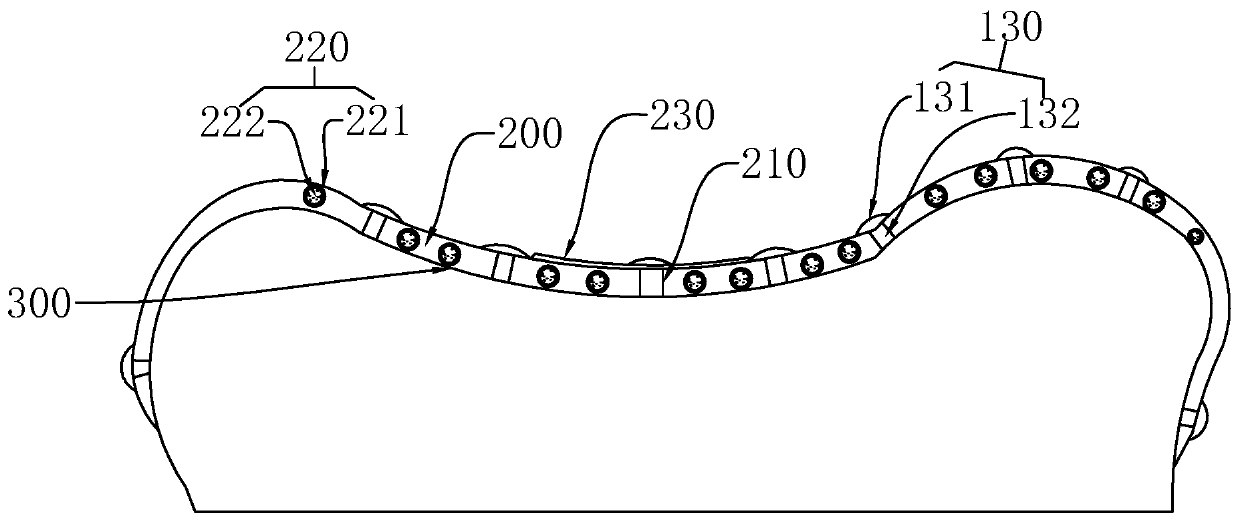

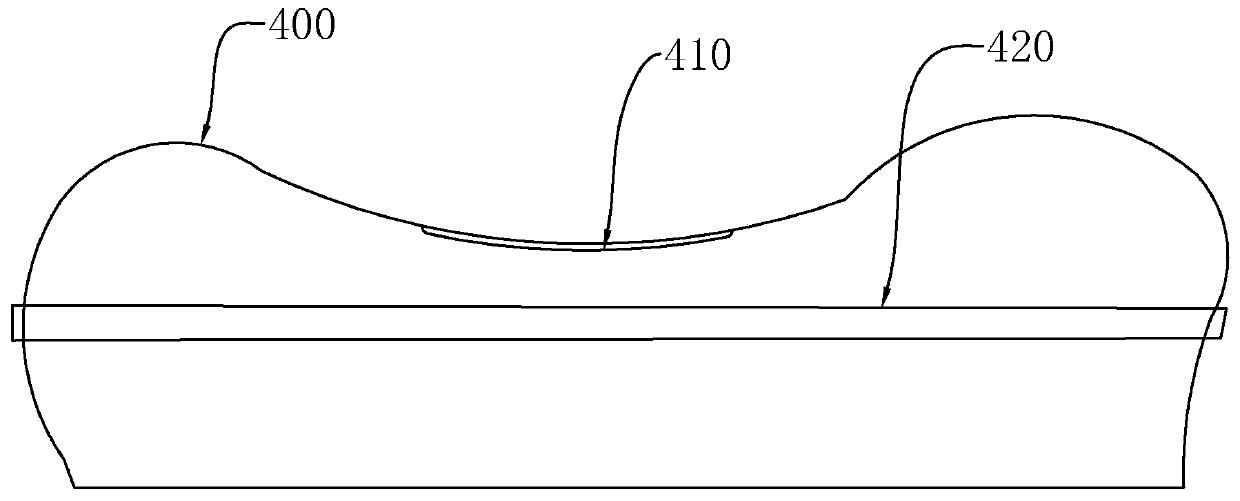

Pillow base body, temperature control pillow and production process of temperature control pillow

The invention relates to the technical field of pillows and production processes, and in particular to a pillow base body, a temperature-controlled pillow and a production process of the temperature-controlled pillow. The pillow base body is made of a silica gel material and comprises a neck supporting part and a head supporting part, the head supporting part is in an arc protruding shape, the head supporting part is in an arc downward-concave shape, massage fixing parts are arranged on the neck supporting part and the head supporting part; a temperature control layer is arranged between the upper part of the massage fixing part and the upper surfaces of the neck supporting part and the head supporting part; wherein the temperature control layer is provided with a positioning hole, the positioning hole is sleeved on the massage fixing part, a temperature control assembly is arranged in the temperature control layer, the upper side edge part of the temperature control layer is providedwith a connecting edge, and the temperature control pillow comprises a pillow cover and the pillow base body, and has the beneficial effects that the temperature control pillow conforms to the ergonomic principle, is easy to clean, has a temperature control function and is high in use comfort.

Owner:济南市易丰纺织有限公司

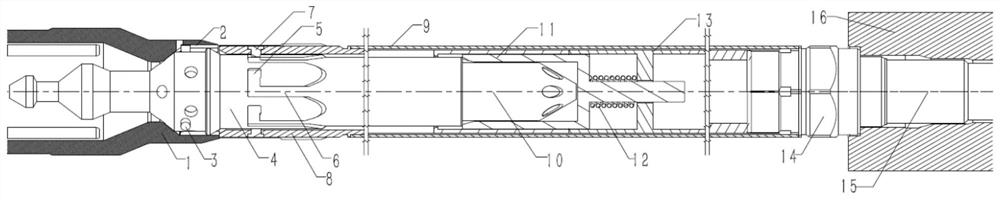

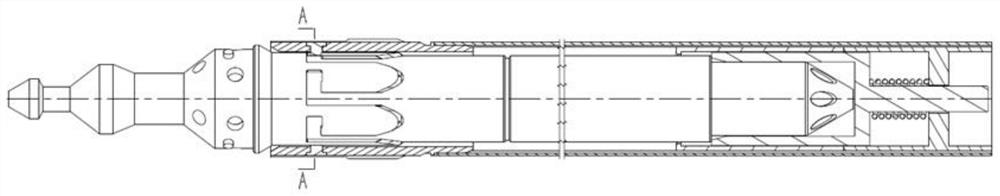

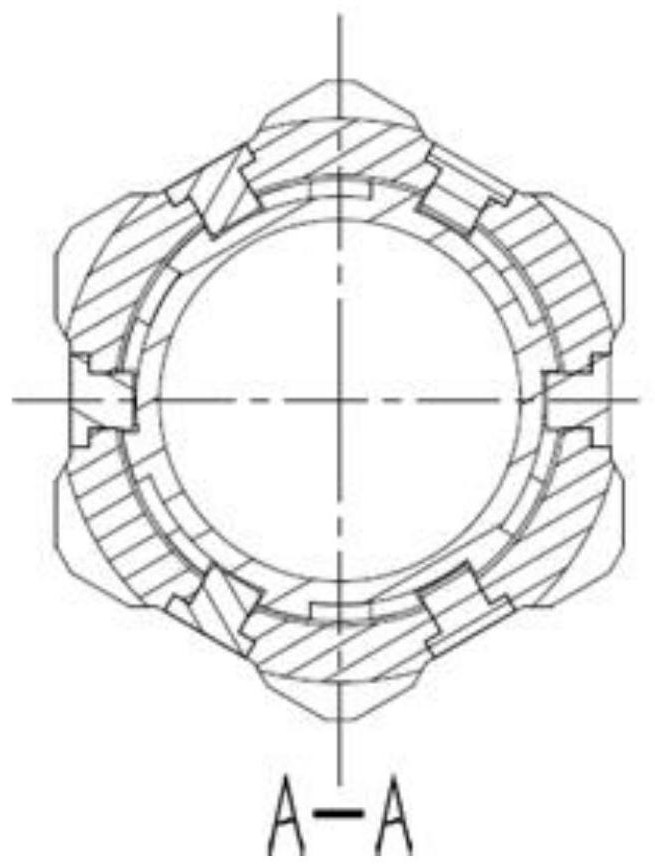

Special rotary refueling structure for replacing moving body of control rod assembly

ActiveCN112863715AReliable lockingReliable unlockNuclear energy generationReactor fuel elementsTransverse grooveStructural engineering

The invention relates to a special rotary refueling structure for replacing a moving body of a control rod assembly. The special rotary refueling structure comprises an outer sleeve assembly, wherein the moving body at least can partially extend into the outer sleeve assembly, and the moving body and the outer sleeve assembly can relatively move or relatively stand still in an axial direction through the action of a locking structure; the locking structure comprises a locking part arranged on the outer sleeve assembly and a locking groove formed in the moving body; the locking groove is L-shaped and comprises a transverse groove and a vertical groove which communicate with each other; during locking, the locking part ascends to a limited position from the vertical groove, then rotates relative to the moving body and enters the transverse groove; and during unlocking, the locking part rotates from the transverse groove to the moving body reversely and relatively to a limited position and then descends along the vertical groove. The special rotary refueling structure of the invention has the following beneficial effects: under the operation of a refueling machine in a reactor core, the outer sleeve assembly can be reliably locked and unlocked with the moving body, and the outer sleeve assembly can participate in the whole refueling process along with the control rod moving body.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

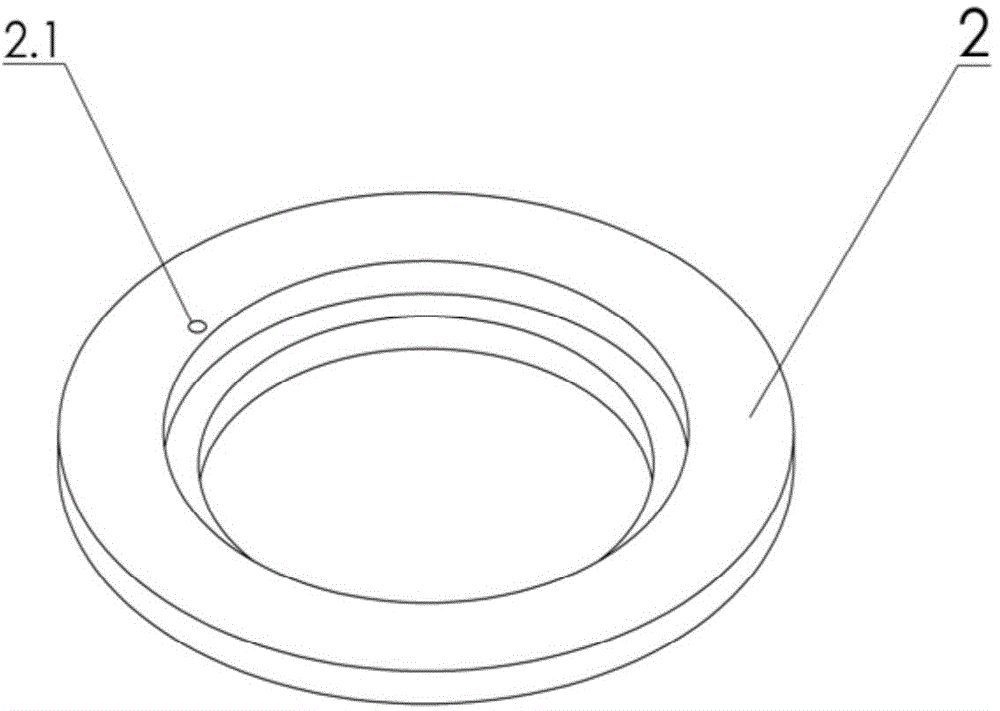

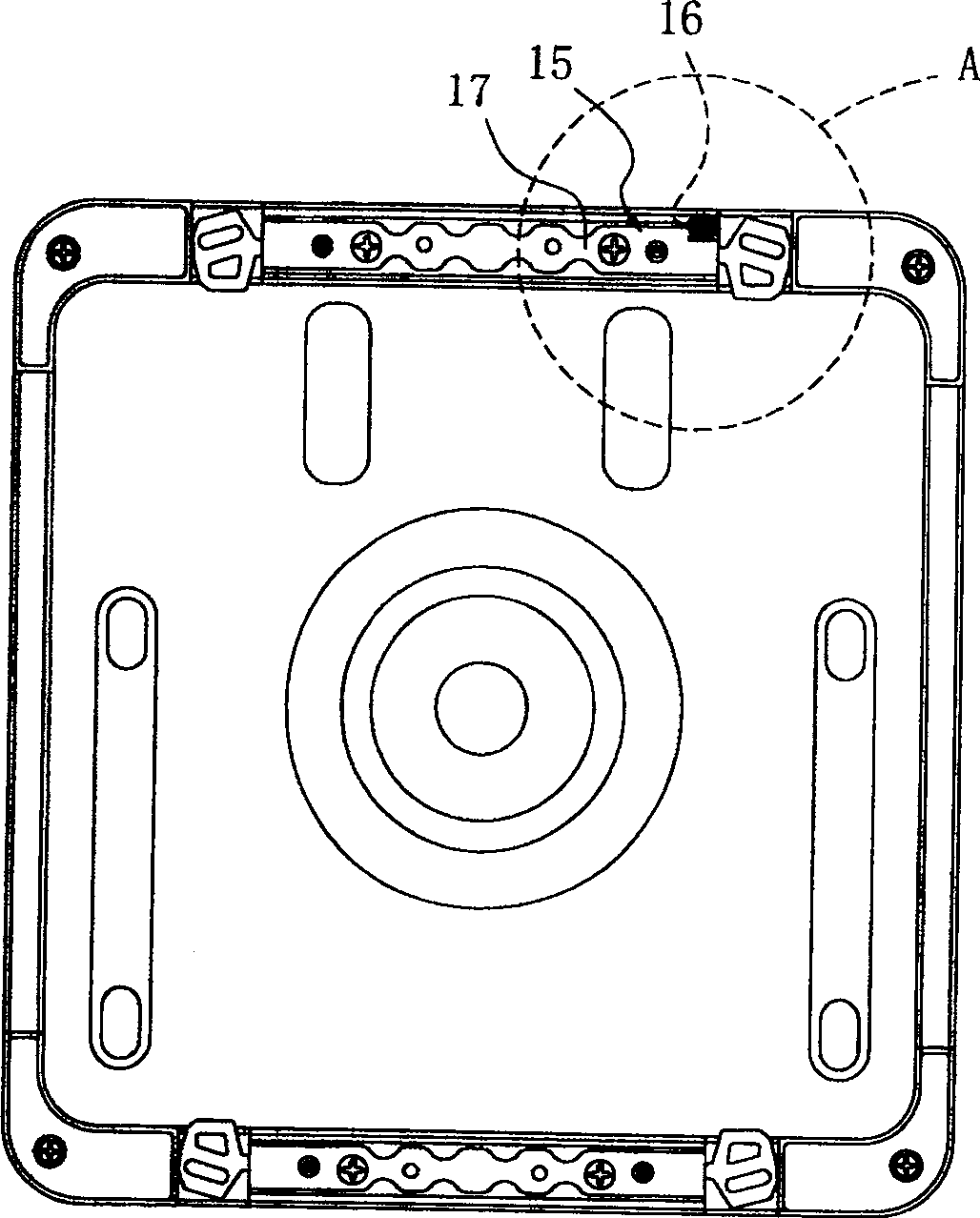

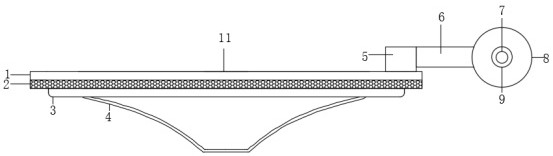

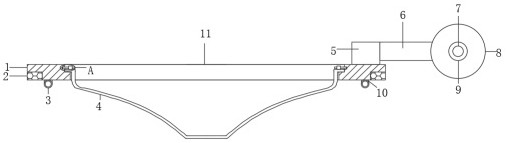

Anti-corrosion washing machine cover plate and production spraying process thereof

PendingCN112941843ARinse and dryImprove corrosion resistanceOther washing machinesAnti-corrosive paintsEpoxyLaundry washing machine

The invention discloses an anti-corrosion washing machine cover plate and a production spraying process thereof, relates to the technical field of washing machine cover plate production, and provides the following scheme for solving the problem that a common washing machine cover plate is prone to corrosion: the anti-corrosion washing machine cover plate comprises a circular plate; a T-shaped through hole is formed in the middle of the circular plate; an observation device is arranged in the T-shaped through hole; a connecting device is arranged on the right side of the circular plate; and a conveying device is arranged in the connecting device. Bowl-shaped glass is arranged in the middle of the cover plate, liquid splashed to the cover plate can automatically slide down in cooperation with mechanical vibration of the washing machine, and the bowl-shaped glass can be washed and dried through cooperation of an annular pipe and a three-way valve; meanwhile, the cover plate is made of an anti-corrosion material, butylated phenolic resin and epoxy resin are added into the spraying liquid, so that the anti-corrosion effect can be improved; and fluorine-containing polyurethane in the coating can achieve the effect that the surface of a spraying layer is not prone to being stained with water.

Owner:滁州市友邦涂装有限公司

Nitrile rubber production process

ActiveCN102532414BImprove the mixing effectThe amount added is easy to controlPolymer scienceNitrile rubber

The invention relates to the technical field of rubber production, aiming to provide an improved nitrile rubber production process, which comprises polymerization, degassing and condensation. Raw materials including acrylonitrile, butadiene, desalinated and deoxidized water, condensed water and molecular weight regulators are fed into a polymerization position, convergence is carried out in a header pipe at the polymerization position, the converged mixture is pre-emulsified sequentially through a pipe pump and a pipe mixer, heat exchange is carried out through an ammonia-cooling heat exchanger for cooling, the cooled mixture, initiator emulsion and activator solution are sequentially fed into a plurality of reactors for polymerization to produce latex, the latex taken out of the reactors and terminating defoamer solution are fed into a maturing reactor and are fully mixed when the rate of polymerization and conversion reaches 70 plus or minus 5 percent, and the mixture is then fed into a degassing tower to be degassed and into a condensation reactor for condensation. The problem of blockage of the heat exchanger can be avoided, the process is simple, the production process is stable and economical, the Mooney of rubber can be controlled easily, and the produced nitrile rubber has high quality.

Owner:NINGBO SHUNZE RUBBER

Method for steam pretreatment of dishwasher sink

ActiveCN109124513BImprove cleanlinessImprove cleaning efficiencyTableware washing/rinsing machine detailsWashing processesThermodynamicsProcess engineering

The invention provides a method for steam pretreatment of a sink of a dishwasher, which is used for solving the problem that the dishwasher is not cleaned due to the solidification of the oil dirt ona dinner plate and a dish chopsticks in the prior art. The method for steam pretreatment of the sink of the dishwasher comprises the following steps: S1, judging whether a preset washing signal is received; S2: If yes, the preset steam pretreatment washing process is called for washing. The method pretreats the dishwasher with steam before the preset washing process, and softens the oil stains onthe dish and the dishchopsticks through the steam pretreatment, thereby improving the cleanliness of the dishwasher and ensuring the cleaning effect of the dishwasher.

Owner:NINGBO OULIN IND CO LTD

a cleaning component

InactiveCN105832261BEasy to wash and dryAvoid enteringCarpet cleanersFloor cleanersCircular discEngineering

Owner:贺新发

Person falling prevention flame retardant safety plain net structure and production technology

PendingCN109138472AImprove insulation performanceStrong heat resistanceBuilding material handlingGlass fiberEngineering

The invention discloses a person falling prevention flame retardant safety plain net production technology. The production technology comprises the following steps of step1, selecting a glass fiber filament, a chemical fiber elongation filament and a chemical fiber non-elongation filament as the raw materials of preparation; step2, weaving the glass fiber filament in the step1 into a net body through a rapier machine or a weaving loom; weaving the chemical fiber elongation filament and the chemical fiber non-elongation filament in the step1 into an external mesh through a net weaving machine;step3, adding an organic silicon coating, a polyethylene anticorrosive coating and a teflon coating in a number one dyeing cylinder, a number two dyeing cylinder and a number three dyeing cylinder, and uniformly stirring and mixing; and step4, putting the net body in the step 2 into the number one dyeing cylinder in the step3, and dipping for 2 to 4 minutes. When a human body falls on a safety plain net from a high place, under the effect of an external force, a glass fiber non-elongation filament is broken, and the glass fiber elongation filament is continuously under the stress till the filament is broken so that the effects of buffering and energy dissipation are achieved.

Owner:泰州市常沪线网有限公司

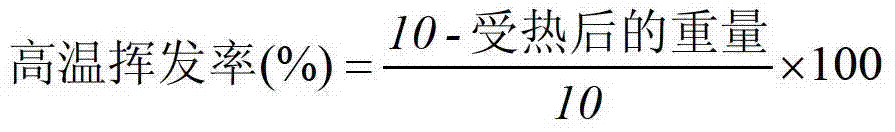

Forage treatment device for livestock breeding

InactiveCN111527892AEasy to cleanEasy to wash and dryCuttersDrying machines with local agitationAnimal scienceCrop livestock

The invention discloses a forage treatment device for livestock breeding. The forage treatment device for livestock breeding comprises a base, wherein a smashing mechanism, a cleaning mechanism and adrying mechanism are sequentially arranged on the upper end face of the base; the smashing mechanism comprises a smashing cavity; a vertical smashing shaft is assembled in the smashing cavity; a plurality of smashing blades are evenly distributed on the smashing shaft; and one end of the smashing shaft is in transmission connection with a smashing motor. According to the forage treatment device for livestock breeding, a material storage cavity is connected with a lifting base and a sliding lead screw, and forage can be conveniently cleaned and dried in order; a rotating shaft is arranged in the material storage cavity, and material turning blades are uniformly distributed on the rotating shaft, so that the surface of the forage can be in full contact when the forage is cleaned or dried, and the cleaning and drying quality is ensured; besides, a funnel-shaped flow guide plates are arranged in a cleaning cavity, so that forage cleaning is facilitated, meanwhile, impurities can be conveniently and completely discharged when the cleaning cavity is cleaned, and follow-up use of the cleaning cavity is facilitated.

Owner:高从新

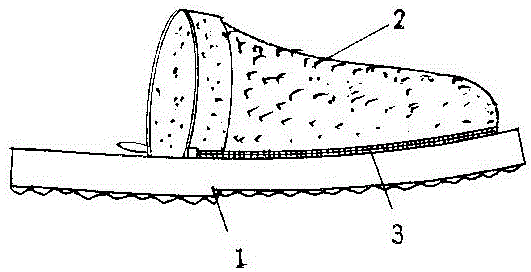

Detachable cleaning cotton slipper

The invention provides a detachable cleaning cotton slipper; a sponge sole and a cotton vamp of the cotton slipper are connected in a detachable whole structure through a zipper; when the slipper needs to be cleaned and aired, the vamp and sole can be separated by the zipper; the detachable cleaning cotton slipper can be conveniently cleaned and aired, and the vamp can be replaced at any time.

Owner:ZHUGELIANG MIDDLE SCHOOL

Combined elastic net mattress

Owner:杨广生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com