Person falling prevention flame retardant safety plain net structure and production technology

A production process and safety net technology, which is applied in the construction of buildings, construction, and the processing of building materials, etc., can solve the problems of inability to prevent falling from high altitudes, poor safety of the safety flat net, and inability to achieve buffering and energy dissipation. The effect of good insulation, improving bearing capacity and shortening service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

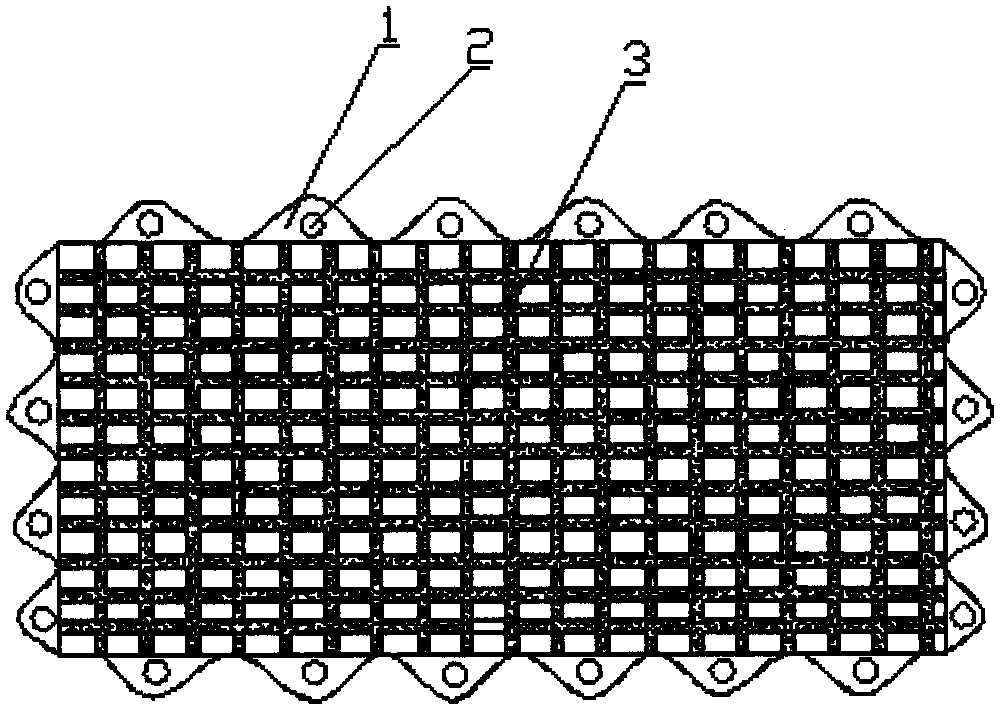

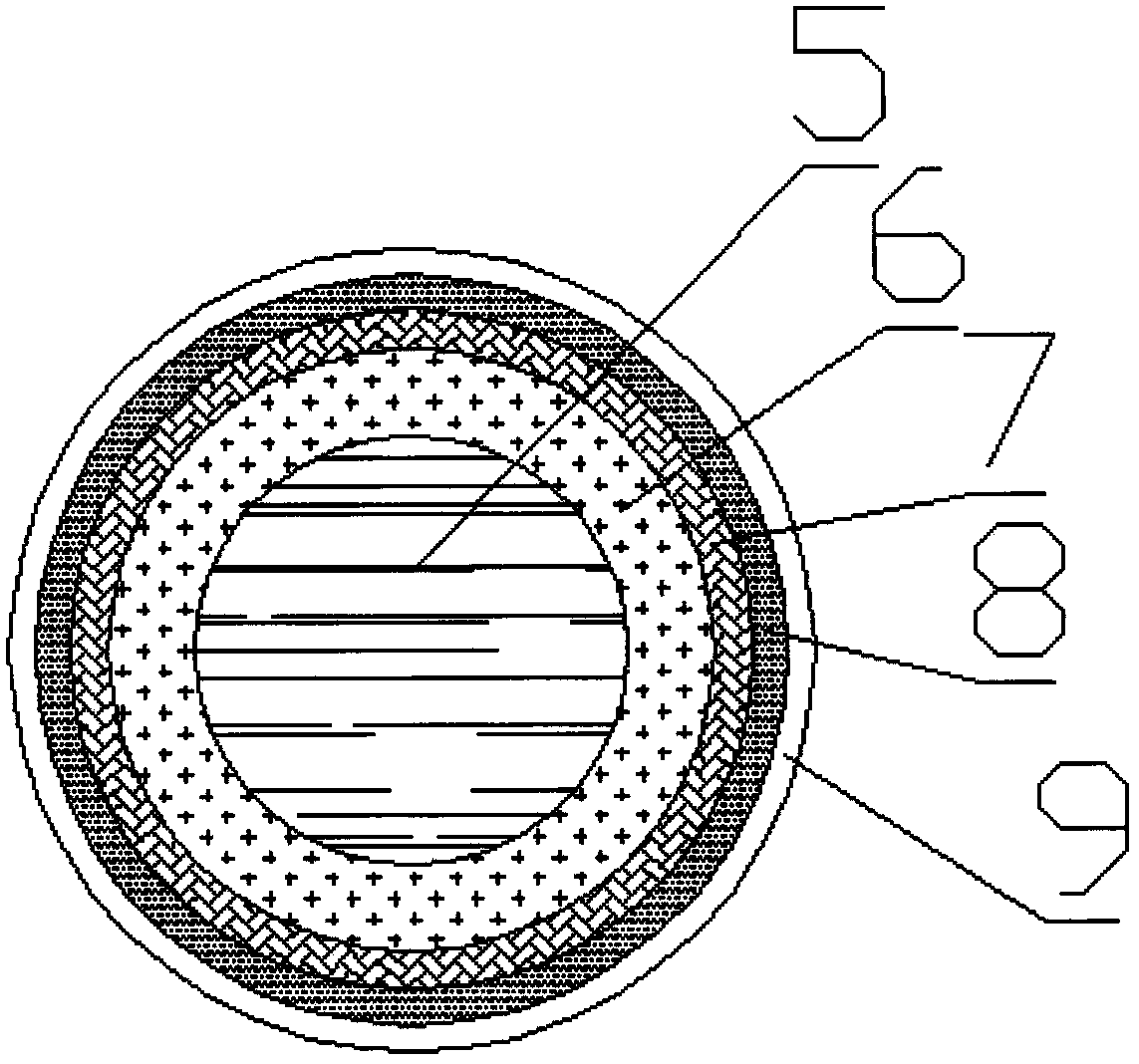

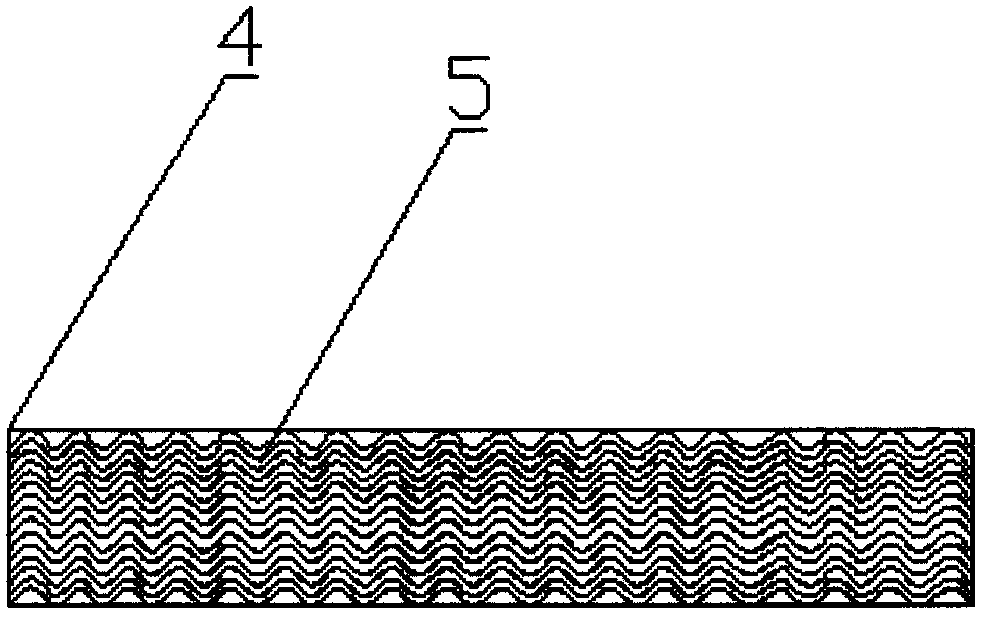

[0028] Such as Figure 1-3 As shown, a production process of a flame-retardant safety flat net for preventing people from falling, the specific production process steps are as follows:

[0029] Step 1: selecting glass fiber filaments, chemical fiber elongated filaments and chemical fiber non-stretched filaments as raw materials for preparation;

[0030] Step 2: Weaving the glass fiber filaments in step 1 into a net body by rapier machine or loom; weaving the chemical fiber elongated filaments and chemical fiber non-elongated filaments in step 1 into external mesh by weaving netting machine;

[0031] Step 3: Add organic silicon coating, polyethylene anti-corrosion coating and polytetrafluoroethylene coating to No. 1 dyeing vat, No. 2 dyeing vat, and No. 3 dyeing vat respectively, and stir and mix evenly;

[0032] Step 4: Put the mesh body in step 2 into the No. 1 dyeing vat in step 3, impregnate for 2-4 minutes, take it out and put it in the drying oven for drying treatment; t...

Embodiment 2

[0043] Such as Figure 1-3 As shown, a production process of a flame-retardant safety flat net for preventing people from falling, the specific production process steps are as follows:

[0044] Step 1: selecting glass fiber filaments, chemical fiber elongated filaments and chemical fiber non-stretched filaments as raw materials for preparation;

[0045] Step 2: Weaving the glass fiber filaments in step 1 into a net body by rapier machine or loom; weaving the chemical fiber elongated filaments and chemical fiber non-elongated filaments in step 1 into external mesh by weaving netting machine;

[0046] Step 3: Add organic silicon coating, polyethylene anti-corrosion coating and polytetrafluoroethylene coating to No. 1 dyeing vat, No. 2 dyeing vat, and No. 3 dyeing vat respectively, and stir and mix evenly;

[0047] Step 4: Put the mesh body in step 2 into the No. 1 dyeing vat in step 3, impregnate for 2-4 minutes, take it out and put it in the drying oven for drying treatment; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com