Laser light-emitting device and preparation method thereof and laser illumination

A light-emitting device and laser technology, applied in the field of laser lighting, can solve problems such as the inability to use LD light sources, the easy burning of mixed fluorescent materials, and the need for research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

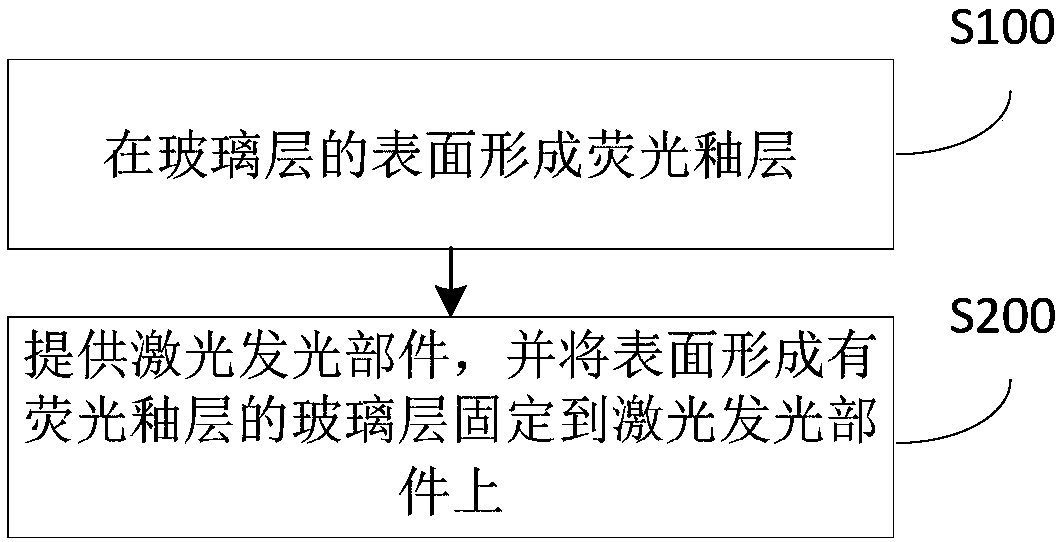

[0068] It should be noted that, in addition to step S100, the preparation method also includes other necessary steps, such as the preparation of the laser light-emitting component, the fixing of the glass layer and the laser light-emitting component, etc., and those skilled in the art can The specific structure is designed and supplemented. In some embodiments of the invention, reference figure 2 , the preparation method can further include:

[0069] S200: Provide a laser light-emitting component, and fix the glass layer with the fluorescent glaze layer formed on the surface to the laser light-emitting component.

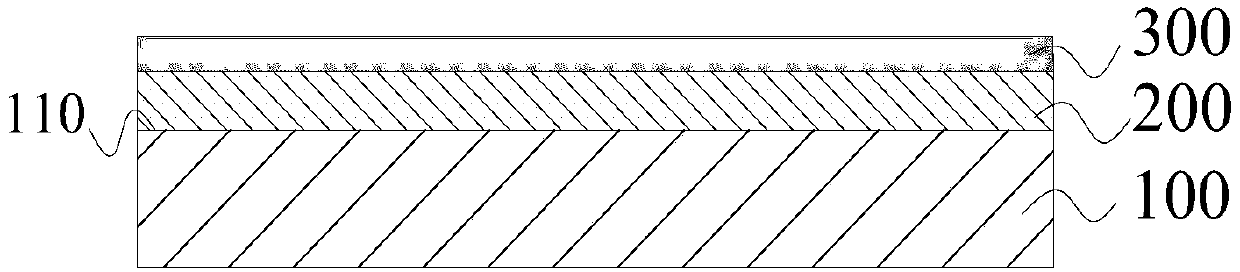

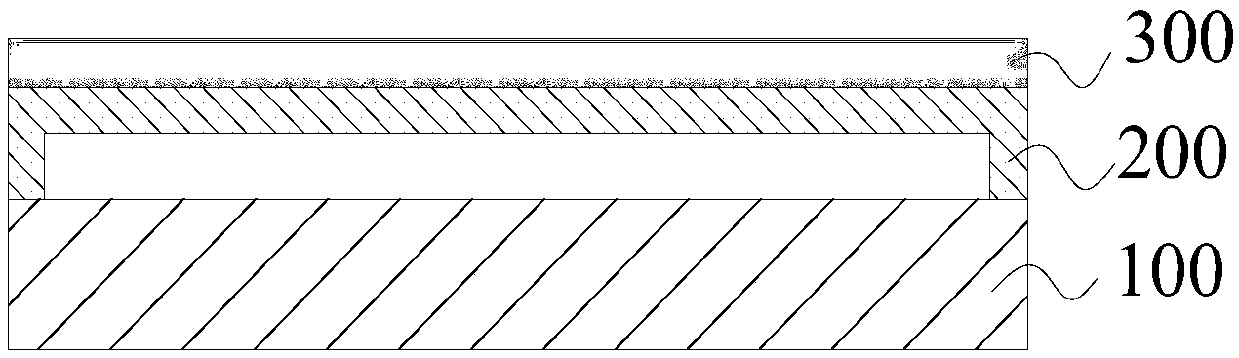

[0070] In this step, a laser light-emitting component 100 is provided, and the glass layer 200 obtained in step S100 with the fluorescent glaze layer 300 formed on its surface is fixed to the laser light-emitting component 100, so as to obtain a laser light-emitting device.

[0071]According to the embodiment of the present invention, the specific method for prov...

Embodiment 1

[0078] In this embodiment, a fluorescent glaze layer on the surface of a glass layer in a laser light emitting device is prepared. Specifically, prepare according to the following steps:

[0079] 1. Evenly mix the low-temperature ceramic glaze, YAG fluorescent powder and water at a mass ratio of 1:1:2 to ensure that the mixed fluorescent glaze slurry has a certain fluidity as a whole. At the same time, wipe the surface of the glass layer 200 with alcohol to remove the surface stains. refer to Figure 5 , using a glue head to drip the uniformly mixed fluorescent glaze slurry 310 and drip it on the glass layer 200, until the fluorescent glaze slurry 320 evenly covers the entire surface of the glass layer 200;

[0080] 2. Put the glass layer 200 evenly distributed with the fluorescent glaze paste 320 in a high-temperature furnace for sintering treatment; and adopt the step-by-step heating method, first set the temperature to 60°C, keep it for 5 minutes after the temperature is ...

Embodiment 2

[0085] In this example, the fluorescent glaze layer on the surface of the glass layer in the laser light-emitting device was prepared according to the same method and conditions as in Example 1. The difference is that, in this example:

[0086] 1. Mix low-temperature ceramic glaze, YAG phosphor and water in a mass ratio of 2:1:2.

[0087] The fluorescent glaze layer formed on the surface of the glass layer of this embodiment can carry out X-ray diffraction analysis (XRD) to the fluorescent glaze layer, and the analysis result shows that the original crystal phase of the fluorescent powder is retained on the surface of the fluorescent glaze layer; The layer was subjected to spectral analysis, and the analysis results showed that the peak wavelength of the emission spectrum was 545nm, and the peak wavelength of the excitation spectrum was 450nm, indicating that the fluorescent glaze layer and the phosphor colloid had the same emission spectrum peak wavelength of 545nm. Therefor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com