Liquid crystal display

A technology of liquid crystal display device and liquid crystal layer, which is applied in the directions of instruments, optics, nonlinear optics, etc., can solve the problems of low transmittance of white display and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

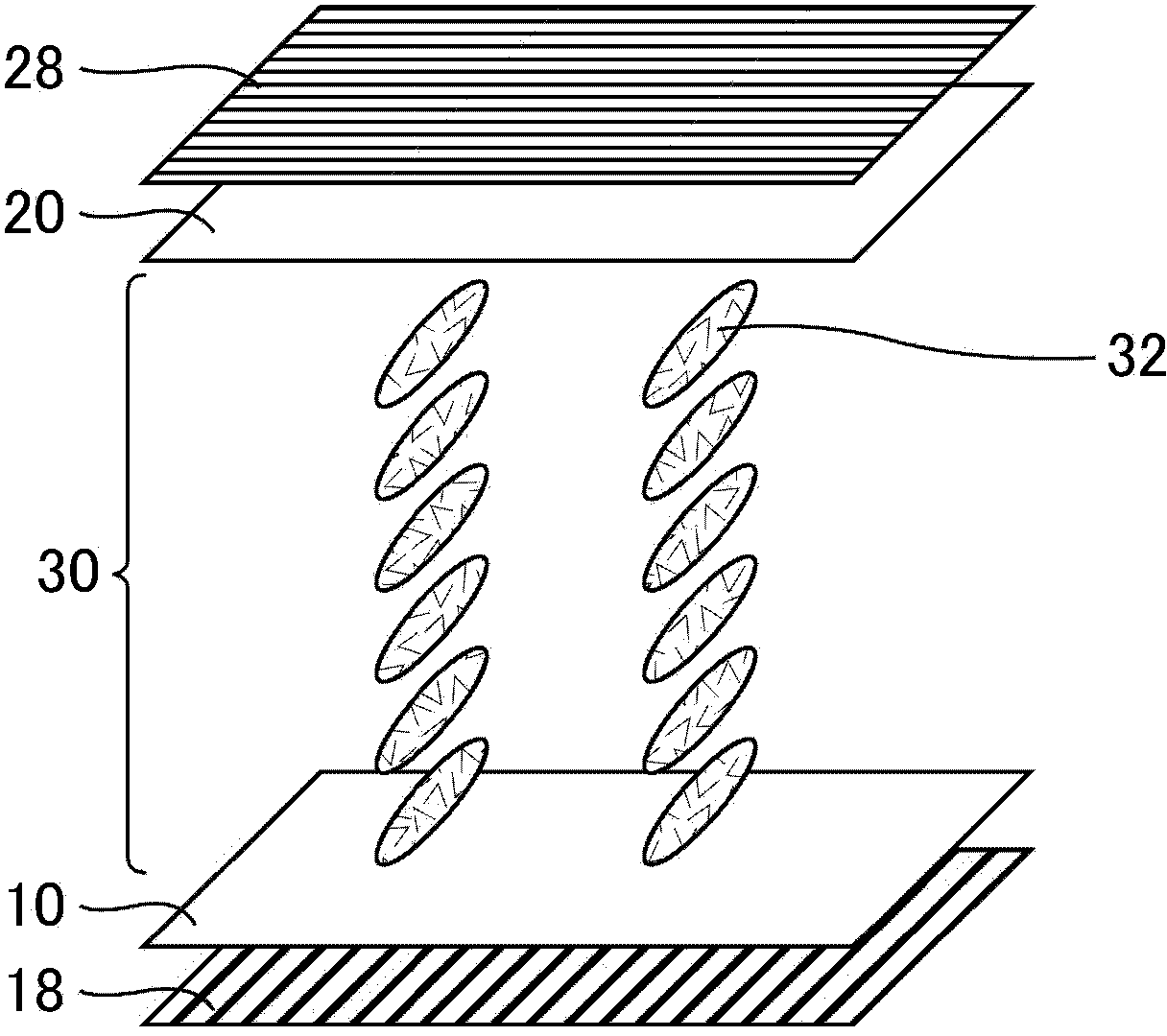

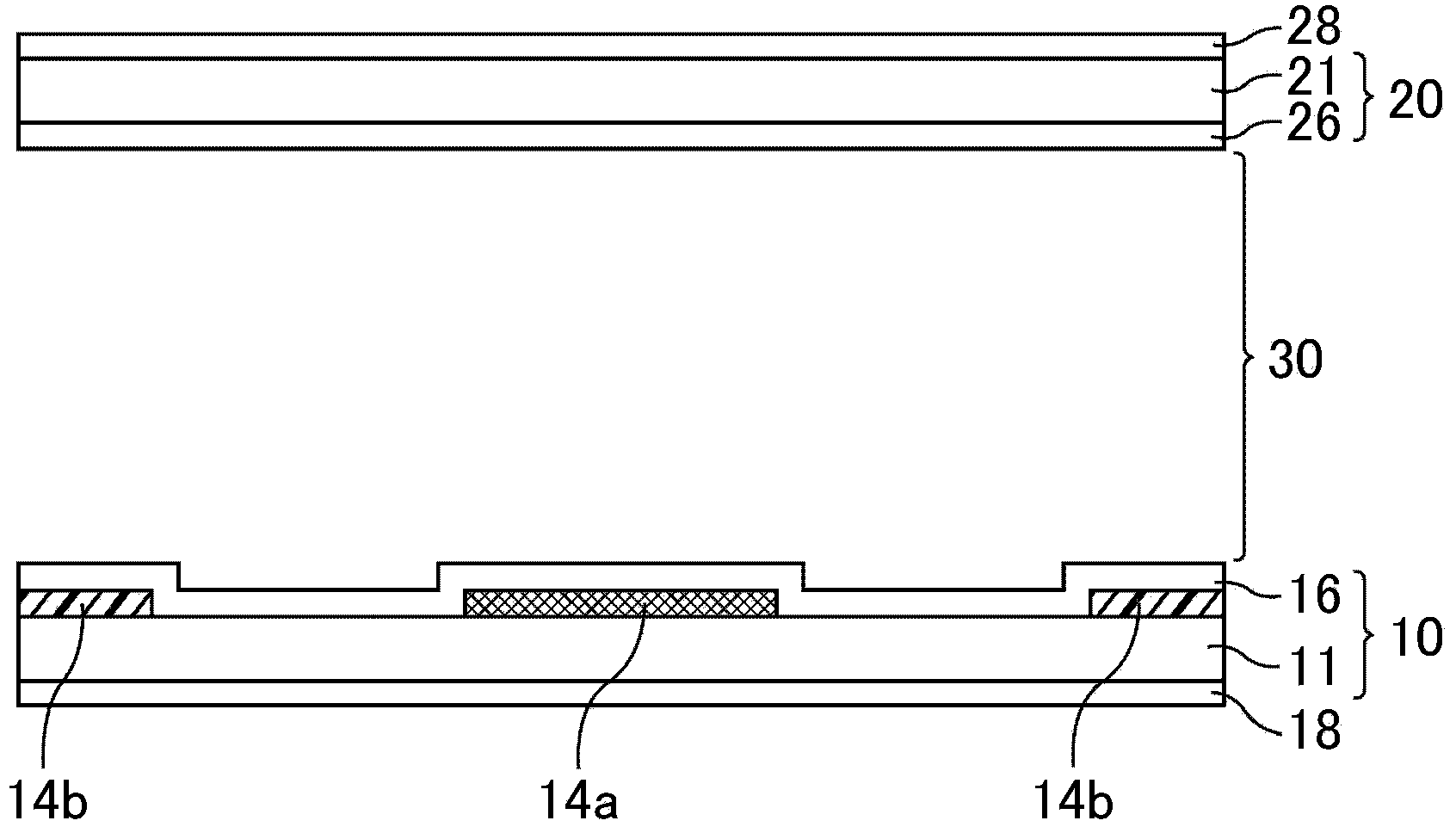

[0108] Embodiment 1 is a liquid crystal display device in which the direction of the polarization transmission axis of the polarizing plate on the front side (observation side) is perpendicular to the liquid crystal alignment direction (initial alignment). The display mode adopts IPS mode. figure 1 It is a schematic perspective view of the liquid crystal display device according to Embodiment 1 when the voltage is lower than the threshold voltage. In the liquid crystal display device according to Embodiment 1, the array substrate 10 , the liquid crystal layer 30 and the color filter substrate 20 are stacked sequentially from the back side of the liquid crystal display device toward the viewing side to form a liquid crystal cell. A rear-side polarizing plate 18 and a front-side polarizing plate 28 are respectively provided on the rear side of the array substrate 10 and the viewing surface side of the color filter substrate 20 .

[0109] exist figure 1 In , the direction of ...

Embodiment 1)

[0122] Prepare a glass substrate (comb-teeth electrode substrate) and a bare glass substrate (counter substrate) having a pair of comb-teeth electrodes as transparent electrodes on the surface, and apply polymer as a material for a horizontal alignment film on each substrate by spin coating. Vinyl cinnamate solution. As the glass of the glass substrate, #1737 (manufactured by Corning Incorporated) was used.

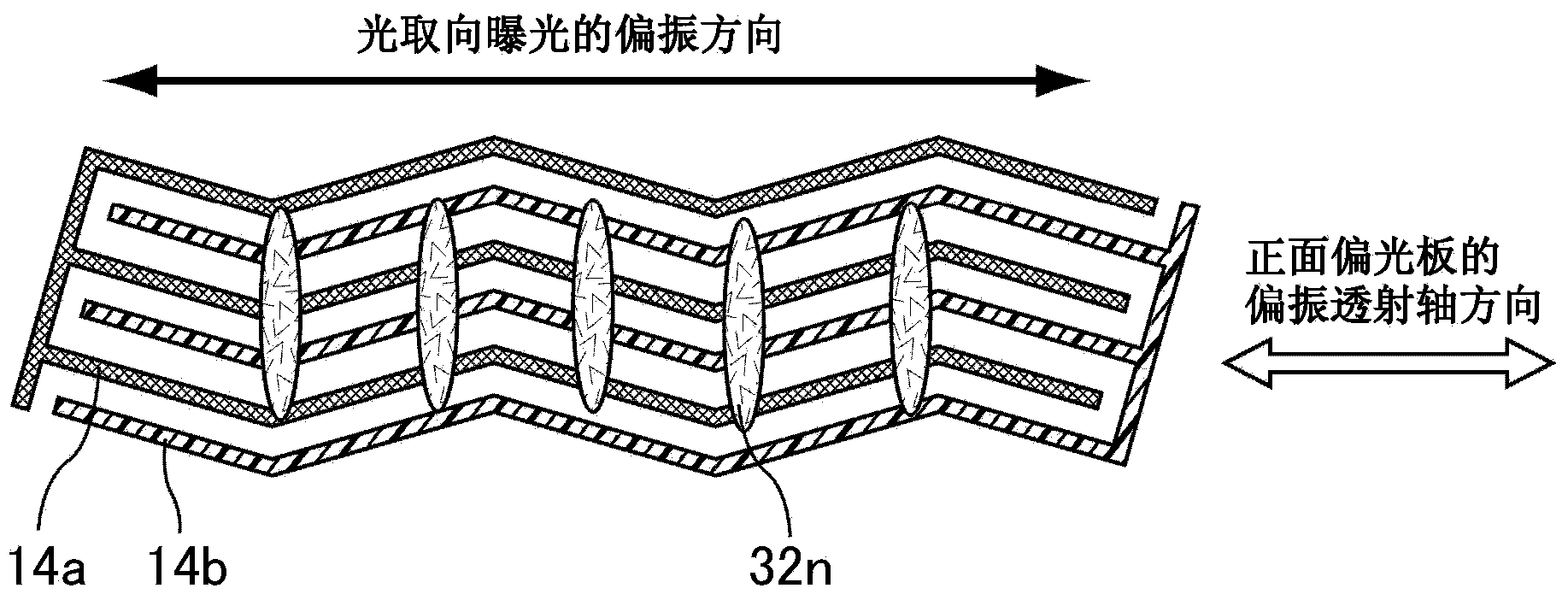

[0123] image 3 It is a schematic plan view showing the irradiation polarization direction, the comb-shaped electrodes, and the liquid crystal alignment direction of the liquid crystal display device according to the first embodiment. A pair of comb electrodes, such as image 3 As shown, the pixel electrode 14a and the common electrode 14b extend approximately parallel to each other, and are each formed in a zigzag shape. As a result, the electric field vector when the electric field is applied is substantially perpendicular to the longitudinal direction of the electro...

Embodiment approach 2

[0149] Embodiment 2 is the same as Embodiment 1, except that a PS layer is provided on the photo-alignment film, and liquid crystals are limited to preferred modes described later. Figure 8 is a schematic cross-sectional view of a liquid crystal display device according to Embodiment 2. FIG. The PS layers 117 and 127 can be polymerized by injecting a liquid crystal composition containing a liquid crystal material and a polymerizable monomer between the array substrate 110 and the color filter substrate 120, and irradiating a certain amount of light or heating the liquid crystal layer 130. Formed by polymerizing monomers. The PS layers 117 and 127 improve the orientation regulation force of the photo-alignment films 116 and 126 . In addition, at this time, by performing polymerization in a state where no voltage is applied to the liquid crystal layer 130 or a voltage lower than a threshold value is applied to the liquid crystal layer 130, the PS layers 117 and 127 having a sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com