Alkyd acrylic graft copolymer paint and preparation method thereof

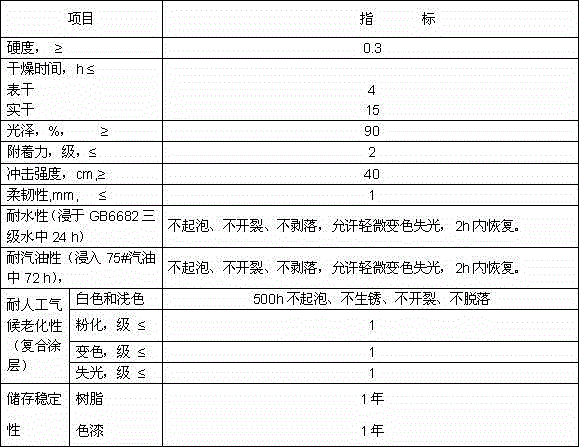

A graft copolymer, alkyd acrylic technology, applied in polyester coatings, coatings, etc., can solve problems such as material performance deterioration, and achieve good weather resistance, good color retention, and excellent aging resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

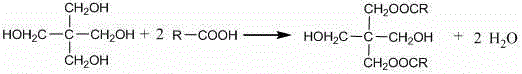

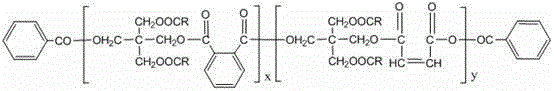

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of alkyd acrylic acid graft copolymer coating, carries out batching by above-mentioned component, and its steps are:

[0032] The preparation steps of alkyd resin are:

[0033] (1) Add soyoleic acid, pentaerythritol, and benzoic acid in sequence according to the formula in the reaction vessel equipped with a stirring device, an oil-water separator, and a thermometer, protect with nitrogen, start stirring and condense water, and heat up to 180°C within 1 hour. When it reaches 120°C, add xylene with a formulation amount of 35%~40%;

[0034] (2) When the temperature reaches 180°C, start to keep warm, keep warm for 40 minutes, and control the temperature at 180-200°C; add 1 / 2 of the formula of phthalic anhydride and maleic anhydride and the remaining xylene, and add the remaining phthalic anhydride and maleic anhydride after 10 minutes; raise the temperature to make the temperature Control at 210-220°C, keep warm for 1h;

[0035] (3) Raise the tempe...

Embodiment 1

[0058] Embodiment 1. The preparation of alkyd resin

[0059] In a 500ml four-necked flask equipped with a stirring device, an oil-water separator and a thermometer, 60g of soyoleic acid, 17.54g of pentaerythritol, and 1.65g of benzoic acid were successively added, protected by nitrogen gas, stirring and condensed water were started, and the temperature was raised to 180°C within 1h (wherein When the temperature reaches 120°C, add 3g of xylene); when the temperature reaches 180°C, start to keep warm, keep the heat for 40 minutes, and control the temperature at 180-200°C; add 8.27g of phthalic anhydride, 0.27g of maleic anhydride and 5.46g of xylene, and add the rest after 10 minutes 8.27g phthalic anhydride and 0.27g maleic anhydride; raise the temperature to control the temperature at 210-220°C, and keep it for 1 hour; continue to raise the temperature to control the temperature at 220-230°C, and start measuring the acid value after holding it for 1 hour; start when the acid va...

Embodiment 2

[0060] Embodiment 2. Preparation of drier

[0061] In 200g of 200# solvent oil, add 11.0g of cobalt isooctanoate, 44.4g of manganese isooctanoate, 44.4g of zirconium isooctanoate, disperse at a high speed of 1500r / mim, and stir for 2 hours to obtain a drier for alkyd acrylic acid graft copolymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com