Patents

Literature

139results about How to "Lightfast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

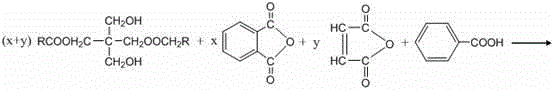

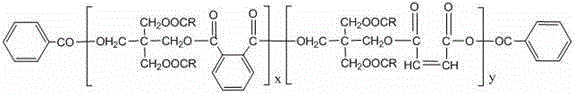

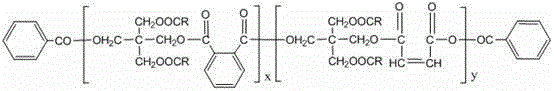

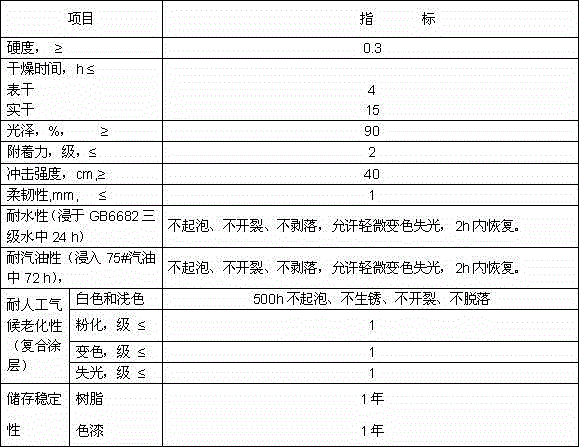

Aqueous alkyd acrylic resin paint and preparation method thereof

The invention relates to an aqueous alkyd acrylic resin paint and a preparation method thereof. According to the invention, high-molecular alkyd resin with main chain containing unsaturated double bond is synthesized through molecular design. Alkyd resin is subjected to free radical graft copolymerization with acrylic monomer. A reaction system is neutralized by using an amine compound, such that water-reducible alkyd acrylic resin is synthesized. Molecular chains of alkyd and acrylic resins are connected through chemical bond, such that the compatibility of the two resins is improved. In a material curing and shaping process, phase separation of the resin is avoided. Deionized water, a pigment, a filling material, an antifoaming agent, a dispersing agent, a siccative, and alkyd acrylic hybrid emulsion are uniformly dispersed, such that the aqueous alkyd acrylic resin paint is obtained. The aqueous alkyd acrylic resin paint comprises the components of: aqueous alkyd acrylic resin 65%-80%, the pigment 3%-4%, the filling material 6-10%, deionized water 10%-20%, the dispersing agent 0.05%-0.5%, the antifoaming agent 0.10%-0.30%, and the siccative 0.9%-3.5%.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Multiple-effect super absorbent resin fertilizer and manufacturing method thereof

ActiveCN103694052AHigh reuse rateFast water absorptionFertilizer mixturesMeth-Sodium hydrogen sulphite

The invention provides a multiple-effect super absorbent resin fertilizer. In the manufacturing process, sodium hydrogen sulfite and ammonium persulfate oxidation-reduction type initiator are used as foundations, and ultraviolet initiation is used as an auxiliary means; N-N'-methylene bisacrylamide is used as a crosslinking foundation, and ethylene glycol diglycidyl ether and glycerol are used as auxiliary means; hydroxyethyl acrylate is added in the polymerized monomer, so that the colloid strength of the high molecular polymer is obviously improved; antioxidant, ultraviolet absorbent and light stabilizer are creatively introduced, thus finally manufacturing super absorbent resin having oxidation resistance, light resistance and degradation resistance; the super absorbent resin is organically combined with humic acid, microbial inoculant and an inorganic fertilizer to perform synergistic action, so that the various effective elements achieve the optimal use effect. Meanwhile, the consumption of the inorganic fertilizer is reduced, the salt content of soil is reduced, the pH value of the soil is improved, the soil environment is improved, and soil hardening is prevented, thus greatly increasing the utilization ratio of nitrogen fertilizers, phosphate fertilizers and potassium fertilizers, and achieving comprehensive effects of water saving, fertilizer saving, yield increase and outcome increase.

Owner:辽宁博科生物科技有限公司

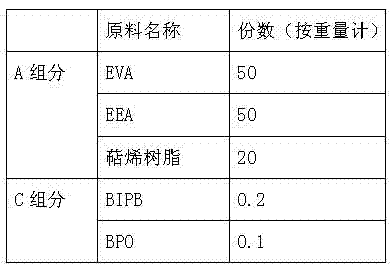

Hot melt adhesive film for adhering sole, and preparation method thereof

ActiveCN103756576APolymerization ControlImproved color stabilityNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceBenzoyl peroxide

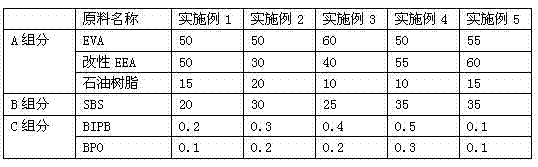

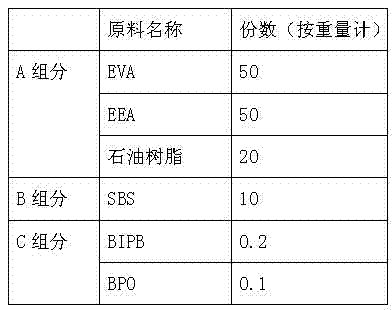

The present invention relates to a hot melt adhesive film for adhering a sole. The hot melt adhesive film comprises the following raw materials by weight: 50-60 parts of ethylene-vinyl acetate (EVA), 30-60 parts of modified ethylene-ethyl acrylate (EEA), 15-35 parts of a styrene-butadiene block copolymer (SBS), 5-20 parts of a terpene resin, 0.1-0.5 part of bis-(tertbutylperoxy isopropyl)benzene (BIPB), and 0.1-0.5 part of benzoyl peroxide (BPO). According to the present invention, the hot melt adhesive film does not contain benzene, toluene, xylene and other harmful solvents, the sole does not require the primer treatment, the operation process is simple, and the environmental requirement requirements are met.

Owner:江阴伟韬塑料新材料有限公司

Waterborne fluorocarbon texture coating and preparation method and application thereof

InactiveCN101851450AImprove water resistancePollution resistantBuilding constructionsCoatingsLow speedWeather resistance

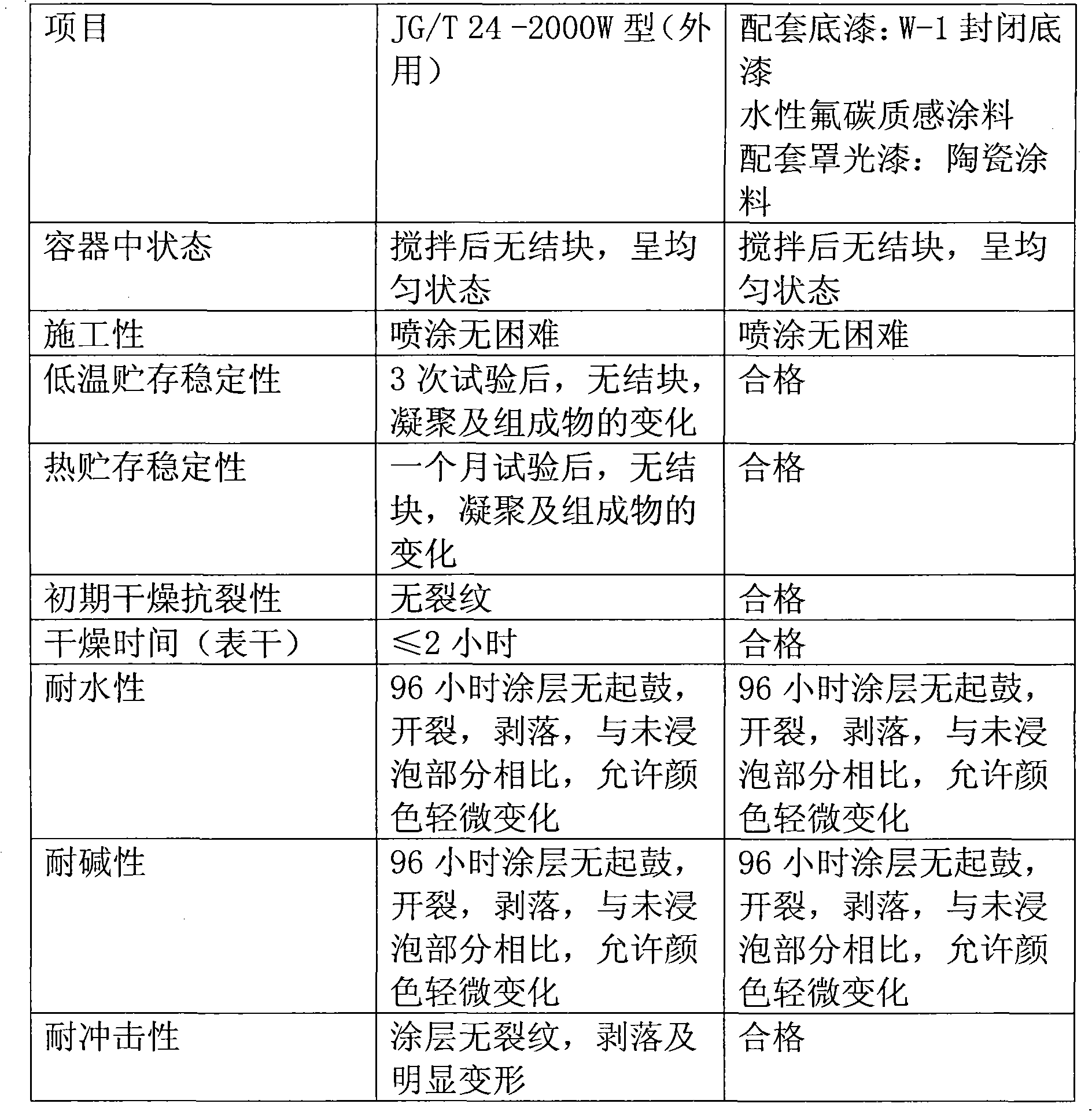

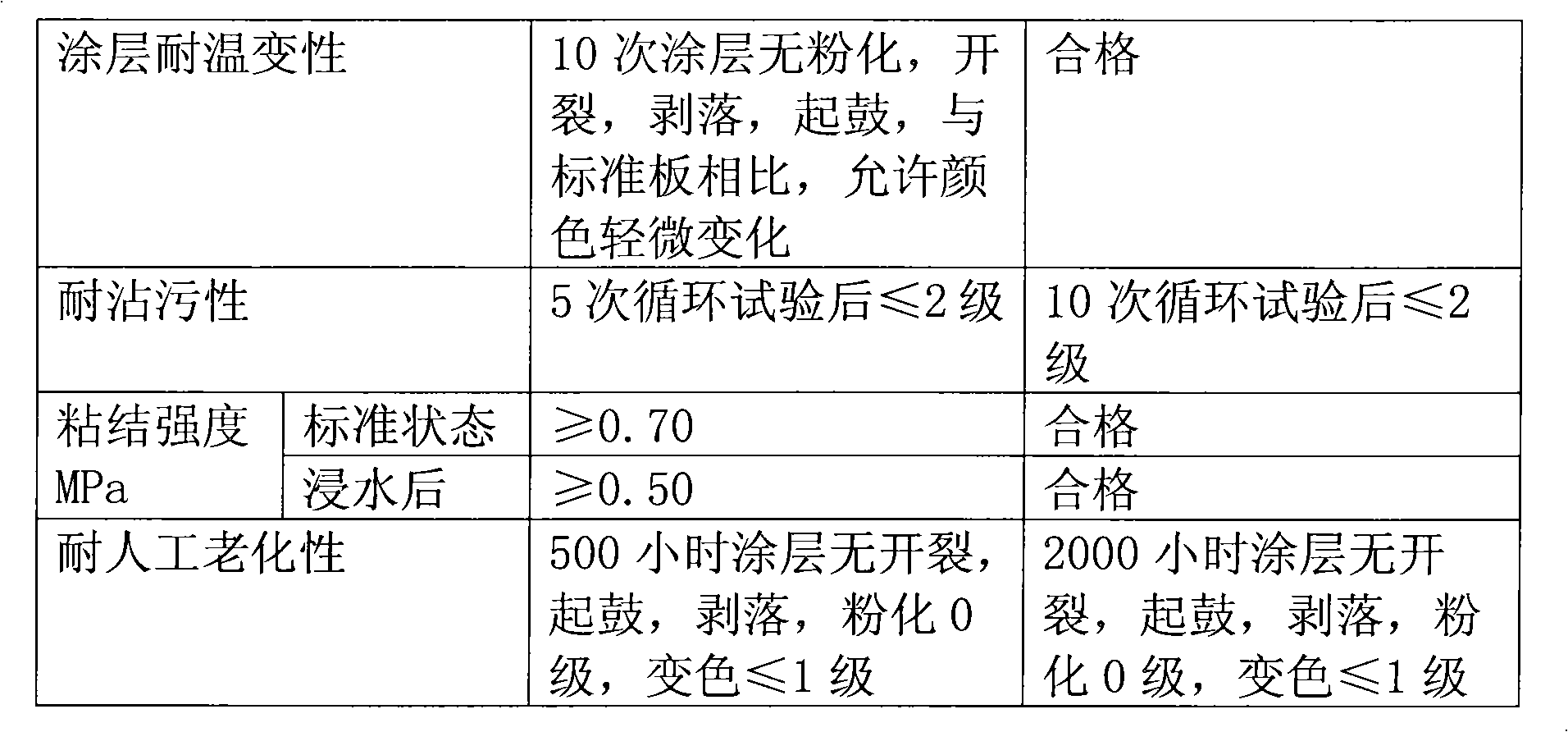

The invention discloses a waterborne fluorocarbon texture coating and a preparation method and application thereof. The coating comprises the following components in part by weight: 141 to 180 parts of fluorocarbon emulsion, 5 to 12 parts of film-forming aid, 5 to 6 parts of cosolvent, 80 to 100 parts of water, 1 to 2 parts of antifoaming agent, 3 to 6 parts of disinfectant, 1 to 3 parts of mildew preventive, 2 to 3 parts of pH regulator, 5 to 10 parts of thickening agent, 600 to 1,000 parts of color sand, and 0 to 89 parts of sheet. The preparation method comprises the following steps of: under the stirring at a high speed, adding the film-forming aid, the cosolvent, the antifoaming agent, the disinfectant, and the mildew preventive in turn, stirring at the high speed and reducing the stirring speed; adding the fluorocarbon emulsion, regulating the pH value, and regulating the viscosity by using the thickening agent to obtain pulp; stirring the pulp at a low speed, adding the color sand and sheet, and mixing to obtain the waterborne fluorocarbon texture coating. The waterborne fluorocarbon texture coating applied to a coated outer wall surface has good protection functions of water resistance, weather resistance, smudge resistance, and the like, and makes the wall surface have elegant, harmonious and serious aesthetic feeling.

Owner:SHANGHAI HENGFENG FLUOROCARBON MATERIAL

Water radon-screening emulsion paint

A radon-screening water emulsoid paint used as decorative paint for preventing radon, benzene, xylene and formaldehyde from being educed from wall and adsorbing them contains water, hydroxyethyl cellulose, disperser, defoaming agent, levelling agent, light calcium carbonate, titanium oxide, bentone, talc powder, ethanediol, film forming agent, PVDF-acrylate copolymer and vinyl acetate-acrylate copolymer emulsion, and antibacterial mildew-proof agent.

Owner:陈伟常 +1

High-temperature-resistant environment-friendly composite pigment and production method thereof

InactiveCN104861742AImprove light fastness and weather resistanceBright colorPigment physical treatmentPigment treatment with non-polymer organic compoundsWeather resistanceNickel oxides

The invention relates to the technical field of chemical pigment fabrication and discloses a high-temperature-resistant environment-friendly composite pigment and a production method thereof. Inorganic titanium yellow pigment carriers are enveloped with organic yellow pigments to form the composite pigment. The preparation method comprises processing titanium dioxide and nickel oxide into mixed-phase inorganic titanium yellow pigment carriers to be mixed with organic yellow pigments with negative charges, and performing enveloping treatment through positive and negative charge particle attraction action to achieve composition of organic and inorganic pigments. By nanometer fine processing, surface charges are increased, the envelop is dense, the structure force is large, the composition process is environmentally friendly, the composite pigment is non-toxic, the composite titanium yellow carriers can protect the sensitive organic pigments from ultraviolet attack like ultraviolet absorbers, and accordingly, the weather resistance and the light resistance of the pigment are improved greatly, and the pigment has the advantages of being environmentally friendly, weather resistant, light resistant, heat resistant, anti-ageing, bright in organic pigment color and high in tinting strength.

Owner:HUNAN JUFA TECH

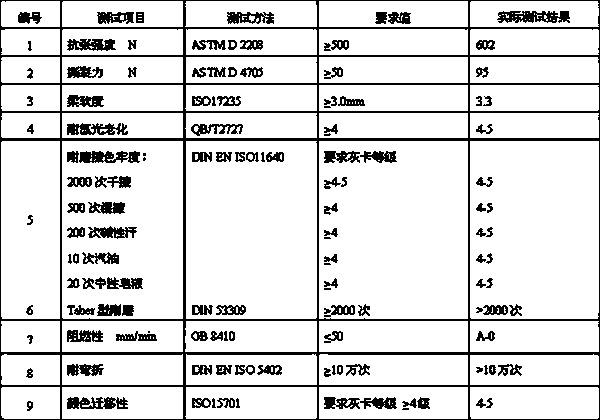

Production process of anti-staining automobile interior leather

ActiveCN103602764AAnti-aging leather bodyFeel comfortableTanning treatmentPre-tanning chemical treatmentDyeingEngineering

The invention relates to the field of the manufacturing of industrial leather, and in particular relates to a production process of anti-staining automobile interior leather. The production process comprises the steps of soaking, fleshing, liming, fleshing splitting, deliming, softening, pickling, tanning, aging, shaving, conditioning, retanning, neutralizing, dyeing, electrostatic conditioning, wringing stretching, wet vibrating, vacuum drying, vibrating, milling, bottom layer coating, electrostatic treatment, knurling, intermediate painting, anti-staining top layer preparing, anti-staining reinforced layer preparing, measuring and warehousing, wherein anti-staining top layer paint and anti-staining reinforced layer paint are respectively proportioned according to the appropriate components and then are sprayed onto the leather surface according to the appropriate coating amount, and then the leather is dried. Through the combined action of different functions, not only is the anti-staining performance strong, but also the anti-staining effect is remarkable, stains which are not repelled are easy to scrub and clean due to the difficulty in combination and permeation, and the automobile interior leather which is anti-staining and easy to clean can be achieved.

Owner:HAINING SENDE LEATHER

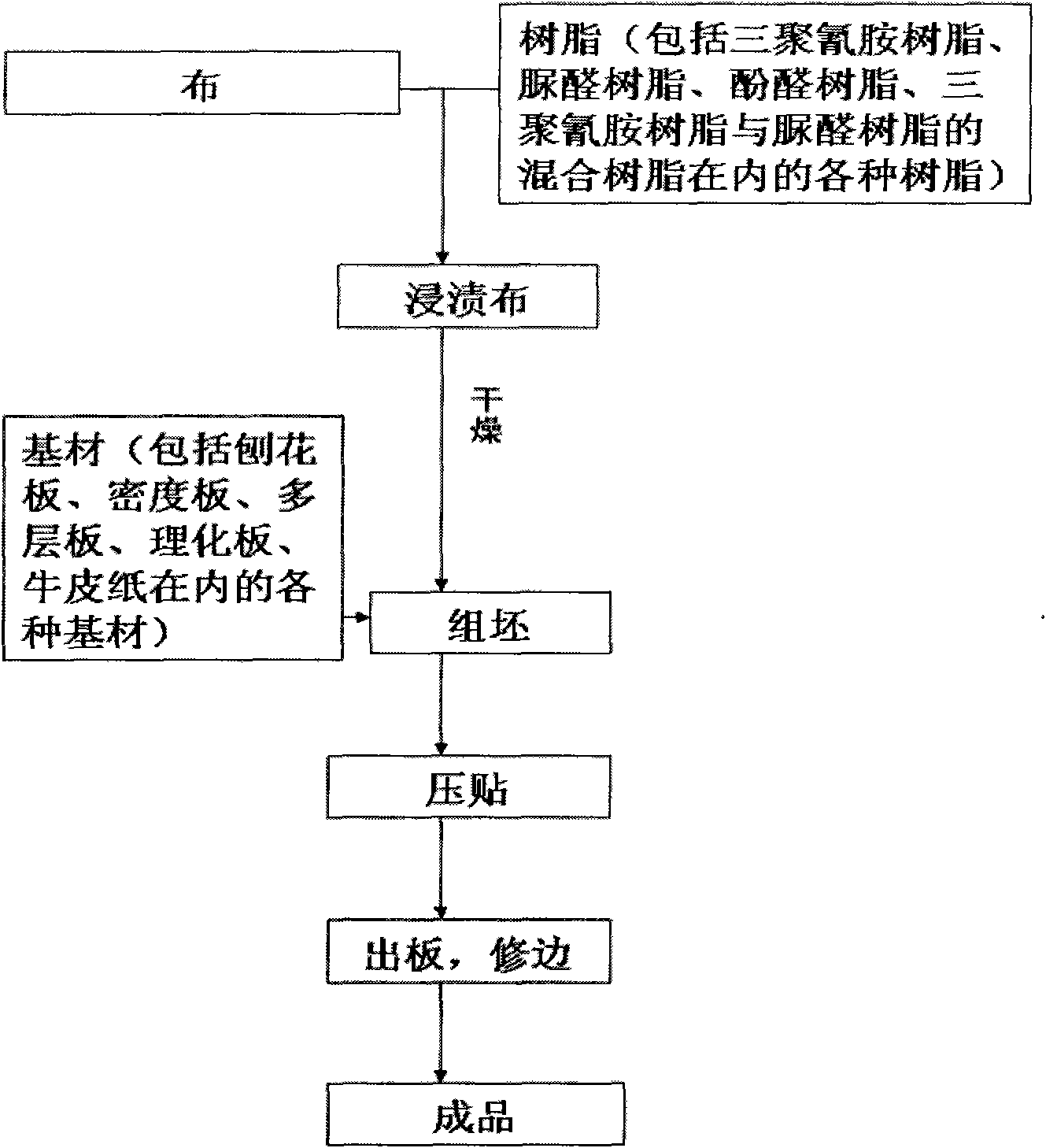

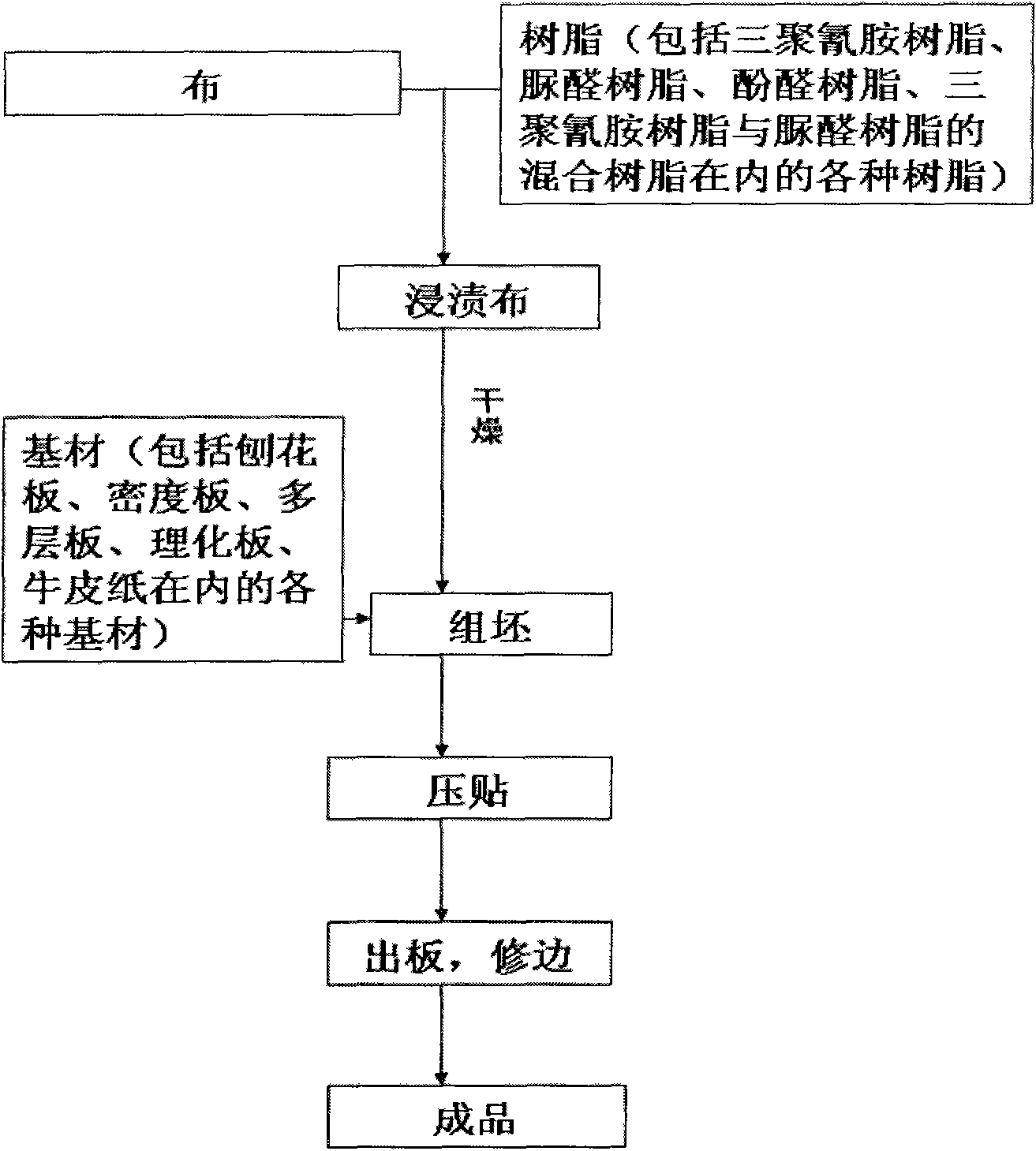

Resin impregnated cloth veneer and manufacture technology thereof

InactiveCN102049960ADry heat resistantBurn-resistantLamination ancillary operationsSynthetic resin layered productsCrack resistanceManufacturing technology

The invention relates to a resin impregnated cloth veneer and a manufacture technology thereof, wherein the resin impregnated cloth veneer comprises a base material and a cloth; the cloth is pressed on the surface of the base material; the resin impregnated cloth veneer is characterized in that the cloth is a resin impregnated cloth; the surface of the cloth is impregnated with resin which is melamine resin or urea resin or phenolic resin, or the mixed resin of the melamine resin and the urea resin. During manufacture, a proper cloth is selected; and the cloth is impregnated and cemented in various manners, so as to obtain the impregnated cloth. And then, the impregnated cloth is covered on the base material and fed into a multilayer laminating machine, wherein the laminating time is 10 seconds to 60 minutes; the hot pressing temperature is 100 to 200 DEG C; and the loaded weight is 300-20000 tons. Finally the resin impregnated cloth veneer is obtained. Therefore the surface of the veneer has the characteristics of dry heat resistance, burning resistance, crack resistance, light fastness, corrosion resistance and the like.

Owner:吴根水

Aqueous alkyd acrylic resin printing ink and preparation method thereof

The invention relates to an aqueous alkyd acrylic resin printing ink and a preparation method thereof. According to the invention, high-molecular alkyd resin with main chain containing unsaturated double bond is synthesized through molecular design. Alkyd resin is subjected to free radical graft copolymerization with acrylic monomer. A reaction system is neutralized by using an amine compound, such that water-reducible alkyd acrylic resin is synthesized. Molecular chains of alkyd and acrylic resins are connected through chemical bond, such that the compatibility of the two resins is improved. In a material curing and shaping process, phase separation of the resin is avoided. Deionized water, a pigment, a filling material, an antifoaming agent, a dispersing agent, a siccative, and alkyd acrylic hybrid emulsion are uniformly dispersed, such that the aqueous alkyd acrylic resin printing ink is obtained.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Aging-resistant silver-plastic composite pipe

An anti-aging silver-plastic composite tube takes polyethylene, polypropylene or polyvinyl chloride as the matrix material and is composed of an outer tube and an inner tube. The composition and content of the outer tube are as follows (by weight parts): low-density polyethylene (LDPE0 and / or high-density polyethylene (HDPE), polypropylene (PP) or polyvinyl chloride (PVC) 100, silver powder 0.1-10, silver ash 0.1-5, antioxidant 1010 0.5-3, wax 0.5-3 and stearic acid HST 0.5-3. The inner tube is an LDPE, PP, PVC or metal tube. The composite tube in silver-white color has the advantages of good appearance, anti-ageing effect, resistance against deformation, brittle rupture and discoloration, long service life, recyclable materials, reduced material cost, and increased product quality.

Owner:姜晓兵

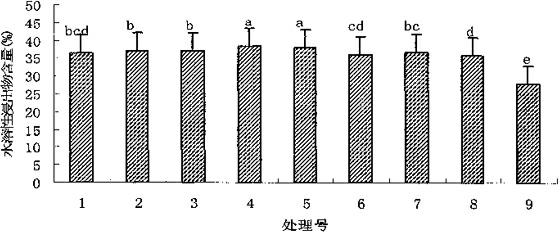

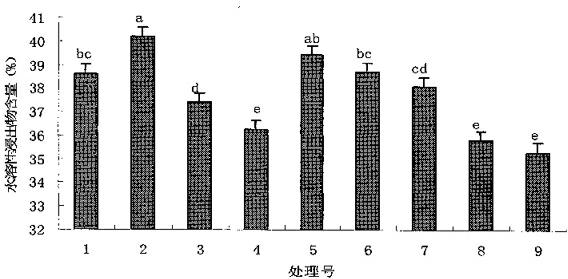

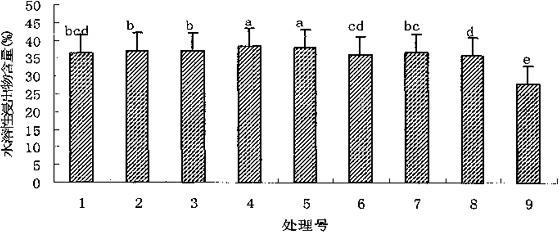

Safflower tea and preparation method thereof

InactiveCN102422955AAnti-inflammatoryAntioxidantTea substituesCodonopsisRadix Astragali seu Hedysari

The invention relates to a safflower tea and a preparation method thereof. The safflower tea is characterized in that: the safflower tea comprises the following active raw materials, by weight, 3-10 parts of safflower tea leaf, 6-12 parts of wolfberry fruit, 9-30 parts of Radix Codonopsis, 9-30 parts of Radix Astragali, and 6-15 parts of jujube. The preparation method of the safflower tea is characterized in that: the preparation method comprises steps of harvesting, choosing, airing, enzyme deactivating, and rolling. The safflower tea has the following advantages: a safflower bud tea has a greenish yellow color, and tea water has a light fragrance, a thin taste and a slightly bitter mouthfeel after the safflower bud tea is processed under optimum conditions; a safflower corolla tea friedwith vinegar has a dark red color and a heavy fragrance, tea water has a light reddish brown color, a thin taste and a slightly bitter mouthfeel, and the extract content reaches 38.2654%; and a safflower corolla tea fried with wine has a dark red color and a light fragrance, tea water has a reddish brown color, a thin taste and a slightly bitter mouthfeel, and the extract content reaches 40.1742%.

Owner:兰州市农业科技研究推广中心

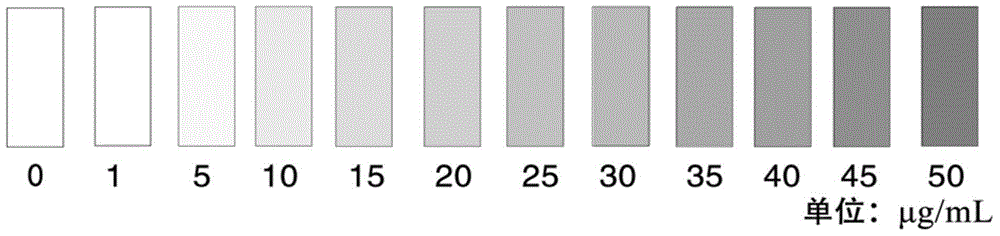

Test paper for rapidly testing nitrite and standard colourimetric card and application of test paper

InactiveCN104535712AUniform infiltrationExcellent gas barrier propertiesAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorPolyvinyl alcoholN-(1-Naphthyl)ethylenediamine

The invention belongs to the field of chemical detection and particularly relates to test paper for rapidly detecting nitrite and a preparation method and application of the test paper. According preparation method, the test paper for rapidly detecting the nitrite is prepared by taking a filter paper body as a carrier, a p-aminobenzene sulfonic acid solution and an N-1-naphthyl ethylenediamine hydrochloride as color developing agents, as well as an ethanol water solution of polyvinyl alcohol as a surface protectant and can be used for detecting the content of the nitrite. The test paper is low in cost, convenient and rapid to use and has long-term stability.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Water-based antirust agent

ActiveCN103614016AImprove bindingImprove adhesionAnti-corrosive paintsWater basedHexamethylenetetramine

The invention discloses a water-based antirust agent which consists of the following components in percentage by mass: 20-40% of film forming agent, 2-10% of corrosion inhibitor, 1-5% of auxiliary and the balance of water, wherein the film forming agent is organic fluorine-modified acrylate emulsion with solid content of 30-33%, the corrosion inhibitor is one of hexamethylenetetramine, triethanolamine, OP-10 and benzotriazole or a mixture of more, and the auxiliary is OP-10, ethylene glycol or mixture thereof. In the water-based antirust agent disclosed by the invention, the organic fluorine-modified acrylate emulsion is used as a film forming agent, and in combination with the corrosion inhibitor and the auxiliary, the binding force between a film layer and a working surface is improved; the water-based antirust agent can form a dense protective film after being applied to a steel surface, thus contact of the oxygen and moisture in the air with the steel surface is effectively isolated, and the aim of rust prevention is achieved; meanwhile, since the organic fluorine-modified acrylate emulsion has light resistance, the natural color of the steel surface can be kept unchanged; moreover, the water-based antirust agent is nonflammable and nontoxic, causes little environmental pollution, ensures simple construction and safe use, and does not influence follow-up processing of a workpiece.

Owner:BENGBU COLLEGE +1

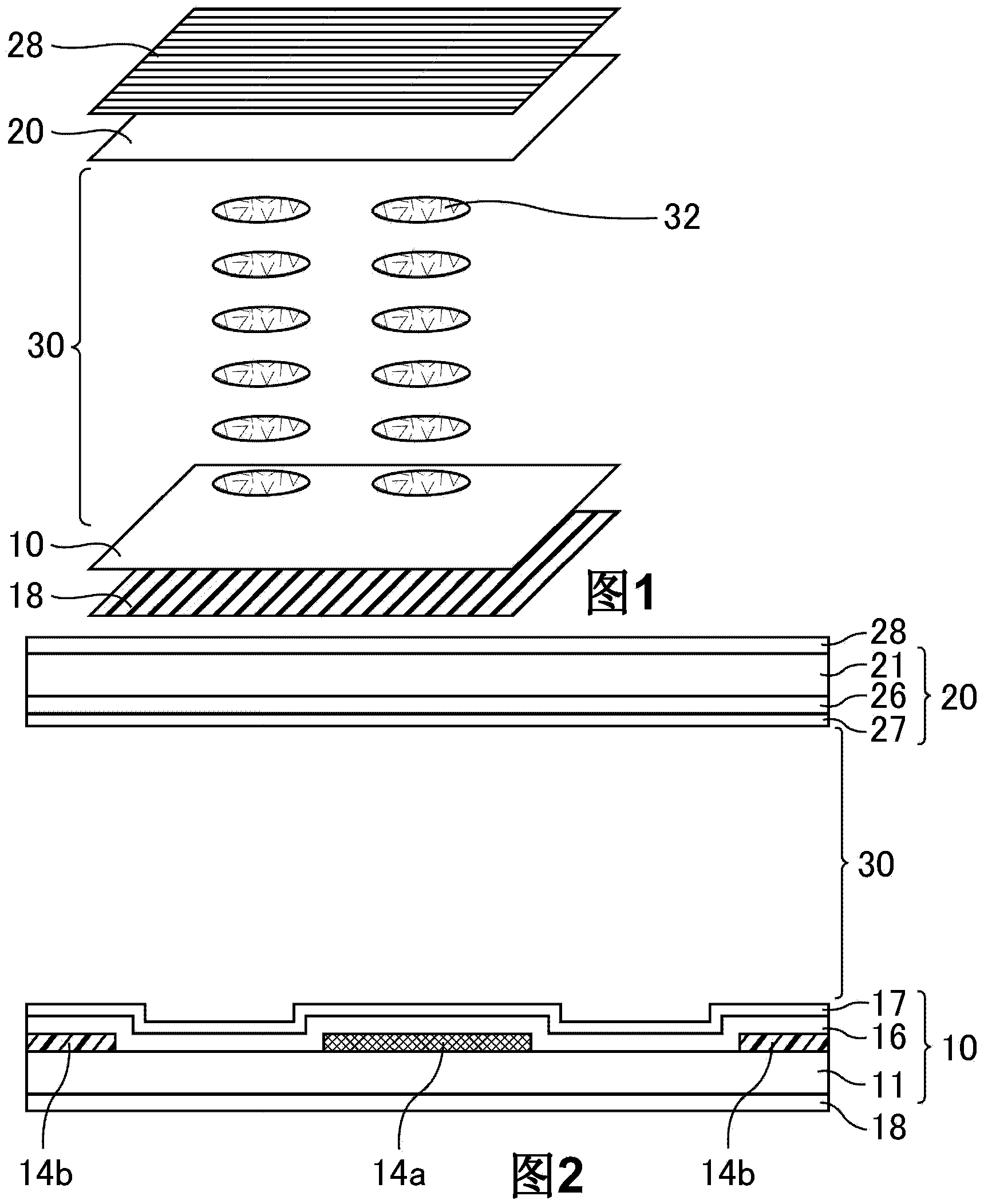

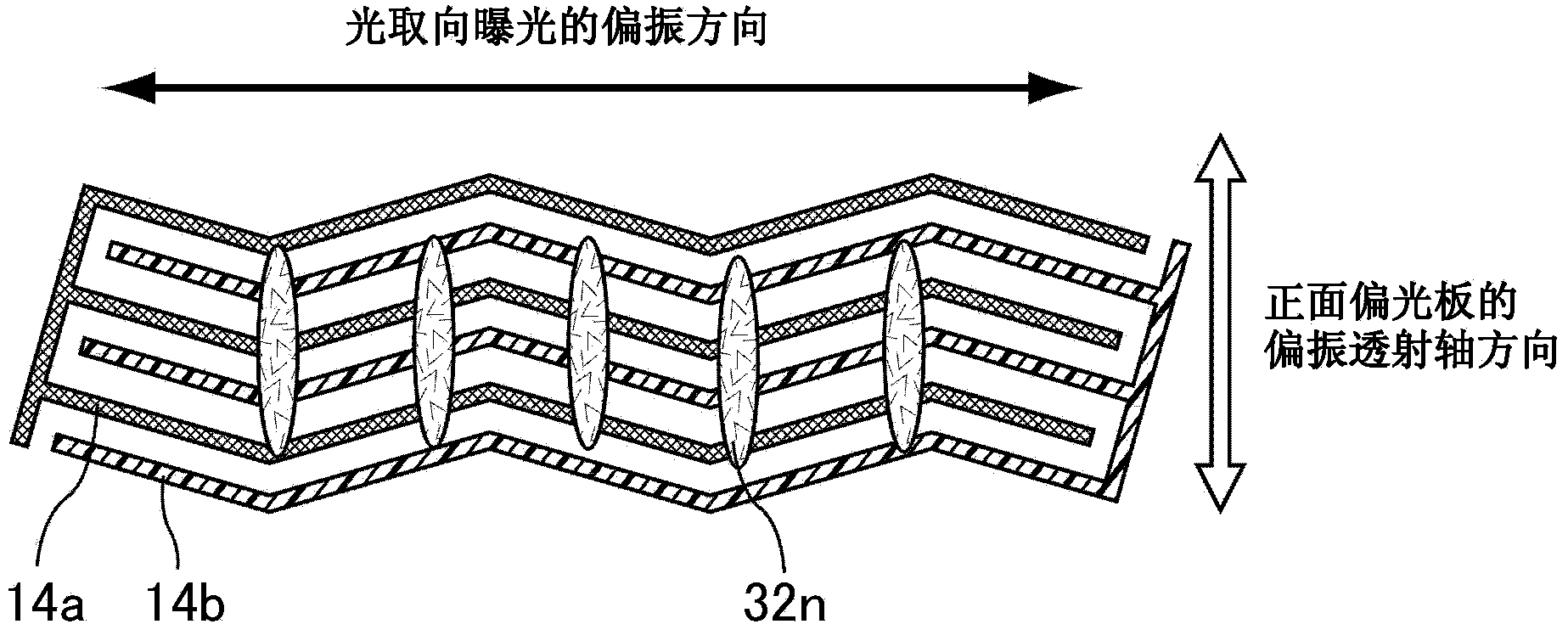

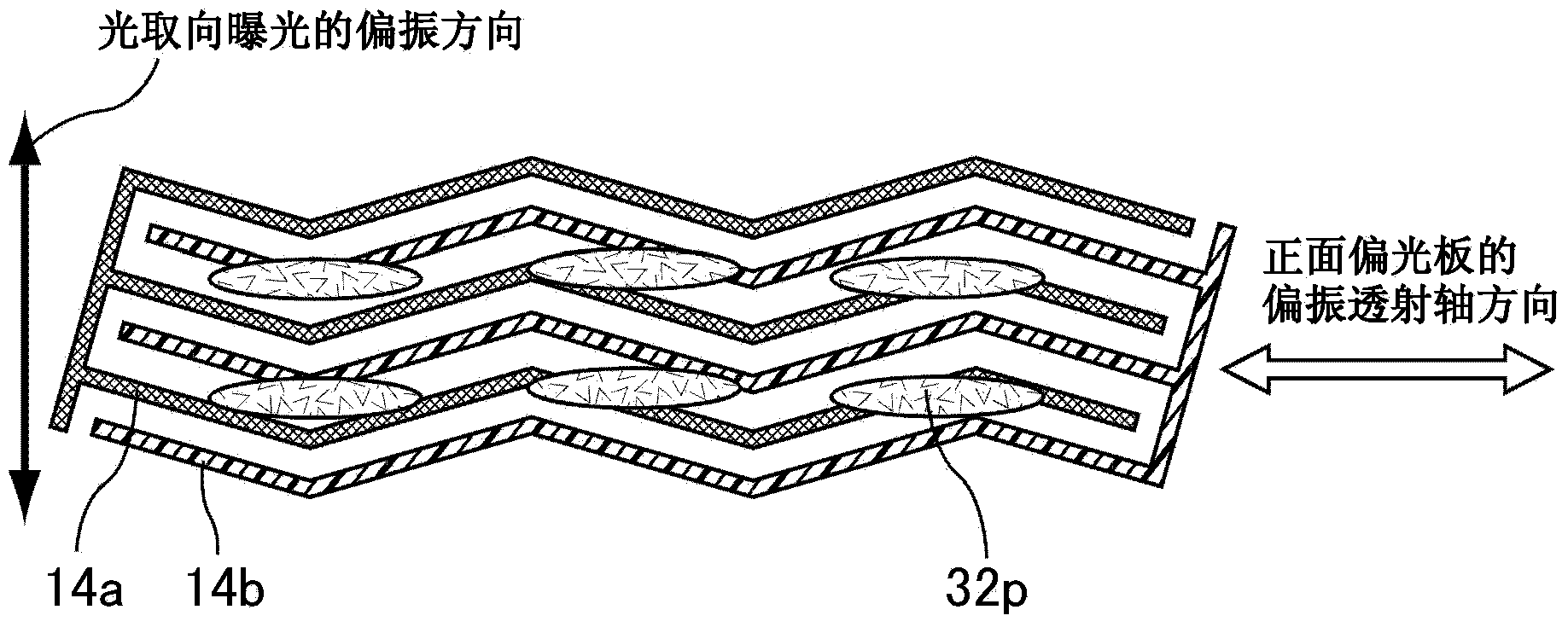

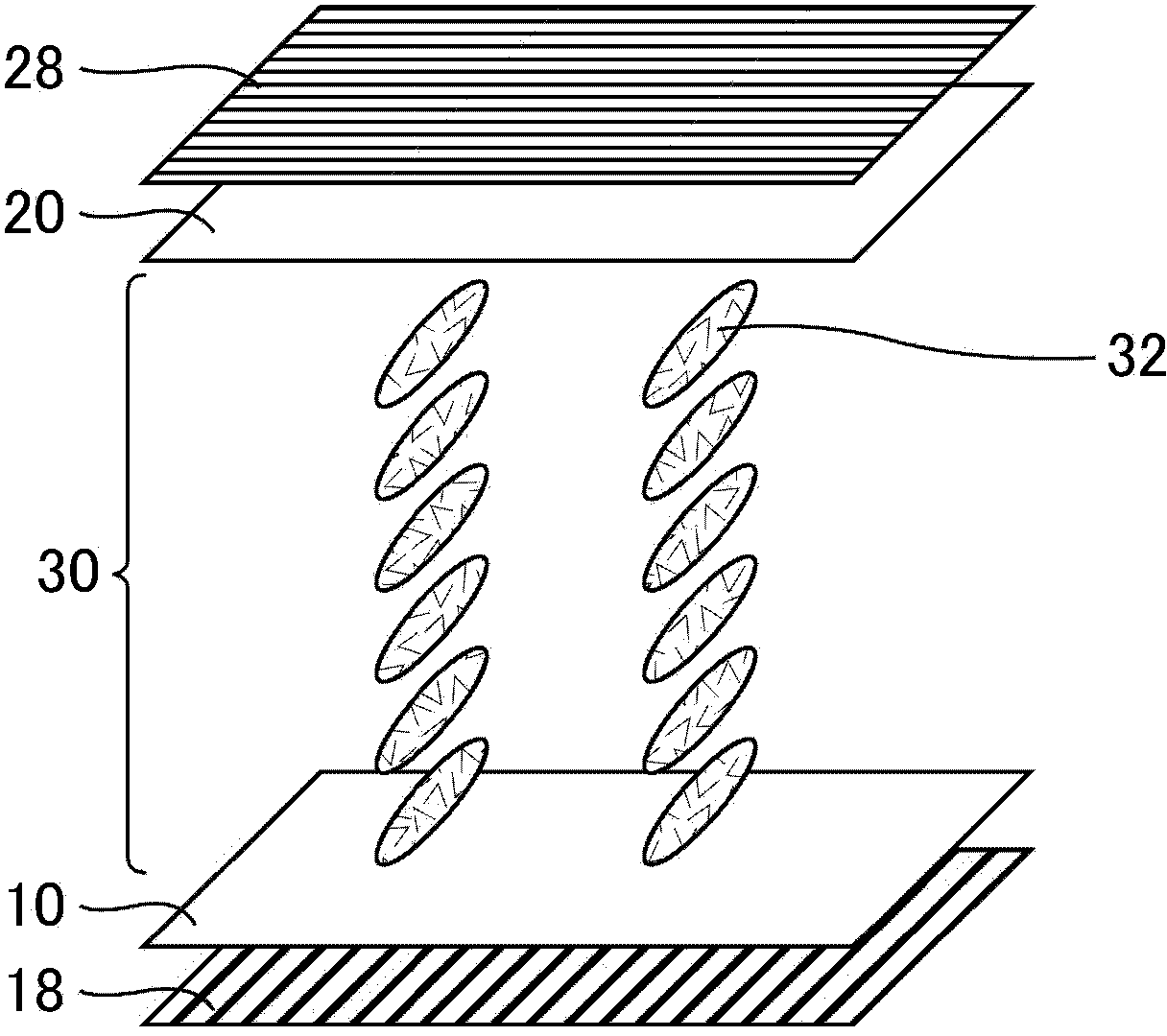

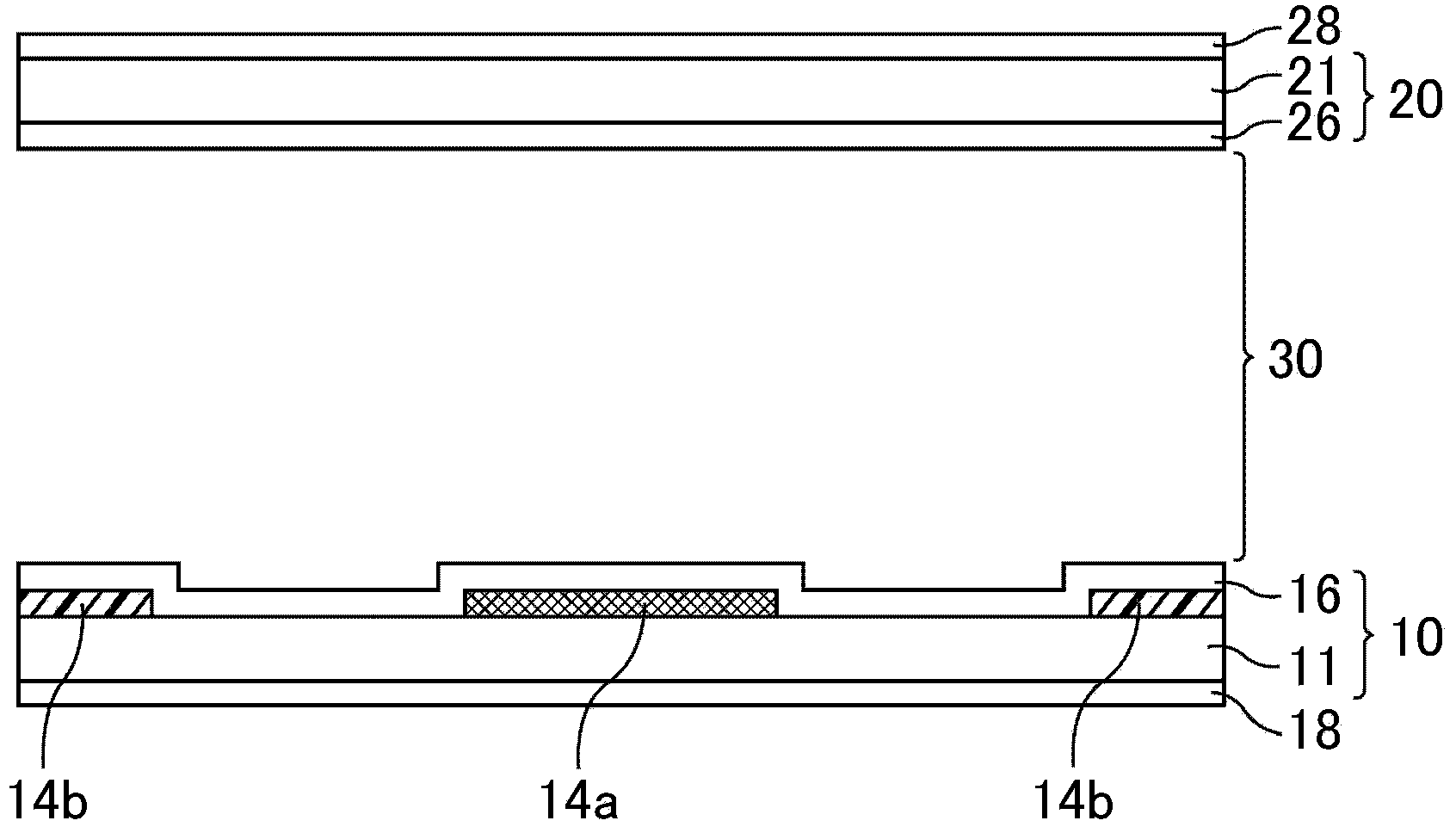

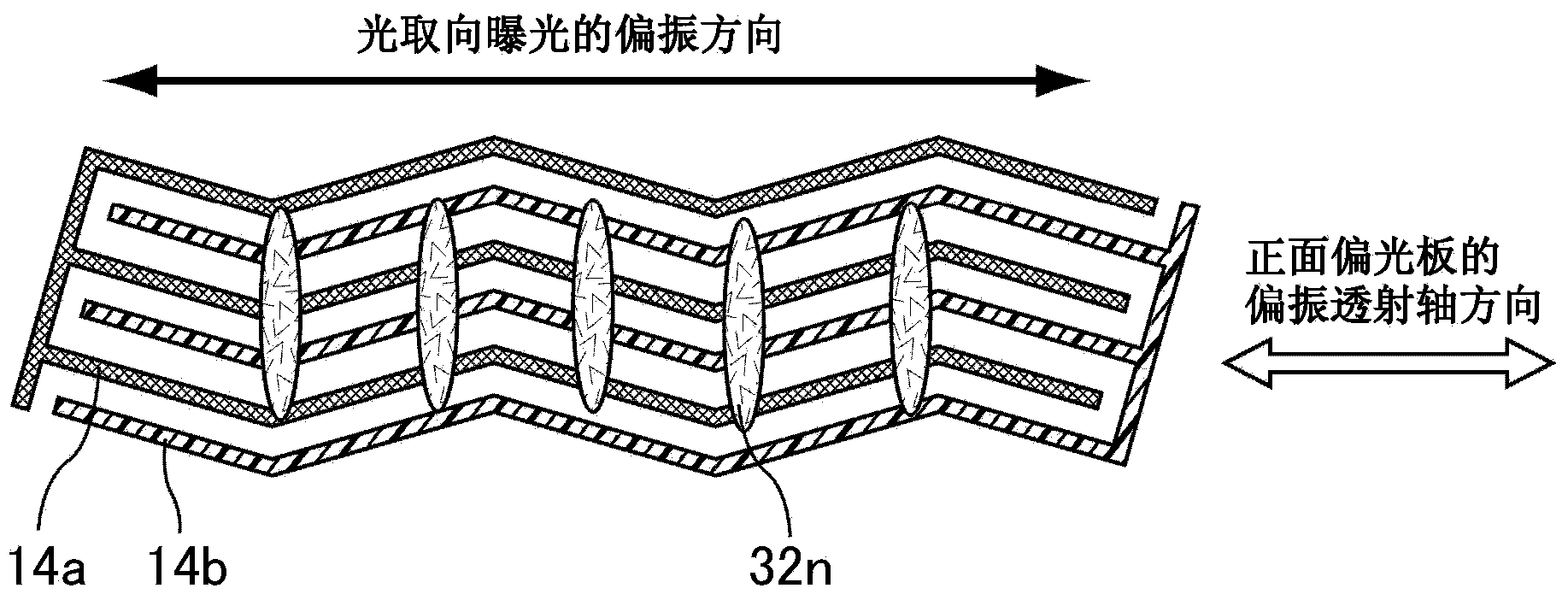

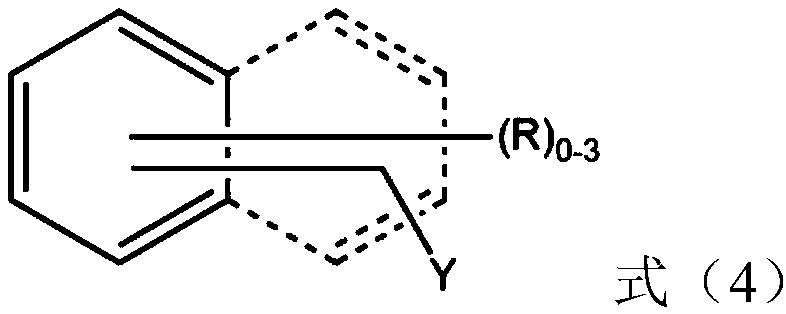

Liquid crystal display

The present invention provides a liquid crystal display having light resistance due to a polymer layer provided on a photo-alignment film, having stabilized liquid crystal alignment and having excellent display quality. In this liquid crystal display, at least one of a pair of substrates has a polymer layer, a photo-alignment film and an electrode in that order from the liquid crystal layer. The photo-alignment film aligns liquid crystal molecules horizontally, and the polarized light transmission axis of a light polarizing element on the observation surface side of the liquid crystal cells extends along the alignment direction of the liquid crystal molecules at less than a threshold voltage. The material configuring the photo-alignment film contains a material which, by means of polarized light irradiated onto the photo-alignment film, aligns the liquid crystal molecules in a direction intersecting the polarization direction of said polarized light.

Owner:SHARP KK

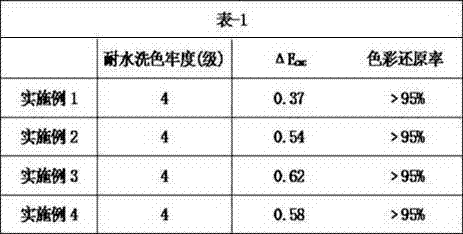

Water-based nano pigment ink for textile printing

The invention relates to ink and in particular relates to water-based nano pigment ink for textile printing. According to the formula, the ink mainly comprises the following components in parts by weight: 12.4-18.6 parts of water-based pigment slurry, 9.5-14.9 parts of a water-based resin, 5.3-9.6 parts of a quick-dry type solvent, 5.4-9.8 parts of a moisturizing solvent, 0.5-2 parts of a surfactant, 0.05-0.2 part of an antibacterial agent and 50.9-65.55 parts of deionized water. According to the ink disclosed by the invention, textiles do not need to be preheated and heated, and the ink refers to healthy and environment-friendly water-based nano pigment ink which can be directly printed on the textiles. Moreover, a digital ink-jet printing textile prepared by the ink has excellent color fastness to washing, color reduction rate and excellent handfeel.

Owner:南京鼎科纳米技术研究所有限公司

Liquid crystal display

ActiveCN103733128ALightfastWith orientation stabilizationNon-linear opticsChemistryThreshold voltage

The present invention provides a liquid crystal display having light resistance, having stabilized liquid crystal alignment and having excellent display quality. In this liquid crystal display, at least one of a pair of substrates has a photo-alignment film and an electrode in that order from the liquid crystal layer. The photo-alignment film aligns liquid crystal molecules horizontally relative to said photo-alignment film, and the polarization transmission axis of a polarizing element on the observation surface side of a liquid crystal cell intersects the alignment direction of the liquid crystal molecules that are at less than a threshold voltage in the liquid crystal layer. The material configuring the photo-alignment film contains a material which, by means of polarized light irradiated onto the photo-alignment film, aligns the liquid crystal molecules in a direction intersecting the polarization direction of said polarized light.

Owner:SHARP KK

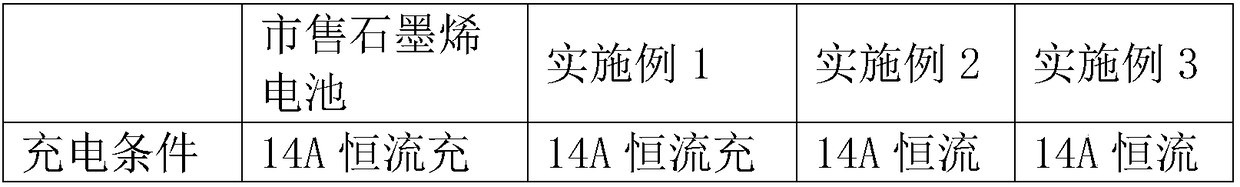

Large-capacity graphene battery capable of rapidly charging

InactiveCN108199039AImprove corrosion resistanceExtended service lifeCell electrodesSecondary cellsCorrosionEngineering

The invention provides a large-capacity graphene battery capable of rapidly charging, and relates to the technical field of batteries. The large-capacity graphene battery capable of rapidly charging,fabricated by the invention, comprises a positive pole plate, a negative pole plate, a separator, an electrolyte and a battery shell, the phenomena of small storage capacity and slow charging speed ofan existing graphene battery are solved, meanwhile, the corrosion resistance of the battery is improved, the service lifetime is prolonged, the large-capacity graphene battery is relatively good in stability, and no harm to a human body and an environment is generated; and compared with a traditional market graphene battery, it is verified that the charging time is obviously shortened by 34.94% under the same charging condition, and the charge-discharge efficiency of the battery can reach 87.73%.

Owner:长沙善道新材料科技有限公司

Formula of inner rubber layer of low-temperature resistant fuel oil rubber tube

The invention relates to a formula of an inner rubber layer of a low-temperature resistant fuel oil rubber tube. The inner rubber layer comprises the following components in part by mass: fluororubber 70-90, epichlorohydrin copolymer 10-30, semi-reinforcing purpose furnace black 15-30, magnesium oxide 3-6, calcium hydroxide 3-6, No.3 vulcanizer 2-5, 2-imidazolidinethione 0.3-1, adipic acid bis(2-ethylhexyl) ester 2-5. The main material of the inner rubber layer of the invention is the fluororubber and the epichlorohydrin copolymer. After adding the epichlorohydrin copolymer and the adipic acid bis(2- ethylhexyl) ester (DOA), the cold resistance is greatly improved, and high rubber elasticity is still maintained in a low-temperature environment.

Owner:TIANJIN PENGYI GRP CO LTD

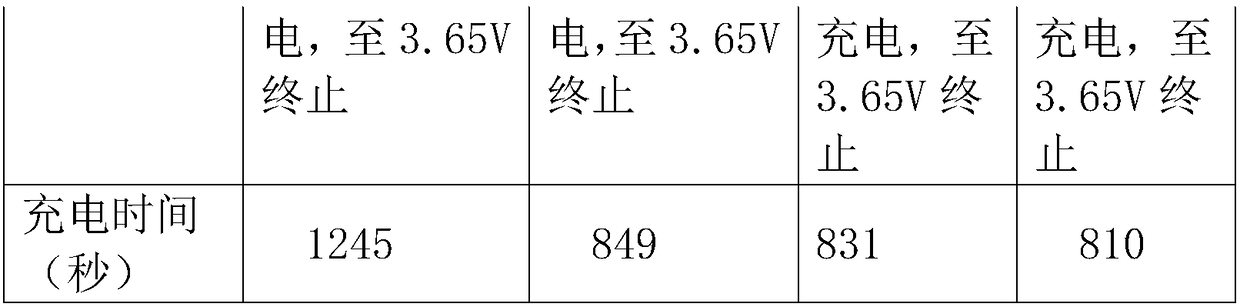

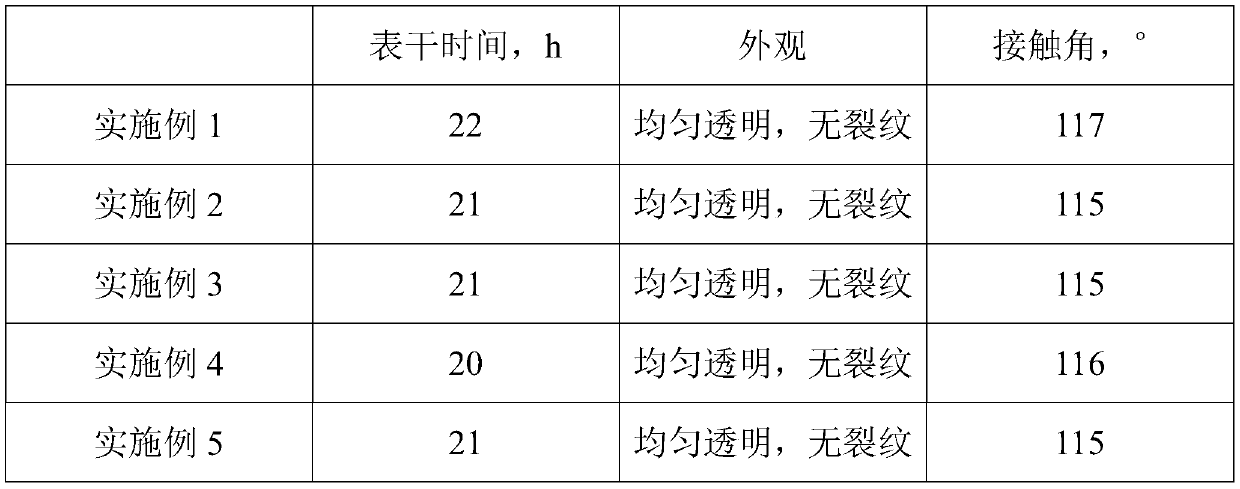

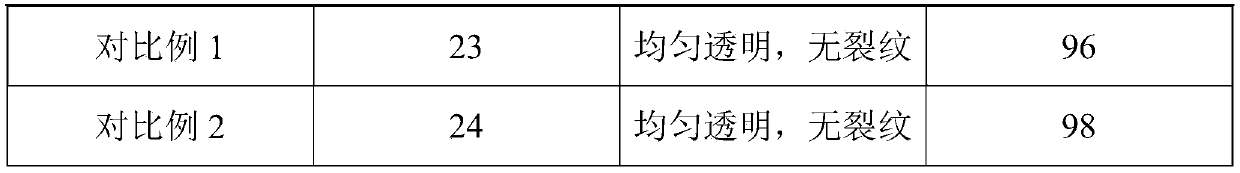

Modified acrylate polyurethane water-based paint for woodware and preparation method thereof

InactiveCN107502116AImprove aging resistanceImprove stain resistanceAntifouling/underwater paintsPaints with biocidesFiberPolyvinyl butyral

The invention provides a modified acrylate polyurethane water-based paint for woodware and a preparation method thereof. The water-based paint comprises the following components in parts by weight: 40-60 parts of an acrylate emulsion, 40-55 parts of a polyurethane emulsion, 2-6 parts of polyethyleneimine, 1-3 parts of polyvinyl butyral, 4-7 parts of a coupling reagent, 0.5-3 parts of brucite fiber, 5-8 parts of additives and 10-20 parts of deionized water. The ageing resistance, pollution tolerance, solvent resistance, ultraviolet resistance, abrasive resistance, and the like of the water-based paint film prepared on the basis of the reasonable formula composition and technology modification according to the invention are obviously improved, the overall compatibility is high, the interlayer adhesive force is high, and the water-based paint is transparent, uniform and fadeless and has high economic benefit.

Owner:安徽名士达新材料有限公司

Epoxy modified acrylic emulsion and preparation method thereof

ActiveCN108752514AInconsistencyFast aggregationPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyMethacrylate

The invention discloses an epoxy modified acrylic emulsion and a preparation method thereof. The epoxy modified acrylic emulsion comprises three components A, B and C, wherein the component A comprises deionized water, an emulsifier, epoxy resin, an acylamino compound, styrene, acrylate, methacrylate and (meth)acrylic acid; the component B comprises deionized water, a buffer agent and an emulsifier; the component C comprises deionized water and an initiator; in the emulsion system, a reducing agent, protective glue, a functional monomer, a neutralizing agent and the like can also be included.The prepared emulsion has the characteristics of fine granules, good elasticity, light resistance, weather resistance, water resistance and the like, and can be applied to waterborne industrial coating, waterborne building coating and waterborne wood coating. The waterborne coating prepared from the emulsion provided by the invention has the characteristics of strong adhesion, high mechanical properties, low curing shrinkage, good water / oil resistance, good temperature change resistance, good heat resistance, excellent aging resistance, excellent electrical insulation, excellent chemical resistance and the like.

Owner:CHANGSHA YUANPENG CHEM TECH

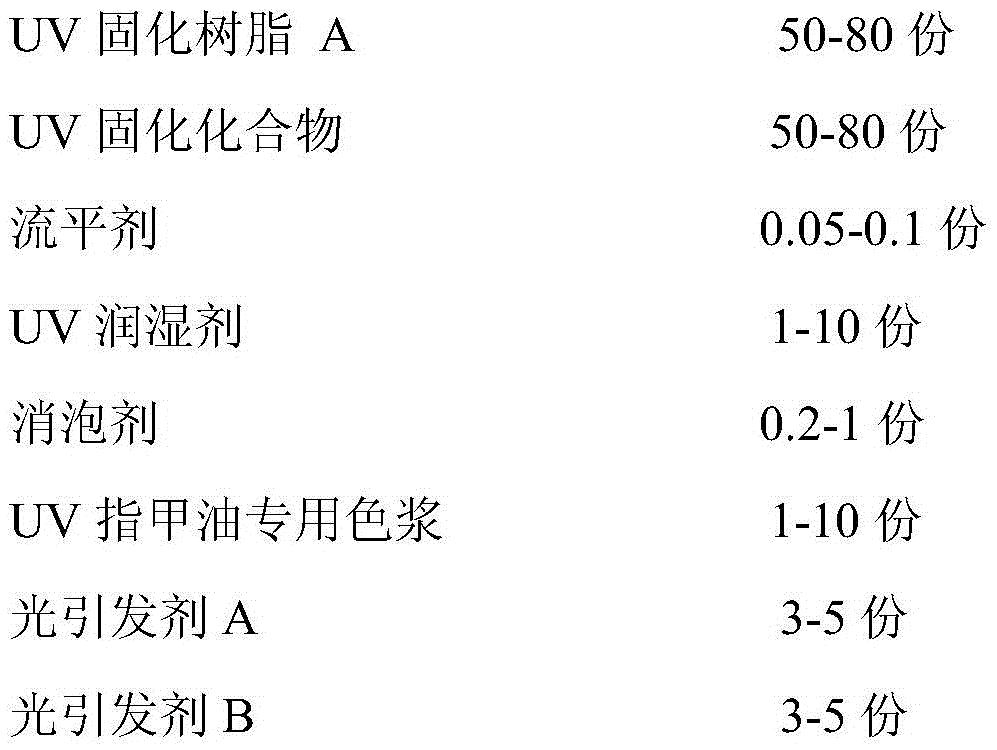

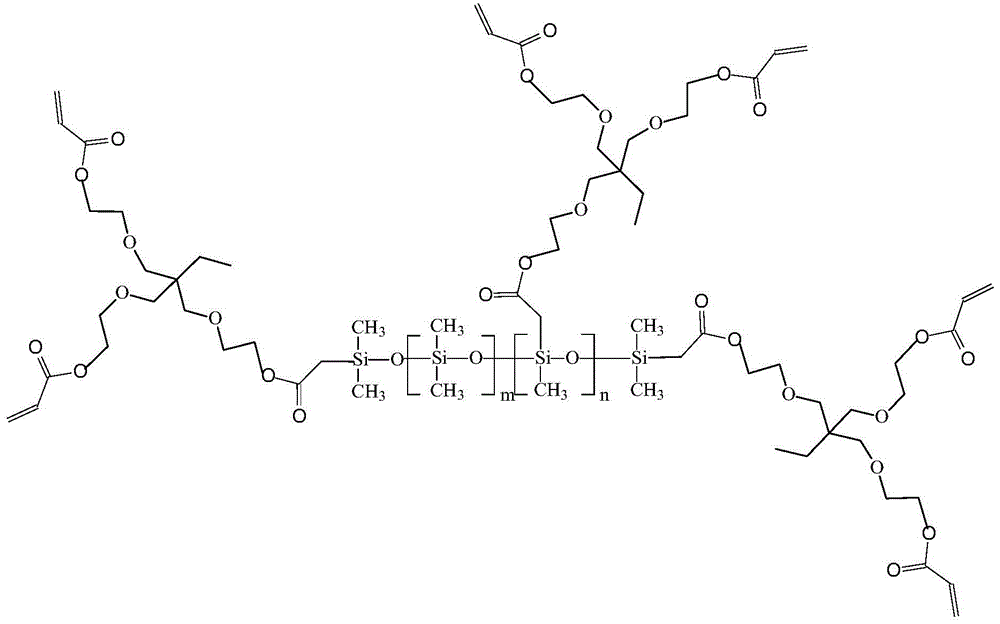

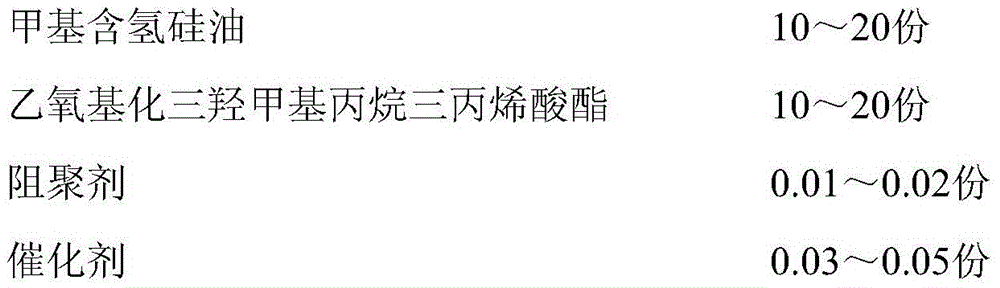

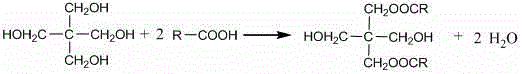

Peelable nail polish and preparation method thereof

InactiveCN105596232AFast curingImprove the decorative effectCosmetic preparationsToilet preparationsPhotoinitiatorNuclear chemistry

The invention discloses a peelable nail polish and a preparation method thereof. The peelable nail polish comprises, by weight, 50-80 parts of UV cured resin A, 50-80 parts of UV curing compound, 0.05-0.1 part of flatting agent, 1-10 parts of wetting agent, 0.2-1 part of defoamer, 1-10 parts of color paste special for UV nail polish, 3-5 parts of photoinitiator A and 3-5 parts of photoinitiator B. The peelable nail polish is capable of being cured rapidly after being irradiated by a 365nm UV-LED light and capable of being applied to fields of nail manicure for different groups of people widely.

Owner:SHANGHAI INST OF TECH

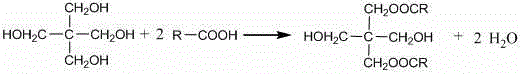

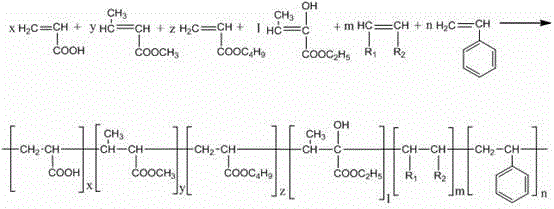

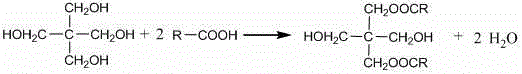

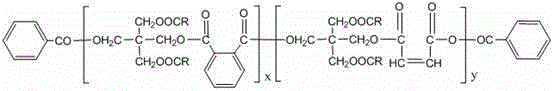

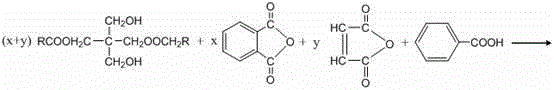

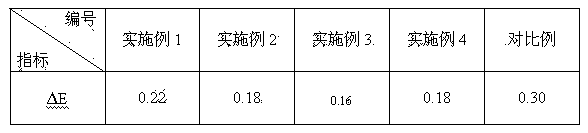

Alkyd acrylic graft copolymer and preparation method thereof

The invention relates to an alkyd acrylic graft copolymer and a preparation method thereof. According to the invention, high-molecular alkyd resin with main chain containing unsaturated double bond is synthesized through molecular design. The copolymer comprises the components of: soybean oil acid 55%-65%, pentaerythritol 17%-19%, maleic anhydride 1.07%-1.24%, phthalic anhydride 15.54%-17.92%, xylene 7.5%, and benzoic acid 1.55%-1.79%. Synthesized alkyd resin is subjected to free radical graft copolymerization with acrylic monomer, such that the alkyd acrylic graft copolymer is obtained. The copolymer monomer comprises the components of: acrylic acid 0.2%-0.9%, methyl methacrylate 2.7%-10.1%, styrene 2.6%-9.5%, butyl acrylate 4.0%-14.8%, alkyd resin 9.0%-35.0%, an initiator 0.15%-0.30%, and xylene 60.0%.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Production technology of contrast-effect automobile seat cushion leather

ActiveCN103667542AFlexibleImprove viewabilityTanning treatmentPre-tanning chemical treatmentFolding enduranceRoom temperature

The invention relates to a production technology of contrast-effect automobile seat cushion leather. The protection technology comprises the steps of liming: dissolving Na2S, NaHS and lime into water in a mass ratio of 1:1:2 to form a liming alkali liquor, reacting fur with the liming alkali liquor in a liquor ratio of 100:100 for 6 h, adding the liming alkali liquor step by step to enable the liquor ratio to increase to 100:200, and continuously reacting for 12 h; retanning: for every 100 parts of fur, adding 100 parts of water, 1 part of a pre-fatting agent and 3 parts of a chrome tanning agent or a chrome-free tanning agent, reacting at the normal temperature for 1 h, adding 2 parts of sodium formate, reacting at the temperature of 40 DEG C for 1 h, and controlling the pH in a range of 3.6-4.0; and finishing: the finishing comprises the steps of roller coating of a bottom layer, embossing, spraying of a color layer, roller coating of an effect layer and spraying of a top layer. The leather produced through the technology is soft, fine in grain side, full in hand feeling, elastic, safe and environment-friendly and has characteristics of wear resistance, folding endurance, light resistance, color migration resistance and the like; and ornamental and pleasant characteristics of the leather are added due to roller coating of the effect layer, and the rigid and non-flexible appearance of ordinary automobile seat cushion leather is changed.

Owner:HAINING SENDE LEATHER

Preparation method for special rutile titanium dioxide used for papermaking

InactiveCN105504885AHigh temperature resistantLightfastPigment physical treatmentPhosphoric acidSlurry

The invention discloses a preparation method for special rutile titanium dioxide used for papermaking. The preparation method is characterized by comprising the following steps: 1) sanding qualified calcined sulfuric acid-process titanium dioxide from a rotary kiln, then introducing slurry with a qualified sanding particle size into a coated tank, controlling the concentration of the slurry, in terms of TiO2, to be 250 to 350 g / L and carrying out heating to 70 to 75 DEG C; 2) adjusting the pH value of the slurry with dilute sulfuric acid to 2.0 to 3.0; 3) adding a phosphoric acid solution, wherein the concentration of the phosphoric acid solution is 250 to 300 g / L, and in terms of P2O5, the addition amount of the phosphoric acid solution accounts for 1.0 to 5.0 wt% of the total amount of TiO2; 4) adding an aluminum salt solution to adjust a pH value to 6.0 to 7.5 and carrying out curing for 60 min with the pH value maintained; 5) adding the metered aluminum salt solution and a corresponding neutralizing reagent, maintaining the pH value of the slurry to be 5.0 to 6.5 and carrying out curing for 2 h after completion of addition; and 6) carrying out washing three times, flash evaporation and jet milling.

Owner:LOMON BILLIONS GRP CO LTD

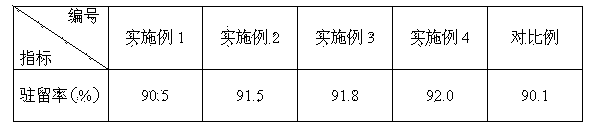

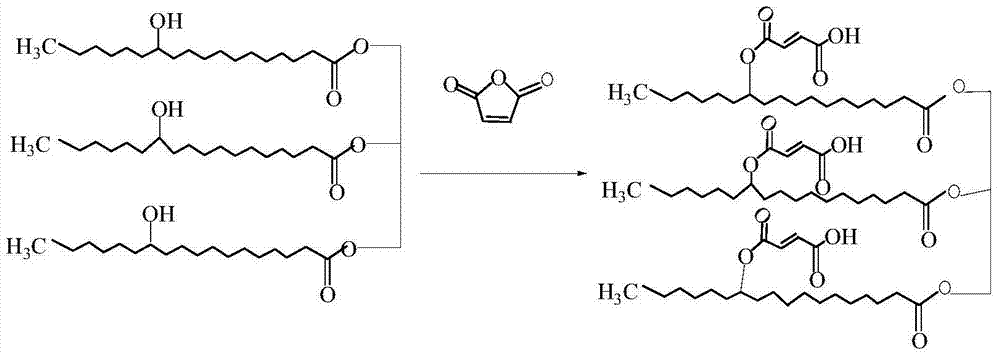

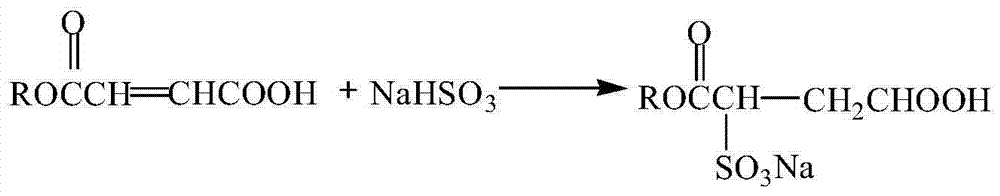

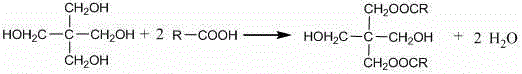

Hydrogenated castor oil sulfosuccinate fatting agent and preparation method thereof

ActiveCN103540694AEasy to degradeLightfastSulfonic acids salts preparationLeather impregnationIncreased thicknessHydroxy compound

The invention discloses a hydrogenated castor oil sulfosuccinate fatting agent and a preparation method thereof. Through maleic anhydride mono-esterification and then sodium hydrogen sulfite sulfonation, the fatting agent is prepared from hydrogenated castor oil containing hydroxyl as an initial raw material. The fatting agent is milky paste, is not layered at a room temperature in 3 months and can be emulsified in water. Based on a dilution ratio of 1: 9, the fatting agent is not layered in 24h and does not produce floating oil and based on a dilution ratio of 1: 4, the fatting agent is not layered in 12h and does not produce floating oil. A result of emulsion detection adopting 100g / L of tannin extract, 100g / L of a chromium salt, 1mol / L of hydrochloric acid and 1mol / L of ammonia water shows that the fatting agent has good emulsion stability, cannot be layered and does not produce floating oil. The fatting agent has good stability and is environmentally friendly. The crust leather granule utilizing the fatting agent has fine surface, increased thickness, good flexibility and fullness.

Owner:许昌鑫瑞德化工科技有限公司

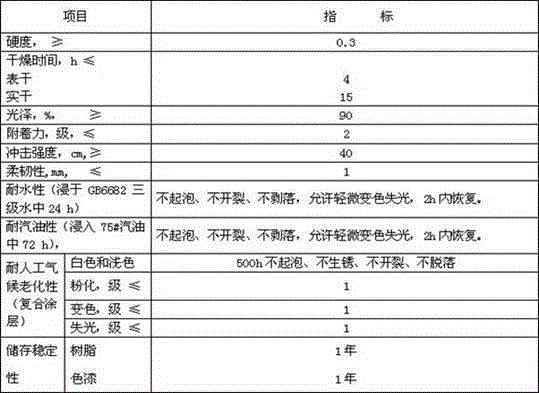

Alkyd acrylic graft copolymer paint and preparation method thereof

The invention relates to an alkyd acrylic graft copolymer paint and a preparation method thereof. According to the invention, high-molecular alkyd resin with main chain containing unsaturated double bond is synthesized through molecular design. Alkyd resin is subjected to free radical graft copolymerization with acrylic monomer. Molecular chains of alkyd and acrylic resins are connected through chemical bond, such that the compatibility of the two resins is improved. In a material curing and shaping process, phase separation of the resin is avoided. A solvent, a pigment, a filling material, an antifoaming agent, a dispersing agent, and the alkyd acrylic graft copolymer are grinded and dispersed; a siccative is uniformly dispersed in the mixture, such that the alkyd acrylic graft copolymer paint is obtained. The paint comprises the components of: alkyd acrylic graft copolymer 65%-80%, the pigment 3%-4%, the filling material 6-10%, xylene 10%-20%, the dispersing agent 0.45%-0.7%, the antifoaming agent 0.10%-0.32%, and the siccative 0.9%-3.5%.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

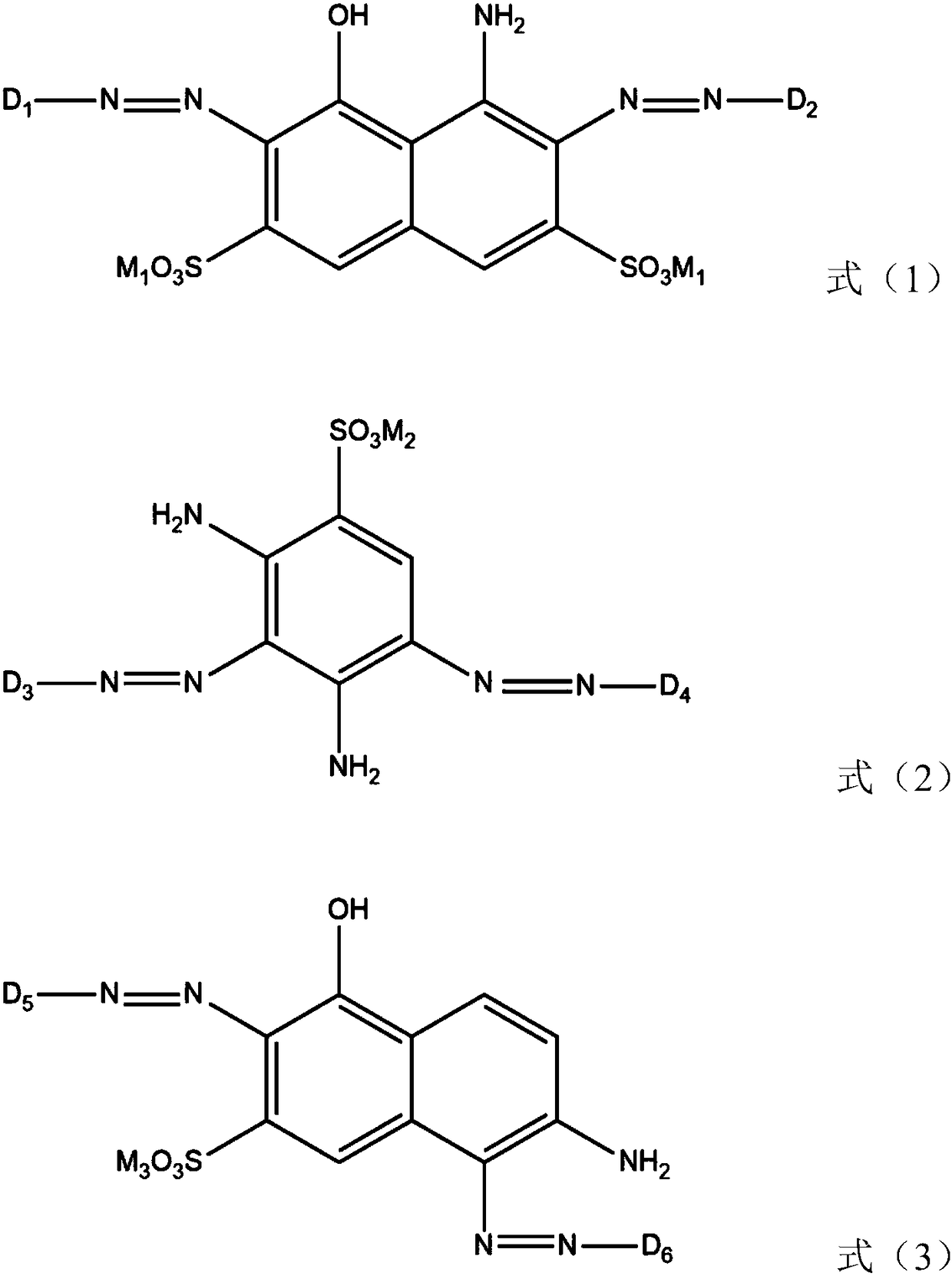

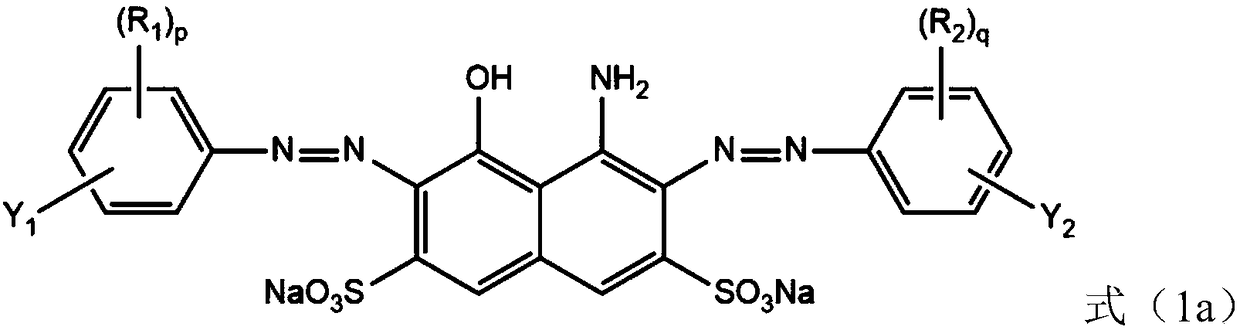

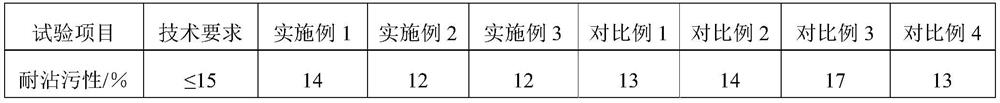

Composite reactive black dye mixture and application thereof

InactiveCN108329717AHigh reactivityHigh color fixing rateOrganic dyesDyeing processFiberChemical compound

The present invention provides a composite reactive black dye mixture. The mixture is characterized in that the composite reactive black dye comprises at least dye compounds represented by a formula (1), a formula (2) and a formula (3) shown in the description, wherein M1, M2 and M3 are independent with one another and are H, Na and K; and D1, D2, D3, D4, D5 and D6 are independent with one anotherand are a fiber active group. The prepared composite reactive black dye mixture provided by the present invention has the characteristics of high reactivity, a high color-fixing rate, high solubilityand high lifting force, and is suitable for dyeing and printing of fiber materials.

Owner:TAIXING JINYUN DYESTUFF

Anti-fingerprint and anti-pollution environment-friendly coating and preparation method thereof

ActiveCN111363428AGood chemical stabilityLightfastAntifouling/underwater paintsPaints with biocidesMeth-Propanoic acid

The invention discloses an anti-fingerprint and anti-pollution environment-friendly coating, which takes polydimethylsiloxane modified polyacrylate as a matrix, trimethylolpropane tri[3-(2-methylaziridinyl) propionate] as a cross-linking agent, and a dysprosium-doped nano titanium oxide / nano strontium titanate core-shell material as a reinforcing filler. The environment-friendly coating further comprises a dispersing agent, a leveling agent and deionized water. The invention further discloses a preparation method of the anti-fingerprint and anti-pollution environment-friendly coating. The prepared environment-friendly coating is good in stability, excellent in antifouling and anti-fingerprint performance, easy to prepare, low in cost, economical and environmentally friendly.

Owner:苏州鼎奕通材料科技有限公司

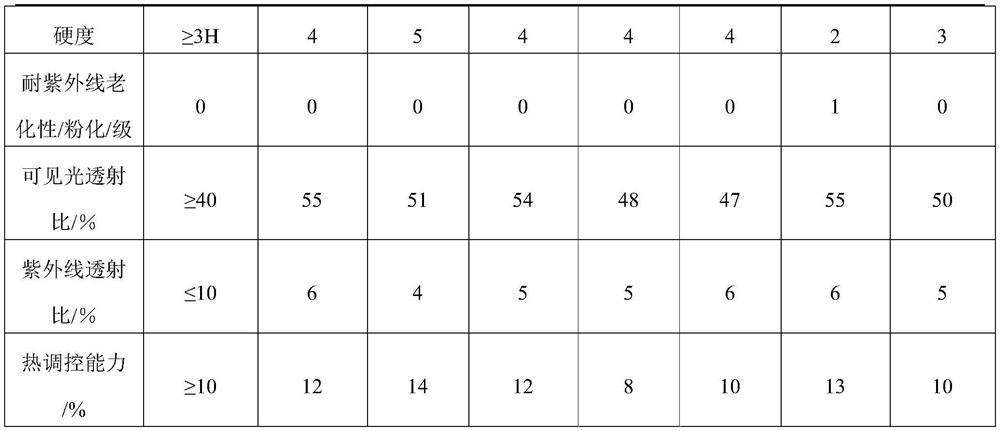

Preparation method of vanadium dioxide-zinc sulfide core-shell structure nano material and heat insulation coating

InactiveCN112239605AExcellent intelligent temperature control performanceHigh hardnessAntifouling/underwater paintsAlkali metal silicate coatingsVanadium dioxideThermal insulation

The invention relates to a preparation method of a vanadium dioxide-zinc sulfide core-shell structure nano material and a thermal insulation coating, and the preparation method of the vanadium dioxide-zinc sulfide core-shell structure nano material comprises the following steps: dispersing a vanadium dioxide nano material in water to prepare a suspension; mixing the suspension with mercapto-alkylacid to prepare modified nano particles; and mixing the modified nano particles, a surfactant, water, a zinc source and a sulfur source, carrying out a reaction, carrying out solid-liquid separation after the reaction is completed, collecting the solid, and drying to prepare the vanadium dioxide-zinc sulfide core-shell structure nano material. The vanadium dioxide-zinc sulfide core-shell structurenano material obtained by the preparation method has high stability and dispersibility, and can effectively improve the intelligent temperature regulation and control effect of the heat insulation coating.

Owner:ASIA PAINT SHANGHAI

Air layer fabric

The invention discloses an air layer fabric comprising a fabric body formed by braiding warp yarns with filling yarns; the warp yarn is formed by blending space cotton with flame retardation fibers; the filling yarn is formed by blending polyester cotton spandex with ice crystal cloth. The air layer fabric is heat retaining, moisture absorptive, light resistant, and heat resistant.

Owner:TAICANG SHENGDANRONG CLOTHING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com