Hydrogenated castor oil sulfosuccinate fatting agent and preparation method thereof

A technology of hydrogenated castor oil and succinic acid, applied in the field of leather making, can solve the problems of poor softness and plumpness, insignificant thickening, and not particularly fine grain surface of raw leather.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

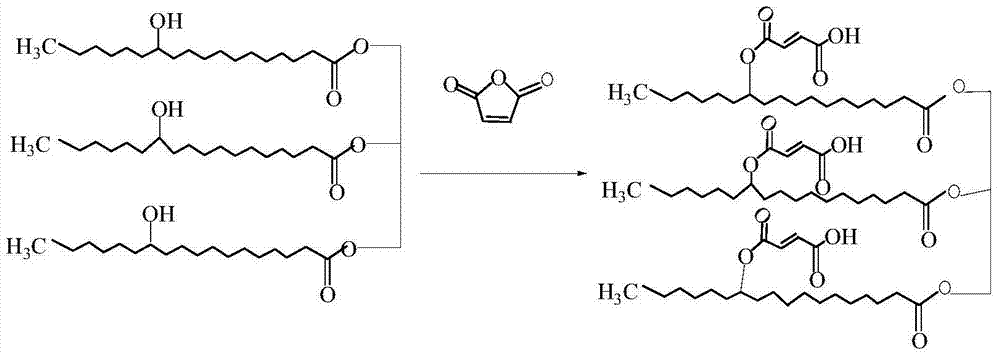

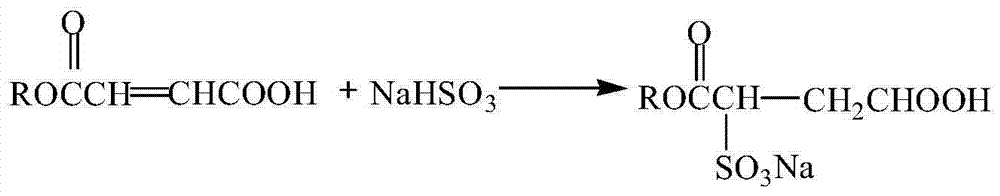

Method used

Image

Examples

Embodiment 1

[0028] 1) Take 20 parts of hydrogenated castor oil, 6.493 parts of maleic anhydride and 6.890 parts of sodium bisulfite in parts by mass;

[0029] 2) Add hydrogenated castor oil into a three-necked flask, adjust the oil bath temperature control device to keep the hydrogenated castor oil at 115°C for 1 hour; then replace the oil bath temperature control device with a water bath, adjust the temperature of the water bath to keep the hydrogenated castor oil at 90°C It is in a molten state at ℃ and maleic anhydride is added. After 3 hours of reaction, the acid value of the obtained system A is constant, and then the temperature is lowered to 68 ℃, and hydrogen sulfite with a mass concentration of 20% made of sodium bisulfite is added. Sodium aqueous solution, and adjust the pH value of the obtained system B to 8.0 with ammonia water, react for 3 hours, then lower the temperature to 45°C, add deionized water to make the solid content 40%, and stir for 40 minutes to obtain succinate s...

Embodiment 2

[0031] 1) Take 20 parts of hydrogenated castor oil, 7.4197 parts of maleic anhydride and 7.8744 parts of sodium bisulfite in parts by mass;

[0032] 2) Add hydrogenated castor oil into the three-necked flask, adjust the oil bath temperature control device to keep the hydrogenated castor oil at 115°C for 1 hour; then replace the oil bath temperature control device with a water bath, adjust the temperature of the water bath to make the hydrogenated castor oil It is in a molten state at 85°C and maleic anhydride is added. When reacting for 2 hours, the acid value of the obtained system A is constant. Then cool down to 68°C and add sulfurous acid with a mass concentration of 20% made of sodium bisulfite. Sodium hydrogen aqueous solution, and adjust the pH value of the obtained system B to 8.0 with ammonia water, react for 3 hours, then lower the temperature to 45°C, add deionized water to make the solid content 40%, and stir for 40 minutes to obtain succinate sulfonated hydrogenate...

Embodiment 3

[0034] 1) Take 20 parts of hydrogenated castor oil, 6.493 parts of maleic anhydride and 7.234 parts of sodium bisulfite in parts by mass;

[0035] 2) Add hydrogenated castor oil into a three-necked flask, adjust the oil bath temperature control device to keep the hydrogenated castor oil at 115°C for 1 hour; then replace the oil bath temperature control device with a water bath, adjust the temperature of the water bath to keep the hydrogenated castor oil at 95°C It is in a molten state at ℃ and maleic anhydride is added. After 2 hours of reaction, the acid value of the obtained system A is constant, and then the temperature is lowered to 65 ℃, and hydrogen sulfite with a mass concentration of 20% made of sodium bisulfite is added. Sodium aqueous solution, and adjust the pH value of the obtained system B to 7.5 with ammonia water, react for 3 hours, then lower the temperature to 45°C, add deionized water to make the solid content 40%, and stir for 40 minutes to obtain succinate s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com