Resin impregnated cloth veneer and manufacture technology thereof

A technology of resin impregnation and manufacturing process, which is applied in the field of panel and its manufacturing process, which can solve problems such as difficulty in mass production, surface scratches or pollution, and lack of protective film, etc., to facilitate mass production and avoid scratches Or pollution, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

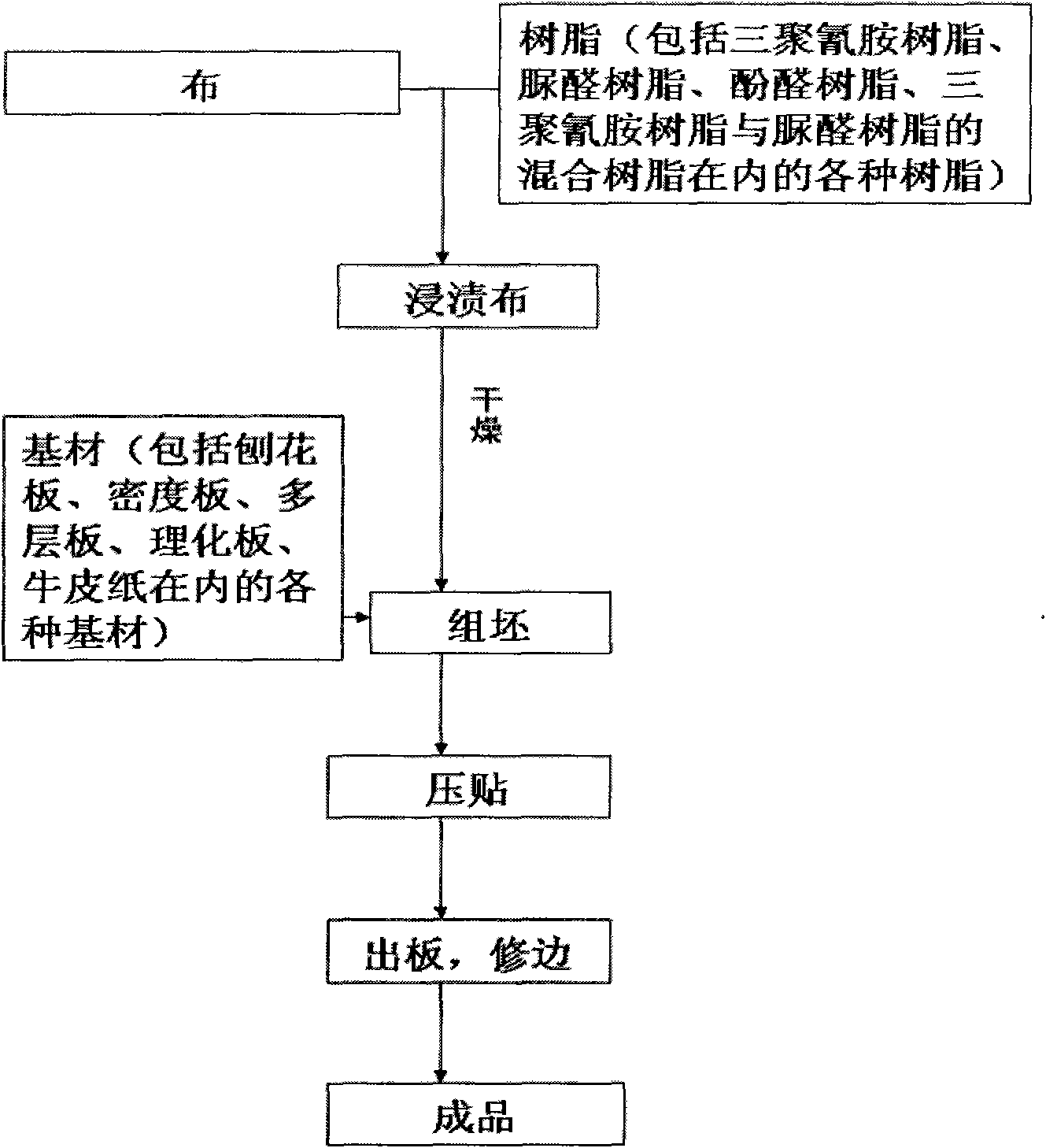

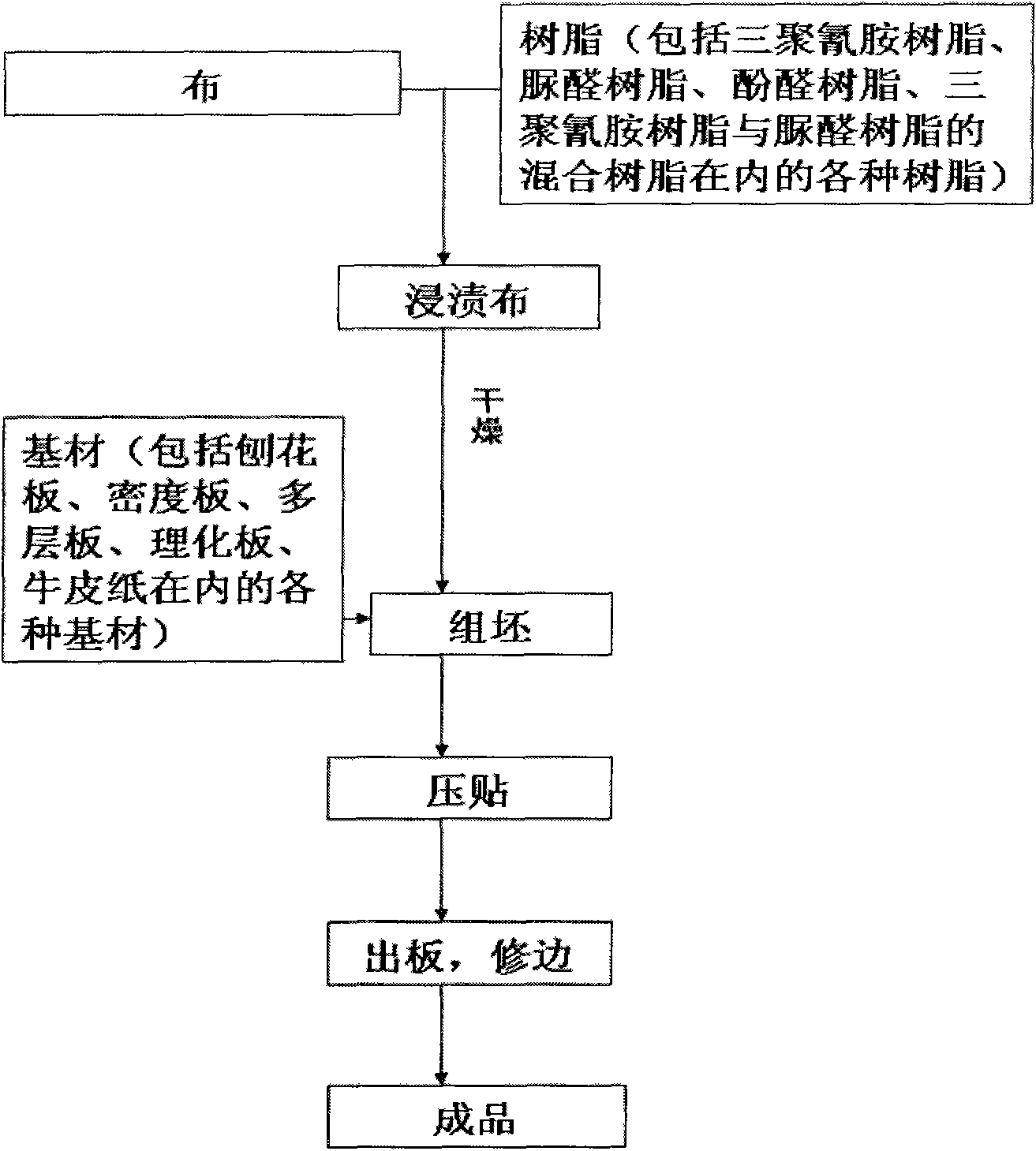

Method used

Image

Examples

Embodiment 1

[0034] Select a woven non-woven fabric with a specification of 1220mm×2440mm, and impregnate the non-woven fabric with melamine resin by dipping, and the gluing rate of the melamine resin is 150%, and dry it to a suitable dryness.

[0035] Afterwards, choose 1220mm×2440mm×18mm particleboard, brush off the dust on it, and cover the melamine-impregnated cloth on the particleboard that has been brushed off. Next, use a heat-conducting oil-type hydraulic press, select a pitted steel formwork, put the particleboard and melamine-impregnated cloth into the press, and ensure that the centerline of the particleboard coincides with the centerline of the press.

[0036] Then, close the press and start pressing. Specifically, the pressing time is 10 seconds, the hot pressing temperature is 100° C., and the loaded weight is 300 tons. After the completion, the panel is unloaded, the edge is trimmed, and the resin-impregnated cloth veneer is obtained, and it can be covered with a film after...

Embodiment 2

[0038] Select the knitted cotton cloth with a specification of 750mm×3660mm, and spray the mixed resin of melamine resin and urea-formaldehyde resin evenly on the cotton cloth by spraying glue. Specifically, the glue adhesion rate of the mixed resin is 100%, and it is dried to a suitable dryness.

[0039] Afterwards, select a multi-layer board of 750mm×3660mm×38mm, brush off the dust on it, and cover the impregnated mixed resin cotton cloth on the multi-layer board that has been brushed off. The steam heat conduction hydraulic press is used to prepare with the mirror steel template. Then, put the multilayer board and the dried cotton cloth into the press, and ensure that the centerline of the multilayer board coincides with the centerline of the press.

[0040] Then, close the press and start pressing. Specifically, the pressing time is 60 minutes, the hot pressing temperature is 120°C, and the loaded weight is 500 tons. After the completion, the panel is removed and the ed...

Embodiment 3

[0042] Select the knitted blended fabric with a specification of 1220mm×2440mm, spray urea-formaldehyde resin evenly on the acrylic fabric by gluing, the gluing adhesion rate is 200%, and dry to a suitable dryness.

[0043]Afterwards, select a 1220mm×2440mm×18mm multi-layer board, brush off the dust on it, and cover the urea-formaldehyde resin acrylic cloth on the density board that has been brushed off. The steam heat conduction hydraulic press is adopted, and the suede steel formwork is selected. Then, put the density board and urea-formaldehyde resin acrylic cloth into the press, and ensure that the centerline of the density board coincides with the centerline of the press.

[0044] Then, close the press and start pressing. Specifically, the pressing time is 60 seconds, the hot pressing temperature is 200°C, and the loaded weight is 2000 tons. After the completion, the board is removed and trimmed to obtain a resin-impregnated cloth decorative panel made of urea-formaldeh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com